Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Reach the effect of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

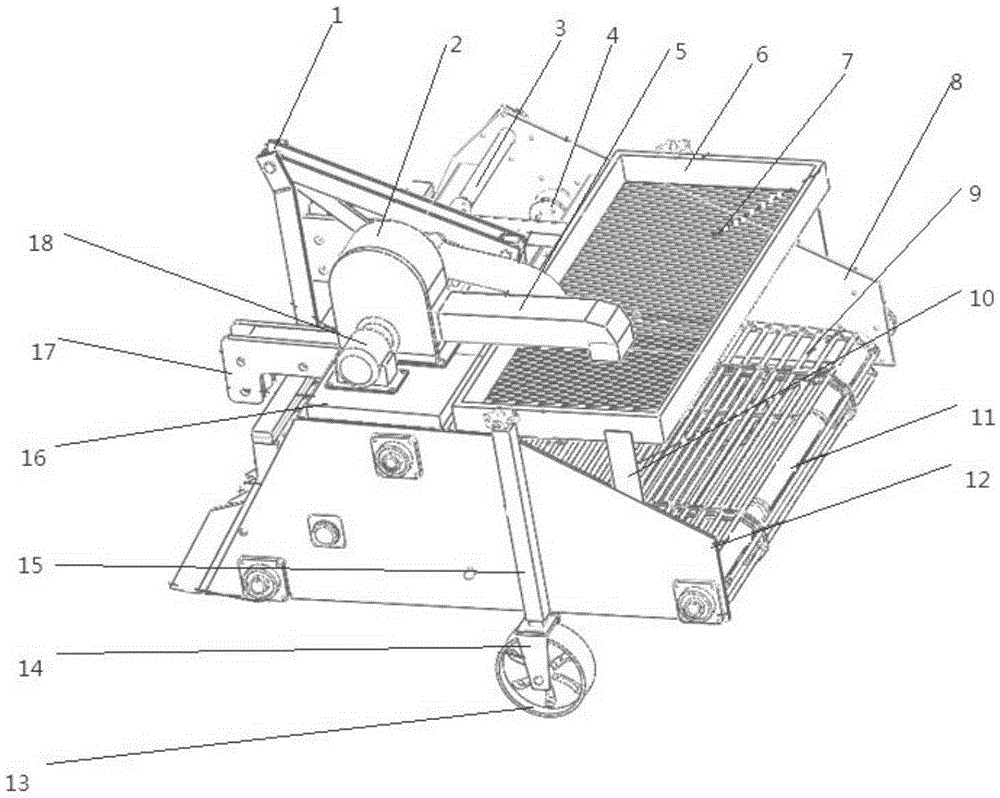

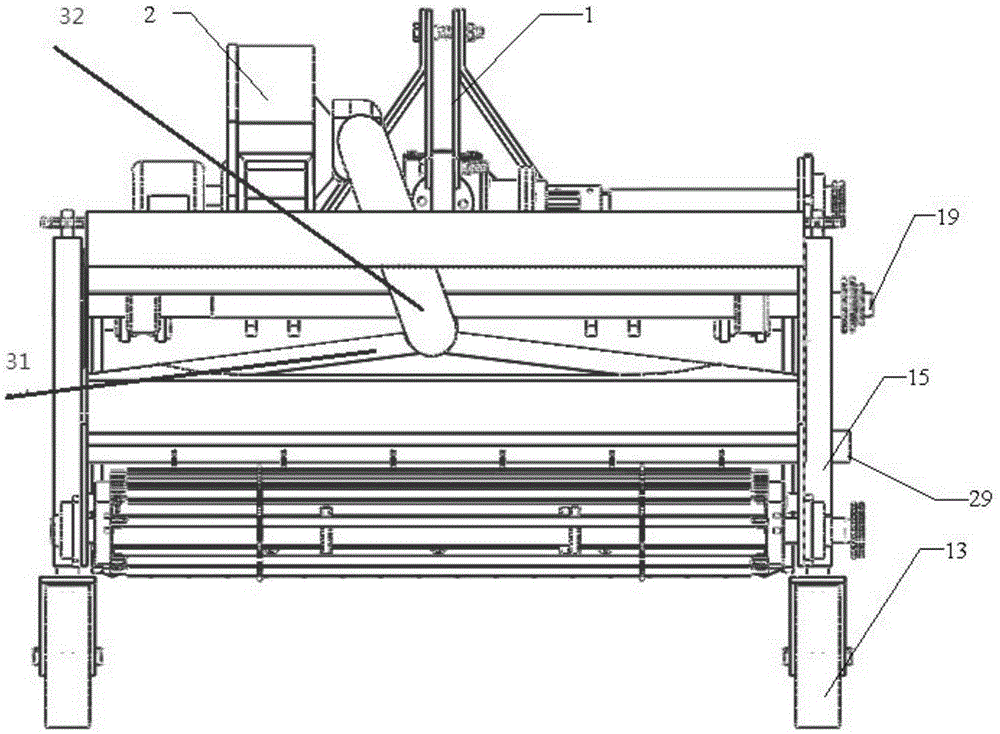

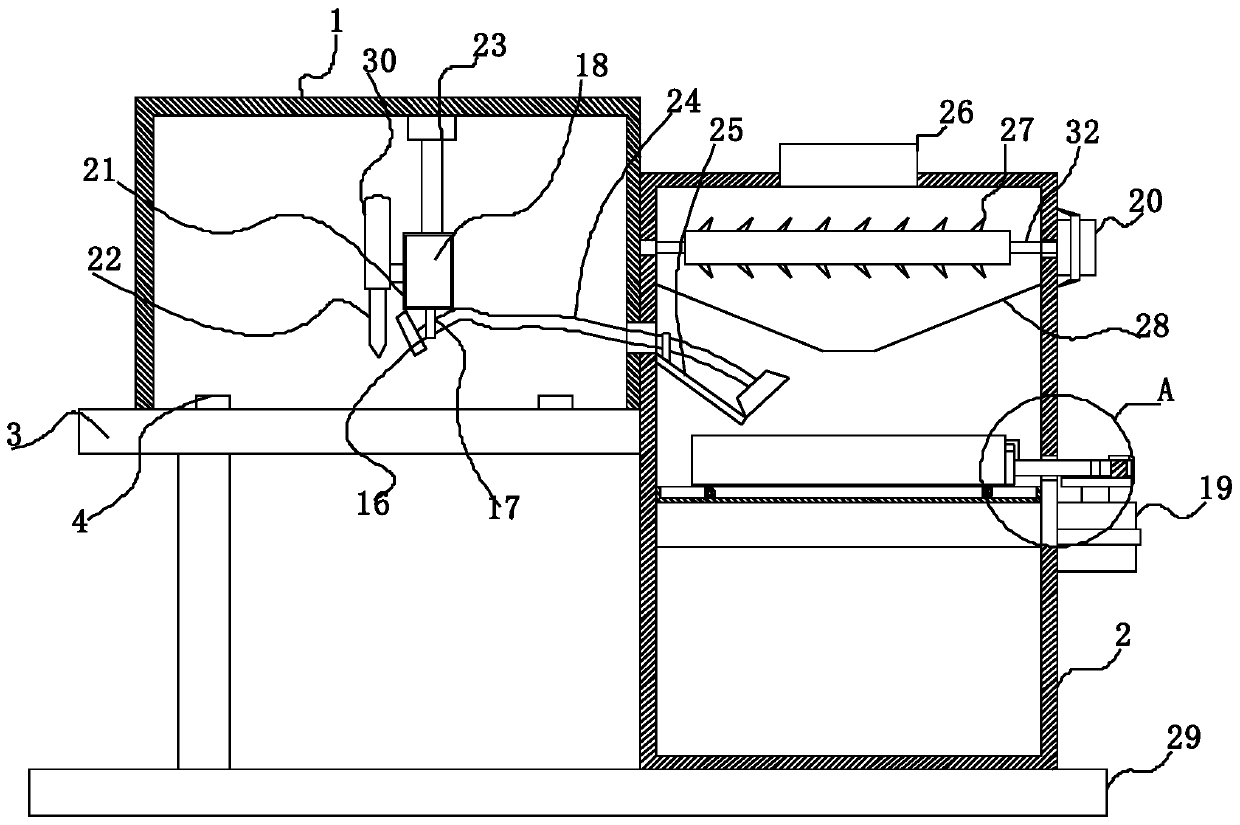

Deep plastic film residue screening and recycling machine

InactiveCN104186042AReach the effect of recyclingAchieve the purpose of collectionGatherer machinesAgricultural engineeringPlastic film

The invention relates to the technical field of agricultural machinery, in particular to a deep plastic film residue screening and recycling machine matching with a four-wheel tractor in use. The deep plastic film residue screening and recycling machine is hung on the four-wheel tractor through a connecting frame, the entire deep plastic film residue screening and recycling machine uses a left side plate and a right side plate for connection and land wheels as supports, a transmission is fixedly on a transmission support fixed on the rear side of the connecting frame and in power connection with the four-wheel tractor through a spline connecting shaft, a first driving chain wheel is fixed to the middle of a transmission main shaft of the transmission, and a second driving chain wheel is fixed on the outer side of the right side plate of the right end of the transmission main shaft; an exhaust inlet and a centrifugal fan are fixed in the rears of the left side plate and the right side plate through a fan support frame; a collection box is fixed at the rear ends of the left side plate and the right side plate through a collection box support frame. The deep plastic film residue screening and recycling machine is simple in structure, easy to operate, convenient to use and clean and thorough in plastic film recycling and is a satisfactory agricultural machine for protection of cultivated land.

Owner:青海林丰农牧机械制造有限公司

Process of treating and utilizing acid waste water containing heavy metal

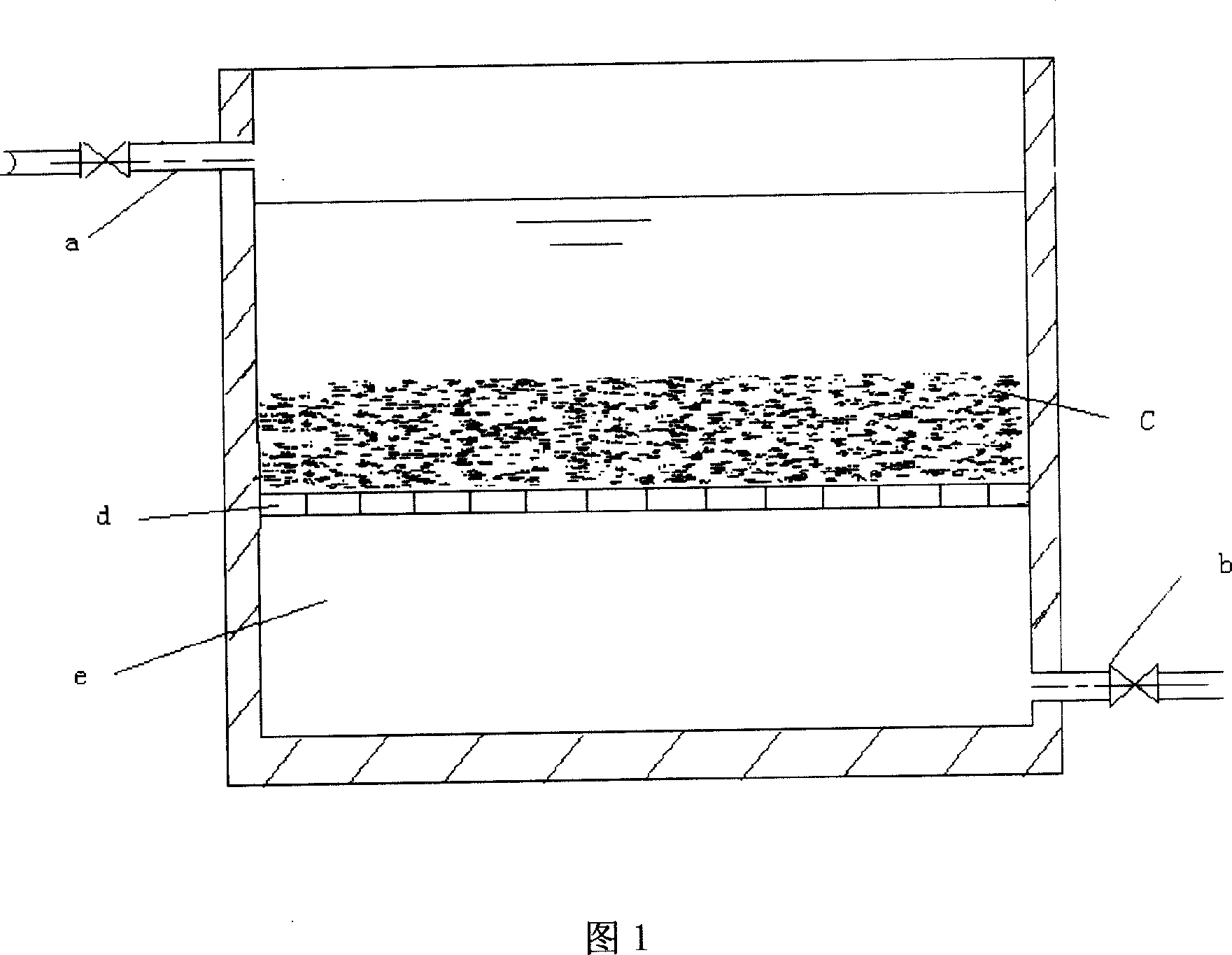

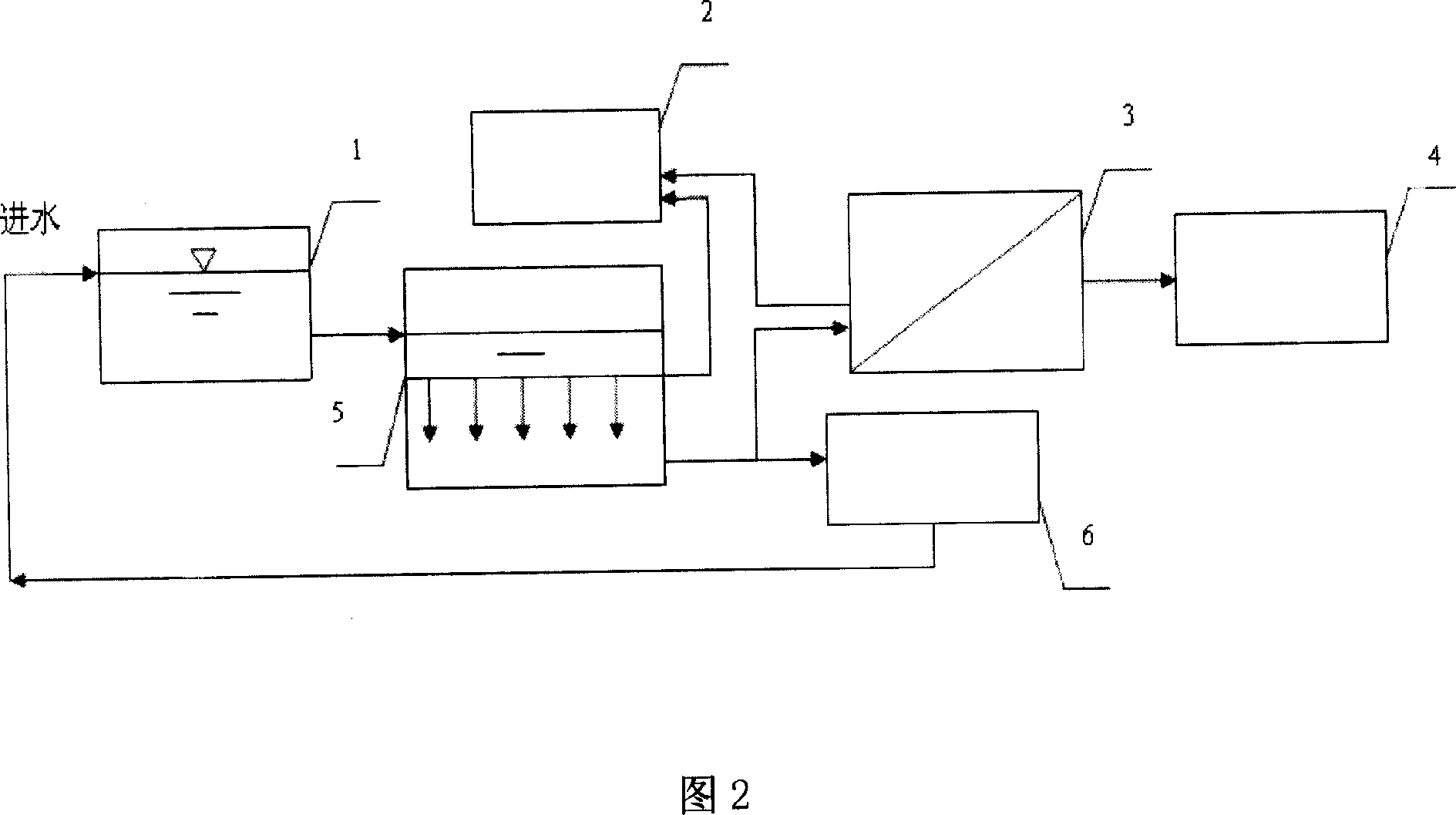

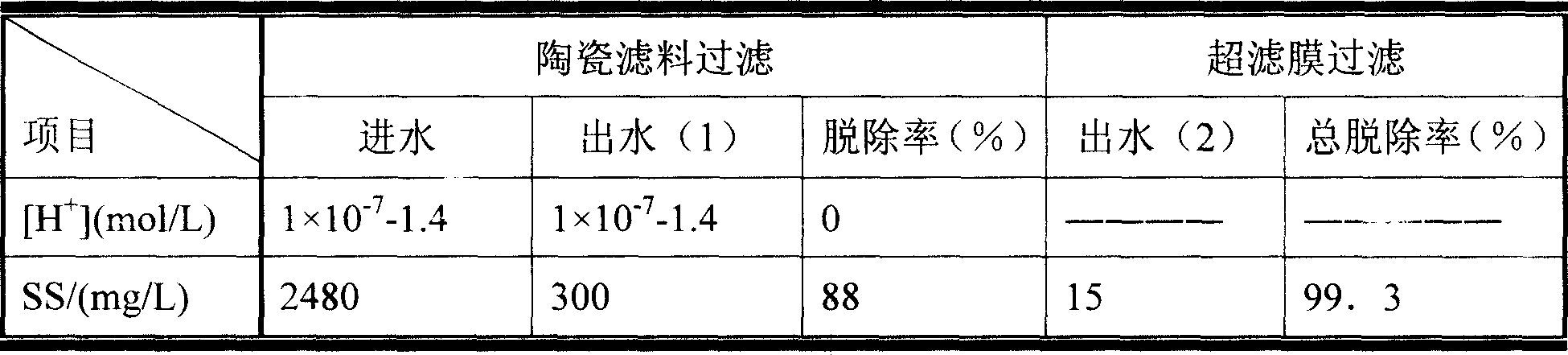

InactiveCN1931729AAchieve reuseReduce water consumptionWater/sewage treatmentFiltration circuitsSludgeAcid concentration

The process of treating and utilizing acidic waste water containing heavy metal includes the following steps: filtering the acidic waste water containing heavy metal in two filters with specific material; 2. purifying water and producing acid; and 3. reutilizing the treated waste water with relatively low acid concentration. The present invention has low cost, saving in resource, long equipment service life, high treating effect and other advantages.

Owner:天津佰腾生产力促进中心有限公司

Method for synchronously recovering nitrogen and phosphorus from wastewater by magnesium hydroxide modified sepiolite

InactiveCN108325498APromote generationPromote growthOther chemical processesAlkali orthophosphate fertiliserActive agentSurface-active agents

The invention provides a method for synchronously recovering nitrogen and phosphorus from wastewater by magnesium hydroxide modified sepiolite. The magnesium hydroxide modified sepiolite is prepared from natural sepiolite is used as a raw material, MgCl2 as a magnesium source and alkyl sulfonate as a surfactant. Nitrogen and phosphorus in medium and high concentration wastewater are synchronouslyrecovered by adsorbability of the sepiolite in combination with a struvite precipitation method on the basis of the prepared modified sepiolite as a precipitant, and the recovered filter residues arecollected and dried for use as a soil conditioner or slow release fertilizer. The method has the advantages of being energy saving and environmentally friendly; according to the treated wastewater, ammonia nitrogen concentration and total phosphorus concentration are both well reduced, and synchronous recovery of nitrogen and phosphorus is realized.

Owner:BEIJING UNIV OF TECH

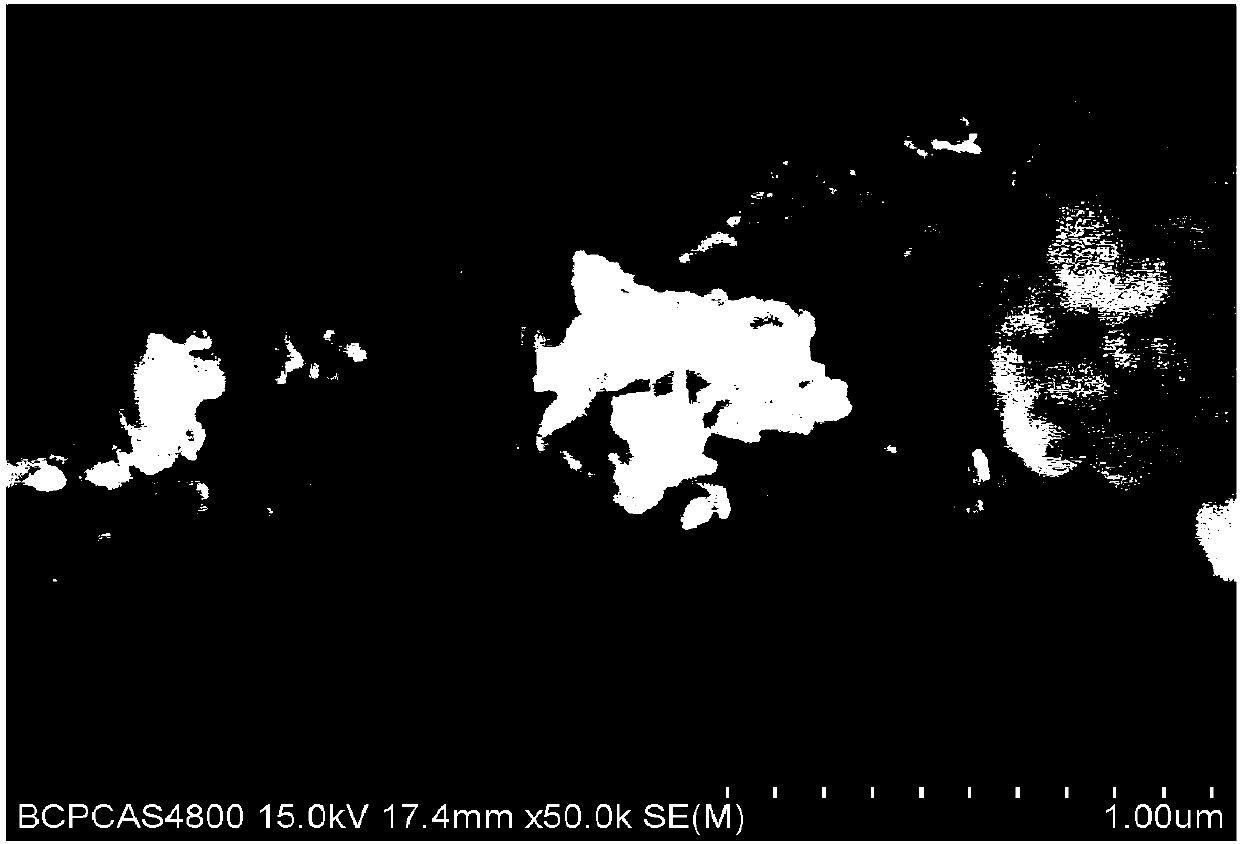

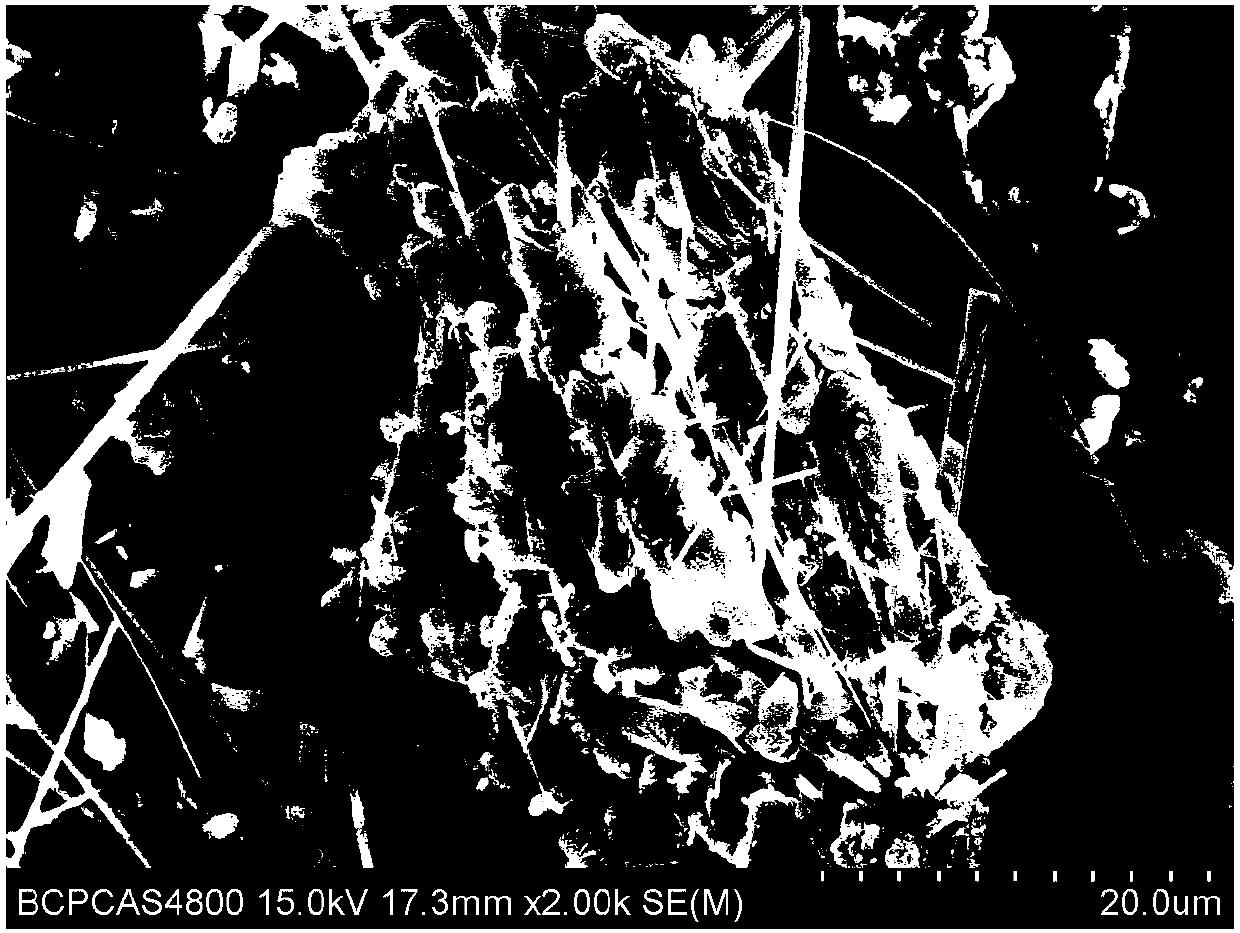

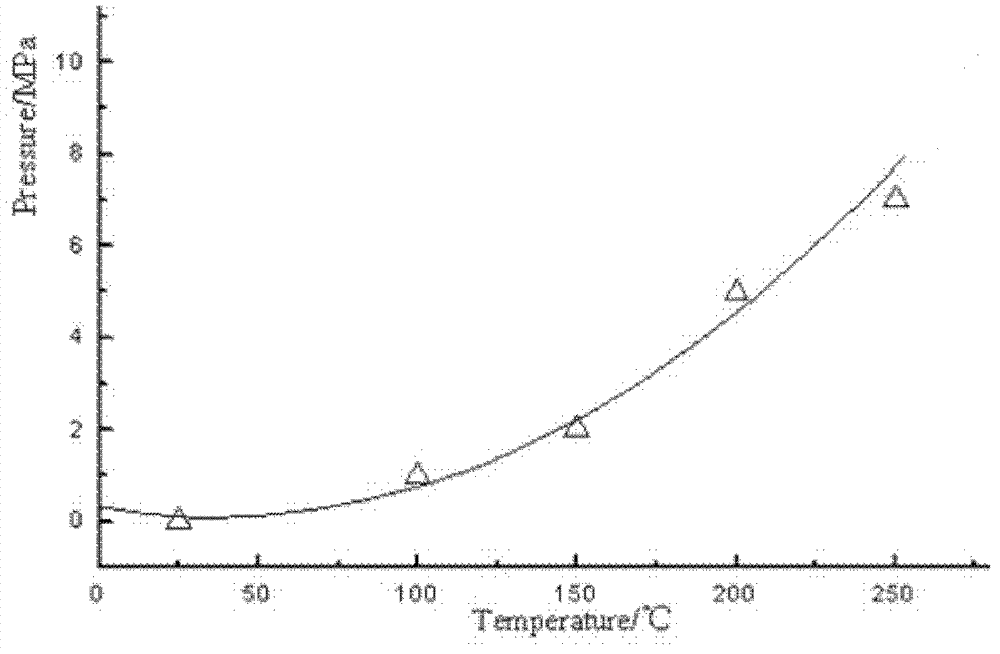

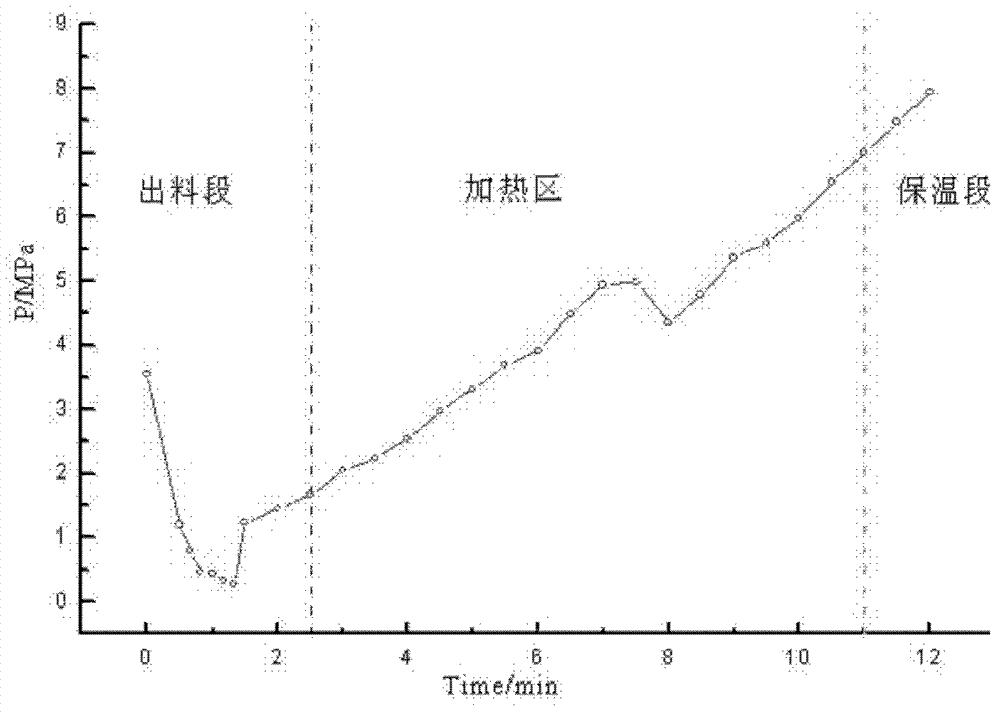

Hydro-thermal treatment method for electroplating sludge

InactiveCN103011535ATo achieve the effect of continuous automationLow dissolution rateSludge treatment by pyrolysisWaste water treatment from metallurgical processSludgeAcid washing

The invention discloses a hydro-thermal treatment method for electroplating sludge, which comprises the following steps of: firstly mixing electroplating sludge with water so as to form electroplating sludge fluid; feeding the electroplating sludge fluid into a continuous high-temperature and high-pressure reaction kettle, and after a fixed volume is achieved, stopping feeding; raising the internal temperature of the kettle so as to carry out hydro-thermal treatment; after the hydro-thermal treatment is completed, discharging heavy metal sludge hydro-thermal residues subjected to reaction, and carrying out filter pressing on the discharged heavy metal sludge hydro-thermal residues so as to obtain solid-phase hydro-thermal residues and liquid-phase hydro-thermal water; carrying out immersion cleaning on the solid-phase hydro-thermal residues by using a sulfuric acid and carrying out filter pressing on the solid-phase hydro-thermal residues so as to obtain acid-washing liquor and hydro-thermal residue precipitates, and drying and grinding the hydro-thermal residue precipitates subjected to each acid-washing process; and uniformly mixing the acid-washing liquor and the liquid-phase hydro-thermal water obtained each time, and then preparing ferrite by using a chemical co-precipitation method. According to the hydro-thermal treatment method disclosed by the invention, the leaching of heavy metals can be efficiently realized, and the heavy metals can be subjected to effective separation and recycling by taking subsequent separation measures. The moisture content of sludge can be greatly reduced through a plate-and-frame filter press, so that the volume of the sludge residues is reduced, the heavy metal dissolution rate of the residues is greatly reduced, and the form is more stable.

Owner:SHANGHAI JIXIANG ENVIRONMENTAL PROTECTION TECH DEV

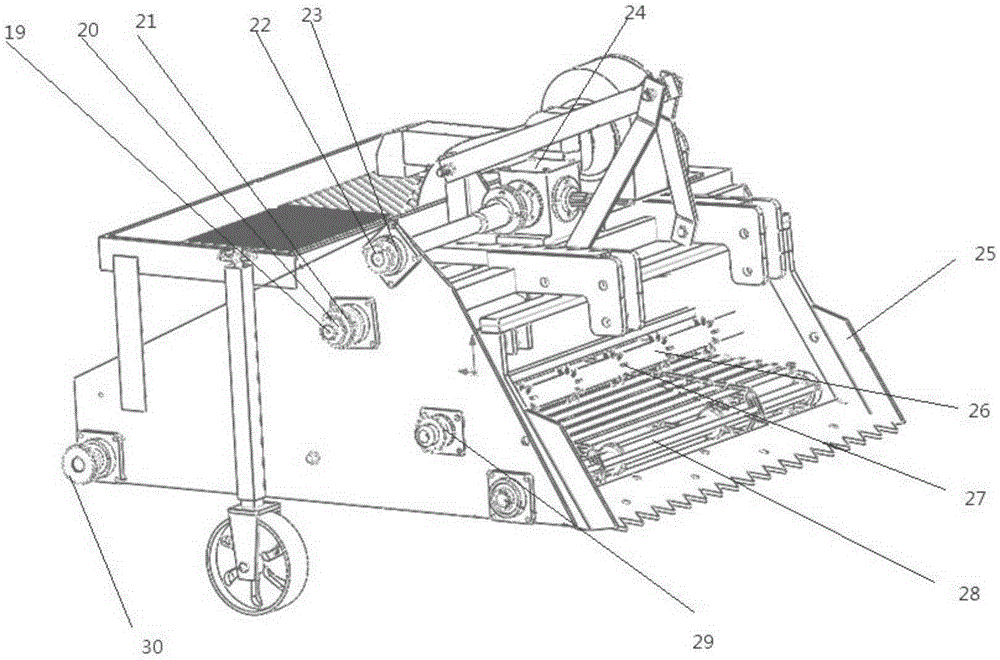

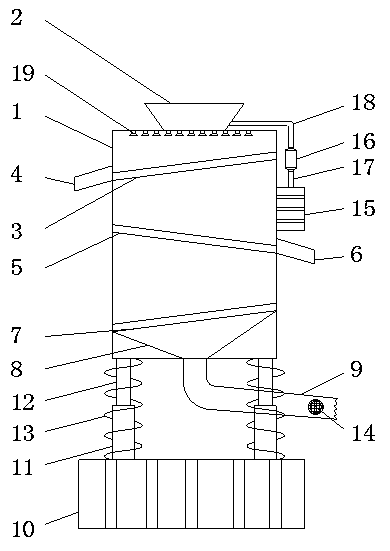

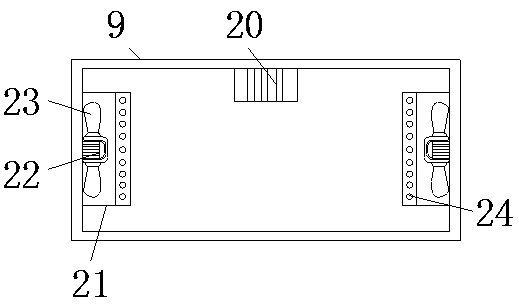

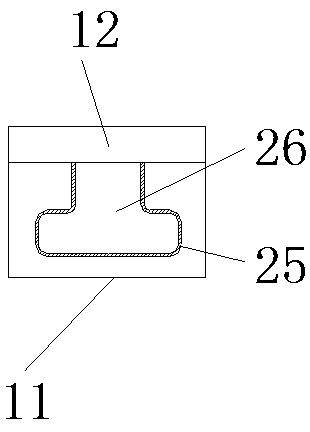

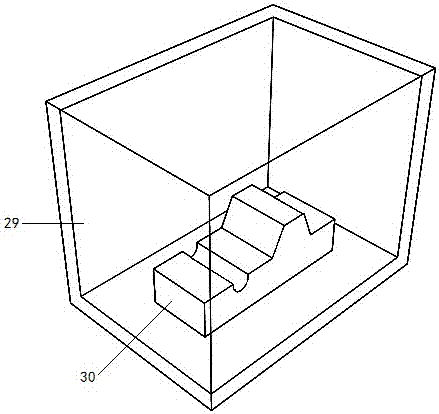

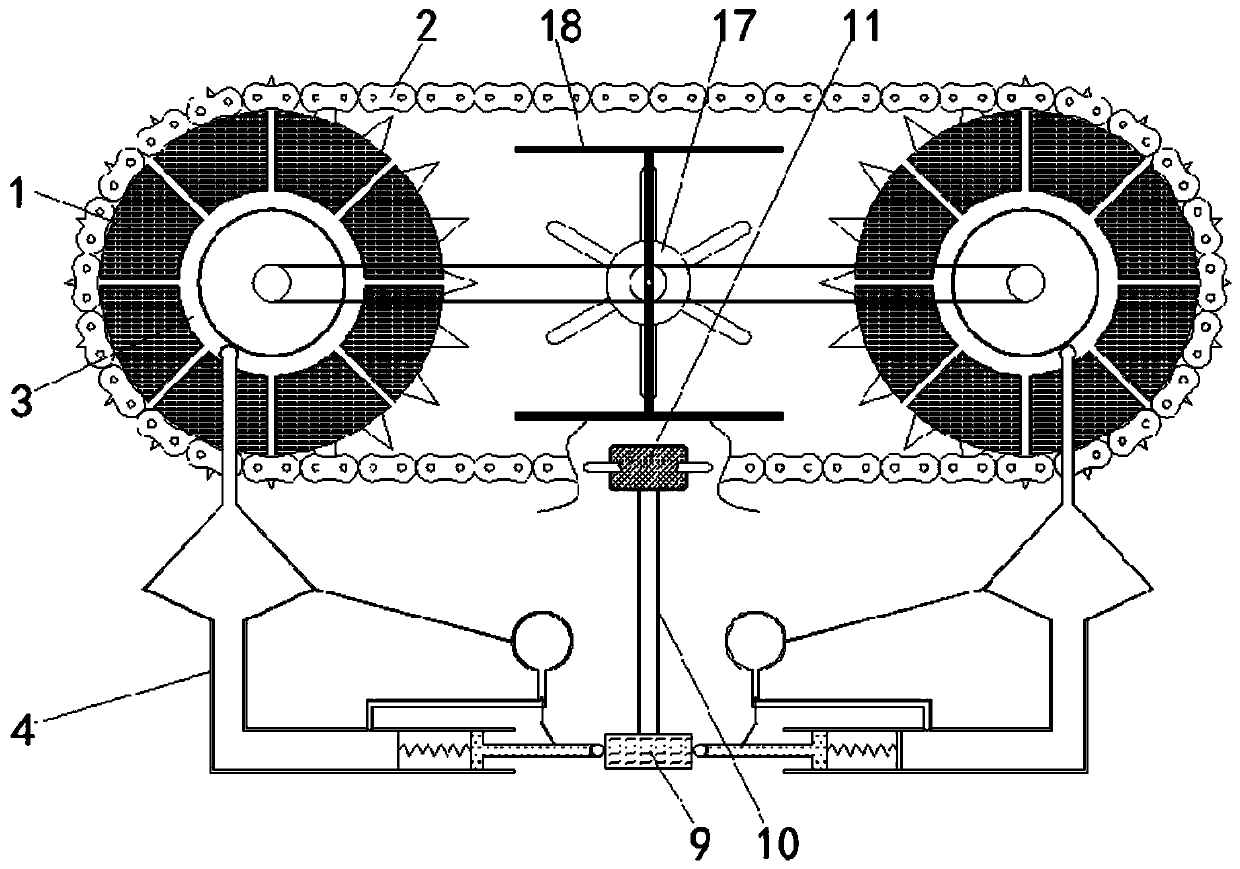

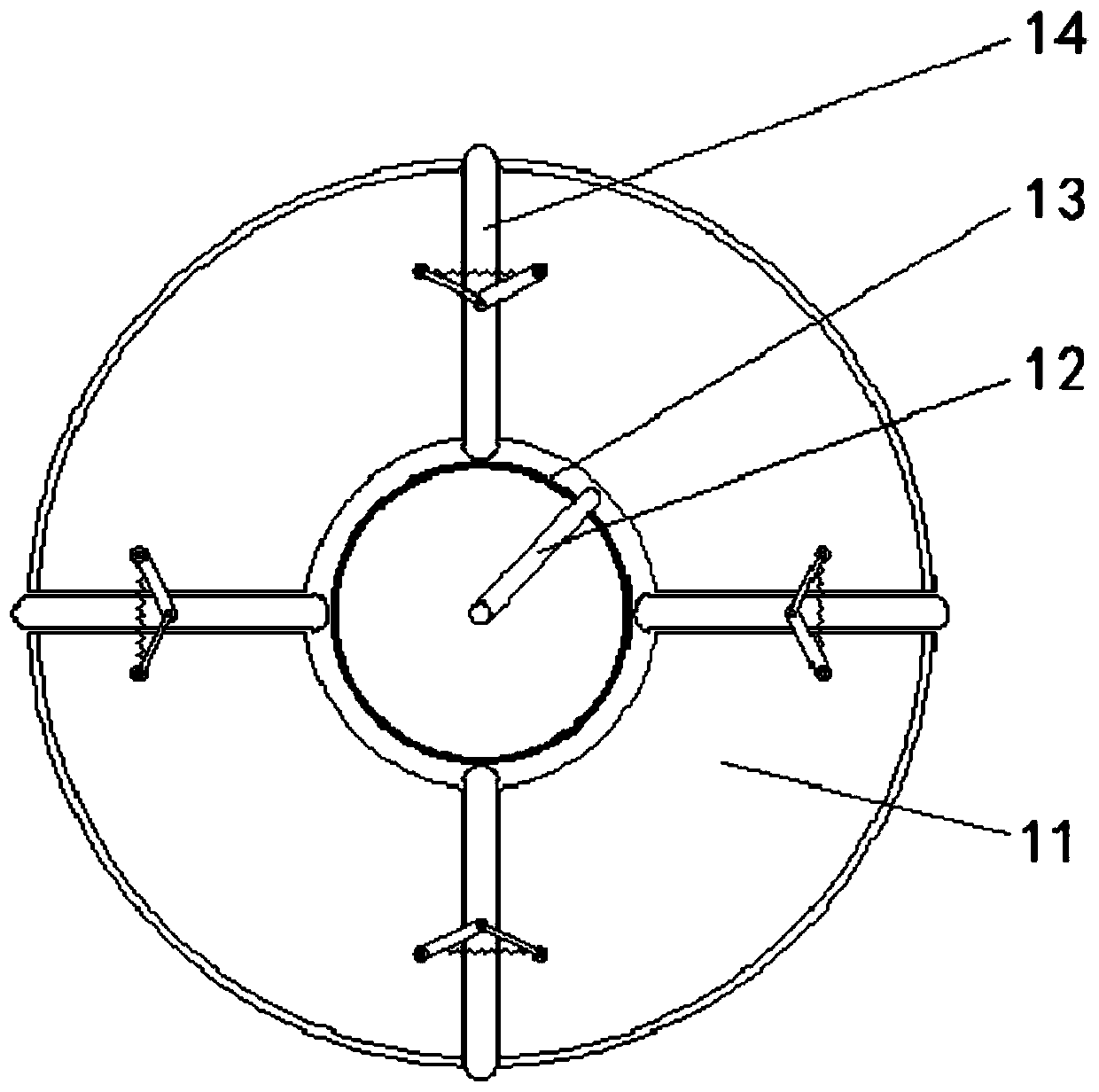

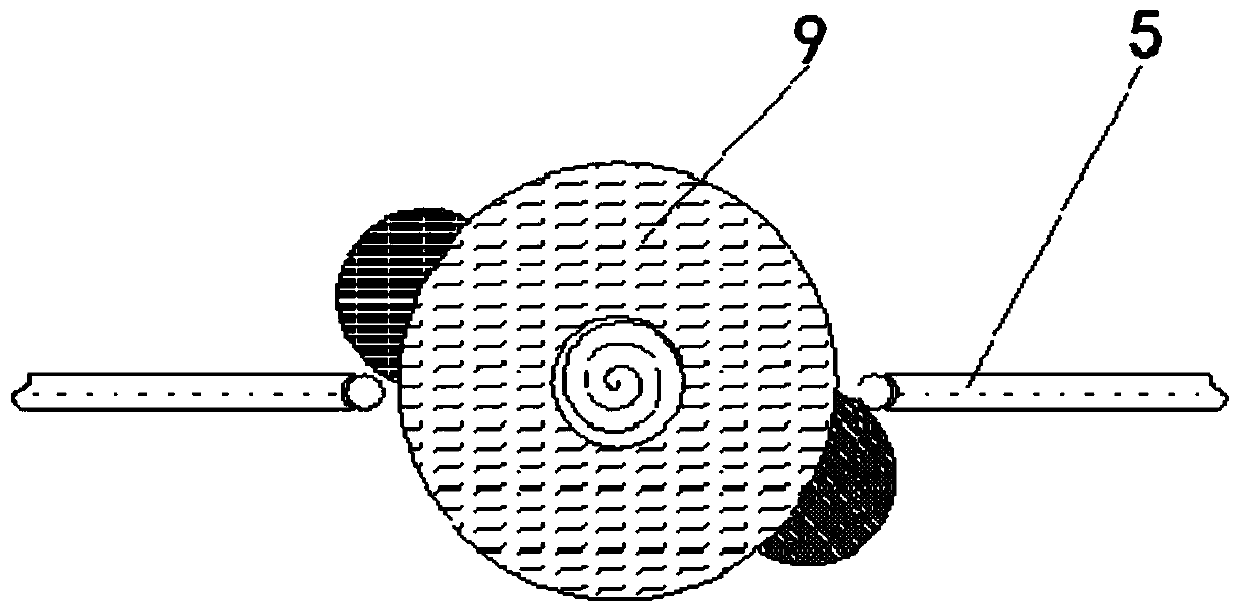

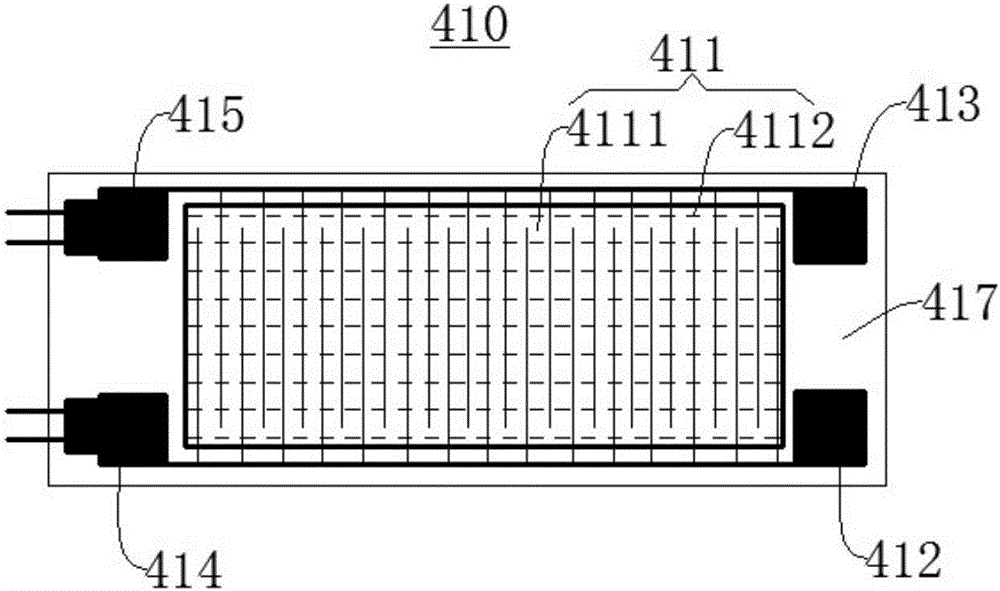

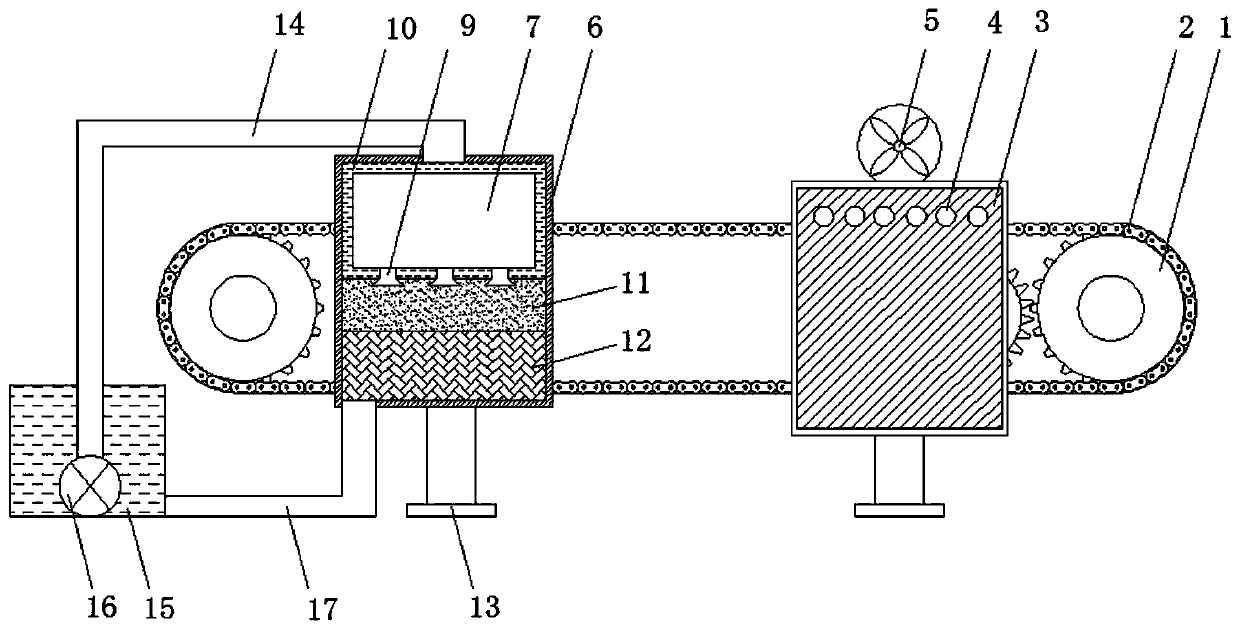

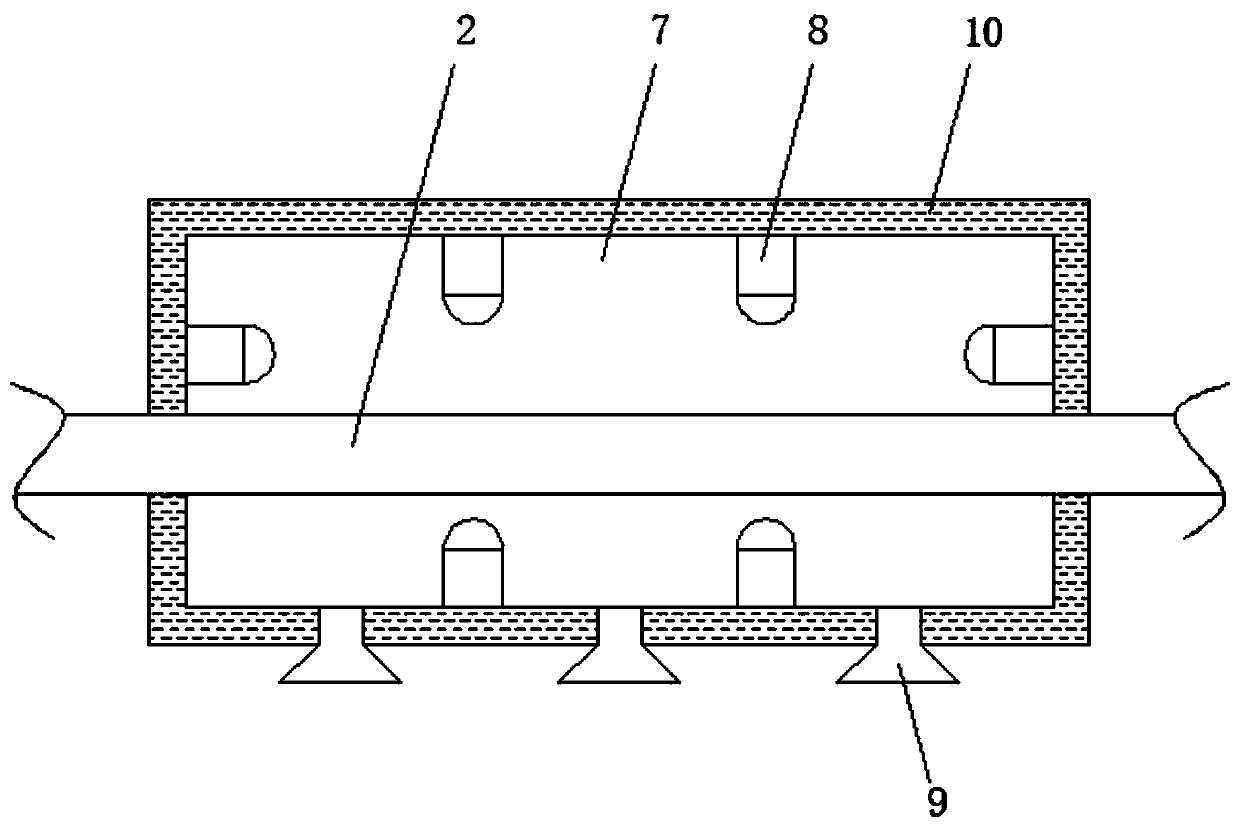

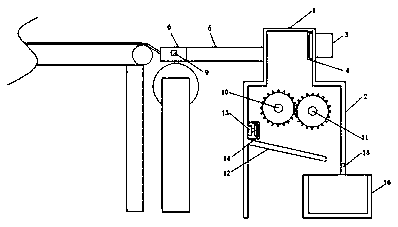

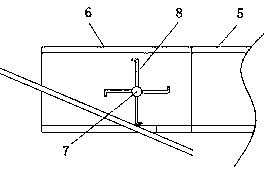

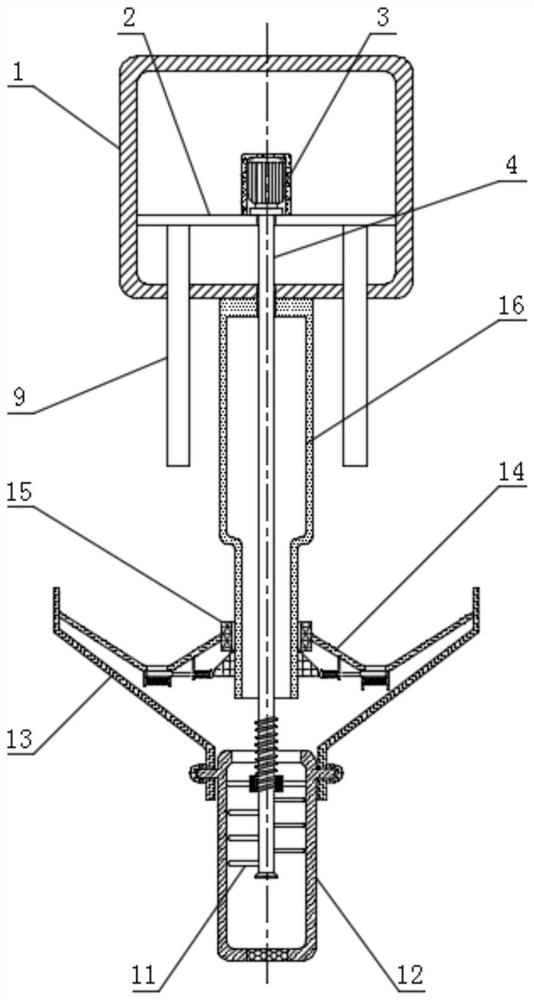

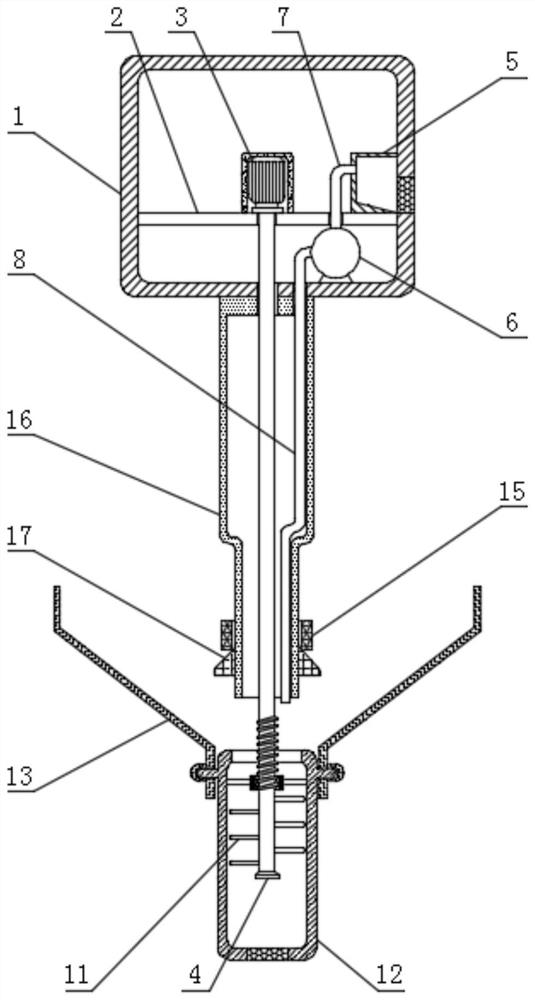

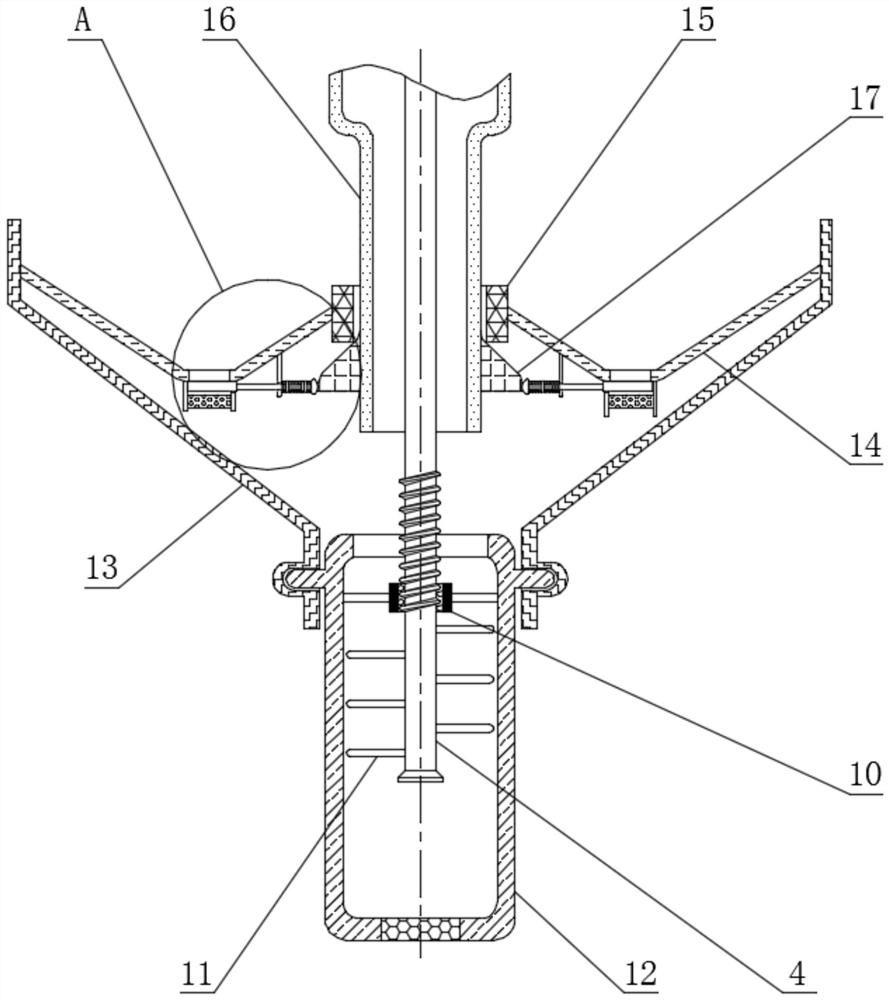

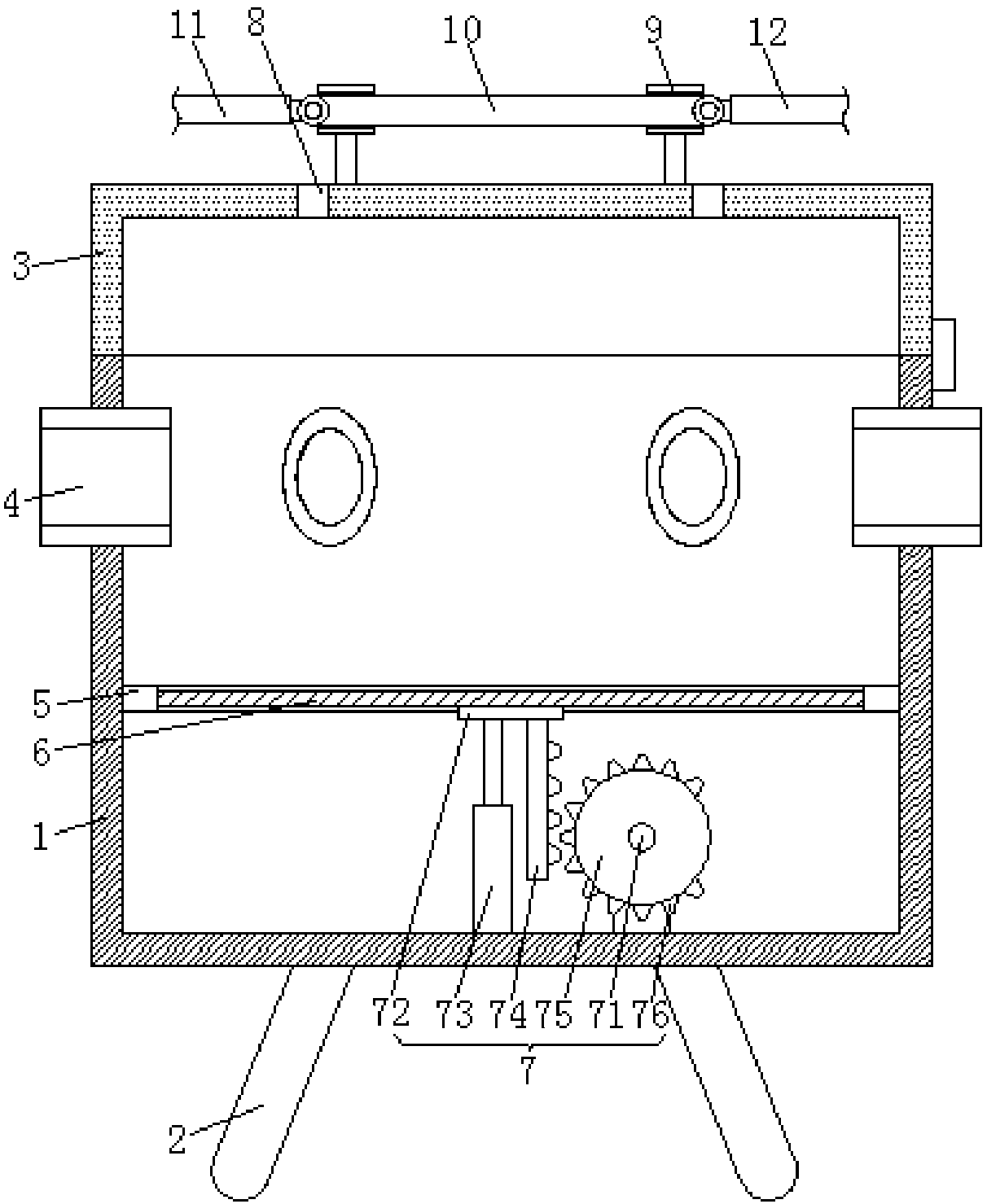

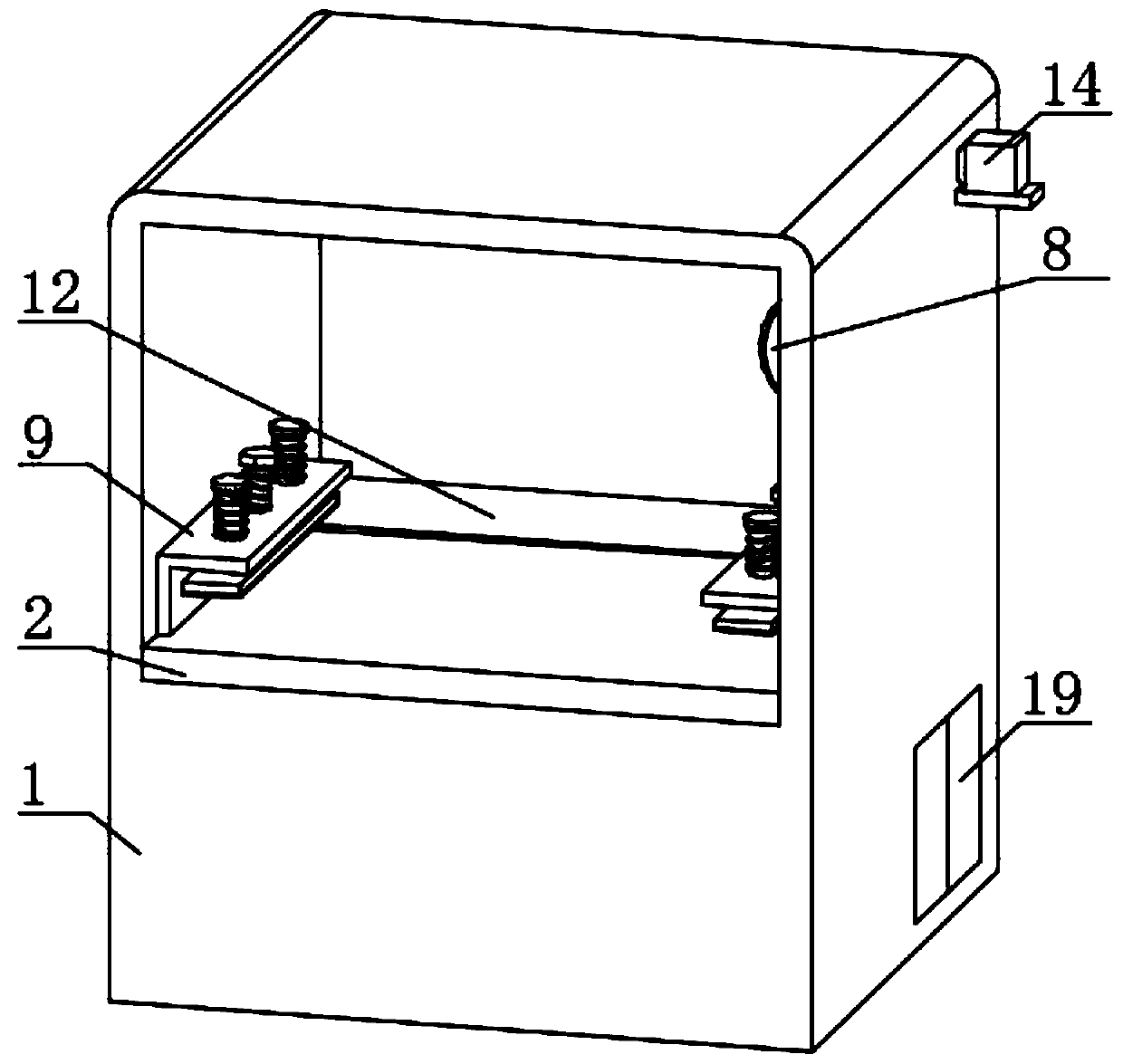

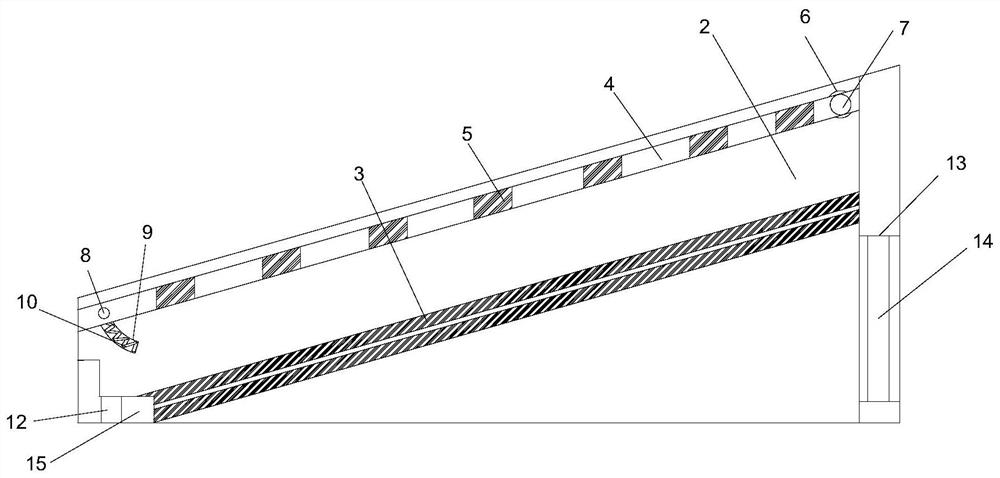

Potato residue membrane device recycling machine

InactiveCN105230157AReach the effect of recyclingAchieve the effect of the initial screeningGatherer machinesDrive shaftEngineering

The invention discloses a potato residue membrane device recycling machine, which comprises a digging shovel assembly, wherein a pushing chain plate is arranged above the digging shovel assembly, a side plate 1 and a side plate 2 are arranged on the two sides of the digging shovel assembly, the two sides of the pushing chain plate are respectively connected with the side plate 1 and the side plate 2, support rolling devices are arranged outside the side plate 1 and the side plate 2, a winding device is arranged between the side plate 1 and the side plate 2 which are arranged above the pushing chain plate, two hanging ear plates are arranged above the winding device, and are connected onto the side plate 1 and the side plate 2 through a big frame, a connecting frame is connected between the hanging ear plates, one end of the connecting frame is connected with a transmission device, and the other end of the connecting frame is connected with a four-wheel tractor. Power is transferred to a gear box through the connecting frame, enables a main transmission chain wheel to rotate by driving a main transmission shaft after the power is reduced through the gear box, and then drives various devices to go forward and rotate. The potato residue membrane device recycling machine has the characteristics of simple structure, one-stage molding and convenient use.

Owner:青海林丰农牧机械制造有限公司

Plastic-wood plate cutting and recycling integrated equipment

InactiveCN111185950AQuality assurancePromote environmental protectionWood working apparatusGrain treatmentsAgricultural engineeringWood plank

The invention discloses plastic-wood plate cutting and recycling integrated equipment. The plastic-wood plate cutting and recycling integrated equipment comprises a crushing box, an operating table, afiltering frame, a sleeve rod and a fixing ring, a feeding inlet is formed in the top end of the crushing box, a third driving motor is fixedly connected to the outer side of the crushing box, an output shaft of the third driving motor is fixedly connected with a rotating shaft, sliding grooves are formed in supporting plates, an L-shaped plate is fixedly connected to the end, close to the thirddriving motor, of the filtering frame, a second driving motor is fixedly connected to the outer side of the crushing box, an output shaft of the second driving motor is fixedly connected with a rotating plate, and a connecting rod is fixedly connected to the end, deviating from the second driving motor, of the rotating plate. According to the plastic-wood plate cutting and recycling integrated equipment, by arranging a dust collector, a guiding pipe, the crushing box and a crushing roller, generated sweeps and wood particles can be recycled and crushed to be conveniently reprocessed into a wood plate, environmental protection is facilitated, the recycling effect is achieved, and the problem that the sweeps and wood particles generated during cutting are not utilized, and consequently, environmental protection is not facilitated is solved.

Owner:浙江格林特木塑材料有限公司

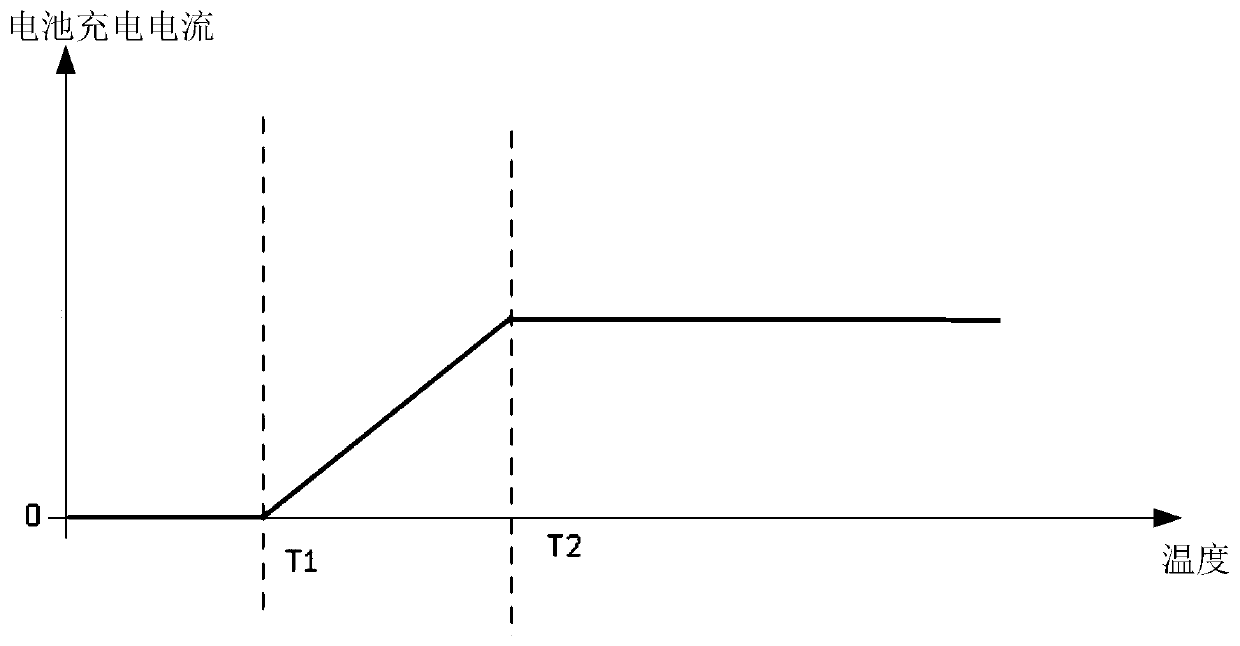

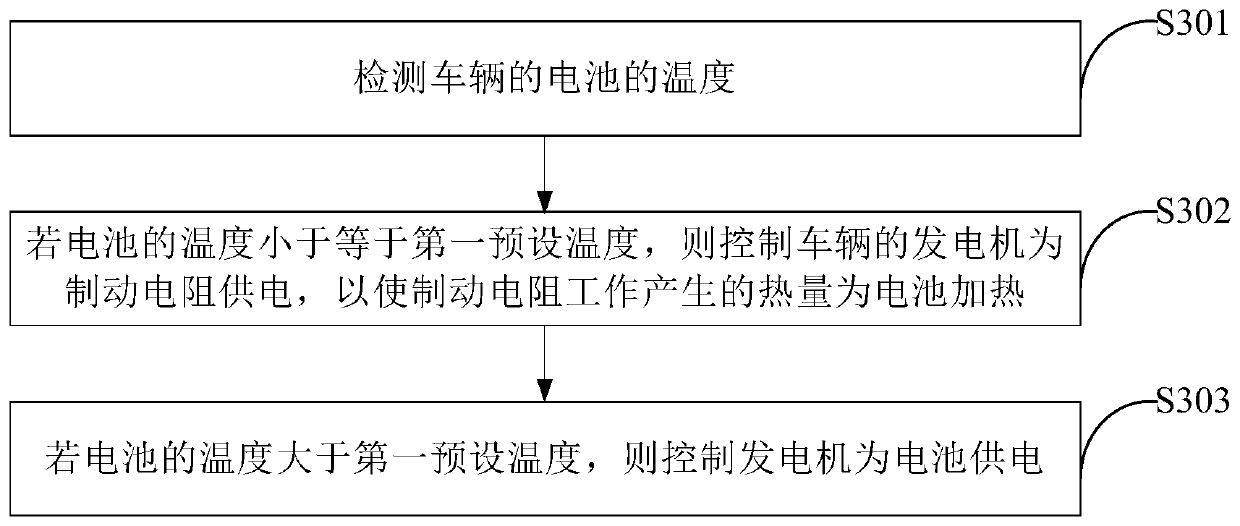

Battery heating control method, device and system, storage medium and vehicle

InactiveCN111430846AImprove charging effectImprove battery lifeSecondary cellsVehicular energy storageElectrical batteryHeat control

The invention provides a battery heating control method, device and system, a storage medium and a vehicle. The method comprises the steps of detecting the temperature of a battery of the vehicle; ifthe temperature of the battery is less than or equal to a first preset temperature, controlling a generator of the vehicle to supply power to a brake resistor to heat the battery with the heat generated when the brake resistor works; and if the temperature of the battery is greater than the first preset temperature, controlling the generator to supply power to the battery. When the temperature ofthe battery is lower than the first preset temperature, the braking energy is used for heating the battery so as to improve the charging capacity of the battery; and after the battery temperature is higher than the first preset temperature, the braking energy is used for supplying power to the battery, and the braking energy recycling effect is achieved. Through the method, the charging performance of the battery of the vehicle in a low-temperature environment can be improved, the braking energy recovery efficiency is improved, and the endurance mileage of the vehicle is prolonged.

Owner:WEICHAI POWER CO LTD

Efficient screening device for construction waste

InactiveCN108453037AReach the effect of recyclingEasy to recycleSievingScreeningEngineeringSecond screen

The invention discloses an efficient screening device for construction waste. The efficient screening device comprises a machine body shell, a conveying pipe, a vibration table, first connecting rods,a water tank, fixed frameworks and blowers, wherein a feeding opening is formed on the upper part of the exterior of the machine body shell, a first screen is arranged above the interior of the machine body shell, and a first outlet is formed in the left side of the exterior of the machine body shell; a second screen is arranged below the first screen, a second outlet is formed in the right sideof the exterior of the machine body shell, a third screen is arranged below the second screen, and electric heating tubes are arranged on the fixed frameworks; and sliding grooves are formed inside the first connecting rods, and sliding blocks are arranged on second connecting rods. According to the device, the machine body shell, the first screen, the third screen, the conveying pipe, the vibration table, the blowers and the electric heating tubes are arranged, so that the problems that in a garbage screening process, the efficiency is low, and a large amount of dust can be generated and cannot be treated in time during the garbage screening process are solved.

Owner:XINXIANG DONGZHEN MACHINERY

Efficient replacement air purifier based on fixed space three-dimensional scanning technology

ActiveCN107166557AEasy to passPrevent leakageMechanical apparatusLighting and heating apparatusAir purifiersAir cleaning

The invention discloses an efficient replacement air purifier based on a fixed space three-dimensional scanning technology, and relates to the technical field of indoor air purification. The air purifier comprises a purifying assembly, an air storage device and a recovery device; the purifying assembly comprises a shell arranged indoors and fixedly connected with a wall; a sealing cover is matched and mounted at the upper end of the shell; an intake pipe communicates to the upper end of the side wall of the shell, and a freeing pipe communicates to the lower end; the freeing pipe communicates with multiple branch pipes; the bottom end of the shell is fixedly and tightly connected with a mounting base; an exhaust pipe communicates through the mounting base; an electromagnetic valve is mounted on the exhaust pipe; the intake pipe and the exhaust pipe both tightly penetrate through the wall; and a filter box is fixedly mounted at the upper part in the shell. The air purifier has the following beneficial effects: clean air is used for replacing untreated air by using a space three-dimensional scanning technology to achieve the air purifying effect in specific closed space, so that the purifying effect is good, and the efficiency is high.

Owner:绍兴蓝之印家纺有限公司

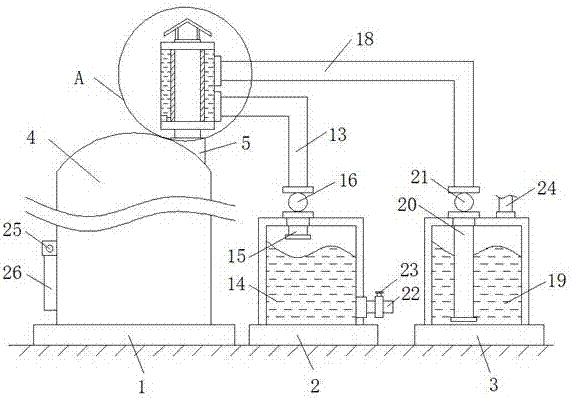

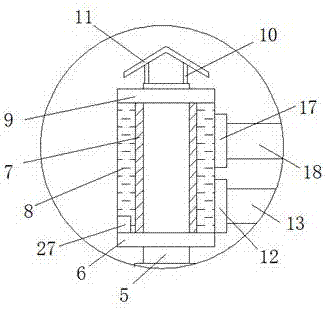

Heat recycling device of smelting furnace

InactiveCN107990745AExtended service lifeIncrease profitCharge treatment typeIncreasing energy efficiencyEngineeringWater collection

The invention relates to the technical field of smelting furnaces, and discloses a heat recycling device of a smelting furnace. The heat recycling device of the smelting furnace comprises a first base, a second base and a third base, wherein a furnace body is fixedly connected to the top part of the first base; a chimney fixedly communicates to the top part of the furnace body; a first fixing ringis fixedly sleeved on the bottom part of an outer surface of the chimney; a heat exchange guide plate located above the first fixing ring is fixedly sleeved on the outer surface of the chimney; and ahot water collection tank is fixedly sleeved on an outer surface of the heat exchange guide plate. According to the heat recycling device of the smelting furnace, the heat exchange guide plate can beused for heating water in the hot water collection tank through collecting heat on the chimney, and water is conveyed to a hot water tank through the pumping of the first pump and is then dischargedfrom a drainage pipe for the use by people, so that the outer wall of the chimney can be cooled, the service life of the chimney is prolonged, meanwhile, an effect on recycling waste heat is achieved,the energy is saved, and the energy utilization ratio is improved.

Owner:佘峰

Method for removing GaN-based epitaxial layer on substrate

InactiveCN103531678AGood effectReach the effect of recyclingSemiconductor/solid-state device manufacturingSemiconductor devicesCavity pressureChemistry

The invention provides a method for removing a GaN-based epitaxial layer on a substrate. The substrate and the GaN-based epitaxial layer on the substrate form an epitaxial wafer. The method comprises the steps as follows: putting the epitaxial wafer in a reaction cavity and introducing chlorine gas (CL2) into the reaction cavity, wherein the chlorine gas (CL2) is used for reacting with the GaN-based epitaxial layer at a preset temperature and a preset cavity pressure in the reaction cavity to etch the GaN-based epitaxial layer, but the substrate does not react with the chlorine gas (CL2), so that the substrate with the GaN-based epitaxial layer removed is obtained. According to the invention, the substrate with the GaN-based epitaxial layer removed can be used for epitaxial growth again.

Owner:HANGZHOU SILAN AZURE

Factory assembly line conveying chain-chain intelligent lubricating oil spraying and smearing equipment

The invention discloses factory assembly line conveying chain-chain intelligent lubricating oil spraying and smearing equipment. The equipment comprises transmission gears. The surfaces of the transmission gears are connected with a conveying chain in an engaged manner. A centrifugal channel is formed in each transmission gear. A guide pipe is arranged below each transmission gear. An extrusion rod is in sliding connection in each guide pipe. The surface of each guide pipe is fixedly connected with an oil charging pipe. The tops of the oil charging pipes are fixedly connected with an oil storage box. A V-shaped plate is arranged in each oil charging pipe. A pointer is rotationally connected in a friction wheel. The side face of the pointer is in sliding connection with a scale disc. An airblowing gear is arranged between the two transmission gears. An I-shaped wind shield is rotationally connected in the air blowing wheel. According to the factory assembly line conveying chain-chain intelligent lubricating oil spraying and smearing equipment, through cooperative use of an extrusion wheel and the friction wheel, the effects that lubricating oil is automatically sprayed and smearedto the conveying chain, and a baffle and other protection mechanisms do not need to be dismounted are achieved.

Owner:绍兴市华获智能装备有限公司

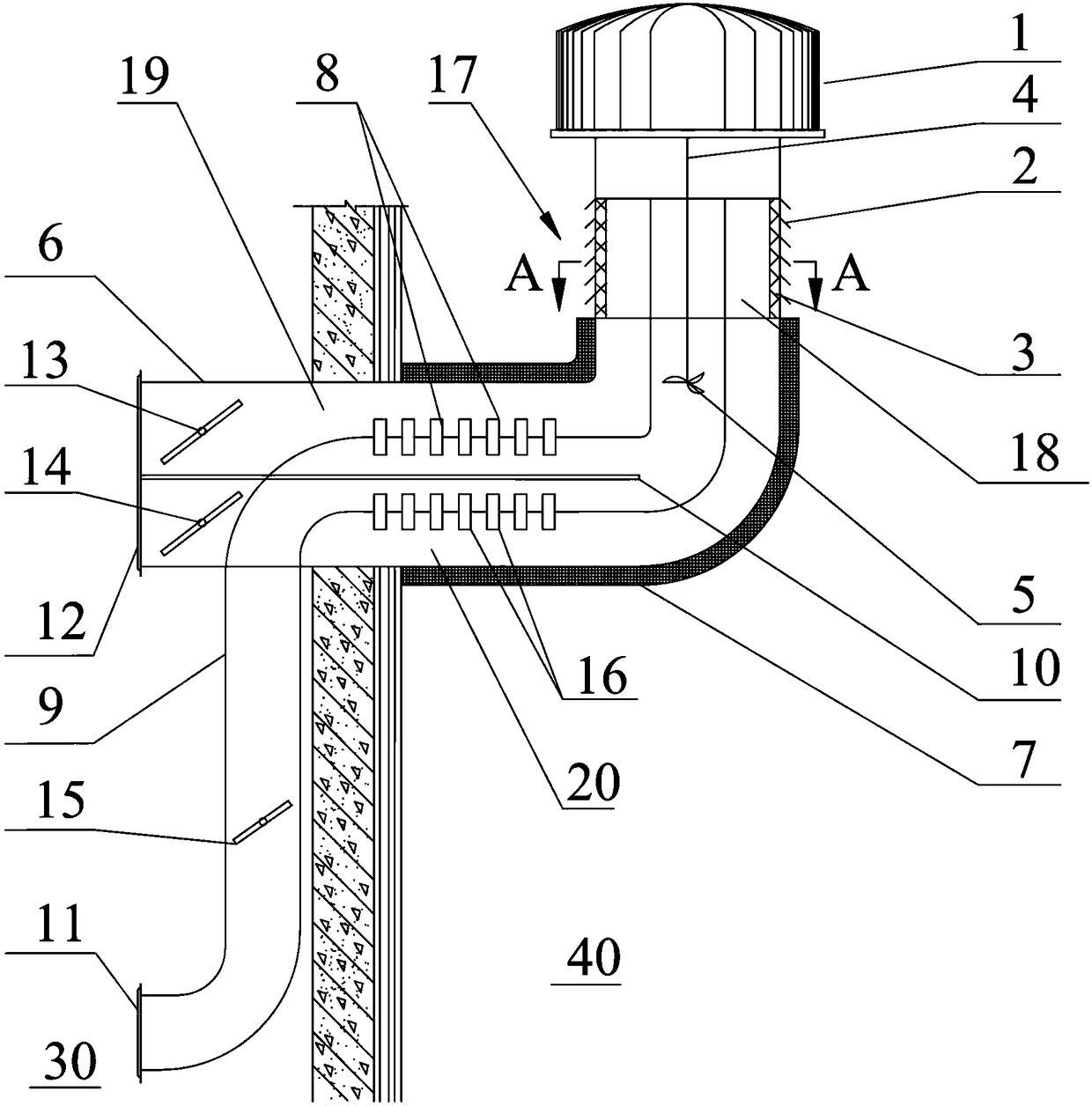

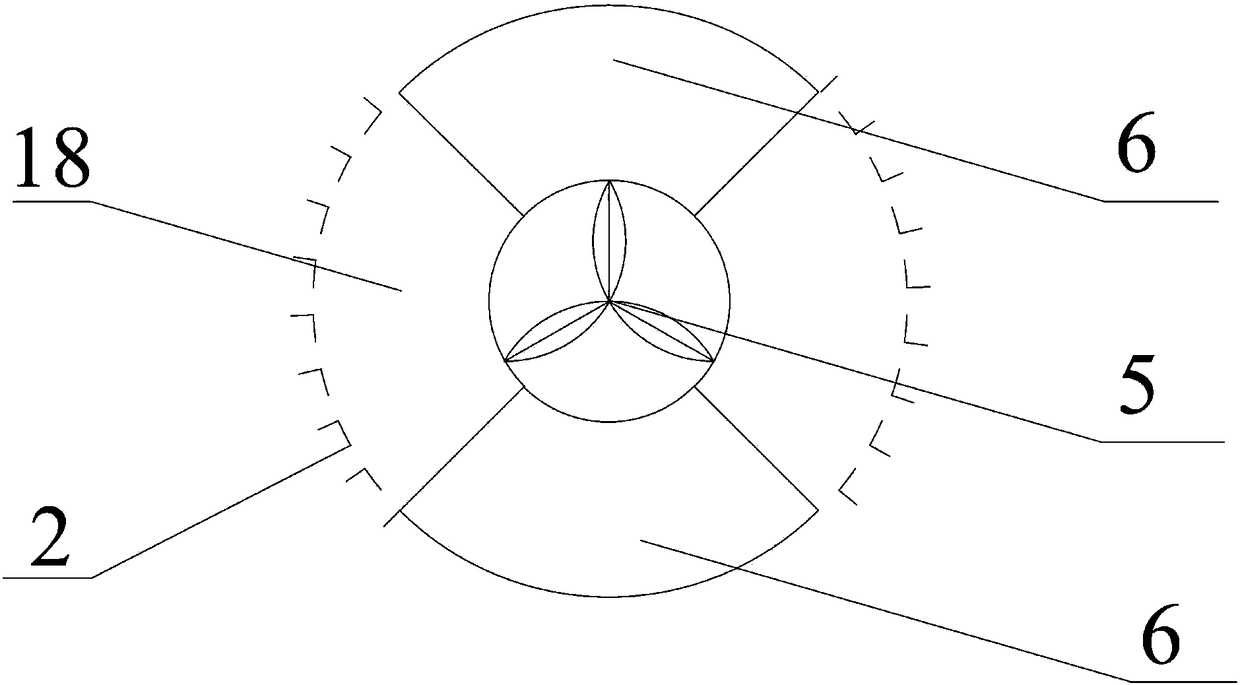

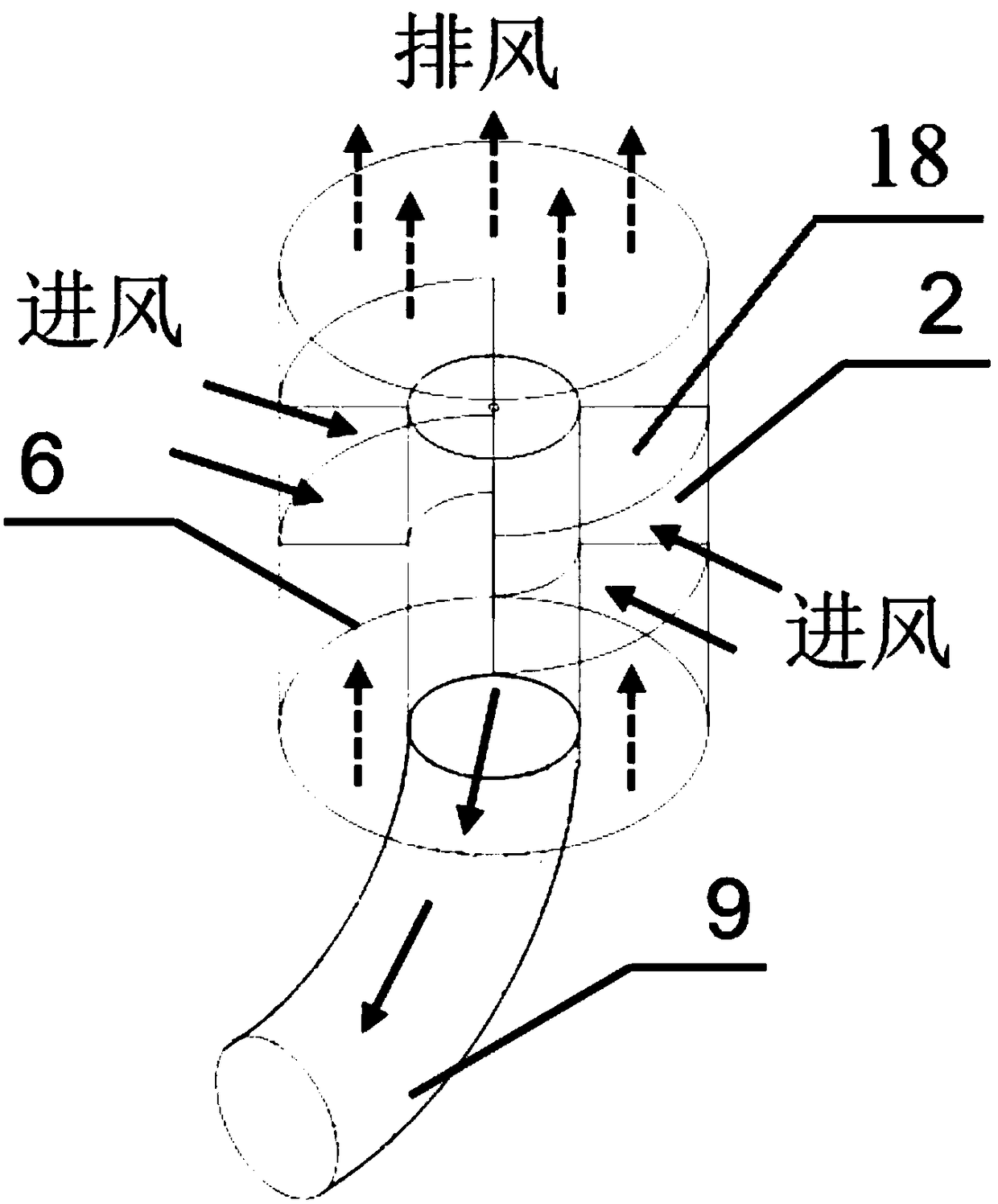

Unpowered ventilation device

ActiveCN108613311AAchieve recyclingReduce churnEnergy recovery in ventilation and heatingLighting and heating apparatusImpellerExhaust valve

The invention discloses an unpowered ventilation device. The unpowered ventilation device comprises an exhaust pipe, an air inlet pipe, an impeller, a first heat pipe, a second heat pipe and a separation plate; the exhaust pipe communicates an indoor space with an outdoor space; one end, which is located outdoors, of the exhaust pipe is provided with a rotary air cap; the air inlet pipe penetratesthrough the pipe wall, which is located indoors, of the exhaust pipe form the pipe, which is located outdoors, of the exhaust pipe and extends indoors; the pipe wall, which is located outdoors, of the exhaust pipe is provided with an outdoor air inlet which communicates with the air inlet pipe through a communication block; the impeller is arranged in the air inlet pipe and is connected onto therotary air cap through a transmission connection rod; the evaporation section and the condensation section of the first heat pipe are located on the inner and outer parts of the air inlet pipe; the condensation section and the evaporation section of the second heat pipe are located on the inner and outer parts of the air inlet pipe; the separation plate separates the first heat pipe from the second heat pipe and divides the exhaust pipe into a first exhaust passage and a second exhaust passage; and the first and second exhaust passages are internally provided with a first exhaust valve and a second exhaust valve correspondingly. By adopting the unpowered ventilation device, sufficient fresh air is provided for the indoor space; besides, the indoor heat loss can be lowered; and the utilization rate of energy is improved.

Owner:CHINA ACAD OF BUILDING RES

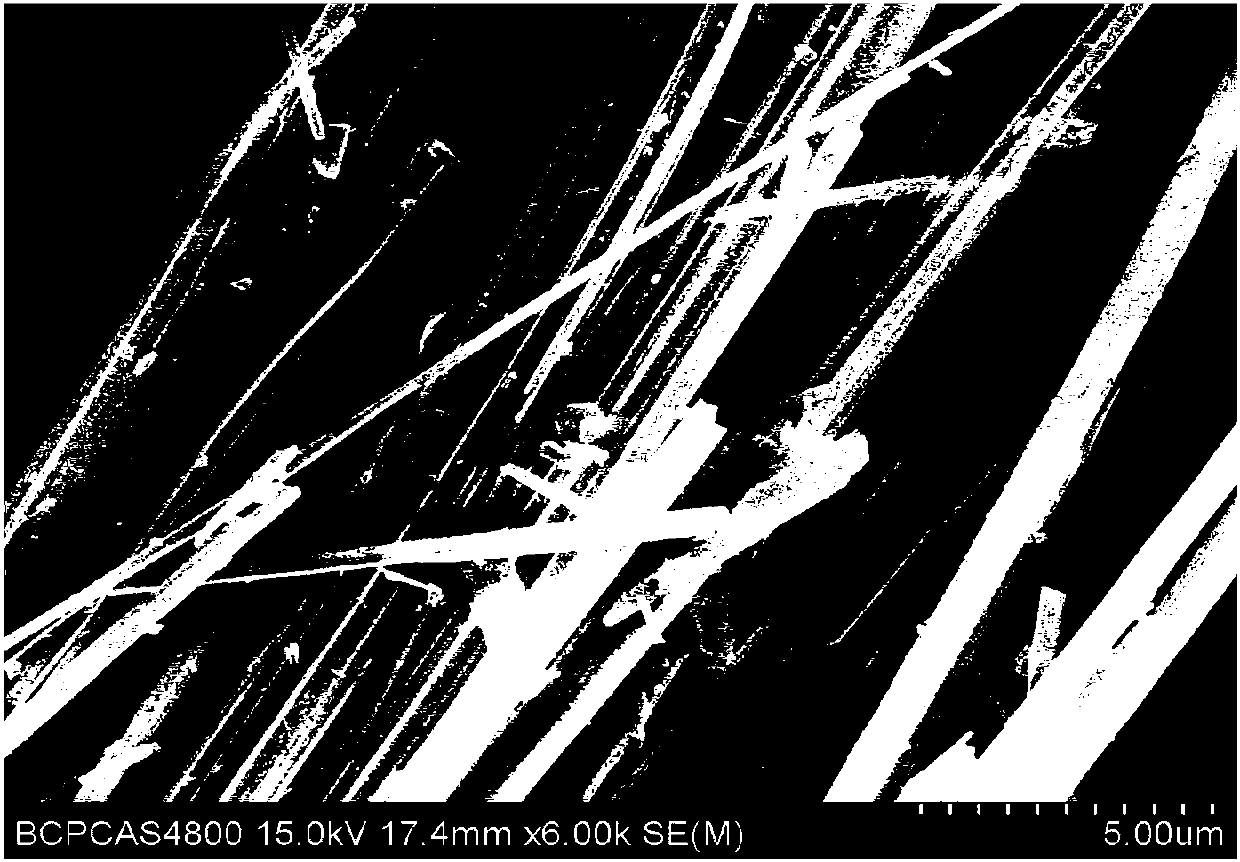

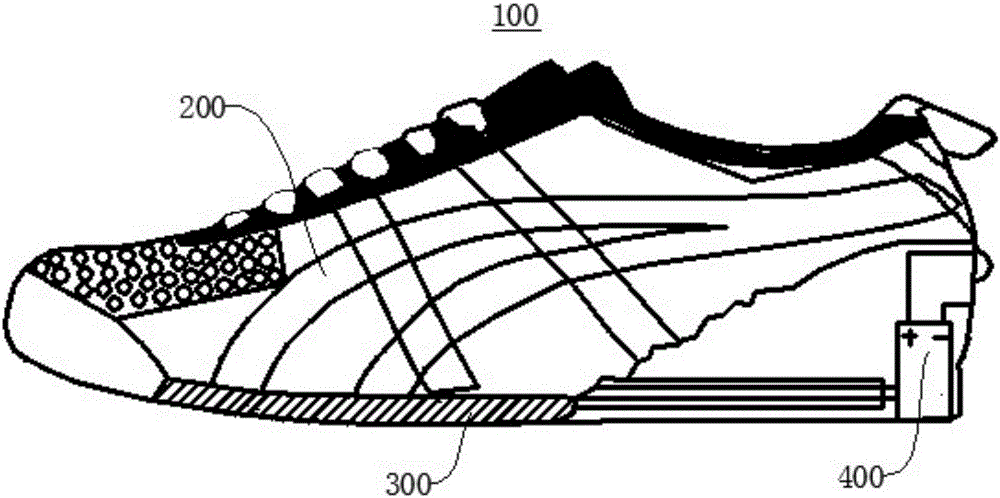

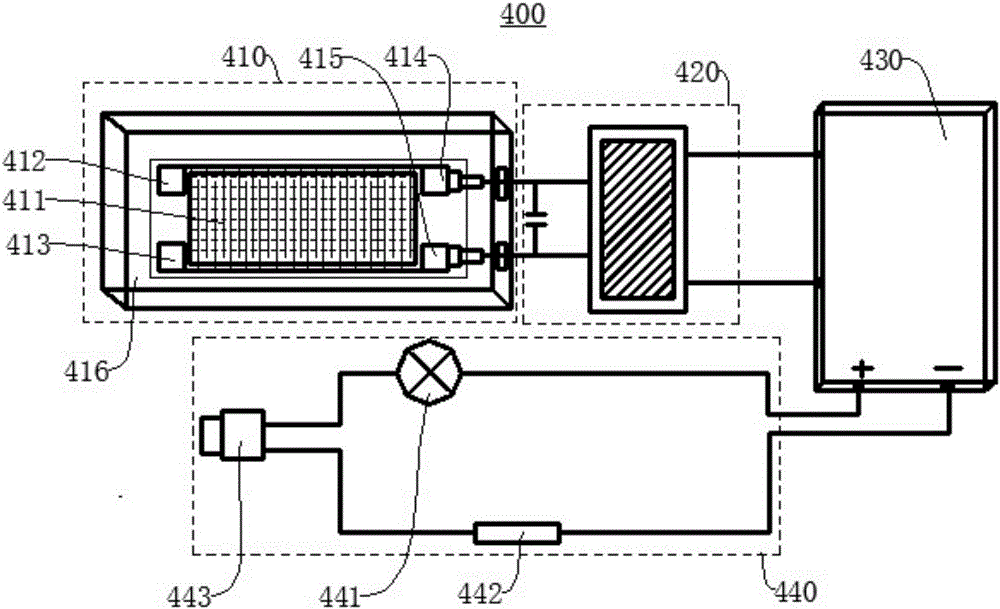

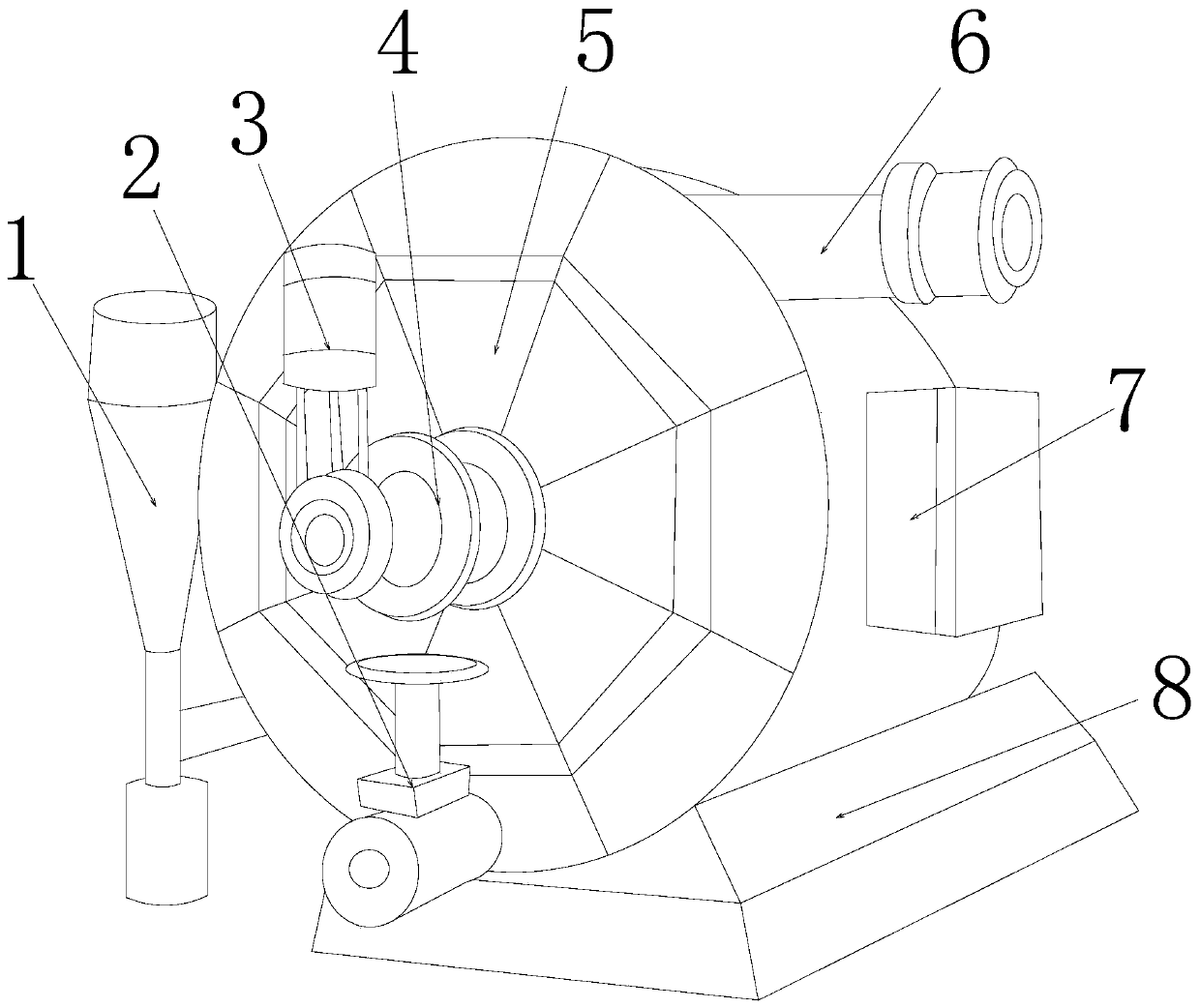

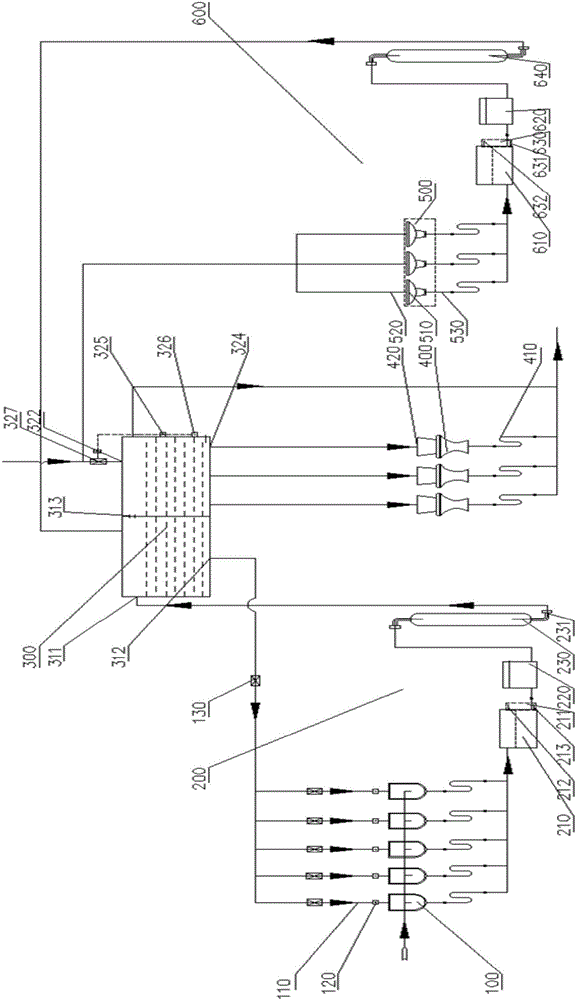

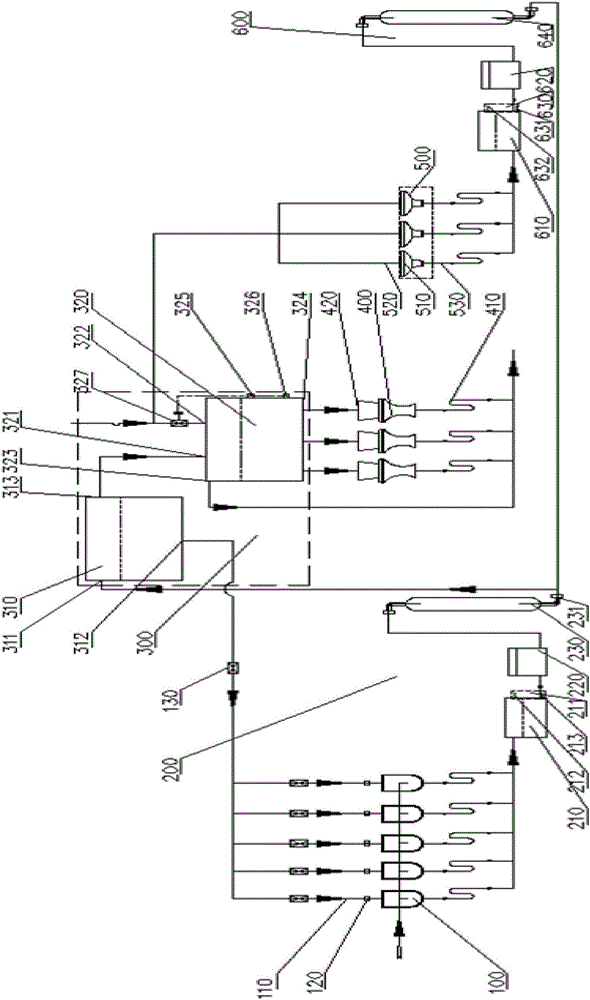

Piezoelectric ceramic fiber power generation system, power generation shoes and power generation tire

ActiveCN106356973AEffective use of piezoelectricityReach the effect of recyclingTyre partsBatteries circuit arrangementsElectricityCollection system

The invention provides a piezoelectric ceramic fiber power generation system, a pair of power generation shoes and a power generation tire, and relates to the technical field of piezoelectric recycling and conversion. The piezoelectric ceramic fiber power generation system comprises a piezoelectric ceramic fiber driver, an electric energy collection system, an electric energy storage system and an electric energy using system, wherein the piezoelectric ceramic fiber driver comprises a piezoelectric ceramic fiber composite material; the electric energy collection system is electrically connected with the piezoelectric ceramic fiber driver, and is used for collecting electric energy produced by the piezoelectric ceramic fiber composite material; the electric energy storage system is electrically connected with the electric energy collection system, and is used for storing electric energy collected by the electric energy collection system; the electric energy using system is electrically connected with the electric energy storage system, and is used for utilizing the electric energy stored by the electric energy storage system to work. The piezoelectric ceramic fiber power generation system has the advantage that the electric energy is produced by utilizing the deformation of the piezoelectric ceramic fiber composite material, and is finally provided for other electric appliance equipment to use, so as to effectively convert the waste mechanical energy into electric energy.

Owner:盐城宇欣陶瓷科技有限公司

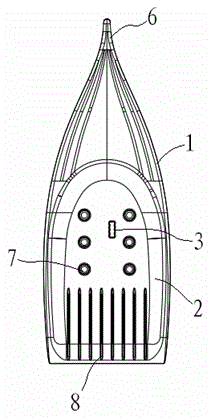

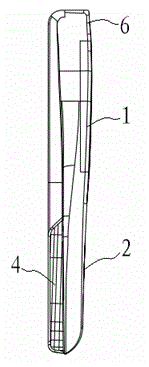

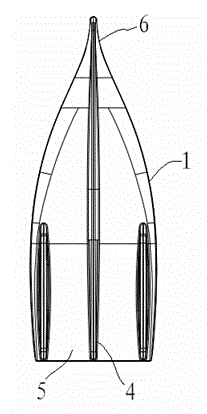

Rotational molding surfboard and manufacturing technology thereof

InactiveCN104139835AReduce resistanceChange the height of the arc and use the defectWaterborne vesselsCoatingsSurfboardingEngineering

The invention discloses a rotational molding surfboard and a manufacturing technology of the rotational molding surfboard. The rotational molding surfboard comprises a surfboard body, wherein the surfboard body is of a hollow structure with the front pointed and the rear blunt and is in the shape of a leaf, a streamlined concave portion is arranged on the top of the surfboard body, a plurality of convex tail fins are arranged at the bottom of the surfboard body, and a finished product of the surfboard is made through rotational molding hollow mold opening, material feeding, heating and rotation, forming and mold release, spraying, cooling, mold release and edge scraping processing. The rotational molding surfboard is simple in structure; because the rotational molding surfboard is provided with the tail fins, the effects that the surfboard is safe, durable and easy to operate can be achieved, production efficiency of the surfboard is improved, technological operation difficulty is reduced, and the purposes of standardization and batching are achieved.

Owner:佛山市顺德区和鼎塑料制品有限公司

Method for electrolyzing high-quality nickel from electroless nickel plating wastewater

ActiveCN107083559AUniform nickel layerRelieve pressurePhotography auxillary processesElectrodesTotal phosphorusSide reaction

A method for electrolyzing high-quality nickel from electroless nickel plating wastewater is disclosed, according to the method, the electrolysis current efficiency can be improved greatly, and a nickel layer which is uniform, compact and flat and with metallic luster can be obtained. The method for electrolyzing the high-quality nickel from the electroless nickel plating wastewater includes the following steps of (1) collecting electroless nickel plating wastewater by using a collecting tank; (2) adjusting the PH value of the collected wastewater to an alkalescence condition under which hydrogen evolution side reaction can be reduced; (3) adding polyvinyl alcohol with a volume percent concentration of 1%-5% and sodium persulfate with a mass percent concentration of 1%-10% to the wastewater and mixing, and standing for 12-24 hours; and (4) draining the wastewater being conducted standing to an electrolytic tank and conducting nickel electrolysis. The method for electrolyzing high-quality nickel from the electroless nickel plating wastewater is completely different with traditional electrolysis technologies, the current efficiency can reach to 70%, the COD degradation rate can reach to 70%, and the amount of total phosphorus is decreased 60%; by adoption of the method, the nickel layer which is uniform, compact and flat and with the metallic luster can be obtained, so that the effect of recycling nickel sources is achieved, meanwhile, organics can be degraded and total phosphorus can be removed, and accordingly the method has good application prospects.

Owner:深圳市世清环保科技有限公司

Battery plate washing and drying device

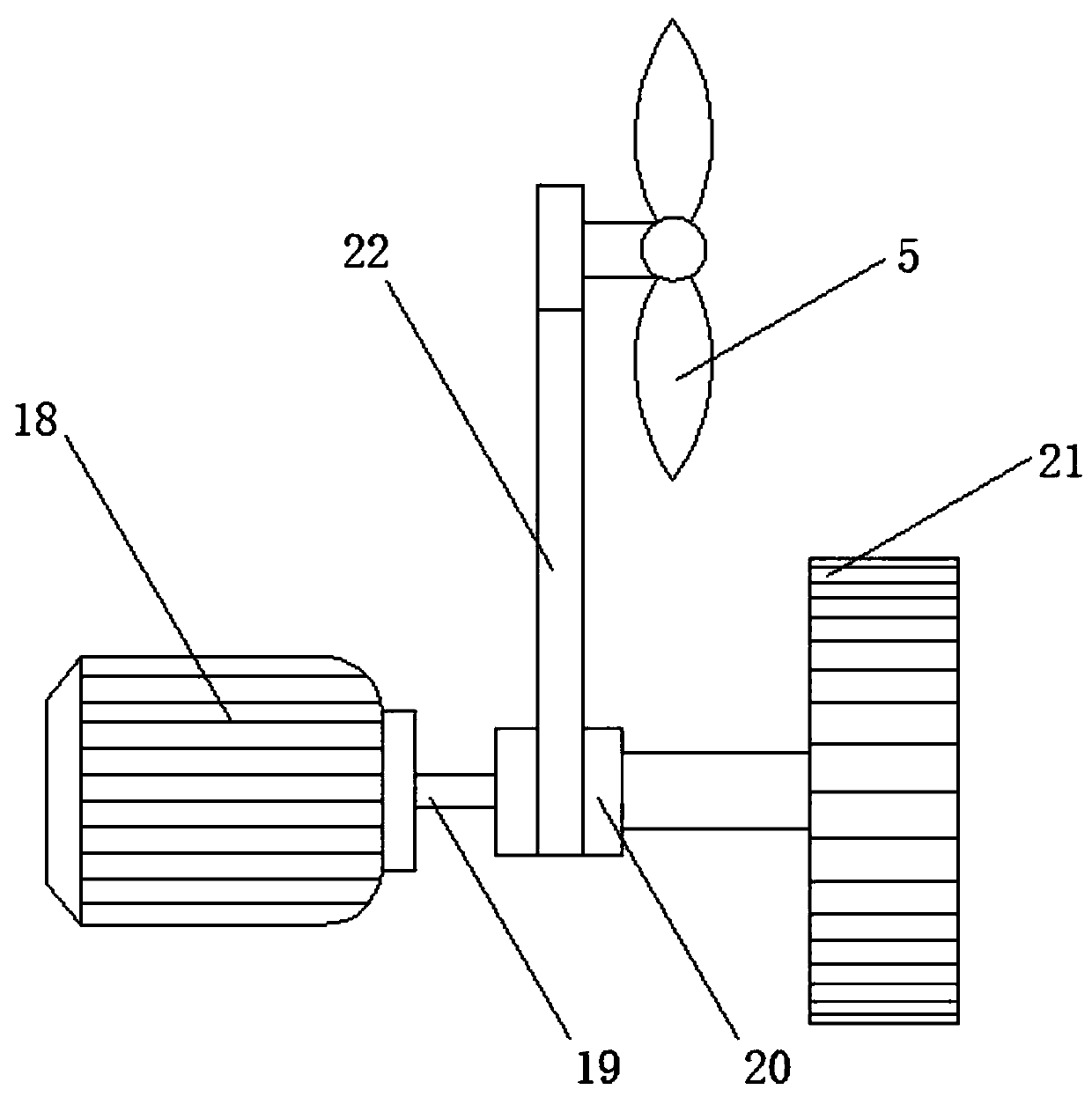

InactiveCN110877029AAchieve multi-angle cleaning effectReach the effect of recyclingDrying gas arrangementsCleaning using liquidsSprayerElectric machinery

The invention relates to the technical field of batteries, and discloses a battery plate washing and drying device. The battery plate washing and drying device comprises a big gear, a guide rail is movably connected to the outer side of the big gear, a drying box body is movably connected to the left end, close to the big gear, of the guide rail, an air outlet hole is formed in the front side of the drying box body, a fan is movably connected to the back side of the drying box body, a washing device is movable connected to the right end of the guide rail, a cleaning box is movable connected tothe upper end of the inner part of the washing device, and sprayers are movably connected to the inner walls of the four sides of the cleaning box. According to the battery plate washing and drying device, the structures of the cleaning box, the sprayers, a water outlet, a water storage layer and the like are used in a matched mode, thus the effect of multi-angle cleaning is achieved, the structures of a water inlet pipe, a water tank, a water pump, a water outlet pipe and the like are used in a matched mode, thus the effect that water can be recycled is achieved, the structures of a motor, arotating shaft, a rotating wheel, the fan and the like are used in a matched mode, and thus the effect that drying can be conducted after cleaning is achieved.

Owner:郑诗永

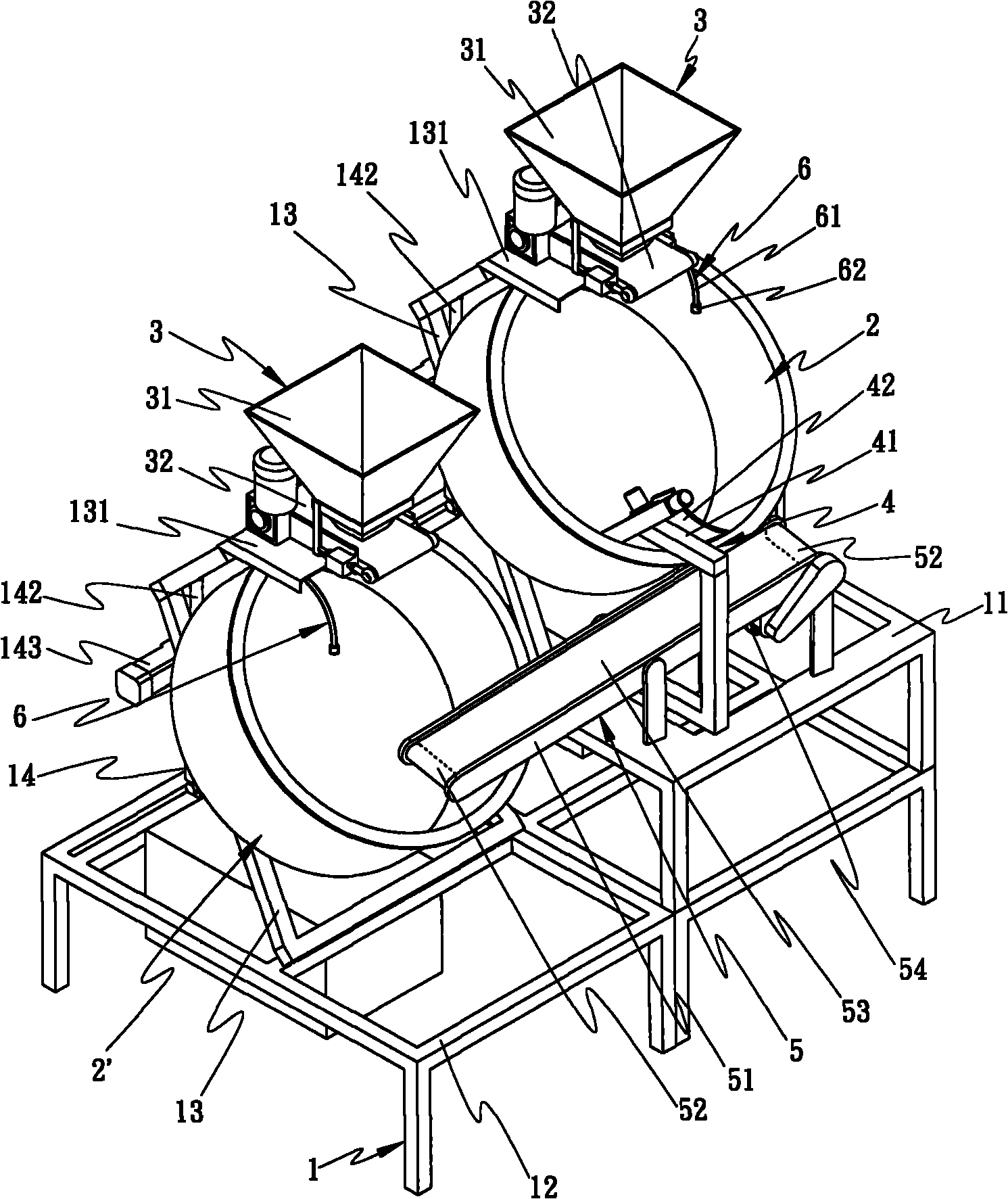

Double-feed disk pelletizer

InactiveCN101791530AReach disposalReach the effect of recyclingGranulation in rotating dishes/pansSlagSewerage

The invention discloses a double-feed disk pelletizer, which is characterized in that: two groups of inclined brackets are arranged on a pedestal, wherein each bracket is combined with a pelletizing barrel which is driven by a motor to revolve respectively; a conveying device is combined below the front edge of the pelletizing barrel; the front edge of one of the pelletizing barrels is combined with a movable arm; the movable arm is combined with an angle adjusting barrel plate, so that the barrel plate is adjusted to an appropriate angle and extends into the pelletizing barrel; a feeding device is combined above each pelletizing barrel respectively to form the double-feed disk pelletizer used for pelletizing recycles wastes, such as sewage sludge and furnace bottom slag into particles; and the surface of the particles is coated with a sludge layer and is sintered into hard environment-friendly stone. Therefore, the effects of environment-friendly treatment and recycling of the wastes are achieved.

Owner:黄兆龙

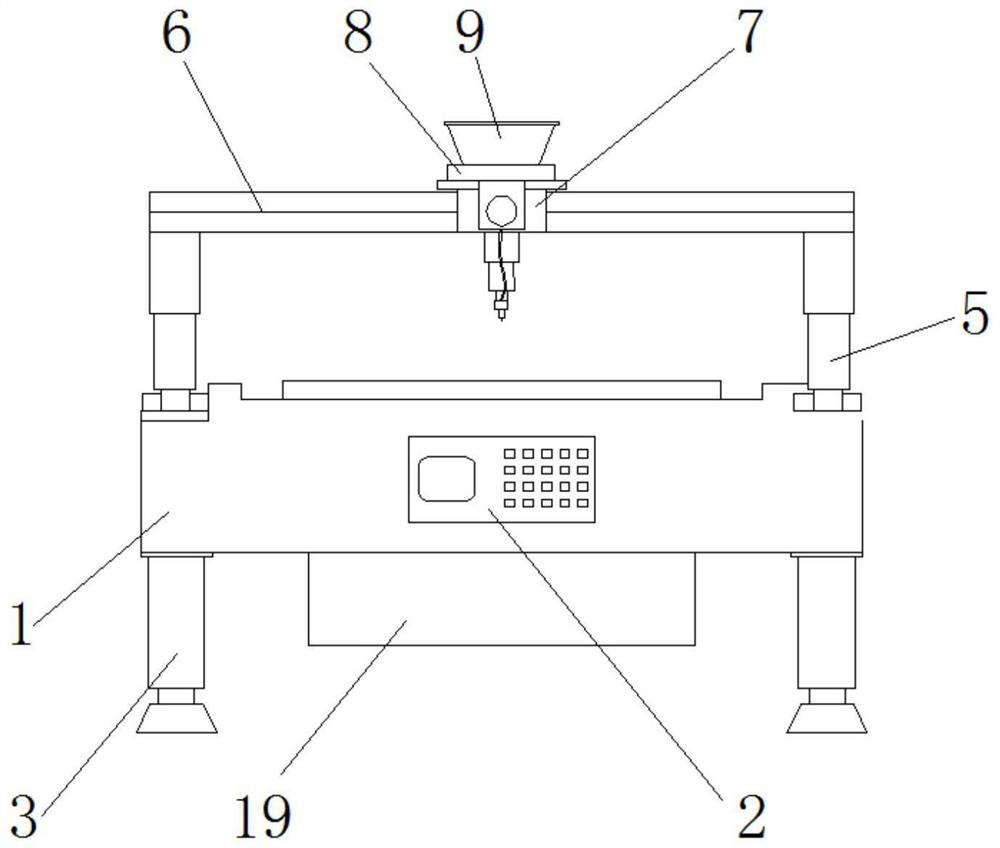

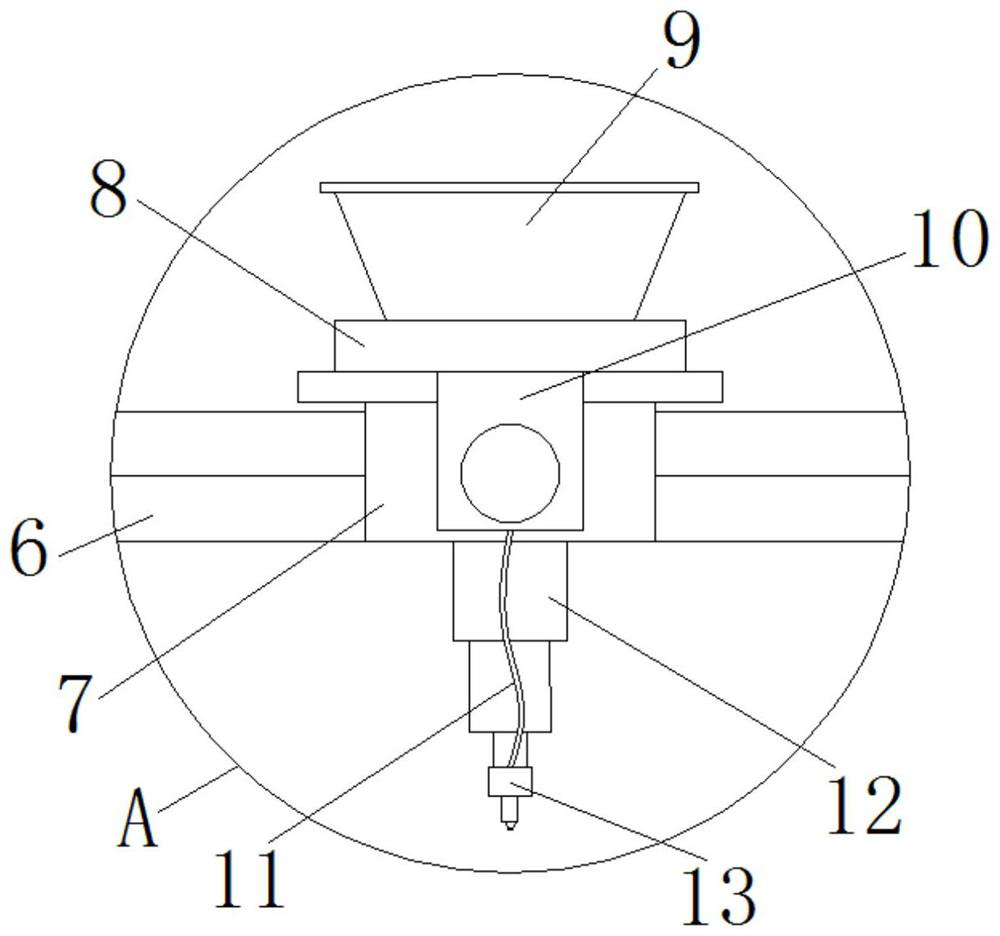

Waste recovery device of 3D printing device

PendingCN112454900AReach the effect of recyclingEasy to transportAdditive manufacturing apparatusManufacturing recyclingElectric machineryWaste material

The invention discloses a waste recovery device of a 3D printing device. The waste recovery device comprises a printing table, wherein a control panel is arranged on the front surface of the printingtable, supporting legs are fixedly connected to the lower surface of the printing table, an electric sliding rail is fixedly connected to the upper surface of the printing table, a telescopic column is arranged on the upper surface of the electric sliding rail, a cross rod is fixedly connected to the top end of the telescopic column, an electric sliding block is arranged on the surface of the cross rod, a fixing base is arranged on the upper surface of the electric sliding block, and a feeding funnel is fixedly connected to the upper surface of the fixing base. According to the waste recoverydevice of the 3D printing device, through the arrangement of the a waste leaking hole, the conveying of waste generated by printing is facilitated, through the arrangement of a crushing box, a crushing motor and a crushing roller, printing waste fed from the first waste leaking hole can be crushed, and through the arrangement of a waste collecting box, the collection of the crushed printing wastein the crushing box is facilitated, and the 3D printing device has the effect of waste recovery.

Owner:北京联袂义齿技术有限公司

Lifebuoy waste recycling device

InactiveCN109663632AEasy to slidePrevent getting involvedDirt cleaningGrain treatmentsWaste materialWaste recycling

The invention discloses a lifebuoy waste recycling device. The lifebuoy waste recycling device comprises a collection box and a crushing box. The collection box is positioned at the top end of the crushing box and is communicated with the crushing box. A negative-pressure fan is arranged on the outer wall of one side of the collection box. A first blocking net cover is fixedly arranged on the inner wall of the side, close to the negative-pressure fan, of the collection box. A collection pipe is arranged on the side, far away from the negative-pressure fan, of the collection box. A collector isfixedly arranged at one end of the collection pipe. The collector is of a cavity structure. A rotating rod is rotationally arranged in the collector. Collecting plates are fixedly arranged on the outer side of the rotating rod. A rotating motor is fixedly arranged on the outer wall of one side of the collector. An output shaft of the rotating motor is fixedly connected with the collecting plates.A driving crushing gear and a driven crushing gear are rotationally mounted in the crushing box. The lifebuoy waste recycling device is reasonable in structure and convenient to use, achieves the effect of recycling the waste material of an air permeable mold lifebuoy and is environmentally-friendly and economical.

Owner:滁州安阳智能科技有限公司

Feeding device capable of recycling excess feed for aquaculture

InactiveCN112400771AReach the effect of recyclingAvoid pollutionClimate change adaptationPisciculture and aquariaAnimal scienceElectric machinery

The invention relates to the technical field of aquaculture, and discloses a feeding device capable of recycling excess feed for aquaculture. The feeding device comprises a storage box, a transverse plate is fixedly connected to the interior of the storage box, a motor is fixedly connected to the top of the transverse plate, and a rotating shaft is rotatably connected to the bottom of the motor; awater pump is fixedly connected to the inner bottom wall of the storage box, a water outlet pipe is fixedly connected between the top of the water pump and the back face of a collecting box, a watersuction pipe is fixedly connected to the back face of the water pump, the rotating shaft is sleeved with a threaded sleeve, and a stirring rod is fixedly connected to the lower portion of the exteriorof the rotating shaft; and a cylinder is fixedly connected to the outer portion of the threaded sleeve, and a movable hopper is fixedly connected to the top of the cylinder. After the water pump is started, the rotating shaft continues to drive the stirring rod to rotate, the stirring rod rotates to drive the feed in the cylinder to evenly float in the cylinder, the feed and pond water can be pumped away together, and therefore the effect that the feed is prevented from being deposited at the bottom of the cylinder and being difficult to recycle is achieved.

Owner:李明雄

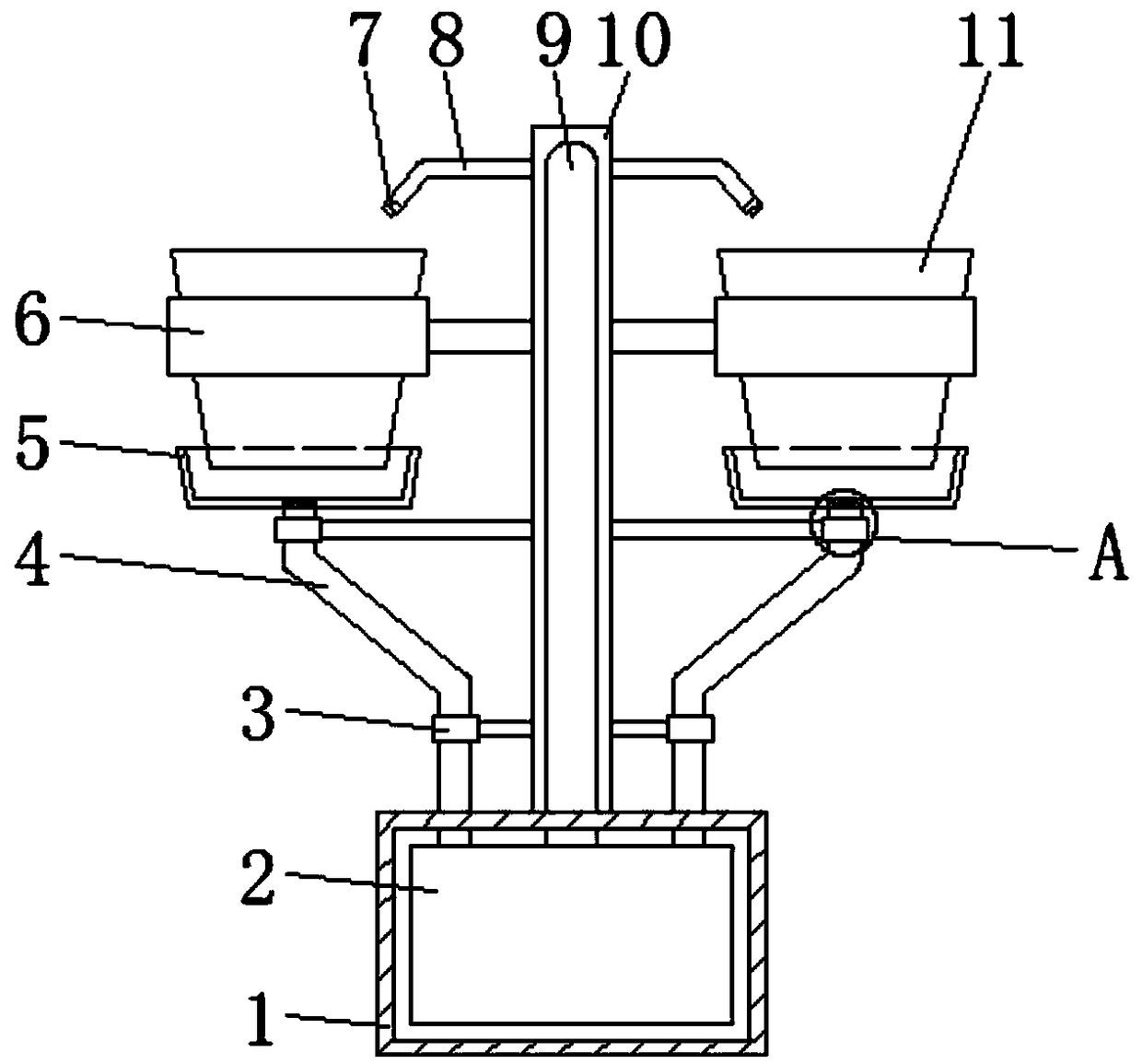

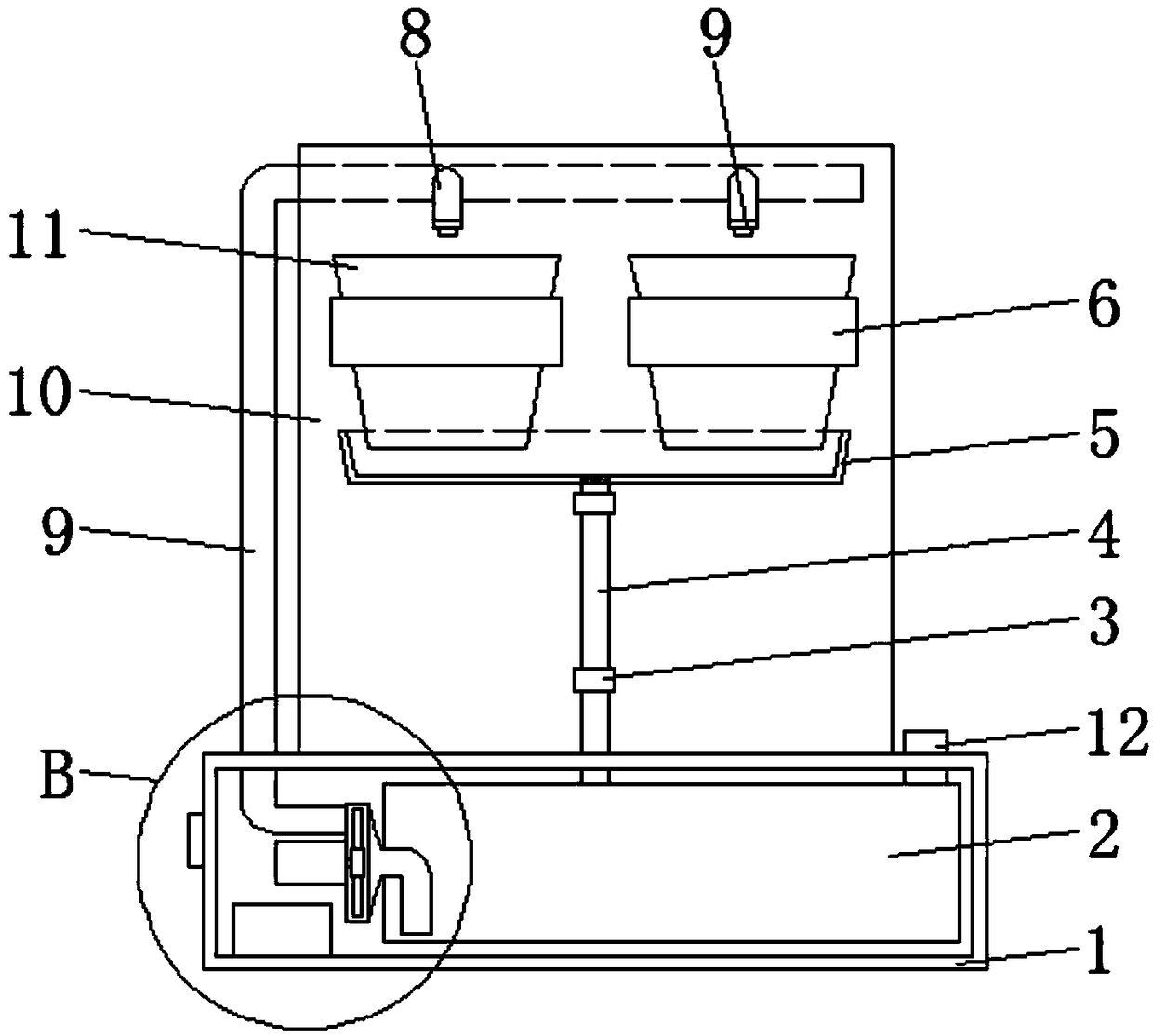

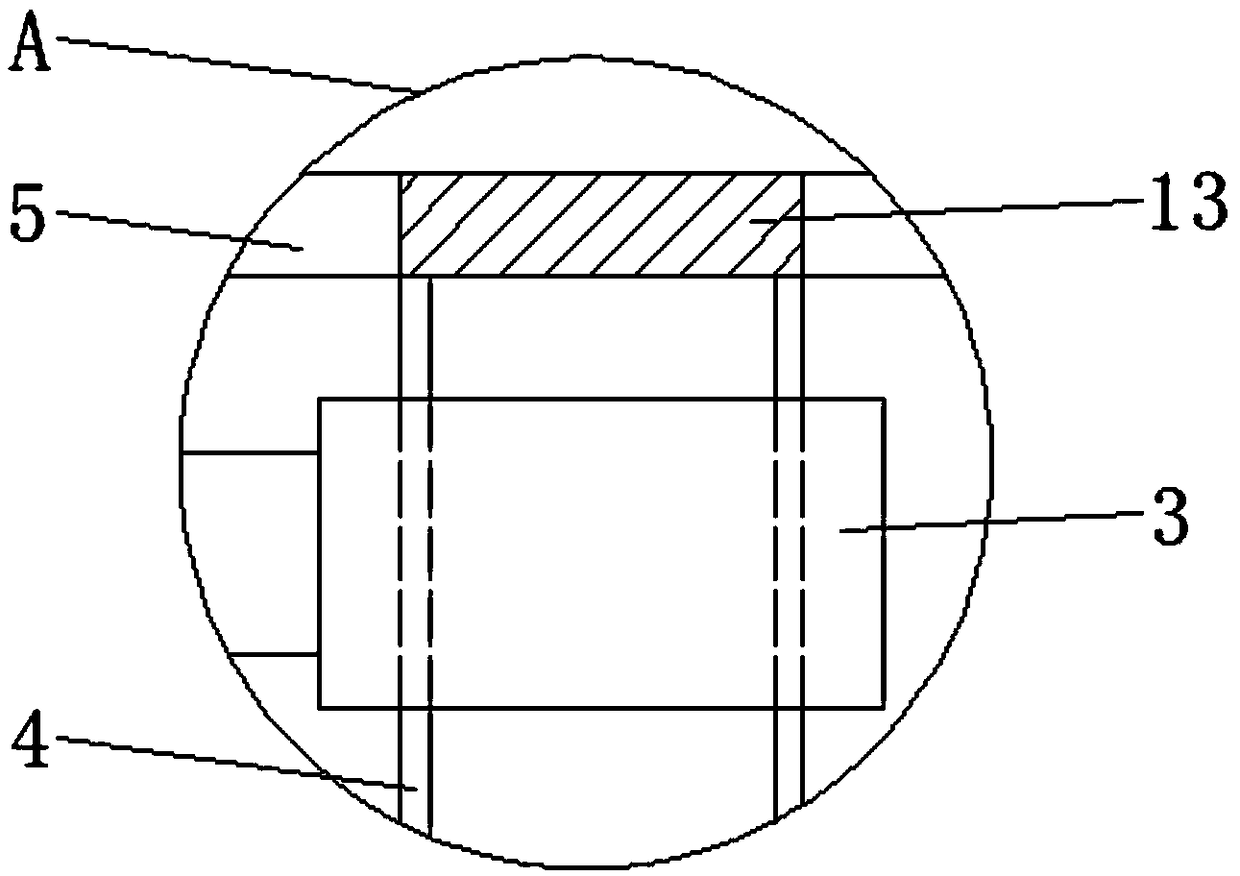

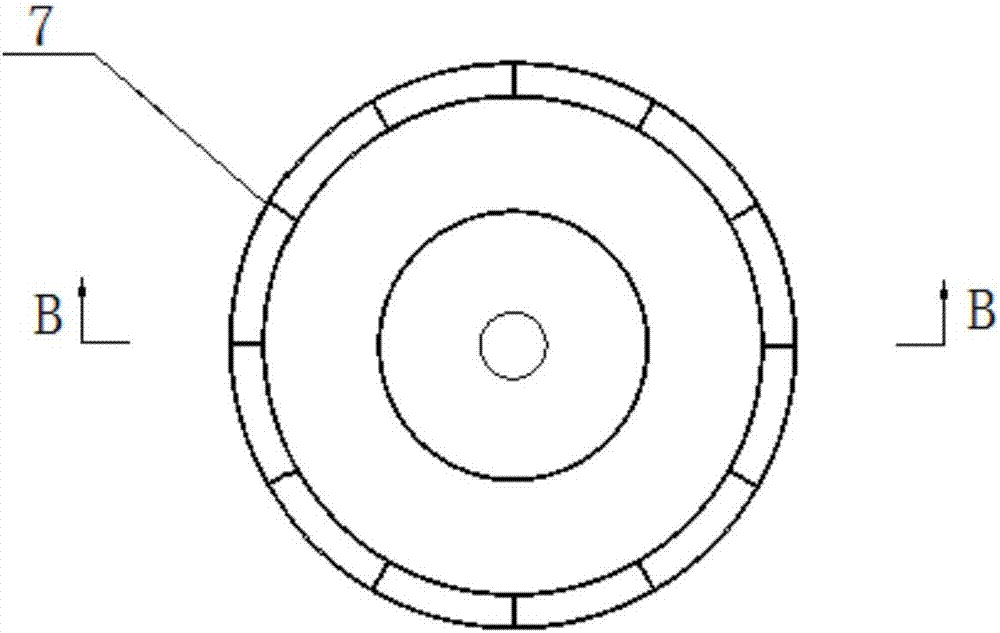

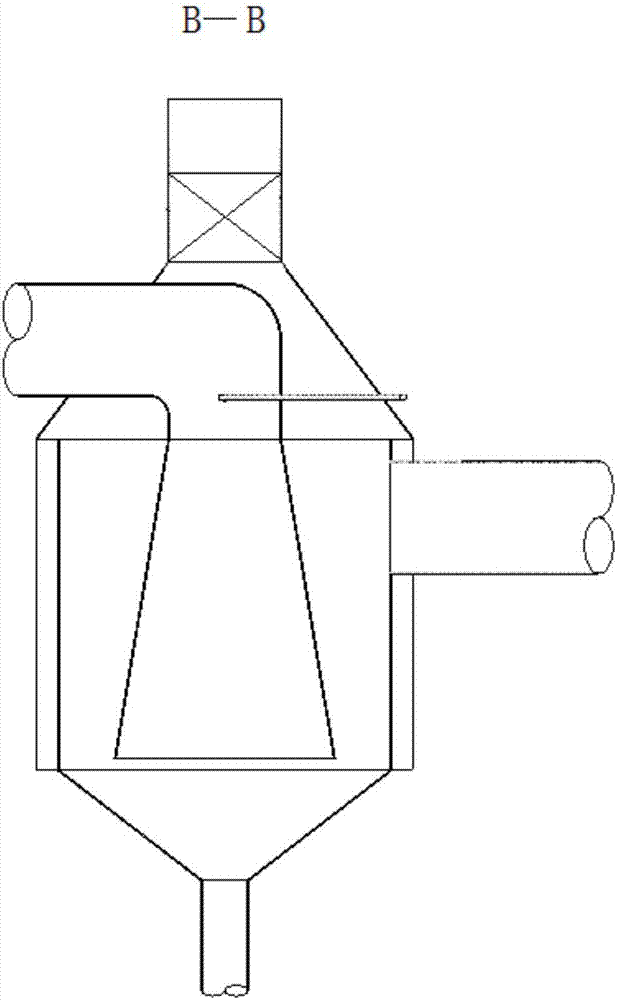

Water-saving device for landscaping

InactiveCN108738851ATo achieve the effect of collection and utilizationReach the effect of recyclingSelf-acting watering devicesReceptacle cultivationWater savingWater resources

The invention discloses a water-saving device for landscaping. The water-saving device comprises a base, a water tank, flower port fixing racks, an installation plate and a water pump, wherein the installation plate is fixed to the upper surface of the base, the flower port fixing racks which are symmetrically distributed are inserted into the two sides of the installation plate, and a collectiongroove is formed under the flower port fixing racks. A filter screen is embedded into the inner wall at the upper end of a water drain pipe, spraying rods are symmetrically inserted into the outer wall on the upper surface of the installation plate, and sprayers are inserted into the lower ends of the spraying rods. A water conveying pipe is inserted into the upper end of the installation plate, the water tank, a timer and the water pump are installed in the base, and the end, inserted into the installation plate, of the water conveying pipe is inserted into one side of the upper end of the water pump. By arranging the timer, the time for irrigating landscaping plants is controlled, the situation that the irrigation time is too long, water resources are wasted is prevented, dripping watercan be collected through the collection groove and recycled, and the effect of reducing the water resource consumption is achieved.

Owner:WUHU CHAOYUANLI IND DESIGN CO LTD

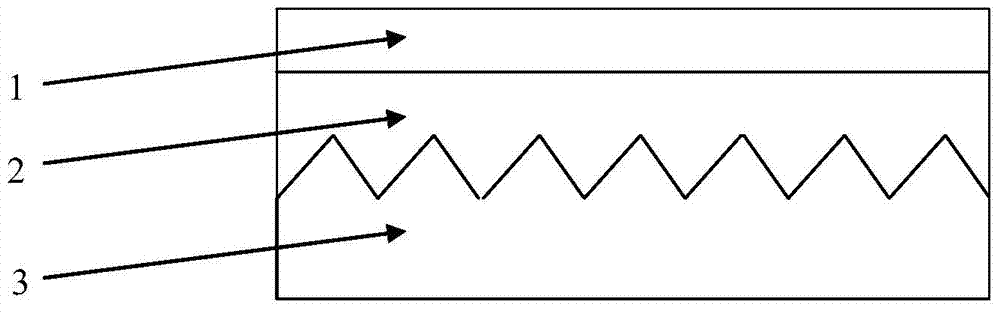

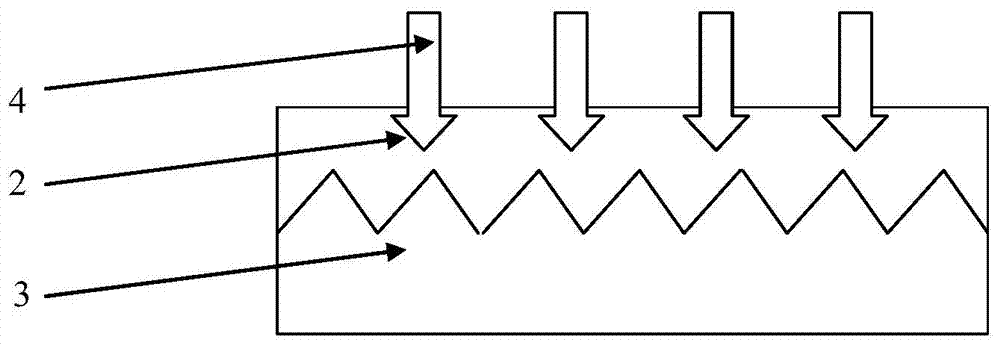

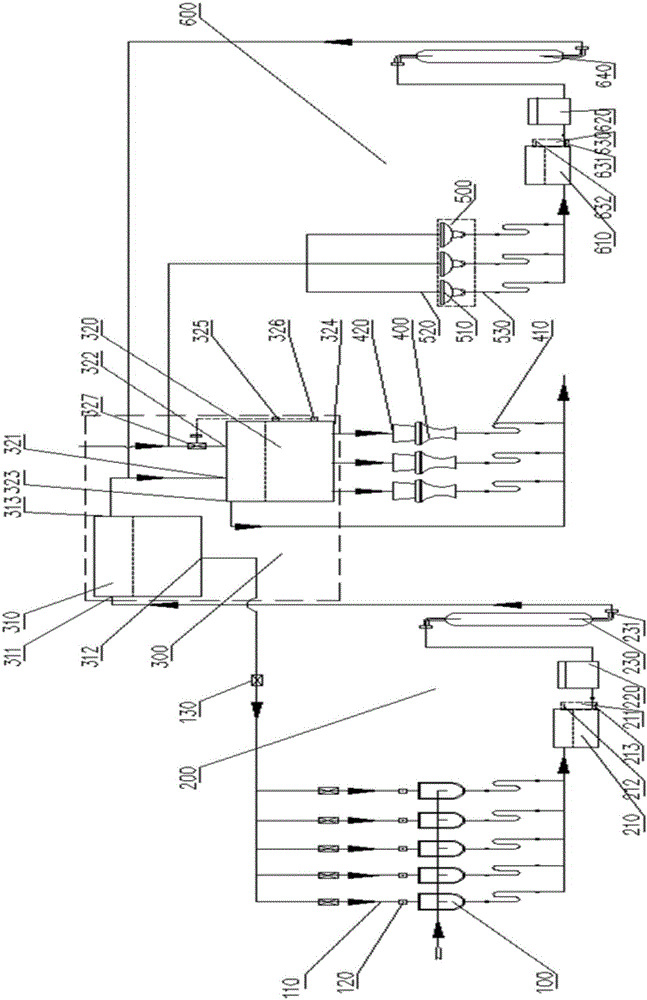

Industrial production smoke cooling, dust reducing and waste heat recycling device and method

PendingCN107270729AReach the effect of recyclingReach the effect of dust reduction in the first stepDispersed particle separationWaste heat treatmentRecovery methodExhaust pipe

The invention discloses an industrial production smoke cooling, dust reducing and waste heat recycling device and method and belongs to the technical field of smoke treatment of various production systems before blast furnace ironmaking. The device comprises an air guide mechanism, a smoke cooling mechanism and a heat exchange device, wherein the air guide mechanism is used for cooling the whole device; the smoke cooling mechanism is located inside the air guide mechanism, and the smoke cooling mechanism and the air guide mechanism are of a cavity loop type structure, and large-particle smoke falls to the bottom of the smoke cooling mechanism due to the facts that the temperature is decreased and the density is increased; the heat exchange device is fixed in an air exhaust pipe at the top of the air guide mechanism, and the heat generated during heat exchange of the air guide mechanism is absorbed through the heat exchange device; and the smoke cooling mechanism is externally connected with a dust-containing smoke guide-in pipe and a dust-reducing smoke guide-out pipe which penetrate out of the air guide mechanism. According to the industrial production smoke cooling, dust reducing and waste heat recycling device and method, the purposes of cooling the dust-containing smoke, dropping and recycling dust-containing particles and recycling and utilizing heat can be achieved, in addition, a cooling air valve can be omitted without fluctuating the technique of the whole system, and the quality of produced products is stable.

Owner:MAANSHAN IRON & STEEL CO LTD

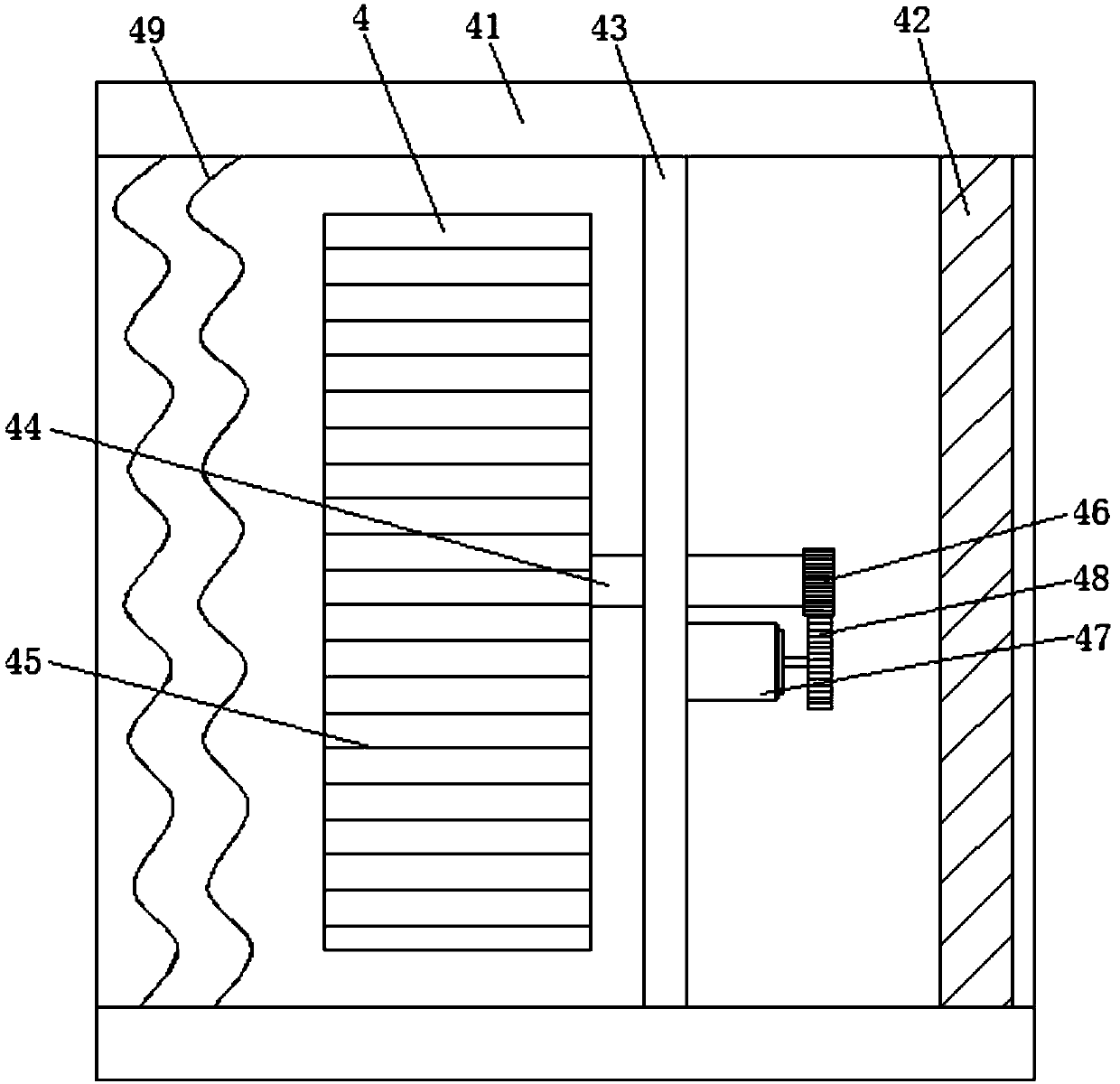

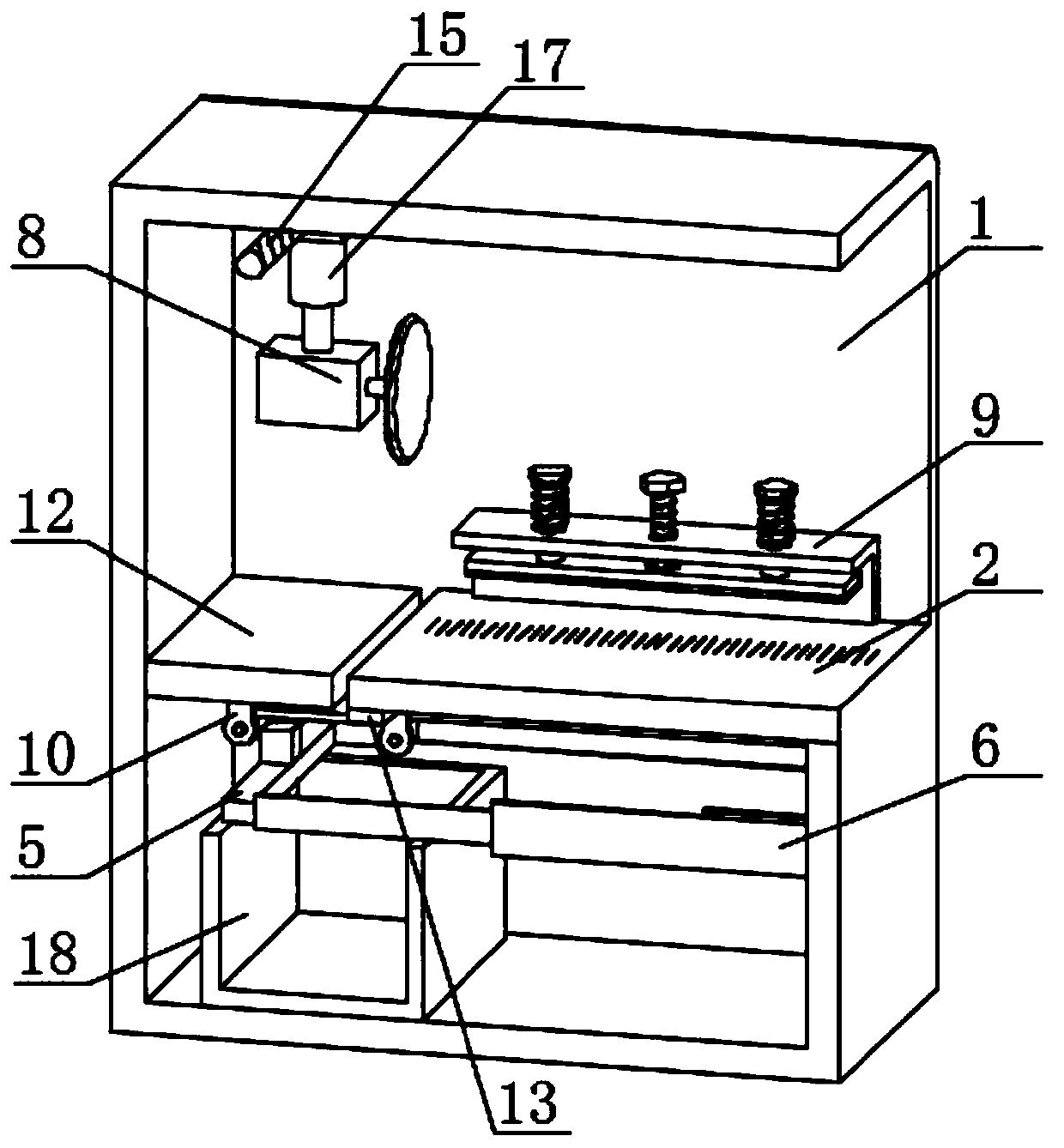

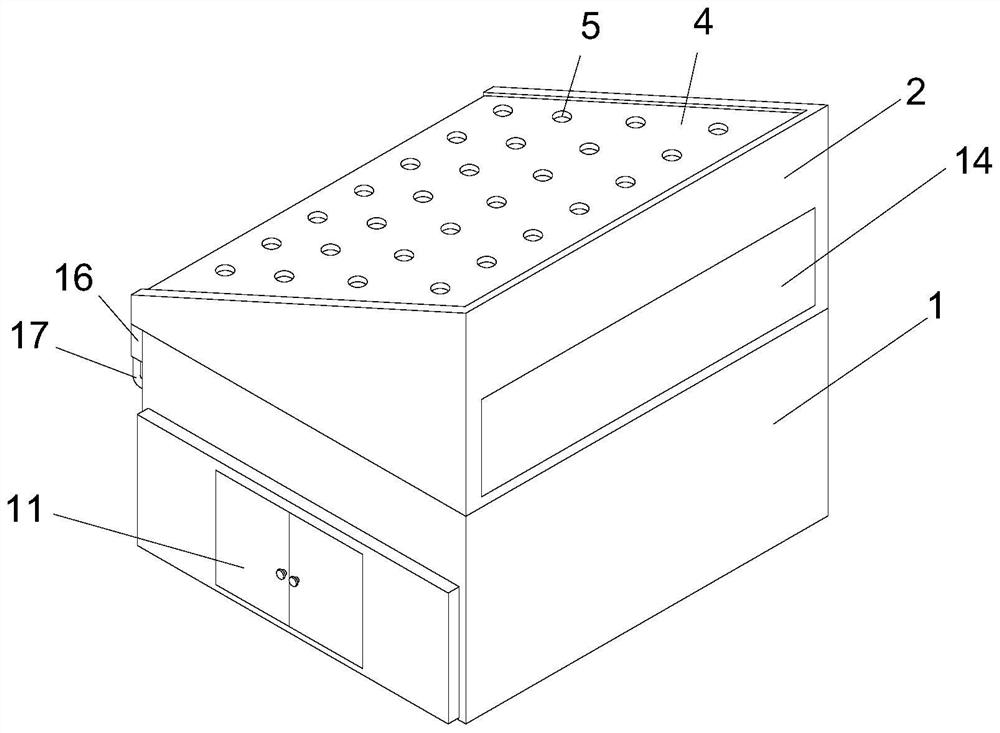

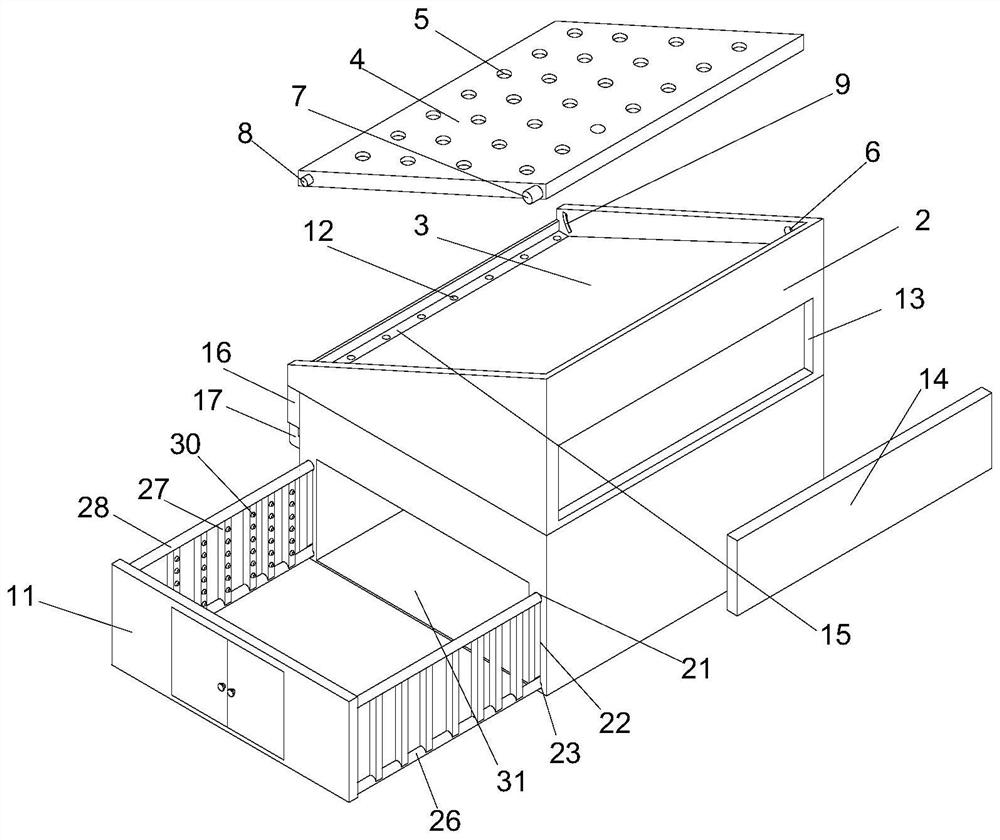

Hot air-type tea leaf enzyme-deactivating machine with heat recycling function

InactiveCN107927221AAvoid uneven heatingLight in massPre-extraction tea treatmentEnzymeThermal energy

The invention discloses a hot air-type tea leaf enzyme-deactivating machine with a heat recycling function. The hot air-type tea leaf enzyme-deactivating machine comprises a box body, wherein supporting legs are fixedly connected to the lower surface of the box body; a box cover is movably connected to the upper side of the box body through hinges; hot air blowers are fixedly connected to the inner wall of the box body; a retainer ring is fixedly connected to the lower side of the inner wall of the box body; an elastic net is fixedly connected to the inner wall of the retainer ring; a drivingdevice is fixedly connected to the bottom of the inner wall of the box body; one side of the driving device is fixedly connected with the lower surface of the elastic net. A speed reducing motor is arranged for driving a wheel disc to rotate, the wheel disc rotates to drive a toothed rod to move down because of engagement of a toothed rail and the toothed rod, and the toothed rod moves down to pull a fixing block so as to deform the elastic net; when the toothed rail rotates to an empty position, the toothed rail and the toothed rod are disengaged, so that the effect of limiting the toothed rod is eliminated, and tea leaves are vertically thrown up by the elastic net; by spreading out the tea leaves, the effect of preventing the tea leaves from being heated nonuniformly due to accumulationof the tea leaves is achieved.

Owner:ZHEJIANG XINCHANG TUANFENG MACHINERY

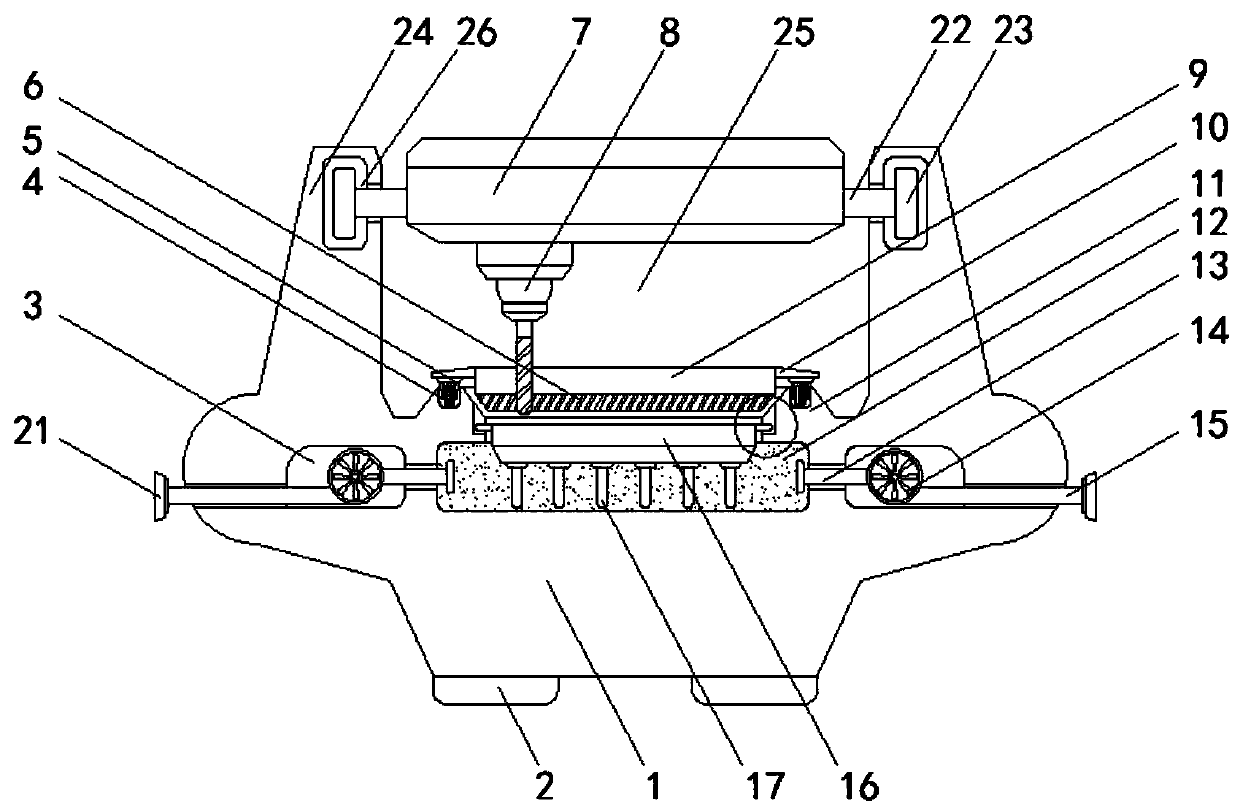

Numerical control milling machine with heat recovery device

ActiveCN110449642AReach the effect of recyclingEasy to cleanMilling machinesMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the technical field of numerical control equipment, and discloses a numerical control milling machine with a heat recovery device. The numerical control milling machine comprises a main body base, two supporting pads are fixedly arranged on the left side and the right side of the bottom of the main body base, and a machining groove is formed in the top of the main body base. According to the numerical control milling machine with the heat recovery device, a heat exchange tank is arranged, so that during the operation of the numerical control milling machine, heat generated by a heat conduction machining plate can exchange heat with heat exchange liquid in the heat exchange tank through heat exchange sheets at the bottom of the heat conduction machining plate, a clearing scraping plate is arranged, in addition, a clearing brush corresponding to the heat conduction machining plate is fixedly arranged at the bottom of the clearing scraping plate, so that a user can move the clearing scraping plate so as to drive the clearing brush to move and clear scraps at the top of the heat conduction machining plate, and therefore the purpose of conveniently clearing thescraps is achieved.

Owner:GAOYOU YONGFA MACHINERY

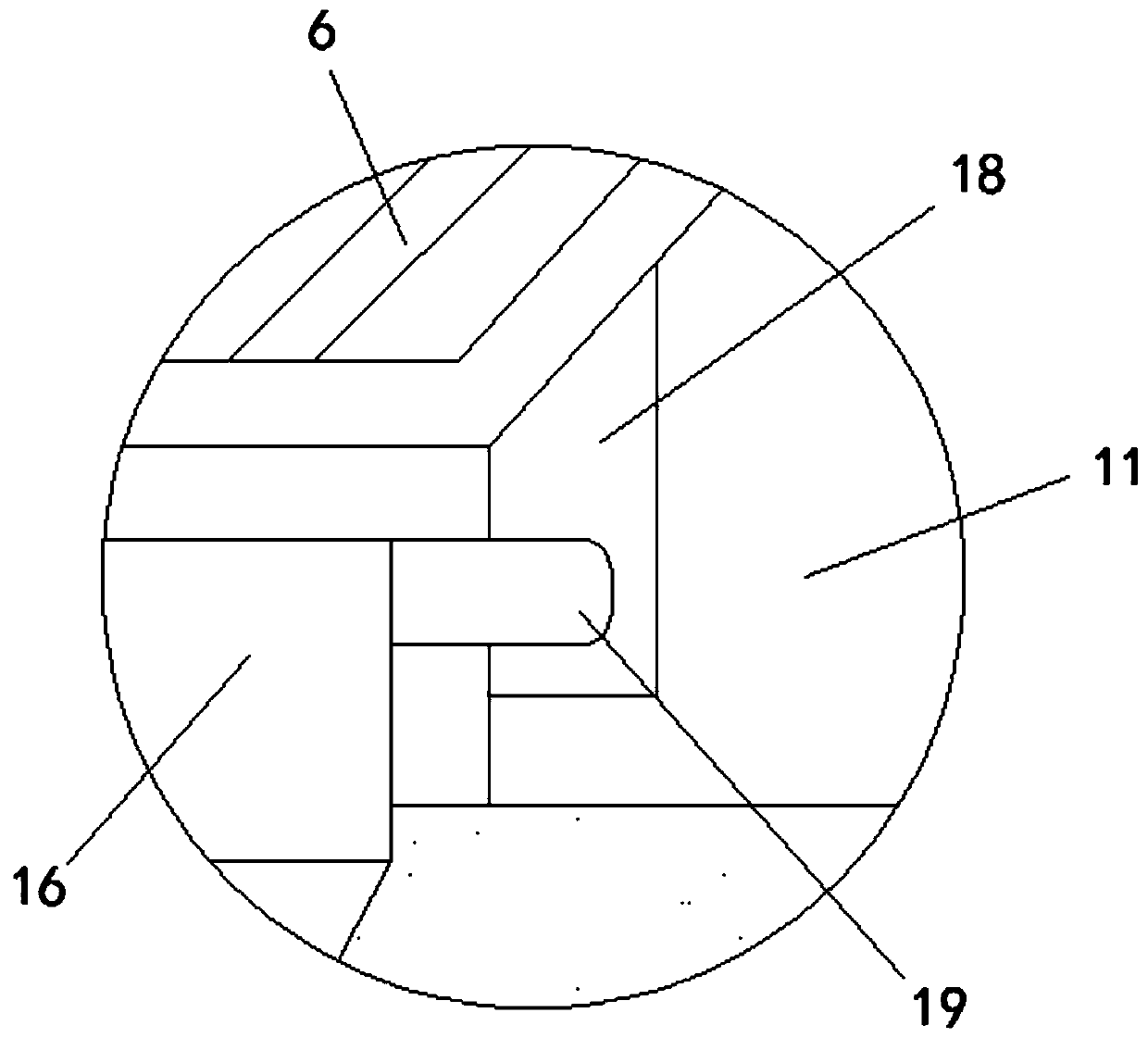

Residual material recyclable type ceramic tile cutting machine for construction site

InactiveCN110815599AImprove stabilitySolve the problem of waste and increase construction costWorking accessoriesStone-like material working toolsElectric machineMechanical engineering

The invention provides a residual material recyclable type ceramic tile cutting machine for a construction site, and relates to the technical field of building. The residual material recyclable type ceramic tile cutting machine for the construction site comprises a shell, a placing table is fixedly connected inside the shell, clamping mechanisms are fixedly connected to the two ends of the top surface of the placing table, sliding grooves are formed in the two sides of the inner wall of the shell, a forward and reverse rotating motor is fixedly connected to one side surface of the shell, and ascrew rod is fixedly connected to the output end of the forward and reverse rotating motor. According to the residual material recyclable type ceramic tile cutting machine for the construction site,a first electric push rod, the sliding grooves, sliding blocks, a push plate, a hinge block, a connecting plate and a recycling plate are arranged, so that the problems that most of traditional cutting equipment cannot recycle residual materials obtained after cuttiing of ceramic tiles, so that waste of the ceramic tiles is caused, and the building cost is improved are solved, the clamping mechanisms and the placing table are arranged, so that the advantage that the stability is high is achieved, and the problem that the ceramic tiles possibly can skew in the cutting process, so that the cutting effect is poor is solved.

Owner:北京享云智汇科技有限公司

Pull net type fiber separator based on sanitary towel cotton yarns and paper pulp membrane sheets

The invention discloses a pull net type fiber separator based on sanitary towel cotton yarns and paper pulp membrane sheets. The pull net type fiber separator structurally comprises a gas discharge column cylinder, a yarn pulling output cylinder, a piston cylinder, an axis rotary pump, a pull net separation roller, a sanitary towel guide pipe, an electric control box and a base block. According tothe invention, the pull net separation roller is matched with the sanitary towel guide pipe to form the counter weight centrifugation and centripetal throwing operation of external winding of cottonyarns and internal filling of water-containing paper pulp, and when the arc buckle sliding brush block of the rail frame ring is matched to scrape and brush the membrane sheet, the debris forms the irregular axis of the paper pulp and the periphery of the paper pulp is wrapped and collected, so that the cotton yarn fiber in the middle position is separated from the paper pulp membrane sheet belt,the membrane sheets bonded by the cotton threads fall off to the sealing ring under the action of strong centrifugation and centripetal force and fall back to the middle position along the centripetalair holes, the purity of the fiber separation operation in the sanitary towel is high, the screened materials are high in collection degree and free of residues, the working period is short, and theprecision and the efficiency of batch fiber separation operation are improved.

Owner:张东先

Water-saving urination and defecation flushing system

The invention relates to a water-saving urination and defecation flushing system. The water-saving urination and defecation flushing system is provided with a urinal, a toilet bowl, water supply tanks and an urination water returning device. The urination water returning device mainly comprises a urine storage tank, a urine booster pump and a urine filter which are successively connected. The urine booster pump is automatically opened and closed according to the liquid level state of the urine storage tank. A water outlet of the water supply tank for the urinal is connected with a water inlet of the urinal via a urinal water inlet tube with an opening and closing control valve, and a water outlet of the water supply tank for the toilet bowl is connected with a water inlet of the toilet bowl via a toilet bowl water inlet tube; a water outlet of the urinal is connected with the urine storage tank of the urination water returning device; a filter outlet of the urine filter is connected with a water inlet of the water supply tank for the urinal via an urination water returning tube. Clear water filtered by the urinal and a washing device is recycled, the urinal and the toilet bowl are flushed by the clear water filtered by the urinal and the washing device, and therefore, the effect of saving water is achieved.

Owner:王立臣

Wild boar breeding room facilitating automatic snow removal

InactiveCN112293276AFacilitates automatic snow removalPrevent crushingAnimal housingSnow trapsSnow removalFishery

The invention relates to the technical field of wild boar breeding, and discloses a wild boar breeding room facilitating automatic snow removal. The wild boar breeding room comprises a main body and afunctional frame, the main body is of an existing structure and is not discussed, a heating system is arranged in the main body, the functional frame is fixedly connected to the main body and is a box-shaped block with a trapezoidal cross section, and the rear wall surface of the functional frame is hollow; and a connecting block is fixedly mounted at the rear end in the functional frame. According to the wild boar breeding room, by arranging two second connecting pipes and two movable blocks, when the room is used, electric telescopic rods in two second movable grooves can be started to drive the two second connecting pipes and the two movable blocks to move towards the left side of the main body and be separated from the interiors of corresponding first movable grooves and second movable grooves, and the movement range of wild boars during breeding is enlarged; and the motion amount of the wild boars in the breeding process can be ensured, meanwhile, a plurality of second connectingpipes are arranged between the second connecting pipes and the movable blocks, so that the problem that the wild boars escape from a pen formed by the two connecting pipes, the two movable blocks anda door plate is solved.

Owner:张海付

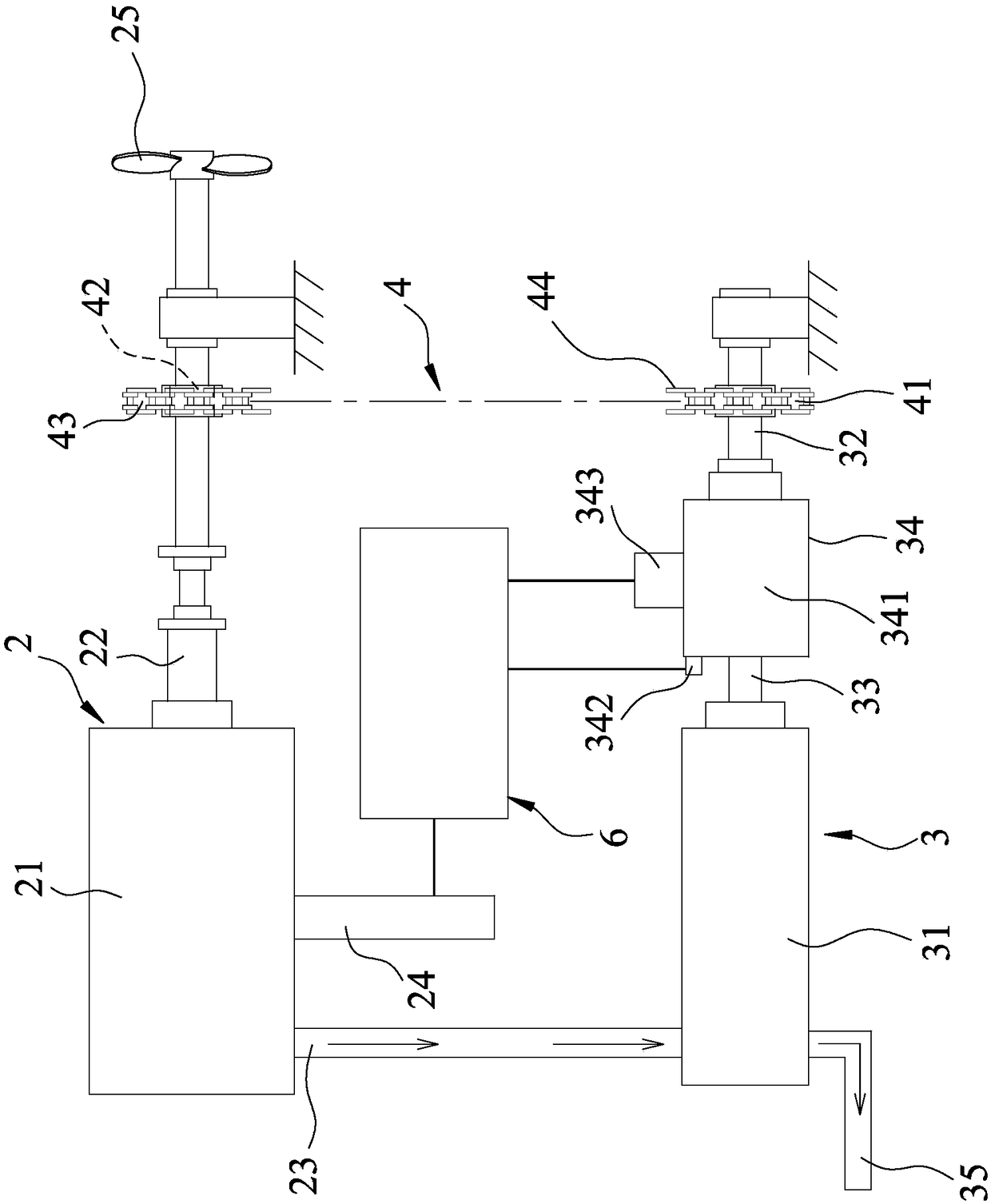

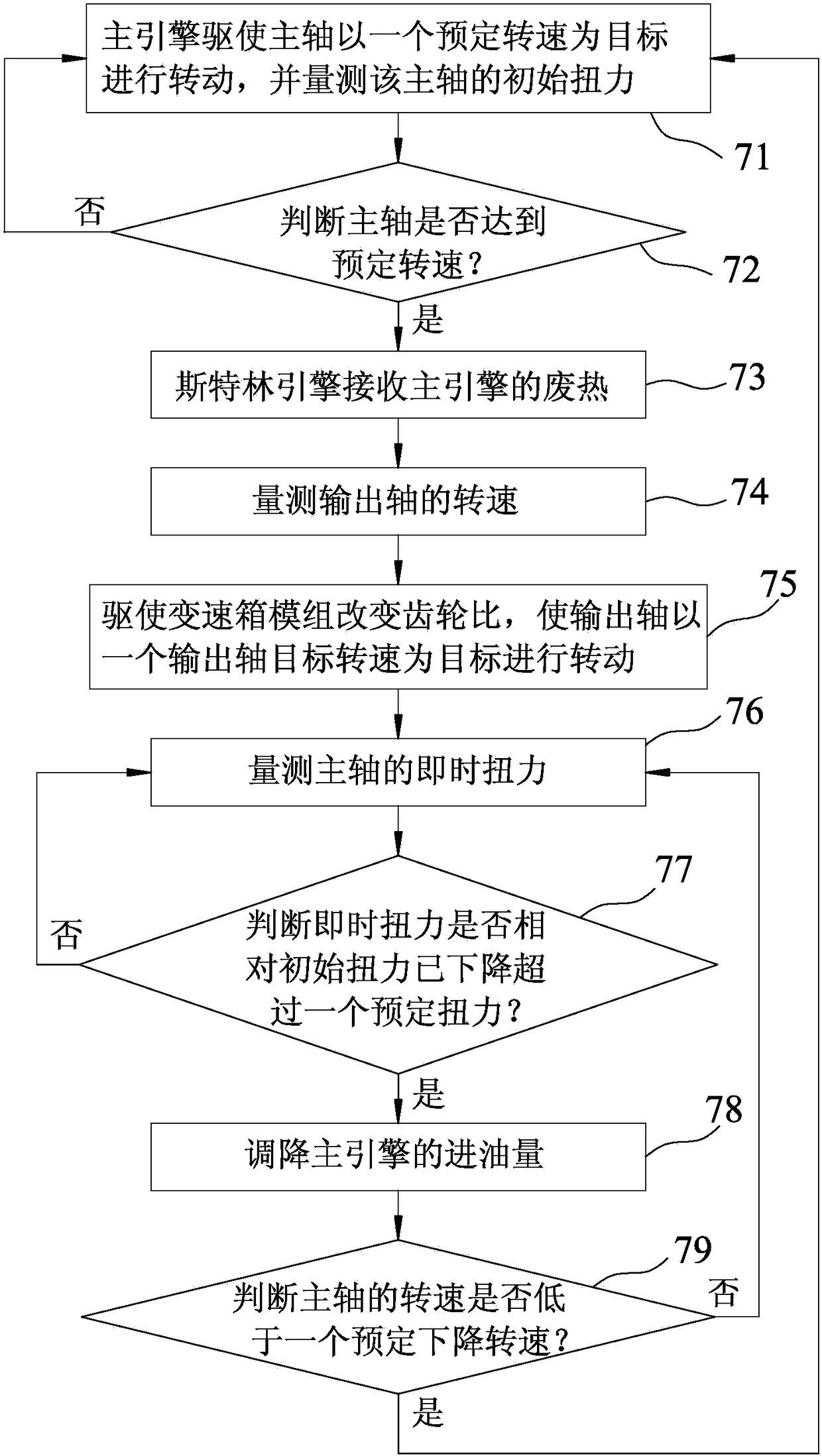

Engine waste heat power recovery system and method

InactiveCN108691689AReach the effect of recyclingInternal combustion piston enginesGearingHeat conductingAuxiliary power unit

An engine waste heat power recovery system comprises a main power unit, an auxiliary power unit and a transmission unit. The main power unit comprises a main engine, a spindle connected with the mainengine and driven by the main engine to rotate, and a heat conducting tube connected with the main engine. The auxiliary power unit comprises a Stirling engine connected with the heat conducting tube,and an output shaft linked with the Stirling engine to rotate. The transmission unit is arranged between the spindle and the output shaft to transmit the torsion of the output shaft to the spindle. Through arrangement of the main power unit, the auxiliary power unit and the transmission unit, waste heat of the main engine can drive the Stirling engine to provide auxiliary torsion, thus the effectof waste heat power recovery is achieved, and the purpose of the engine waste heat power recovery system can be achieved indeed.

Owner:阮家文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com