Supercritical CO2 microemulsion and method for improving oil recovery factor

A microemulsion and supercritical technology, applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems such as failure to achieve miscible flooding, large amount of hydrocarbon gas mixed in, MMP rise, etc. Achieve the effects of reducing the minimum miscible pressure, large application prospects, and enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a supercritical CO 2 Microemulsion, by weight percentage, its raw material composition comprises:

[0041] Surfactant Di-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate 10.0×10 -3 %, absolute ethanol 14.1%, deionized water 1.21%, the balance is CO 2 .

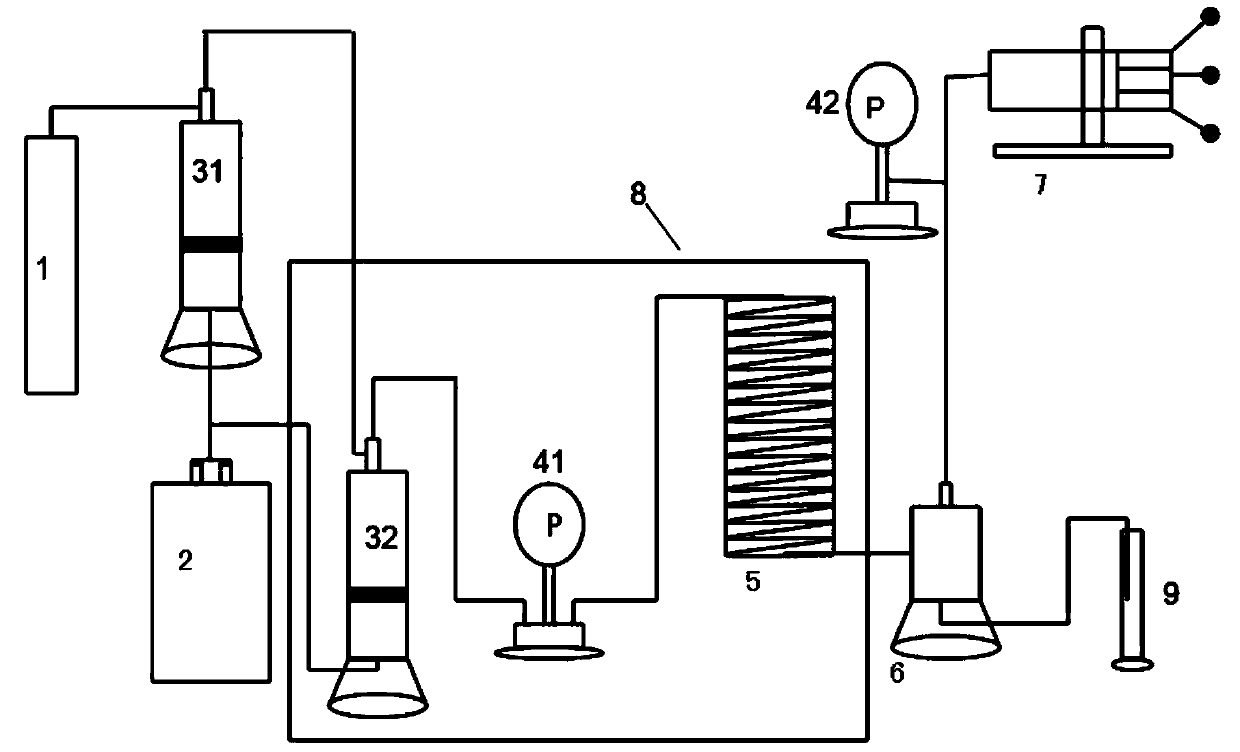

[0042] The supercritical CO 2 Microemulsions are prepared by the following steps:

[0043] Stabilize the temperature at 45°C, add the surfactant bis-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate, absolute ethanol and deionized water into the visible phase tank, will CO 2 The gas is pressed into the visible phase tank until the pressure is 1MPa lower than the predetermined pressure;

[0044] After equilibrating for 20min, slowly inject CO 2 Adjust the pressure of the system in the visible phase state to 19.0MPa (i.e. the predetermined pressure), stabilize it for 10 minutes, and obtain transparent and uniform supercritical CO 2 Microemulsion.

[0045] The above supercritical CO 2 Th...

Embodiment 2

[0056] This embodiment provides a supercritical CO 2 Microemulsion, by weight percentage, its raw material composition comprises:

[0057] Di-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate 8.0×10 -3 %, absolute ethanol 14.0%, deionized water 1.0%, and the balance is CO 2 .

[0058] The supercritical CO 2 Microemulsions are prepared by the following steps:

[0059] Stabilize the temperature at 55°C, add the surfactant bis-(1-ethyl-2-methyl-1-pentyl)sodium sulfosuccinate, absolute ethanol and deionized water into the visible phase state kettle, will CO 2 The gas is pressed into the visible phase tank until the pressure is about 1 MPa lower than the predetermined pressure;

[0060] After equilibrating for 20min, slowly inject CO 2 Adjust the pressure of the system in the visible phase state to 19.0MPa (i.e. the predetermined pressure), stabilize it for 10 minutes, and obtain transparent and uniform supercritical CO 2 Microemulsion.

[0061] The thin tube 5 saturated c...

Embodiment 3

[0066] This embodiment provides a supercritical CO 2 Microemulsion, by weight percentage, its raw material composition comprises:

[0067] Surfactant polyethylene glycol-2,6,8-trimethyl-4-nonyl ether 5.0×10 -3 %, absolute ethanol 13.5%, deionized water 1.5%, the balance is CO 2 .

[0068] The supercritical CO 2 Microemulsions are prepared by the following steps:

[0069] Stabilize the temperature at 55°C, add the surfactant polyethylene glycol-2,6,8-trimethyl-4-nonanyl ether, absolute ethanol and deionized water into the visible phase kettle, and the CO 2 The gas is pressed into the visible phase state tank until the pressure is 1MPa lower than the predetermined pressure;

[0070] After equilibrating for 20min, slowly inject CO 2 Adjust the pressure of the system in the visible phase state to 19.0MPa (that is, the predetermined pressure), and stabilize it for 10 minutes to obtain transparent and uniform supercritical CO 2 Microemulsion.

[0071] The thin tube 5 saturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com