Pull net type fiber separator based on sanitary towel cotton yarns and paper pulp membrane sheets

A fiber separator and sanitary napkin technology, applied in the field of sanitary napkin fiber separation, can solve the problems of loss of diaphragm area, increased difficulty of fiber drawing of sanitary napkins, high viscosity of pulp diaphragm, etc., to improve accuracy and efficiency, without Residual duty cycle, strong collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

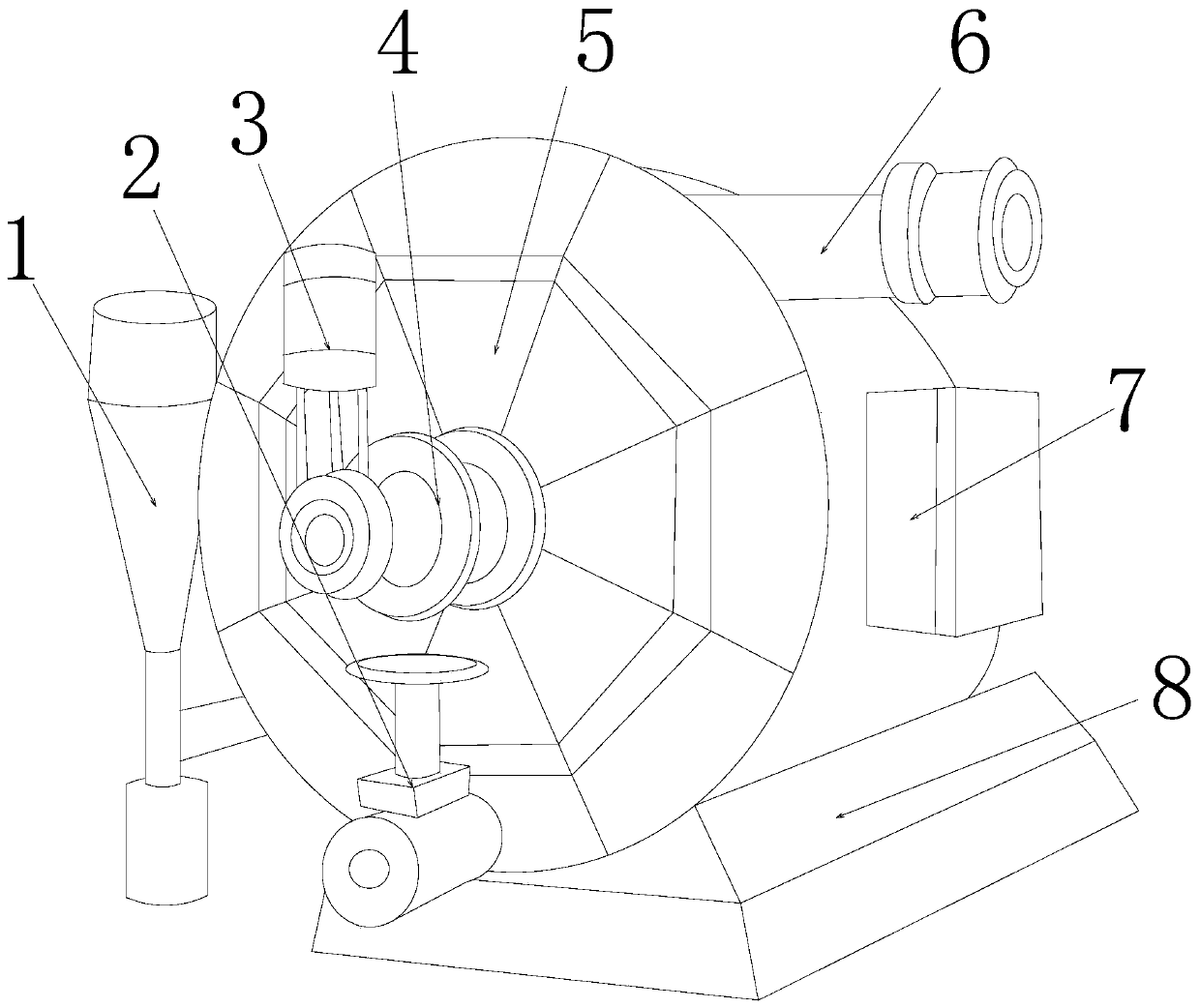

[0032] see Figure 1-Figure 7, the present invention provides a net type fiber separator based on sanitary napkin cotton yarn and pulp film. Net separation drum 5, sanitary napkin conduit 6, electric control box 7, base block 8, the net separation drum 5 is close to the rear side of the axial rotary pump 4 and the axis is collinear, the piston cylinder 3 and The axial rotary pumps 4 are mechanically connected and perpendicular to each other. The exhaust cylinder 1 is installed on the left side of the expanded net separation drum 5. The sanitary napkin conduit 6 is inserted in the upper right corner of the expanded net separation drum 5 and communicates with each other. , the base block 8 is closely attached to the bottom surface of the stretching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com