Method for synchronously recovering nitrogen and phosphorus from wastewater by magnesium hydroxide modified sepiolite

A technology of magnesium hydroxide and sepiolite, which is applied in chemical instruments and methods, alkaline orthophosphate fertilizers, applications, etc., can solve the problems of difficult separation of water, increased difficulty in recovery, and limited development of industrialization, etc. The effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

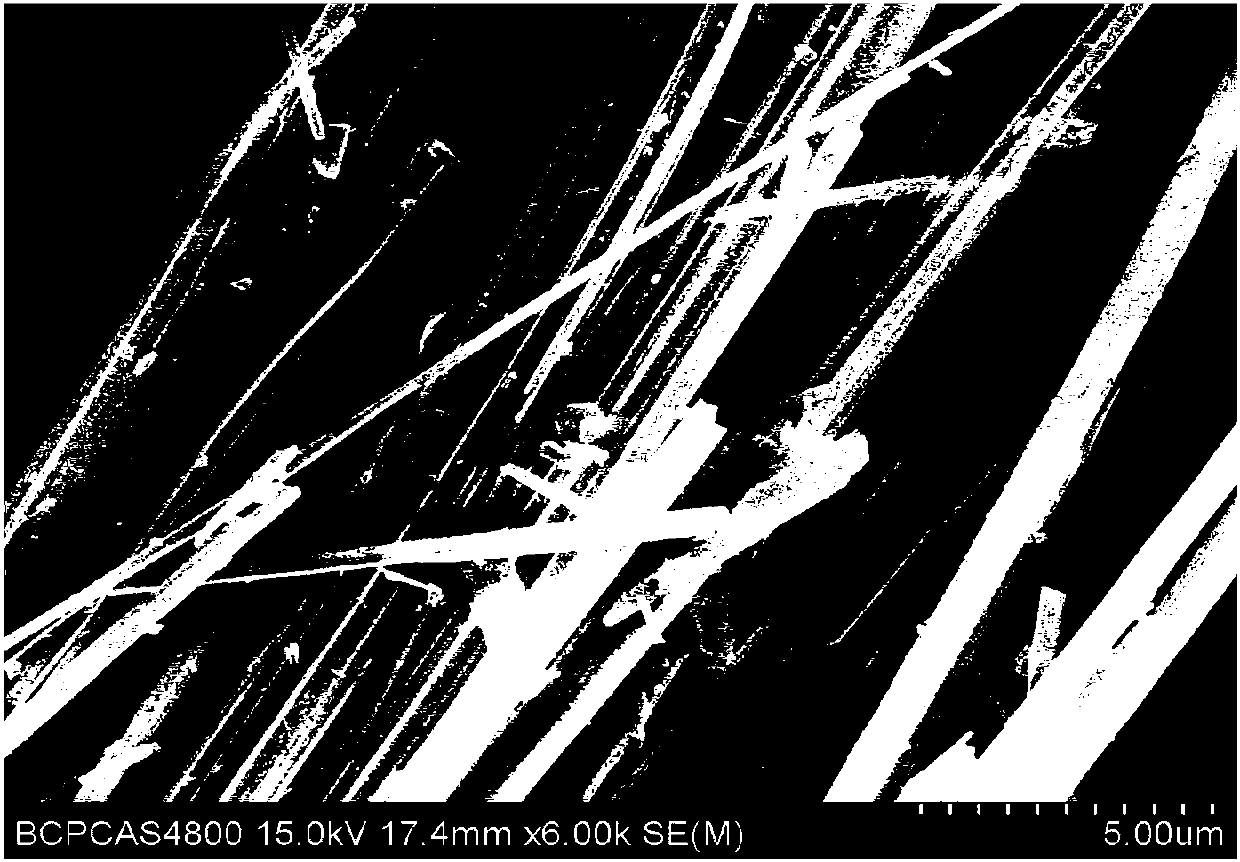

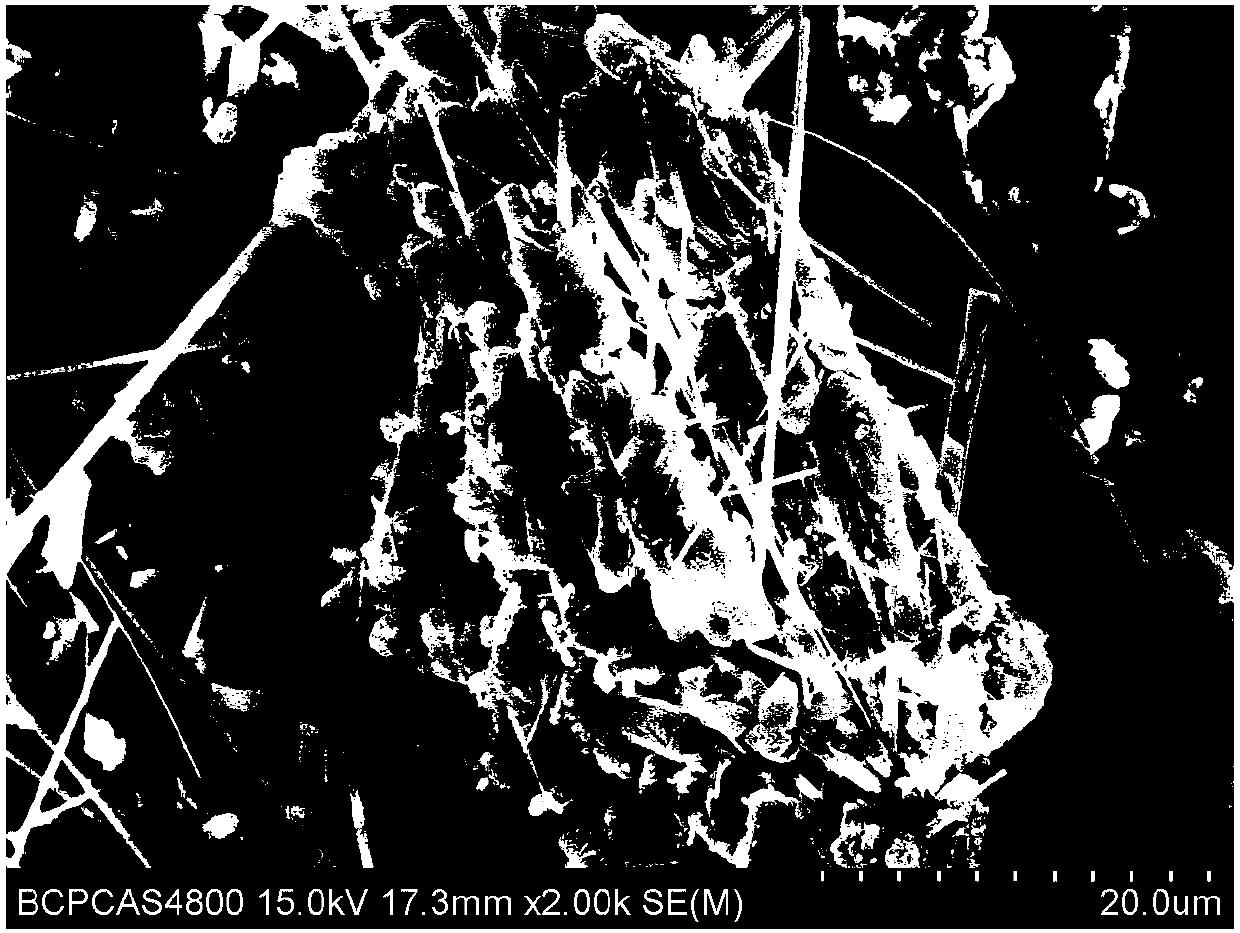

[0037] The preparation of embodiment 1 magnesium hydroxide modified sepiolite

[0038] Take raw sepiolite powder, grind it into fine powder, pass through a 200-mesh sieve, mix it with water at a mass ratio of 2:10, stir at a speed of 300r / min for 20min to make a suspension, and mark it as component A;

[0039] Component A continues to stir, slowly add 25% ammonia water and component A to component A in a mass ratio of 2:10, increase the hydroxyl group for activation, continue stirring at 200r / min for 60min, and mark it as component B;

[0040] MgCl 2 Prepare an aqueous solution with water at a mass ratio of 2:10, marked as component C;

[0041] Component C and component B are mixed at a mass ratio of 1:1, marked as component D;

[0042] Dosing sodium dodecylsulfonate and component D into component D at a mass ratio of 0.1:10, marked as component E;

[0043] Component E was stirred in a water bath at 60°C for 3 hours at a rotational speed of 200r / min, left to stand for 12 ho...

Embodiment 2

[0046] Nitrogen and phosphorus (1) in the simulated waste water was recovered by utilizing the prepared magnesium hydroxide modified sepiolite under the laboratory conditions of embodiment 2

[0047] Take 1L of the simulated wastewater prepared in the laboratory and place them in beakers I and II respectively, and the initial nitrogen and phosphorus concentrations are both 100mg / L. Adjust the pH of the simulated wastewater to 8.5 in advance, add 0.3g of natural sepiolite to beaker I, add 0.3g of modified sepiolite prepared in Example 1 to beaker II, stir rapidly for 20 minutes and then slowly stir After 30 minutes, let it stand for 2 hours, filter, and measure the concentration of ammonia nitrogen and total phosphorus in the supernatant by spectrophotometry. The concentration of ammonia nitrogen in the supernatant of No. 1 beaker was 79.3 mg / L, the removal rate was 20.7%, the concentration of total phosphorus was 76.4 mg / L, and the removal rate was 23.6%; the concentration of ...

Embodiment 3

[0048] Nitrogen and phosphorus (2) in the simulated waste water was recovered by utilizing the prepared magnesium hydroxide modified sepiolite under the laboratory conditions of embodiment 3

[0049] Take 1L of simulated wastewater configured in the laboratory, and the initial nitrogen and phosphorus concentrations are both 500mg / L. Adjust the pH of the simulated wastewater to 8.5 in advance, add 1.0 g of the modified sepiolite prepared in Example 1, stir rapidly for 20 minutes, then stir slowly for 30 minutes, let stand for 2 hours, filter, and measure the supernatant ammonia nitrogen, total phosphorus concentration. The concentration of ammonia nitrogen in the supernatant was 91.5mg / L, the concentration of total phosphorus was 18.0mg / L, and the removal rates were 81.7% and 96.4% respectively.

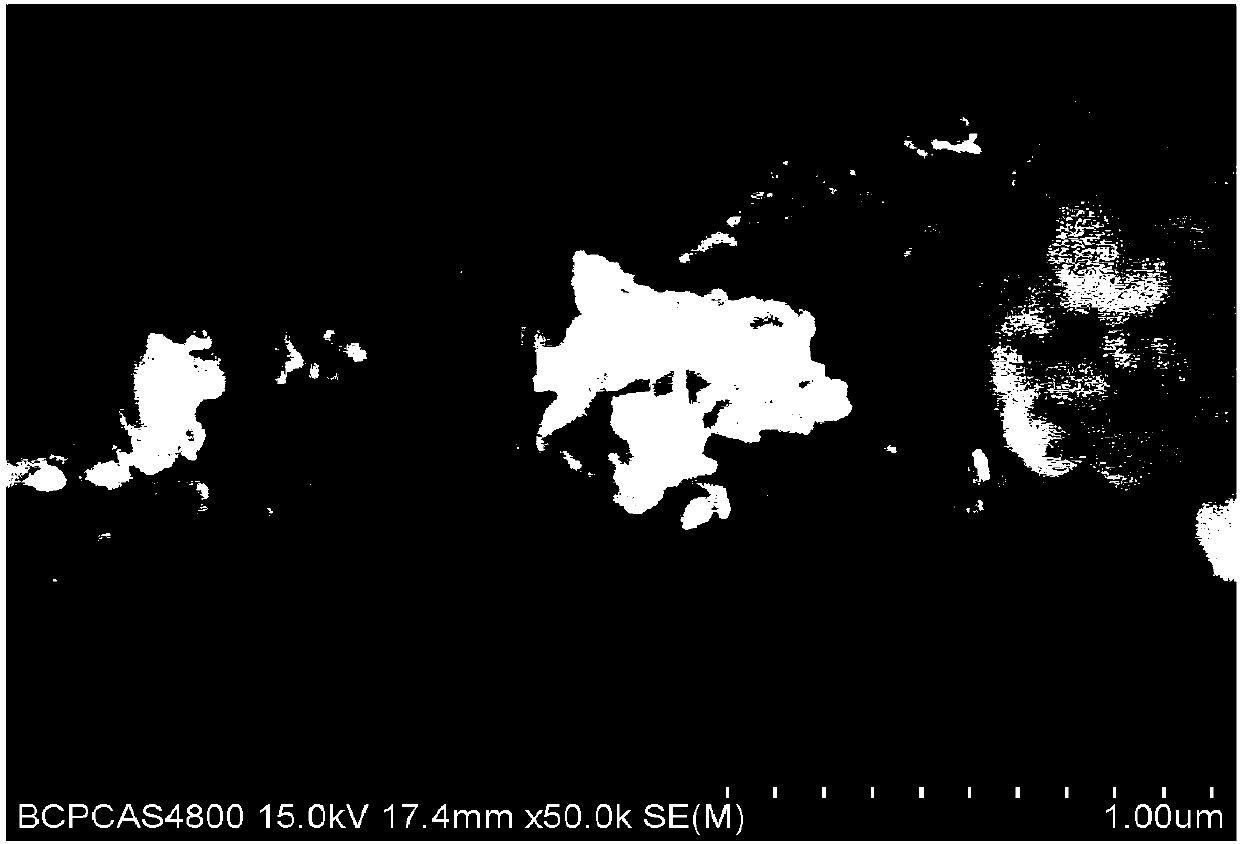

[0050] After the sludge was recovered, it was dried at 40°C, and XRF component analysis was performed. Compared with the content of magnesium in Example 1, the content of magnesium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com