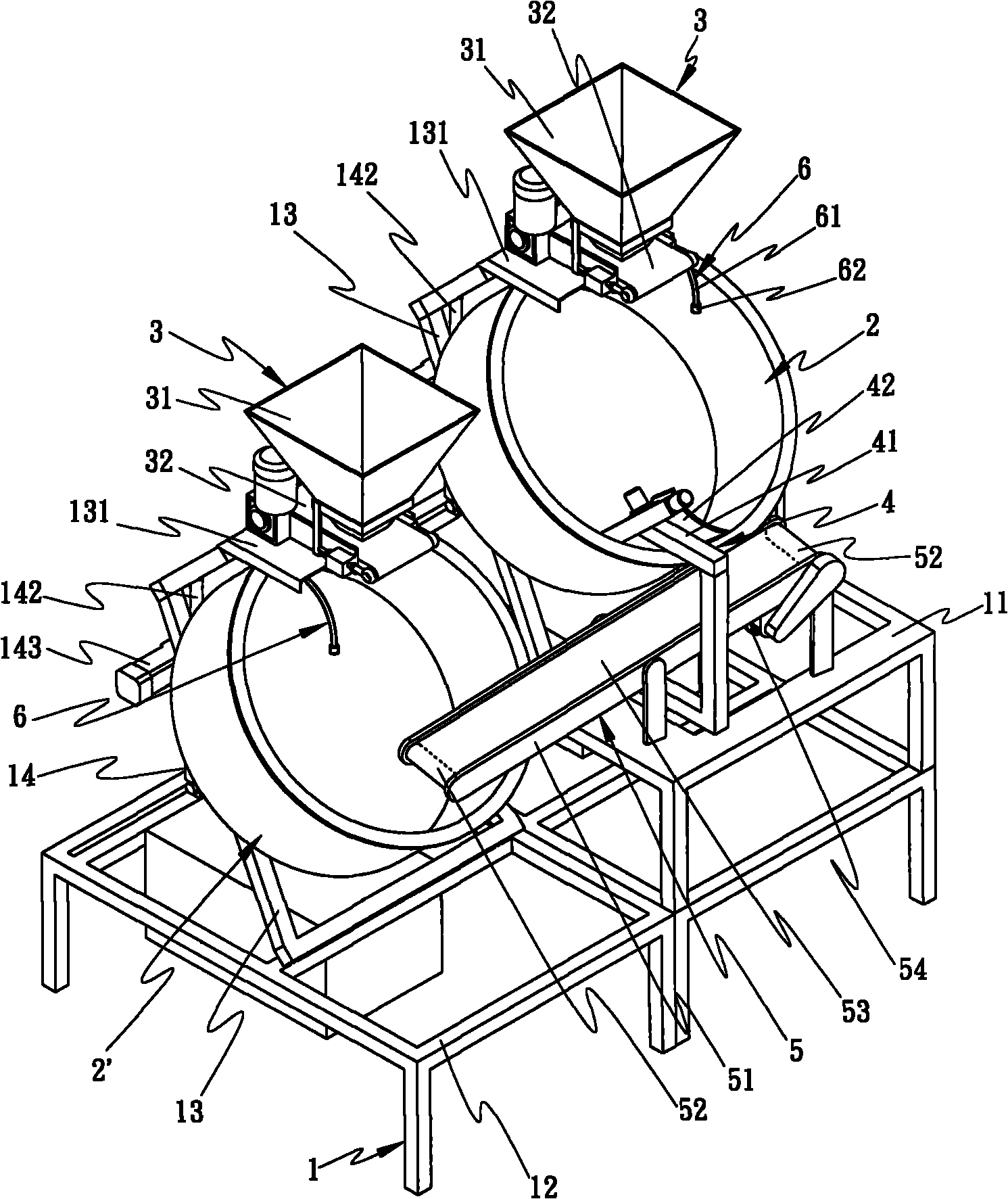

Double-feed disk pelletizer

A disc granulator and granulation technology, which is applied in the direction of granulation in the rotating disk/pan, can solve the problems of difficult stacking places, secondary environmental pollution, and difficult estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] as attached Figure 1-Figure 7 Shown is the double-feeding disc granulator of the present invention, and its preferred embodiment comprises a base 1, a first granulation barrel 2, a second granulation barrel 2', two groups of feeding devices 3, A discharge device 4, a conveying device 5 and two groups of sprinklers 6 are formed, wherein:

[0019] A base 1, such as figure 1 , figure 2 and Figure 4 Shown is a structure with a high platform 11 and a low platform 12, on which two inclined support frames 13 are combined, and an inclined support frame 13 can be combined on the high platform 11 and the low platform 12 respectively. The support frame 13 is a trapezoidal frame composed of steel bars, its lower end is pivotally connected to the base 1 , and its upper end is provided with a fixing part 131 , where the feeding device 3 and the sprinkler 6 are combined. And, the rear of this support frame 13 is provided with a lifting device 14 (as image 3 As shown), the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com