Lubricating oil compositions

a technology of lubricating oil and composition, applied in the direction of lubricant composition, additives, shafts and bearings, etc., to achieve the effects of high deposit reduction, wear and oxidation corrosion inhibition, and low sulfur and sulfate ash conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0096]A low phosphorus lubricating oil composition was prepared by blending together the following components to obtain a SAE 15W-40 viscosity grade formulation:

[0097](1) 750 ppm, in terms of boron content, of a combination of a borated dispersant (8.4 wt. % in the finished oil), a borated glycerol monooleate (0.9 wt. % in the finished oil) and a borated sulfonate (3 mmol / kg in the finished oil) having a total base number (TBN) of 160. The term “Total Base Number” or “TBN” refers to the amount of base equivalent to milligrams of KOH in 1 gram of sample. Thus, higher TBN numbers reflect more alkaline products and therefore a greater alkalinity reserve. For the purposes of this invention, TBN is determined by ASTM Test No. D2896.

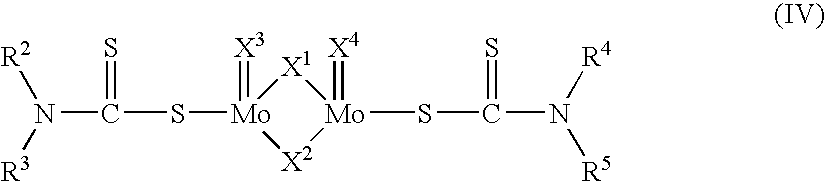

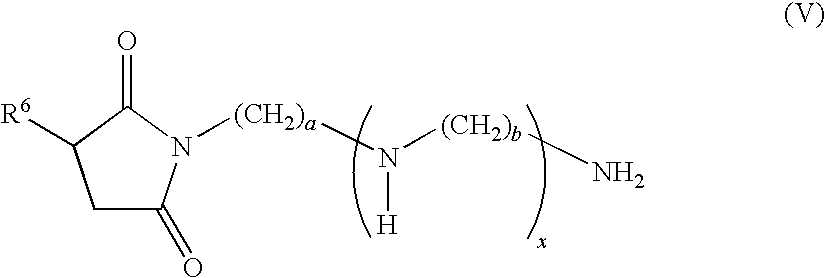

[0098](2) 1200 ppm, in terms of molybdenum content, of a molybdenum succinimide complex.

[0099](3) 2.6 wt. % of a dispersant.

[0100](4) 12 mmol / kg total of one or more detergents.

[0101](5) 1 wt. % of an alkylated diphenylamine antioxidant.

[0102](6) 1 wt. % of a ...

example 2

[0126]A lubricating oil composition was prepared by blending together the following components to obtain a SAE 15W-40 viscosity grade formulation:

[0127](1) 750 ppm, in terms of boron content, of a combination of a borated dispersant (5.2 wt. % in the finished oil), borated sulfonate (3 mmol / kg in the finished oil) having a TBN of 160 and a dispersed hydrated sodium borate (0.5 wt. % in the finished oil).

[0128](2) 1200 ppm, in terms of molybdenum content, of a molybdenum succinimide complex.

[0129](3) 2.6 wt. % of a dispersant.

[0130](4) 12 mmol / kg total of one or more detergents.

[0131](5) 1 wt. % of a diphenylamine antioxidant.

[0132](6) 1 wt. % of a hindered phenol antioxidant.

[0133](7) 0.5 wt. % of a pour point depressant.

[0134](8) 0.7 wt. % of a methylene bis(di-n-butyl dithiocarbamate).

[0135](9) 3.7 wt. % of a dispersant viscosity index improver.

[0136](10) 10 ppm, in terms of silicon content, of a foam inhibitor.

[0137](11) The remainder was diluent oil composed of approximately 63 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com