Preparation method of novel nickel-molybdenum alloy nano-particles and method for treating wastewater by using novel nickel-molybdenum alloy nanoparticles

A nickel-molybdenum alloy, nanoparticle technology, applied in special compound water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as high cost, secondary pollution, poor stability, etc. High electrocatalytic performance and the effect of reducing oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

[0020] 1. Preparation of novel nickel-molybdenum alloy nanoparticles

[0021] (1) MoNiO X / Preparation of CNTs:

[0022] Mix 20mg of carbon tubes with 60ml of ethylene glycol, and disperse them evenly after ultrasonic treatment for 1h. Add it to a 100ml round bottom flask, then add 150mg of Mo(CO) 6 and 100mg of Ni(OAc) 2 , under the condition of 190°C, react at a stirring speed of 1500r / min for 3h, cool to room temperature after the reaction, and wash with ultrapure water several times to obtain the product MoNiO X / CNT.

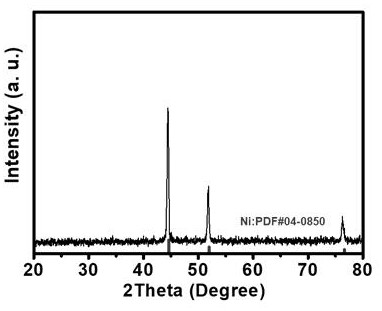

[0023] (2) Preparation of MoNi / CNT nanostructures:

[0024] 30mg of MoNiO X / CNT tiled in the magnetic boat, put the magnetic boat into the tube furnace for heating, after the air in the tube furnace is exhausted, 2 / Ar atmosphere was heated to 500 ° C and kept for 30 min to obtain the product MoNi / CNT.

[0025] According to the ratio of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com