Image forming material, color filter master plate, and color filter

a technology color filter, which is applied in the field of image forming material, can solve the problems of inability to stably fix non-transparent materials or dyes on the desired image receiving materials based on digitized data, and achieve the effects of high sensitivity, high resolution and sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

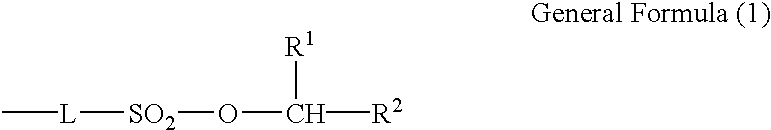

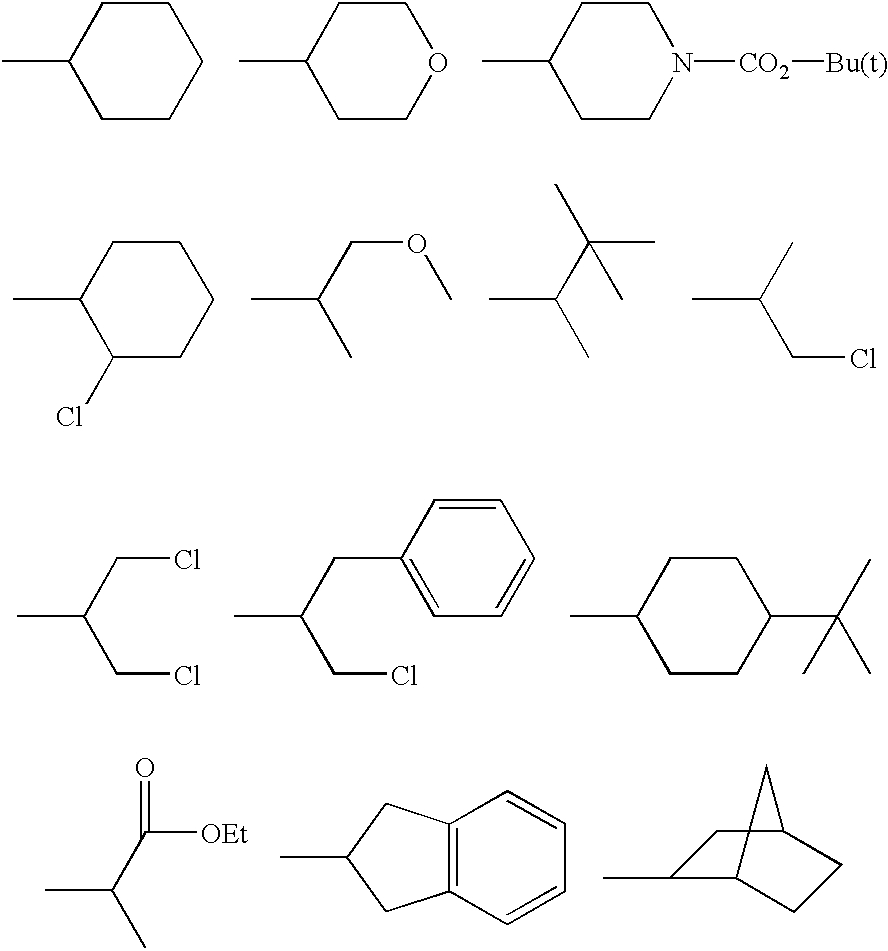

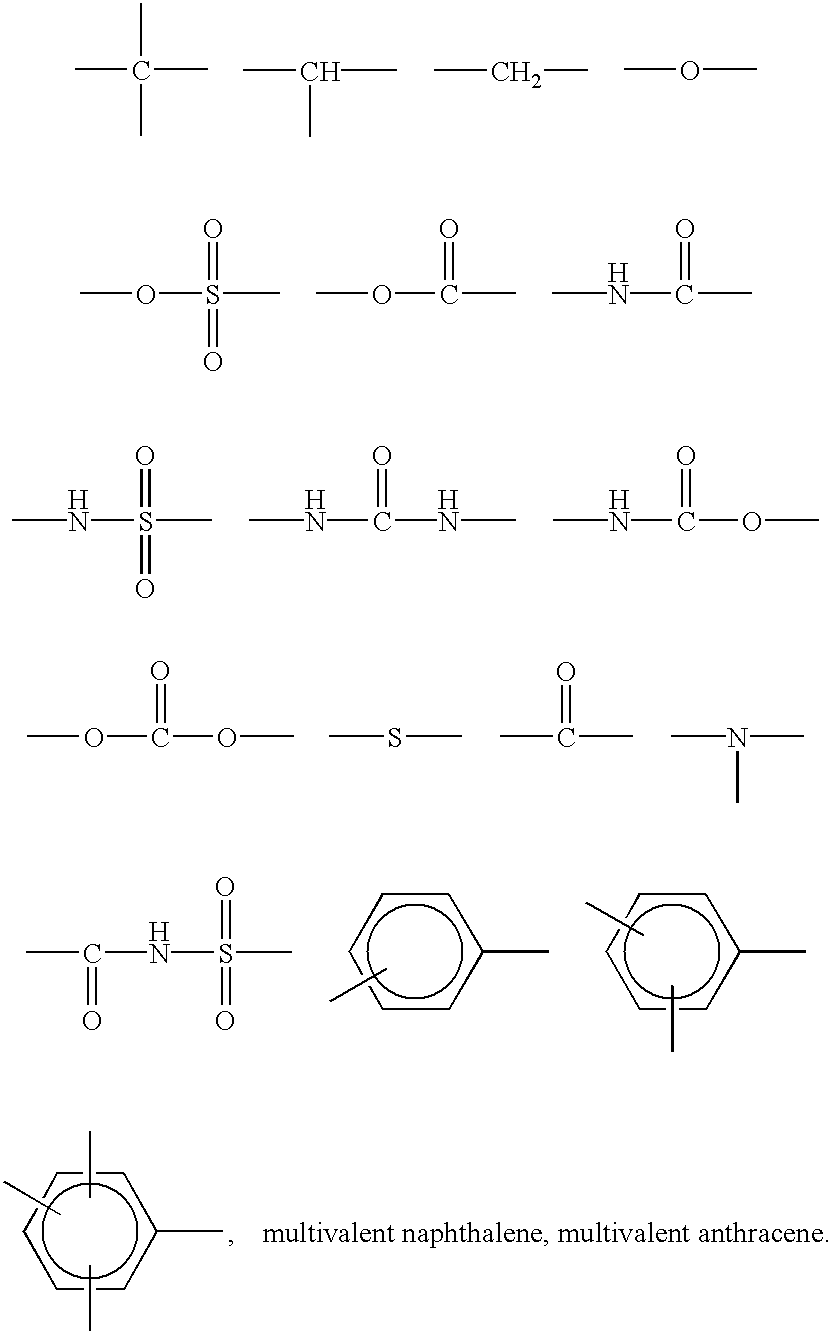

Method used

Image

Examples

example 1

(Image Forming Material: Production of Pattern Forming Material)

[0170]Using a 188 μm-thick corona-treated polyethylene terephthalate film as a substrate, the following composition was coated to the surface of the substrate by a coating bar of rod #10 and dried at 100° C. for 1 minute to form an intermediate layer with a film thickness of 1.6 μm and containing an infrared absorbing agent.

[0171]

(Intermediate layer coating composition)Epoxy resin (Epicoat, Yuka-shell Co., Ltd.)2gInfrared absorbent (IR 125 Wako Pure Chemical Industries Ltd.)0.2g1-methoxy-2-propanol9gmethyl ethyl ketone9g

[0172]An image recording layer was formed by surface graft polymerization by plasma treatment of the obtained substrate surface with the intermediate layer under the following conditions.

[0173]Using a LCVD-01 model plasma treatment apparatus manufactured by Shimadzu Corporation, a peroxide group was introduced into the intermediate layer surface by 10 second treatment in 0.04 torr argon gas atmosphere an...

example 2

(Image Forming Material: Production of Pattern Forming Material)

[0176]A polyethylene terephthalate film extruded biaxially with a thickness of 188 μm which was treated corona (A4100, produced by Toyobo Co., Ltd.), under the following conditions, oxygen glow treatment was carried out for the film using lithographic magnetron sputtering apparatus (CFS-10-EP70, manufactured by Shibaura Eletec Corporation).[0177]Initial vacuum: 9×106 torr[0178]Oxygen pressure: 6.8×103 torr[0179]RF glow: 1.5 kw[0180]Treatment time: 60 sec

[0181]Next, to the film subjected to glow treatment, a methyl ethyl ketone solution (50% by weight) of the following exemplified monomer (M-1) was coated and dried at 100° C. for 1 minute. The film was irradiated with ultraviolet rays (from a high pressure mercury lamp of 400 W for 30 minutes) to carry out graft polymerization and form a graft layer. Further, an acetonitrile solution of 5% by weight of a photo-thermal conversion pigment (IR-A) with the following structur...

example 3

(Production of Color Filter Master Plate C)

[0185]To a 188 μm-thick corona-treated polycarbonate film, the following composition was coated by a coating bar of rod #10 and dried at 100° C. for 1 minute to form a lower layer with a film thickness of 1.6 μm.

[0186]

Epoxy resin (Epicoat, Yuka-shell Co., Ltd.)2.0gInfrared absorbing agent (IR 125 Wako Pure0.01gChemical Industries Ltd.)1-methoxy-2-propanol9gmethyl ethyl ketone9g

[0187]The obtained coating film was subjected to plasma treatment under the following conditions using an LCVD-01 model plasma treatment apparatus manufactured by Shimadzu Corporation. A peroxide group was introduced into the film surface by 20 seconds treatment in 0.05 torr Ar gas atmosphere and exposure to air. The resulting film was dipped in an aqueous solution containing 8% by weight of sodium α-(styrene-4-sulfonyl)acetate before 20 minute-Ar gas bubbling. Then the film was heated at 65° C. for 6 hours to carry out graft polymerization. After the graft polymeriza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical shift | aaaaa | aaaaa |

| chemical shift | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com