Recovery separator of cotton stalk and membrane

A technology of residual film recovery and separation machine, which is applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problems of increased probability of disease occurrence, impact on soil preparation, sowing, and unsatisfactory quality of residual film recovery, etc., to achieve residual film recovery The effect of high net rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

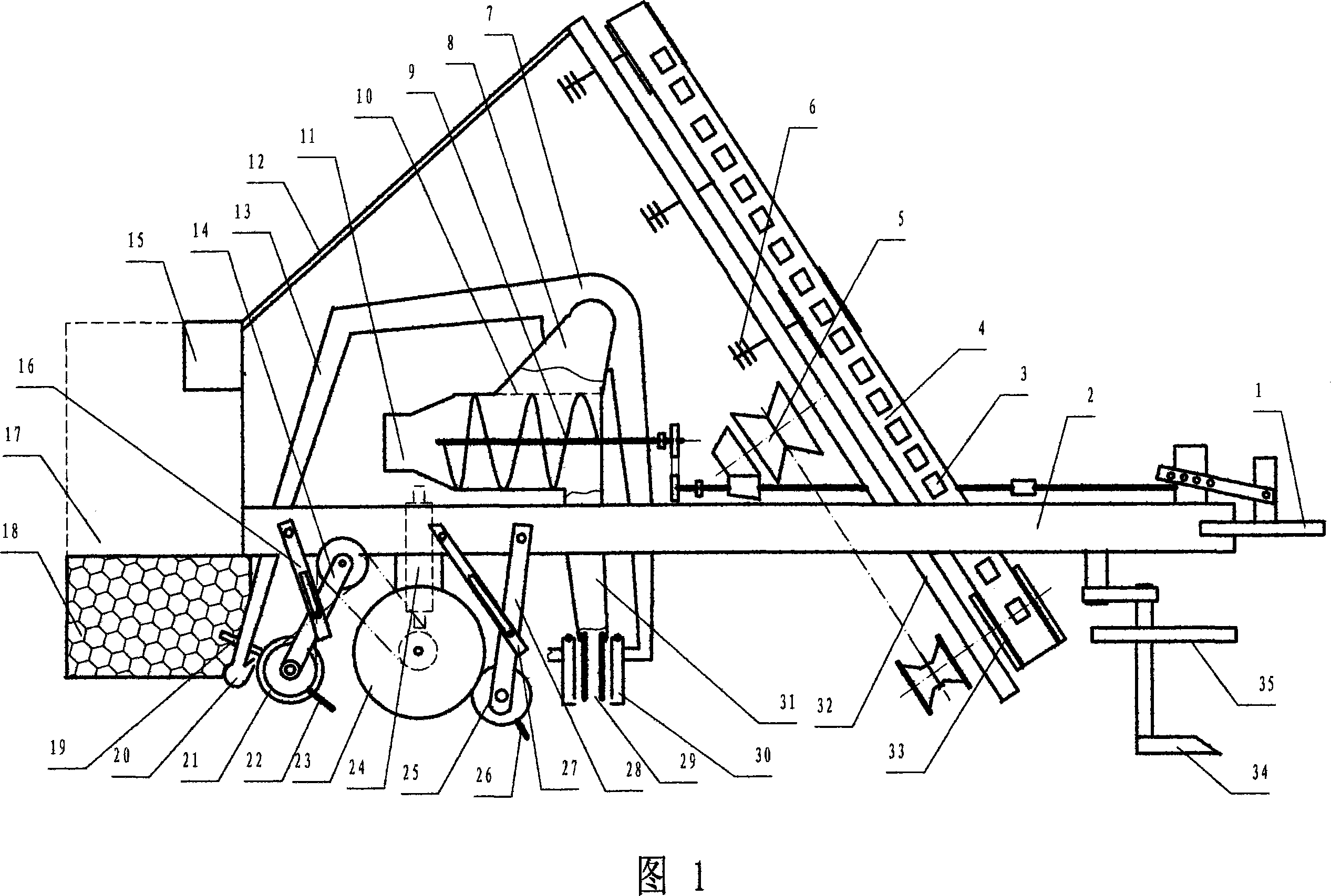

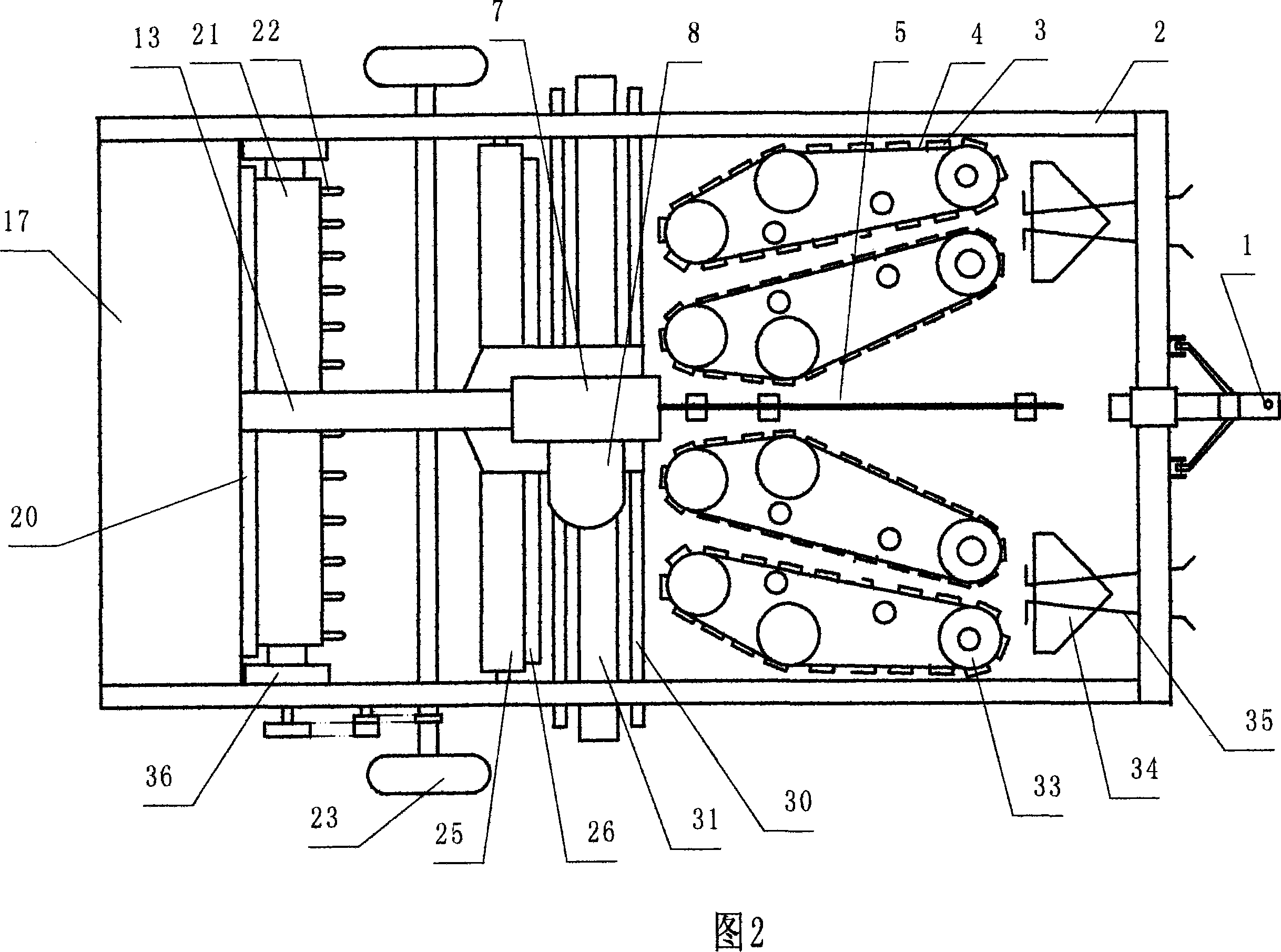

[0024] With reference to accompanying drawing, comprise road wheel (24), traction frame (1), frame (2), transmission mechanism (5), hydraulic mechanism (24), hydraulic mechanism (24) is located at road wheel (24) and frame (2) Between, the cotton stalk collecting device and the residual film collecting device are arranged on the frame.

[0025] Described cotton stalk collecting device comprises cotton stalk collecting box (17), root cutting shovel (34), and root cutting shovel is provided with cotton stalk closing plate (35), and the rear of root cutting shovel and cotton stalk closing plate is provided with cotton The rod lifting conveying device is composed of two sets of conveyor belts (4) with opposite belt surfaces. Pulverizer (15), the cotton stalk pulverizer (15) outlet is connected with the cotton stalk collection box (17) mouth, and the surface that the above-mentioned conveyer belt contacts with the cotton stalk is preferably provided with a raised rubber bump to inc...

Embodiment 2

[0030] Compared with Embodiment 1, the difference of this embodiment is that the cotton stalk lifting and conveying device is a chain type, there is no cotton stalk pulverizer at the tail of the cotton stalk slideway (12), and the cotton stalks directly fall into the cotton stalk collection box (15) .

Embodiment 3

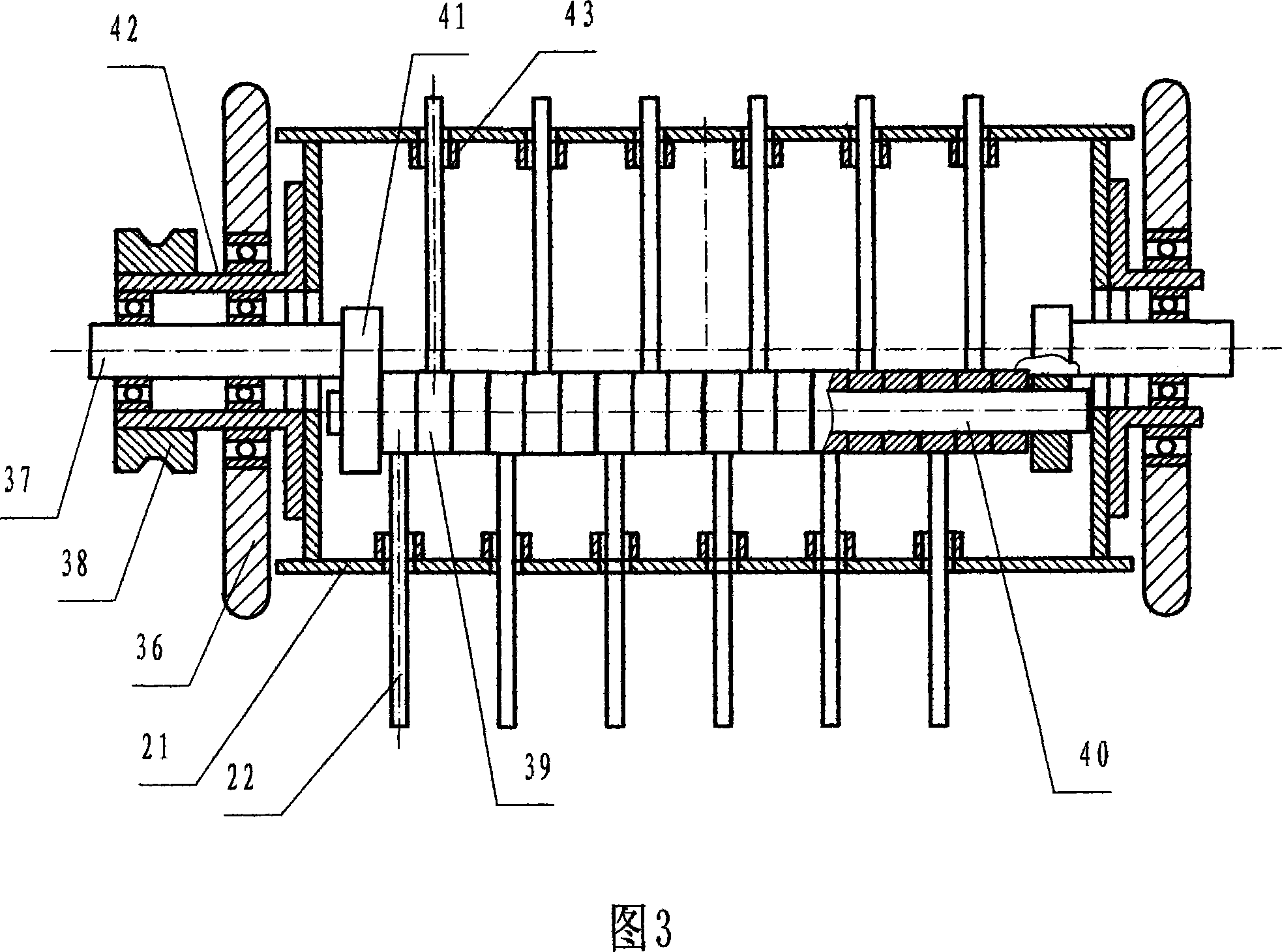

[0032]Compared with Embodiment 1, the difference of this embodiment is that a crank-shaped eccentric shaft is provided in the described film cutting cylinder (25), and the crank-shaped eccentric shaft is fixedly connected with the frame. end is the axis rotation, and the film cutting knife (26) is connected to the crank-shaped eccentric shaft through the bushing and the blade end stretches out of the film-cutting cylinder, and when the film-cutting cylinder rotates with the two ends of the crank-shaped eccentric shaft as the axis, The film cutting knife moves telescopically relative to the drum wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com