Residual film recycling machine

A recycling machine and residual film technology, which is applied in the field of agricultural machinery, can solve problems such as difficulty in lifting machines, reduce operating efficiency, and increase working resistance, so as to ensure the recovery rate of residual film, increase the recovery rate of residual film, and reduce working resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

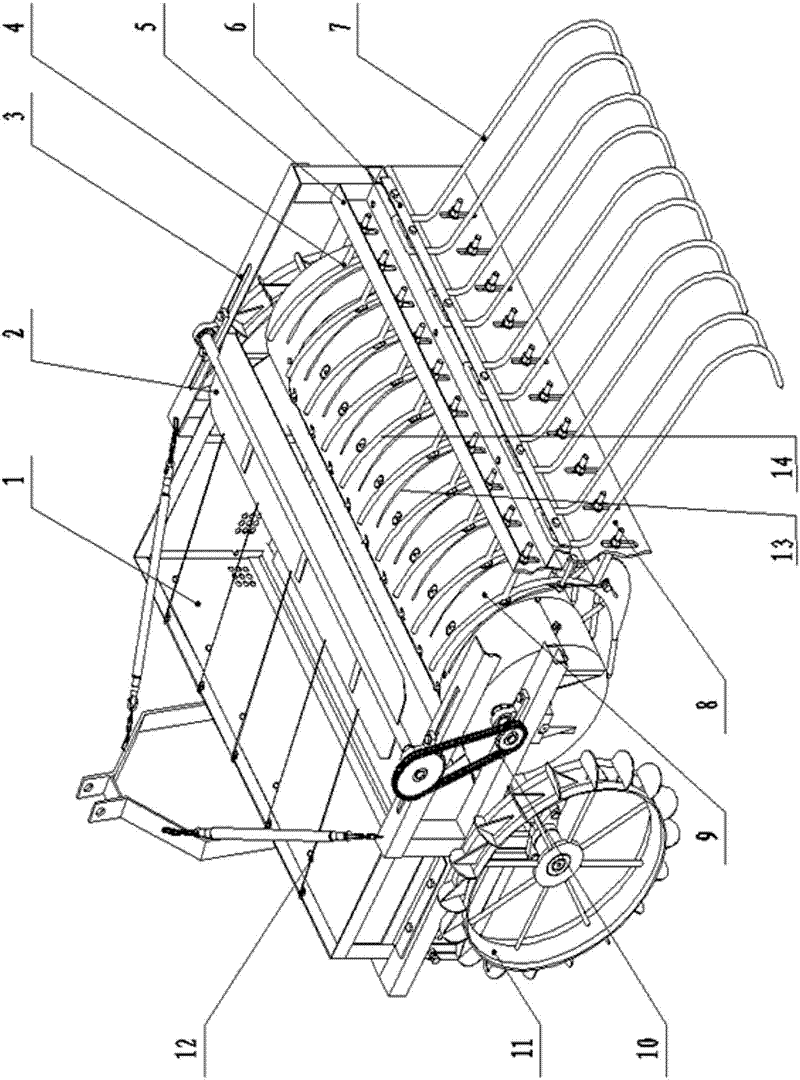

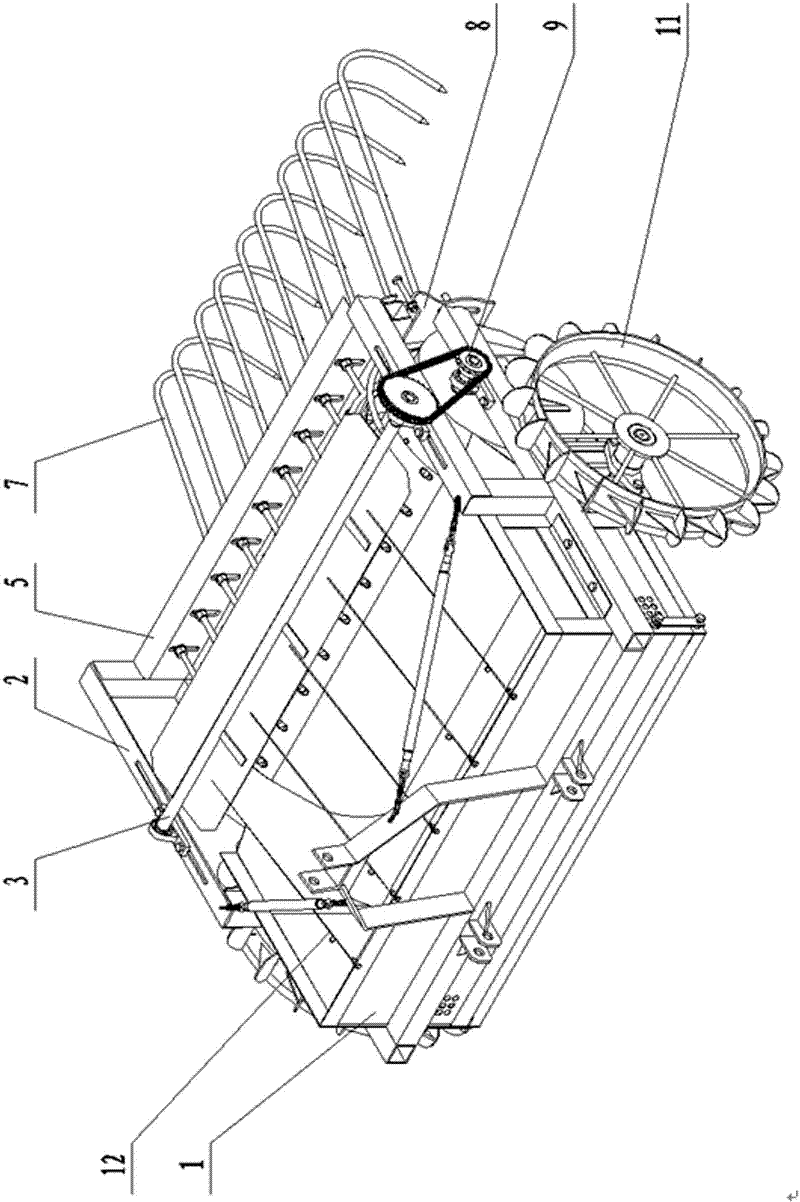

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

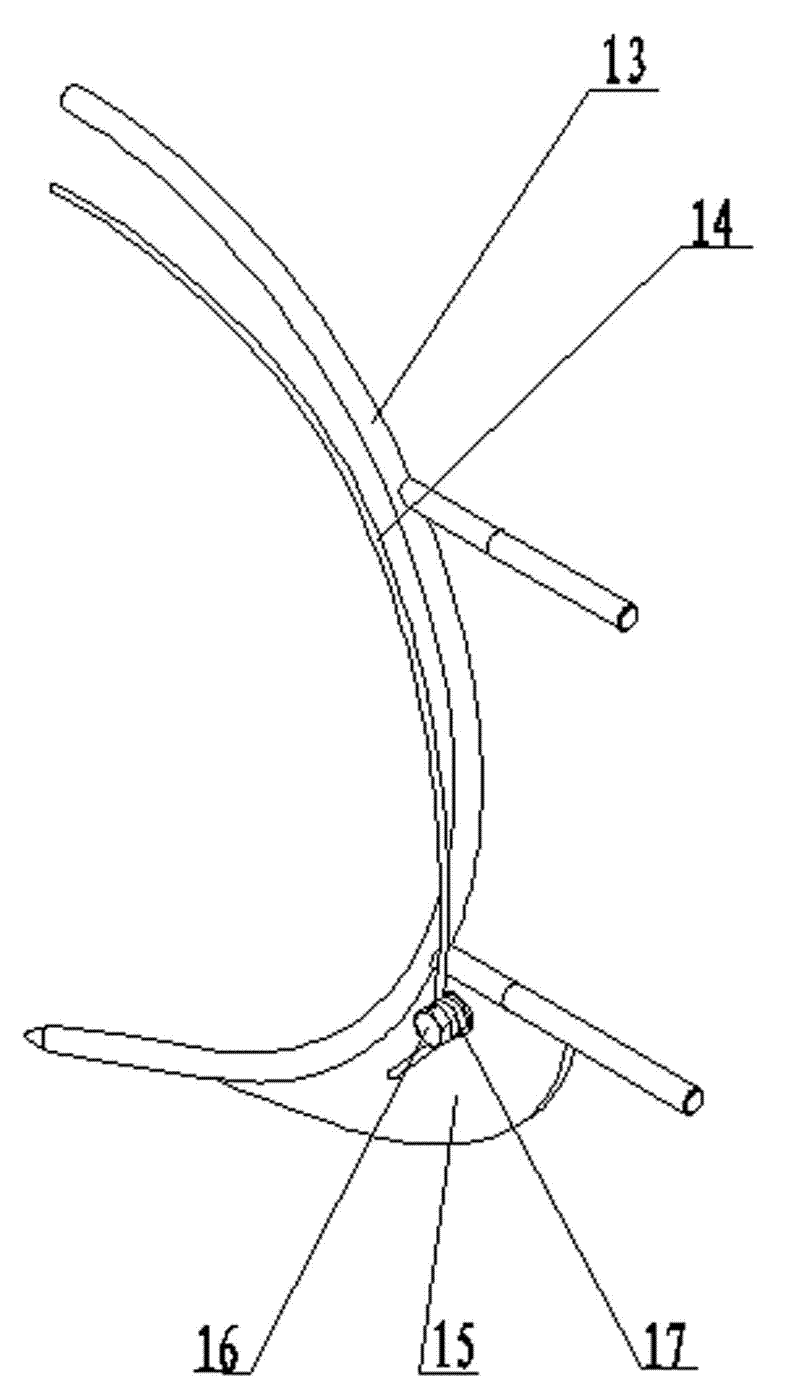

[0019] Such as figure 1 , figure 2 , image 3 As shown, a residual film recycling machine is mainly composed of a film collecting box 1, a film combing mechanism 2, a frame 3, an arc-shaped film lifter 4, a mounting plate I5, a pressing plate 6, a rake 7, a mounting plate II 8, and a picker 9 , chain drive 10, driving wheel 11 and clear film elastic tooth 12 parts and form. The film collecting box 1 is installed in front of the frame 3, the pick-up device 9 is installed behind the film collecting box 1, and the arc-shaped film lifting device 4 is composed of the main teeth 13 and auxiliary teeth 14, and the main teeth 13 are arc-shaped. , the lower end welds the reinforcement block 15, and the upper welding adjustment screw rod 16 in the reinforcement block 15. The auxiliary tooth 14 is arc-shaped, and the lower end is provided with an automatic deformation coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com