Field plastic film residue recycling machine

A recycling machine and residual film technology, applied in the field of agricultural machinery, can solve the problems of unclean recycling of small residual film fragments, residual film containing soil sand and gravel, and large soil fragments, so as to reduce soil carrying capacity and recover Good effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0022] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

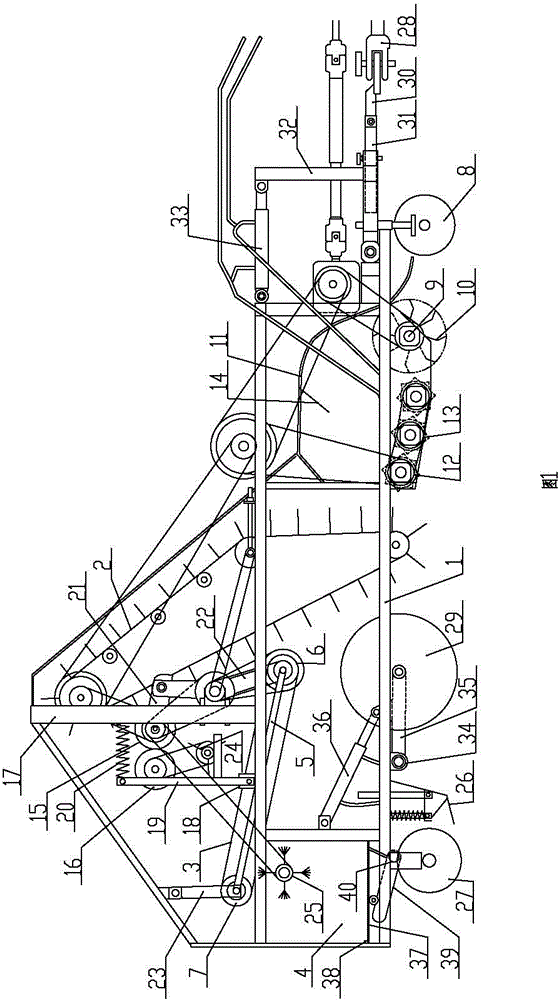

[0023] as attached figure 1 As shown, the field residual film recovery machine includes a frame 1, an earth-digging device, a nail-tooth conveyor belt 2, a conveyor belt 3, a collection box 4 and a power assembly; The frame 1 behind the soil device is provided with a spike conveyor belt 2, the upper part of the spike conveyor belt 2 is inclined in the direction of front, bottom, rear, and upward, and the frame 1 behind the spike conveyor belt 2 is provided with a back and forth reciprocating mechanism. Mesh belt installation frame 5, front mesh belt installation device 6 and rear mesh belt installation device 7 are installed on the mesh belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com