Drilling device for end cover of wind-driven generator

A technology of generator end and drilling device, which is applied in the direction of wind power generation, feeding device, positioning device, etc. It can solve the problems of low efficiency and inability to accurately control the drilling position efficiency, so as to reduce labor intensity, improve drilling efficiency, Avoid the effect of falling on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

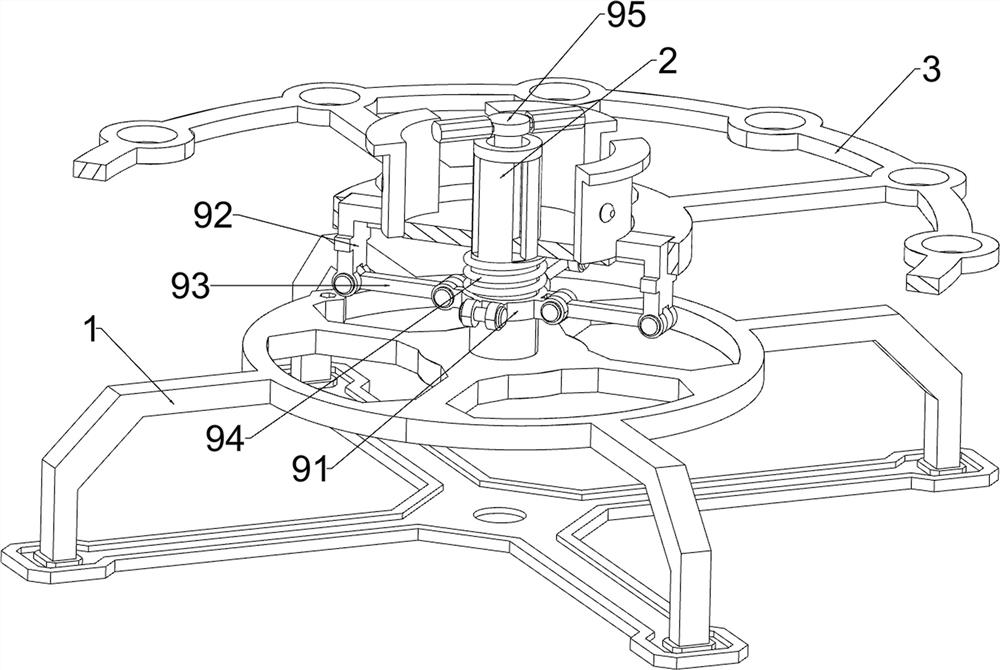

A wind energy generator end cover drilling device, please check Figure 1-4 , including a support frame 1, a first rotating rod 2, a rotating frame 3, a first fixing frame 4, a second rotating rod 5, a first sliding block 6, a first spring 7, an electric drill 8, a fixing mechanism 9 and a rotating mechanism 10 , the middle of the top of the support frame 1 is rotatably connected with a first rotating rod 2, the middle of the first rotating rod 2 is slidably connected with a turret 3, and the right side of the support frame 1 is connected with a first fixed frame 4 by welding. A second rotating rod 5 is rotatably connected to the front side of the fixing frame 4 , a first sliding block 6 is slidably connected to the second rotating rod 5 , and a first sliding block 6 is connected between the top of the first sliding block 6 and the second rotating rod 5 . A spring 7, an electric drill 8 is installed on the rear side of the bottom of the first sliding block 6 through bolts. When...

specific Embodiment approach 2

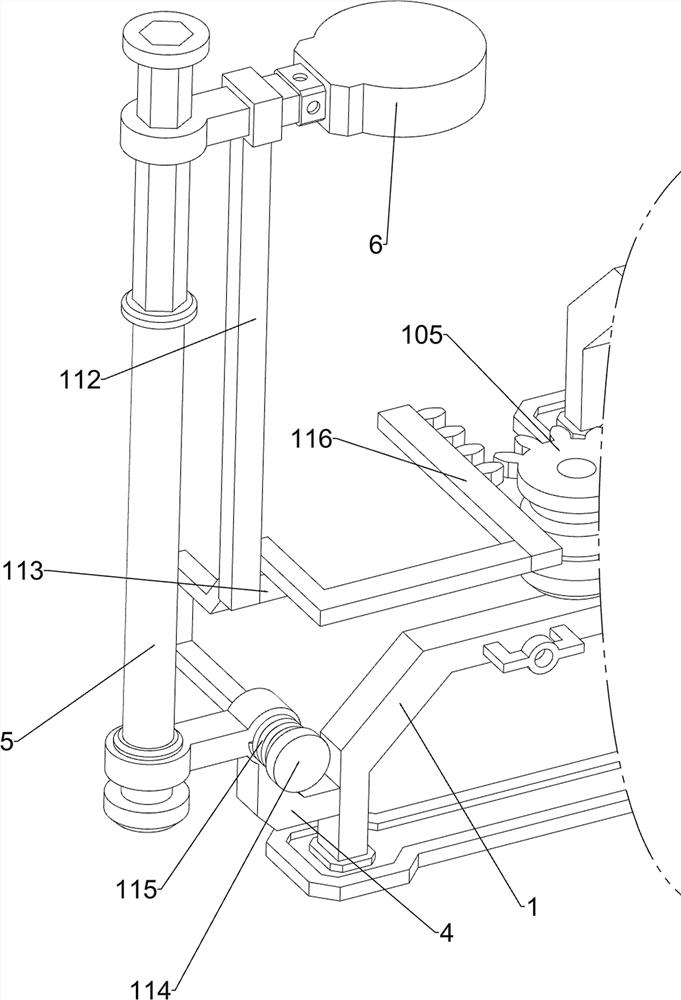

On the basis of the specific embodiment 1, please check figure 1 , Figure 5 and Image 6 , also includes a pressing mechanism 11, the pressing mechanism 11 includes a guide frame 111, a first sliding frame 112, a first wedge block 113, a pressing frame 114, a third spring 115 and a rack 116, the second rotating rod 5 The middle part of the guide frame 111 is connected by welding, the rear side of the guide frame 111 is slidably penetrated by the first sliding frame 112, the top of the first sliding frame 112 is connected to the first slider 6, and the rear side of the first sliding frame 112 is connected with the first sliding frame 112. The bottom is connected with a first wedge-shaped block 113 by welding, the middle part of the first fixing frame 4 is slidably penetrated by a squeeze frame 114, the squeeze frame 114 is in contact with the first wedge-shaped block 113, and the upper part of the squeeze frame 114 is gradually inclined upward. It is convenient to squeeze the...

specific Embodiment approach 3

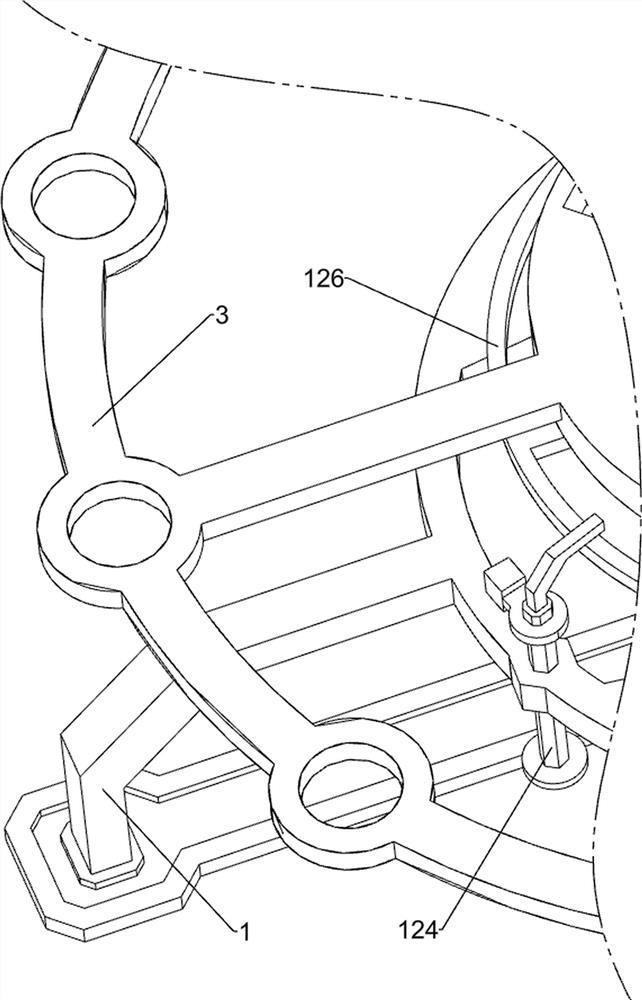

On the basis of the specific implementation mode 2, please check figure 1 , Figure 7 and Figure 8 , also includes a retracting mechanism 12, the retracting mechanism 12 includes a first reel 121, a third fixing frame 122, a second reel 123, a second sliding frame 124, a fourth spring 125, and a toggle frame 126 , a pulling rope 127 and a torsion spring 128, a torsion spring 128 is connected between the second rotating rod 5 and the first fixing frame 4, the torsion spring 128 is sleeved on the second rotating rod 5, and the lower side of the second rotating rod 5 is connected with The first reel 121, the right side of the support frame 1 is connected with a third fixing frame 122 by welding, the third fixing frame 122 is located at the rear side of the first fixing frame 4, and the right side of the third fixing frame 122 is rotatably connected with a The second reel 123, the middle of the bottom of the turret 3 is connected with a toggle frame 126, the top of the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com