Piezoelectric ceramic fiber power generation system, power generation shoes and power generation tire

A technology of piezoelectric ceramics and power generation systems, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, tire parts, etc., and can solve problems such as inability to collect automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

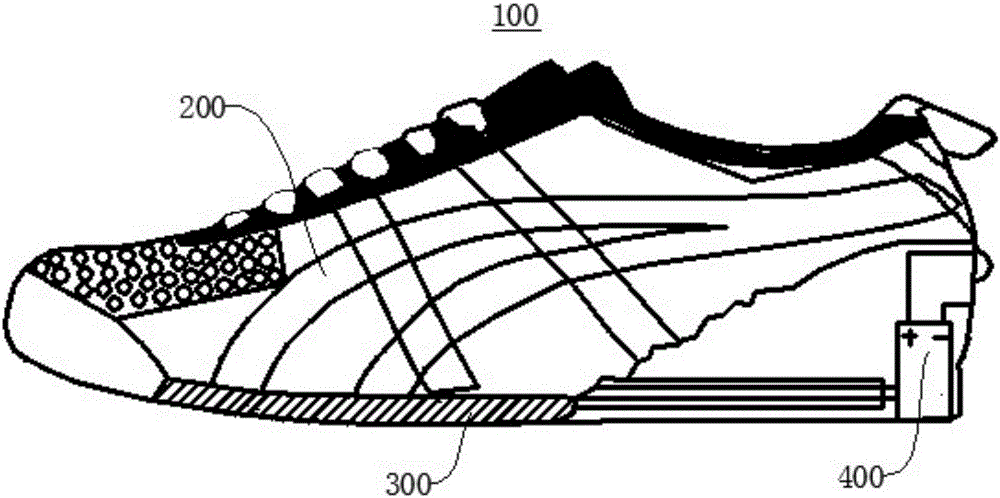

[0036] figure 1 For the structural schematic diagram of the power generation shoes provided by the first embodiment of the present invention, please refer to figure 1 .

[0037]The power generation shoe 100 provided in this embodiment includes a shoe upper 200 , a shoe sole 300 and a piezoelectric ceramic fiber power generation system 400 . The sole 300 is hollow and made of artificial rubber. The piezoelectric ceramic fiber power generation system 400 is installed inside the sole 300 and extends to the outside of the sole 300 for converting the mechanical energy generated during the bending deformation of the sole 300 into electrical energy for use by other electrical or electronic devices.

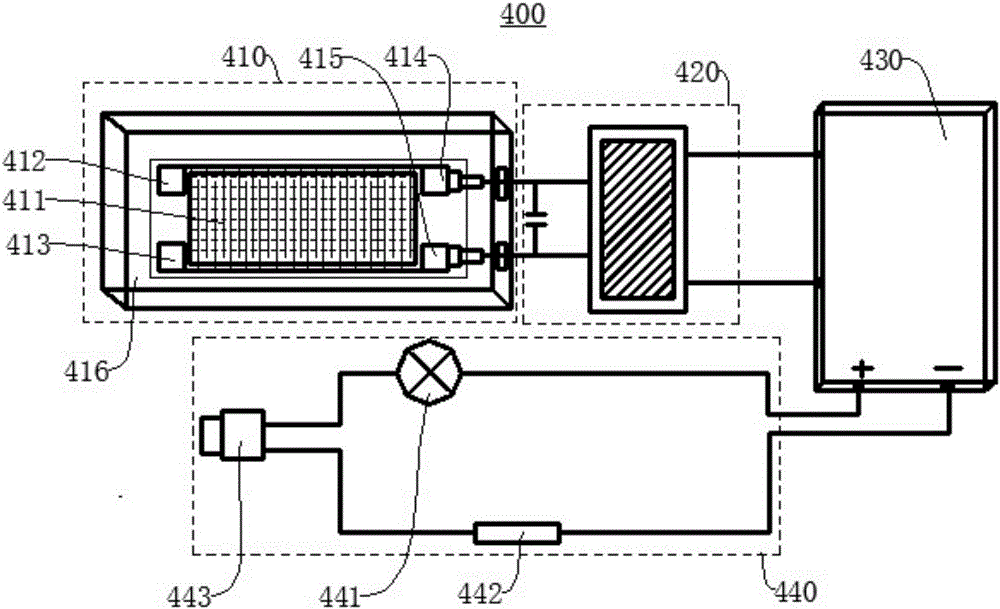

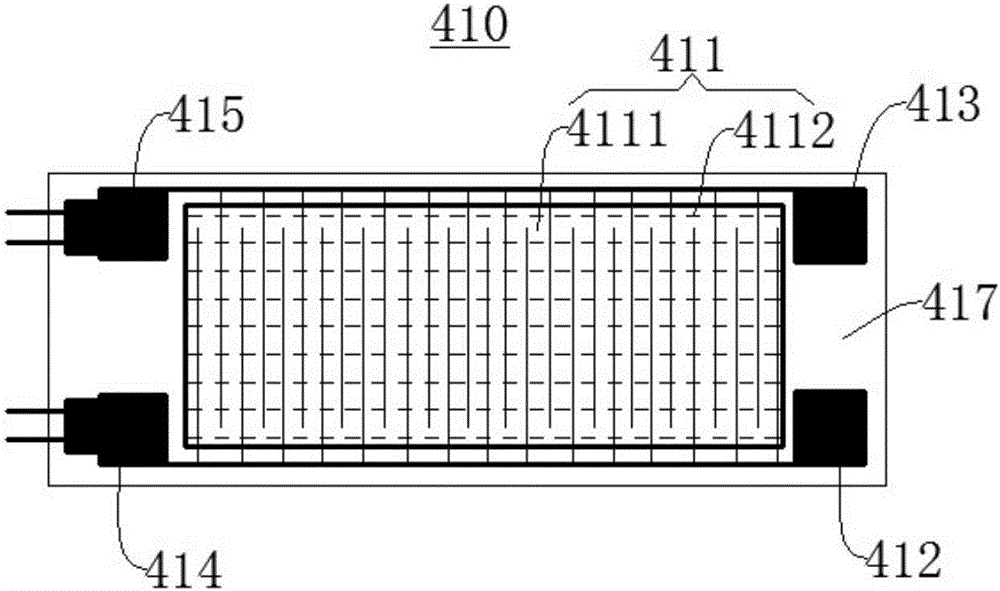

[0038] figure 2 for figure 1 For the structural schematic diagram of the medium piezoelectric ceramic fiber power generation system 400, please refer to figure 2 .

[0039] The piezoelectric ceramic fiber power generation system 400 includes a piezoelectric ceramic fiber driver 4...

no. 2 example

[0055] The power generation tire provided in this embodiment includes a tire body and the piezoelectric ceramic fiber power generation system 400 in the first embodiment. The piezoelectric ceramic fiber driver 410, the electric energy collection system 420 and the electric energy storage system 430 of the piezoelectric ceramic fiber power generation system 400 are arranged inside the tire body, and the electric energy utilization system 440 is arranged outside the tire body. The specific arrangement form between the piezoelectric ceramic fiber power generation system 400 and the tire body is similar to the arrangement form between the piezoelectric ceramic fiber power generation system 400 and the shoe sole 300 in the first embodiment, and will not be repeated here.

[0056] The power generation tire provided in this embodiment deforms during rotation, and the piezoelectric ceramic fiber composite material 411 inside it deforms accordingly to generate electric charges, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com