Process for preparing barium titanate nano-rod

A technology of nanorods and barium titanate, applied in chemical instruments and methods, titanium compounds, calcium/strontium/barium compounds, etc., can solve the problems of easy decomposition of hydrogen peroxide, explosion, and small amount of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

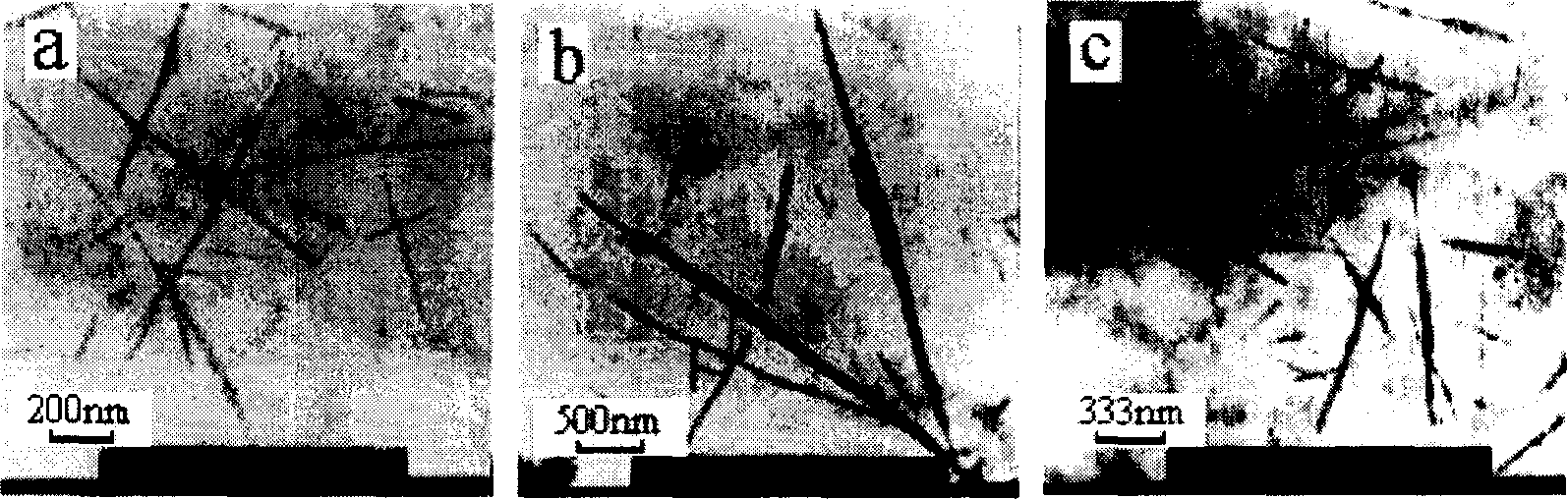

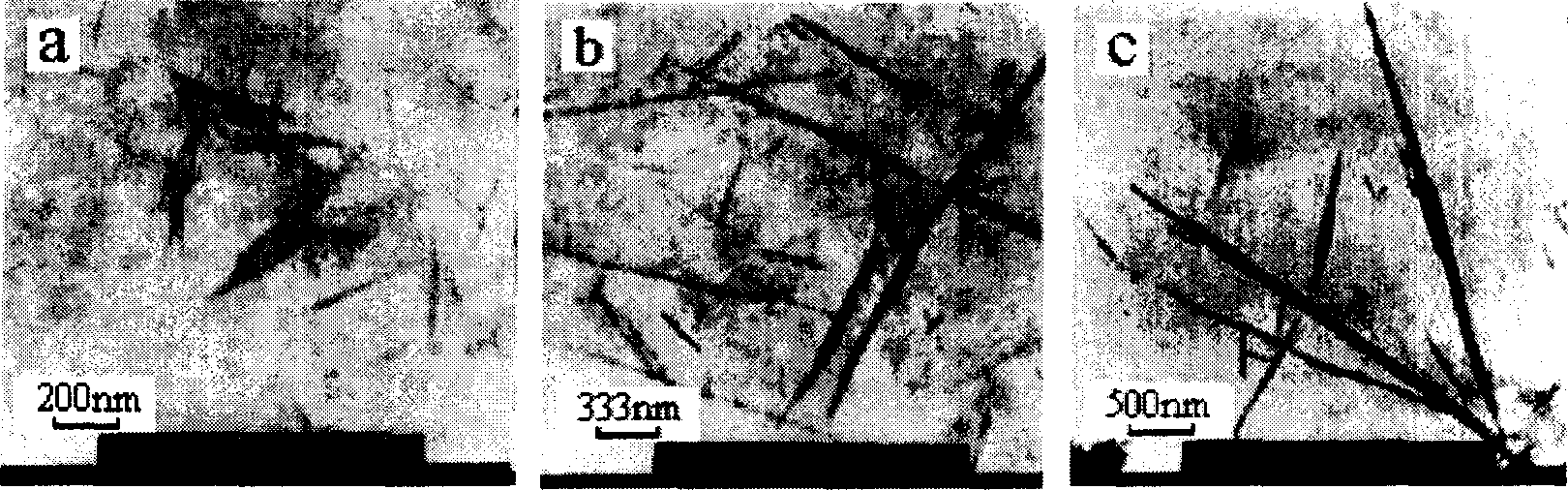

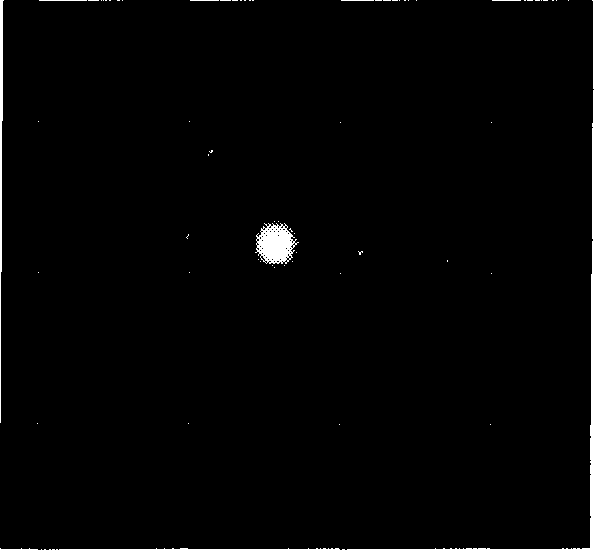

Image

Examples

Embodiment 1

[0026] (1) Take 44.0mL of cyclohexane, 3.52mL of alkylphenol polyoxyethylene (10) ether (OP-10), 0.88mL of n-hexanol and 1.60mL of Ba(OH) with a concentration of 0.20mol / L 2 solution (ω 0 =16, P=1.27) into a three-necked flask, fully mix the components of the above mixture, and vigorously stir on a constant temperature magnetic stirrer for 15 minutes to prepare a uniform and transparent reverse-phase microemulsion; take butyl titanate Soluble in cyclohexane and prepare a solution with a concentration of 0.20mol / L.

[0027](2) Put the microemulsion on a constant temperature magnetic stirrer and heat it to 60°C in a water bath, stir gently for 8 minutes, then slowly add 1.60mL of butyl titanate solution dropwise according to the ratio of the amount of barium and titanium substances to 1.02:1, micro The emulsion immediately turned milky white, reacted at a constant temperature for 2 hours, aged for 24 hours, then centrifuged, and washed away excess surfactant with absolute ethan...

Embodiment 2

[0029] (1) Take 34.5mL cyclohexane, 3.52mL alkylphenol polyoxyethylene (10) ether (OP-10), 0.69mL n-hexanol and 1.20mL concentration of 0.20mol / L barium hydroxide solution (ω 0 =12, P=1.0) into a three-necked flask, fully mix the components of the above mixture, and vigorously stir on a constant temperature magnetic stirrer for 20 minutes to prepare a uniform and transparent reverse-phase microemulsion; take butyl titanate Soluble in cyclohexane and prepare a solution with a concentration of 0.20mol / L.

[0030] (2) Put the microemulsion on a constant temperature magnetic stirrer and heat it to 70°C in a water bath, stir gently for 7 minutes, then slowly add 1.20mL of butyl titanate solution dropwise according to the ratio of the amount of barium and titanium substances to 1.01:1, micro The emulsion immediately turned milky white, reacted at constant temperature for 1.5 hours, aged for 36 hours, then centrifuged, washed away excess surfactant with absolute ethanol to obtain bar...

Embodiment 3

[0032] (1) Take 47.0mL cyclohexane, 3.52mL alkylphenol polyoxyethylene (10) ether (OP-10), 0.94mL n-hexanol and 1.20mL concentration of 0.15mol / L barium hydroxide solution (ω 0 =16, P=1.35) into a three-necked flask, fully mix the components of the above mixture, and vigorously stir on a constant temperature magnetic stirrer for 15 minutes to prepare a uniform and transparent reverse-phase microemulsion; take butyl titanate Soluble in cyclohexane and prepare a solution with a concentration of 0.15mol / L.

[0033] (2) Place the microemulsion on a constant temperature magnetic stirrer and heat it to 50°C in a water bath, stir gently for 6 minutes, then slowly add 1.20mL of butyl titanate solution dropwise according to the ratio of the amount of barium and titanium substances to 1:1, slightly The emulsion immediately turned milky white, reacted at constant temperature for 3 hours, aged for 56 hours, then centrifuged, and washed away excess surfactant with absolute ethanol to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com