Residual material recyclable type ceramic tile cutting machine for construction site

A technology for construction sites and cutting machines, applied in the field of construction, can solve the problems of inability to recover excess materials, increase construction costs, and poor cutting effects, and achieve the effects of increasing construction costs, improving service life, and good clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

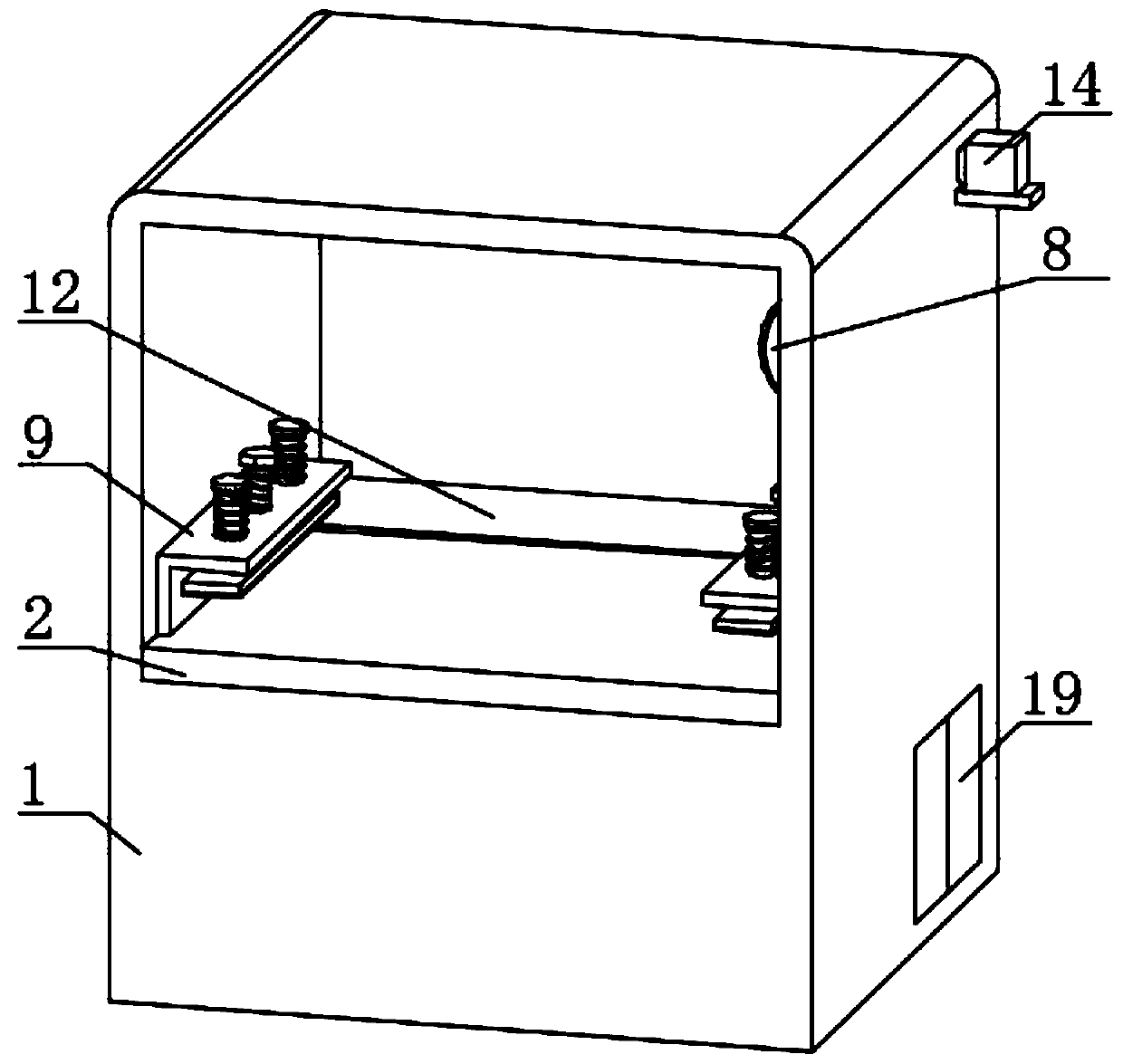

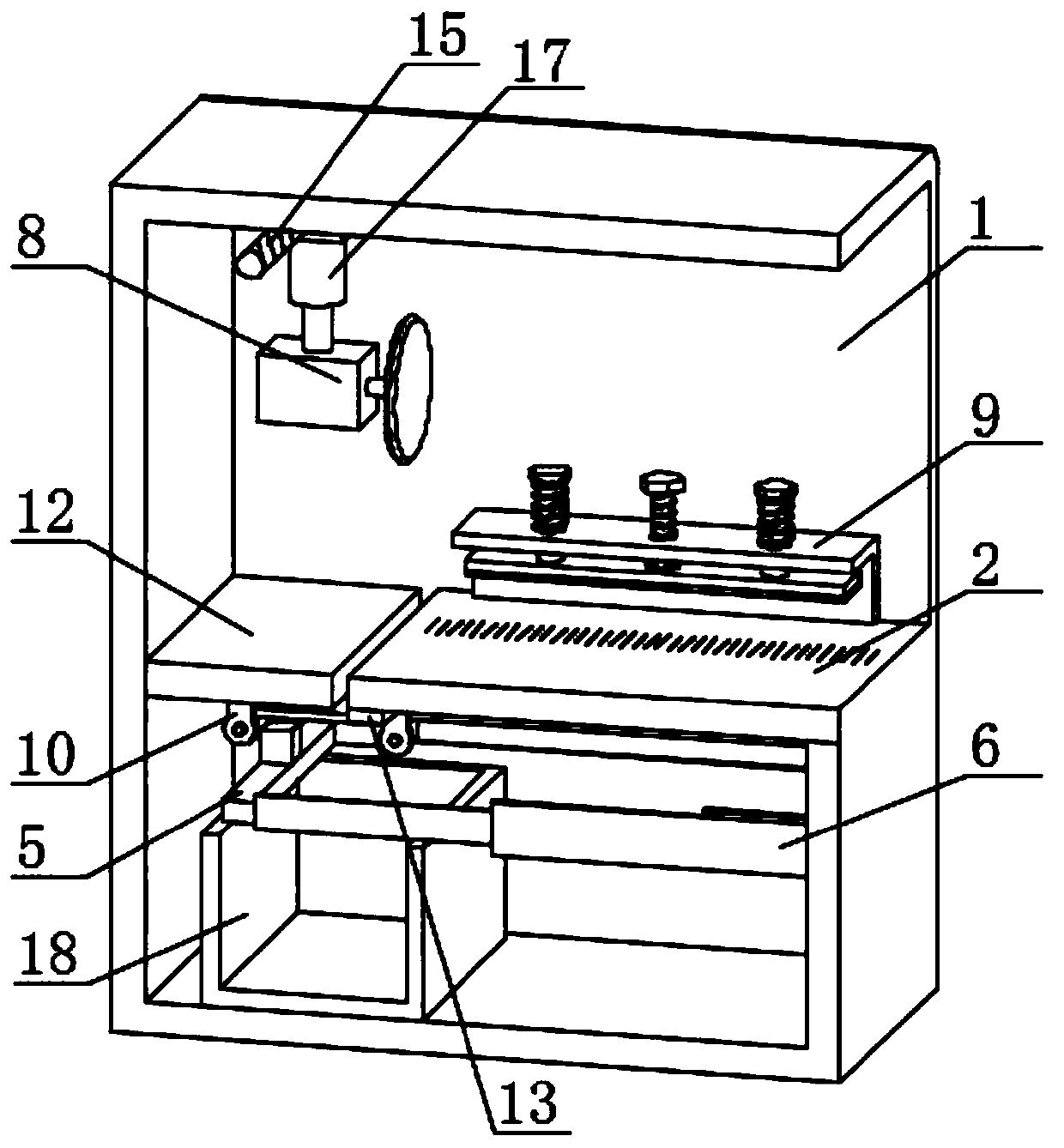

[0024] Such as Figure 1-6 As shown, the embodiment of the present invention provides a tile cutting machine for construction sites with recyclable surplus material, which includes a housing 1, the inside of the housing 1 is fixedly connected with a placement table 2, and both ends of the top surface of the placement table 2 are fixedly connected There is a clamping mechanism 9, and both sides of the inner wall of the housing 1 are provided with chute 3, and the inside of the two chute 3 is slidably connected with a slider 4, and the sides of the two sliders 4 are rotatably connected with each other. Hinged blocks 10, each hinged block 10 is rotatably connected with a connection plate 11 at one end away from the slider 4, the inside of the housing 1 is provided with a recovery plate 12, the bottom surface of the recovery plate 12 is fixedly connected with the top surface of the connection plate 11, placed The bottom surface of platform 2 is fixedly connected with cleaning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com