Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Produced inexpensively and efficiently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

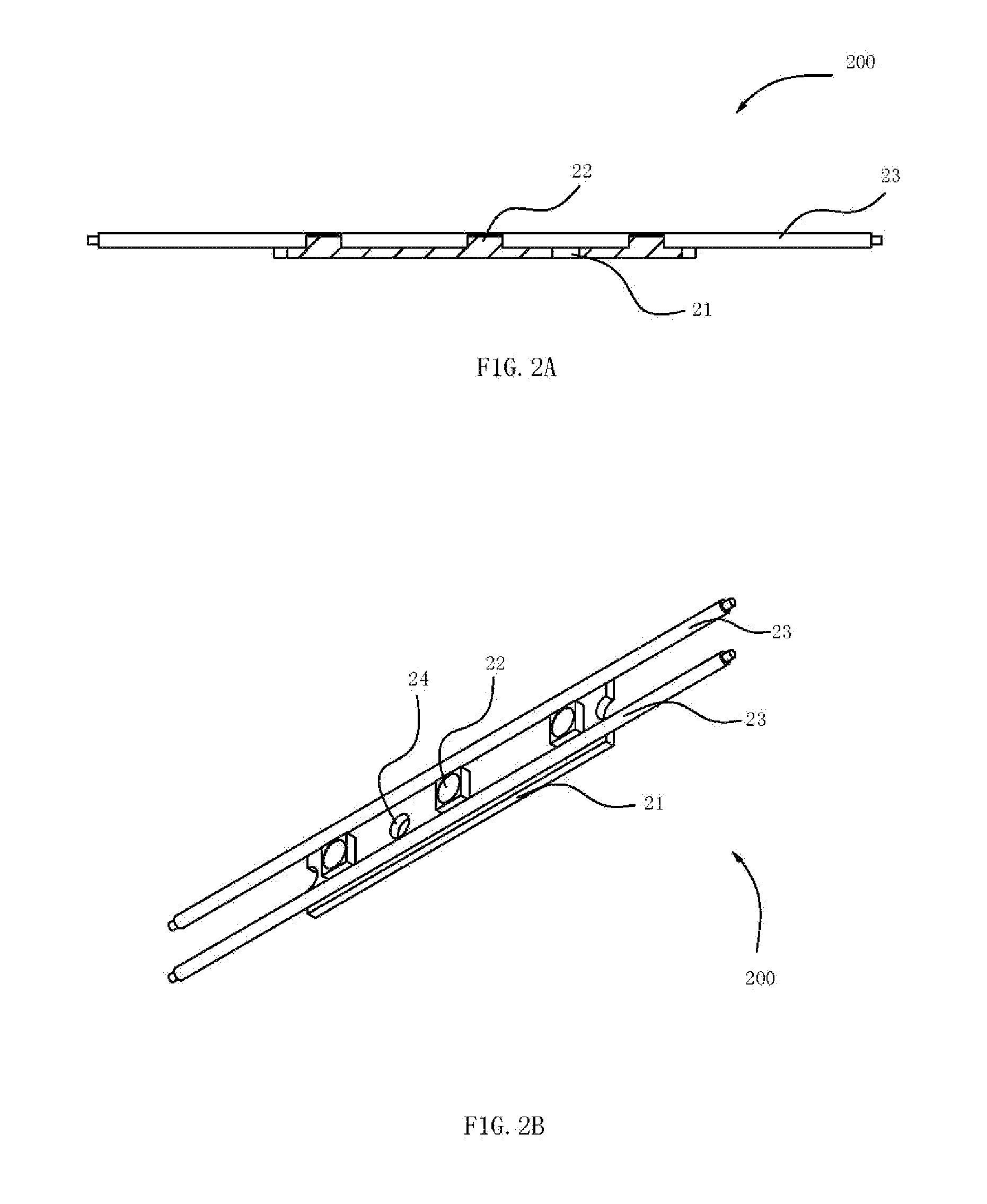

Light emitting diode light source modules

InactiveUS20120002407A1Increase usageLow manufacturing costPoint-like light sourceVehicle interior lightingMetal substrateEngineering

The present invention provides a highly-protective, heat dissipating LED light source module that may be waterproof or non-waterproof. In an embodiment, the present invention provides an LED light source module comprising: a waterproof housing comprising a metal substrate and a plastic cover integrally disposed on one or more surfaces of the metal substrate; and at least one light emitting diode, electronic component, and power line disposed on and operably connected with the metal substrate and encapsulated thereon by the plastic cover. In other embodiments are provided LED light source modules comprising: a circuit board with at least two through holes disposed at selected positions; at least one light emitting diode, electronic component, and power line disposed on the circuit board and operably connected therewith; and a plastic cover comprising at least two pins disposed and shaped for interconnection with corresponding through holes of the circuit board. The simple LED light source models disclosed may be efficiently and inexpensively produced and are capable of withstanding the harsh environments in which they are sometimes used.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

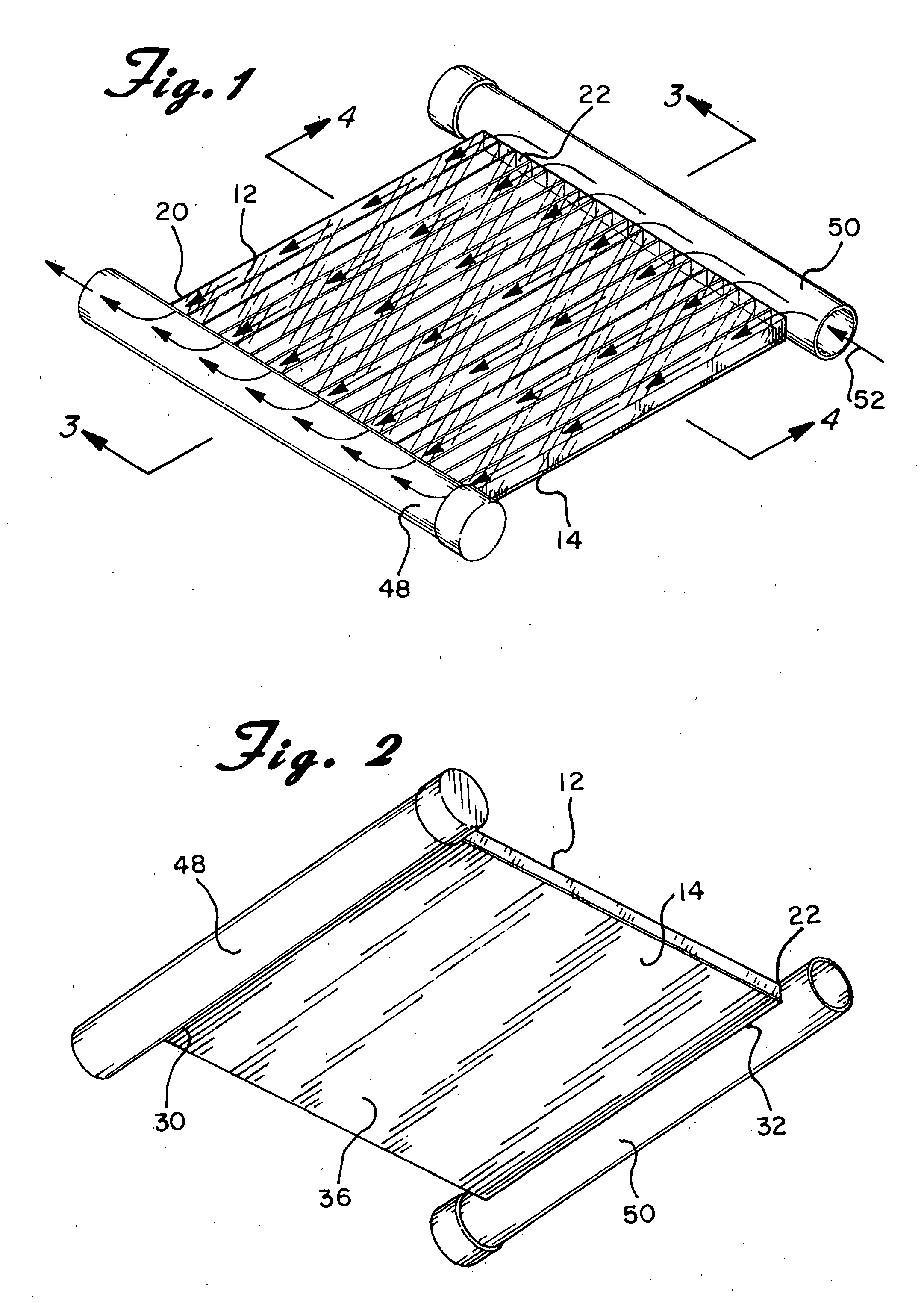

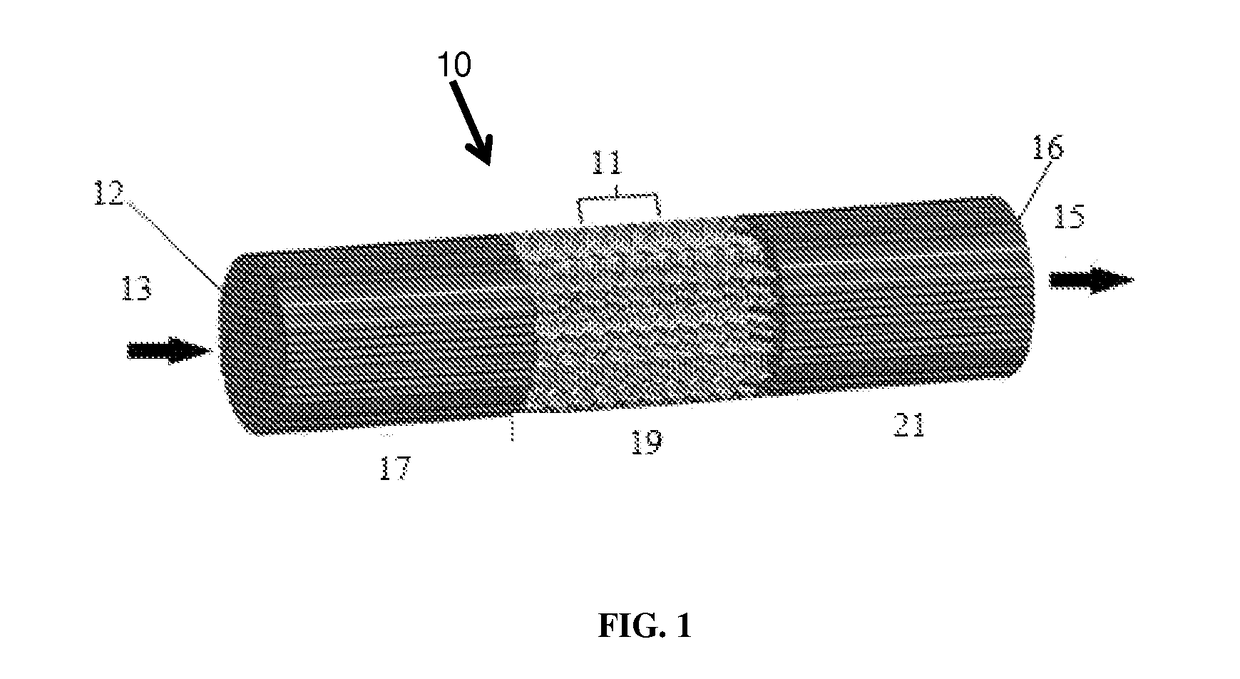

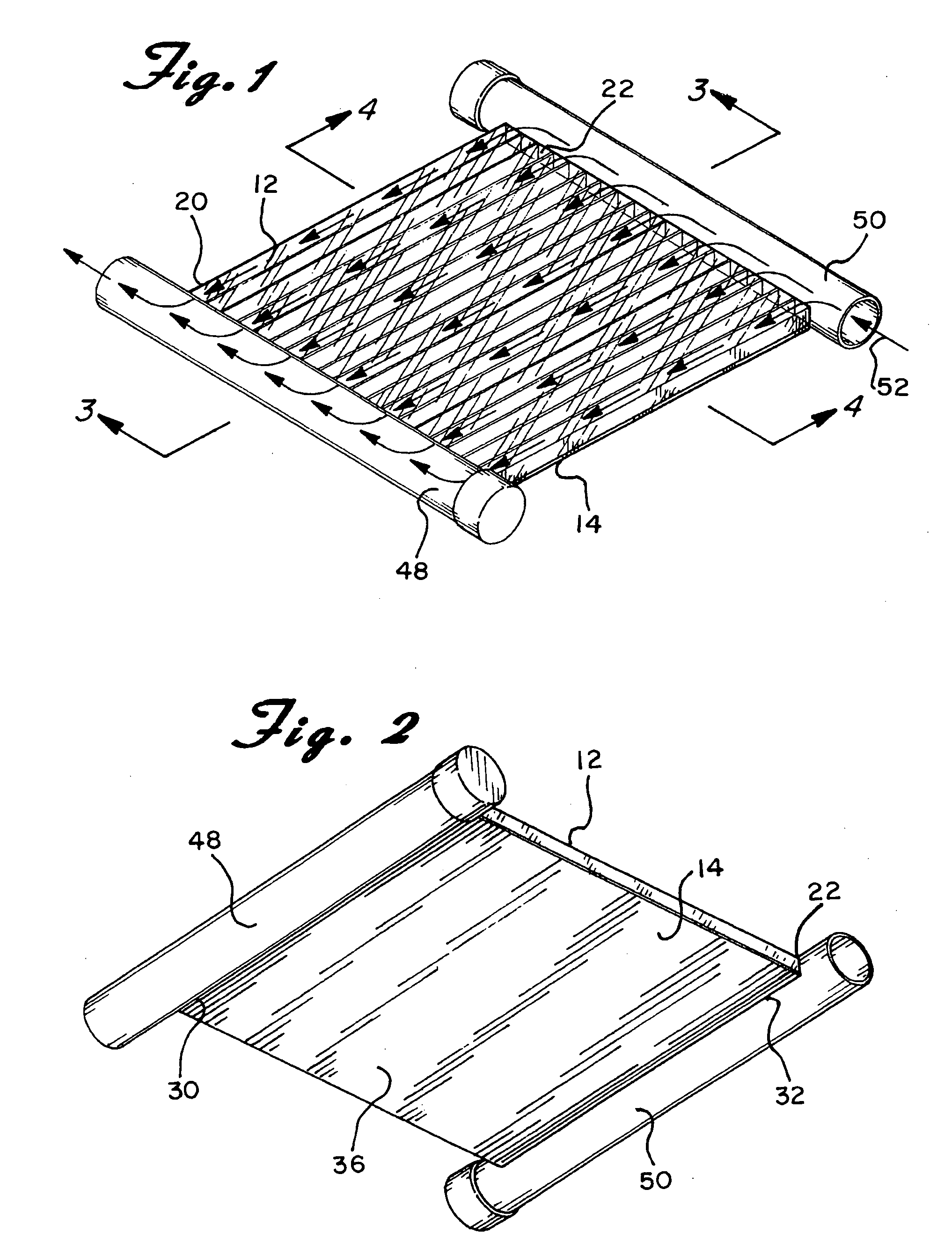

Solar panel

InactiveUS20090095282A1Produced inexpensively and efficientlyEasy to mass produceSolar heating energySolar heat devicesEngineeringGuide tube

A solar panel that utilizes the sun's rays to heat a liquid to be used for providing heat or hot water includes front and rear parallel but spaced apart clear plastic panels. Each panel has a front surface, a back surface and left and right side edges. The front panel is intended to face the sun and is substantially transparent so that the sun's rays can pass therethrough. The rear panel has a reflective coating thereon wherein rays from the sun that pass through the front panel and through the space between the panels is reflective back toward the space. Located within the space between the panels are a plurality of conduits formed by a plurality of internal walls that extend between the front and rear panels and between the left and right side edges. Within the conduits is a darkened oily liquid that is heated by the incoming rays of the sun and by the rays reflected by the rear panel. In a preferred embodiment, the front and rear panels and the internal walls are extruded as a single unit.

Owner:HELIOS PRODS

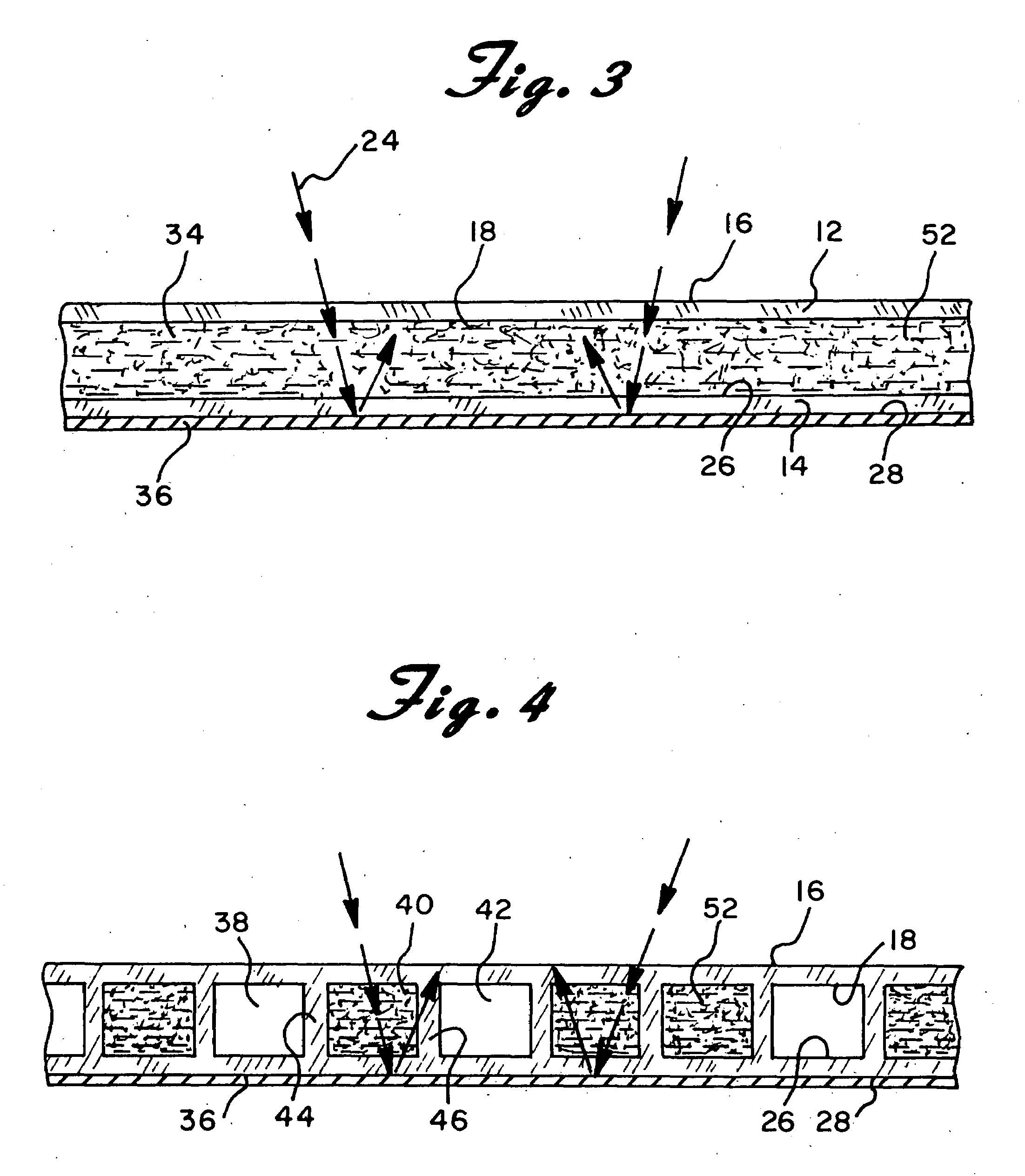

IC token, injection molding die for the IC token manufacturing method for the IC token and an IC token selection device

InactiveUS20060160628A1Low costHigh densityVideo gamesRecord carriers used with machinesEngineeringCrosstalk

An IC token for use in a machine such as a gaming device has an IC tag centrally located within a ring of electromagnet wave-absorbing material. The ring is designed to permit a peripheral attachment to the edges of the IC tag with appropriate molding dies to encapsulate the IC token in a resin. The IC token is adapted to be read by a selection device having an antenna along an inclined guide rail while eliminating the possibility of crosstalk between tokens.

Owner:ASAHI SEIKO CO LTD

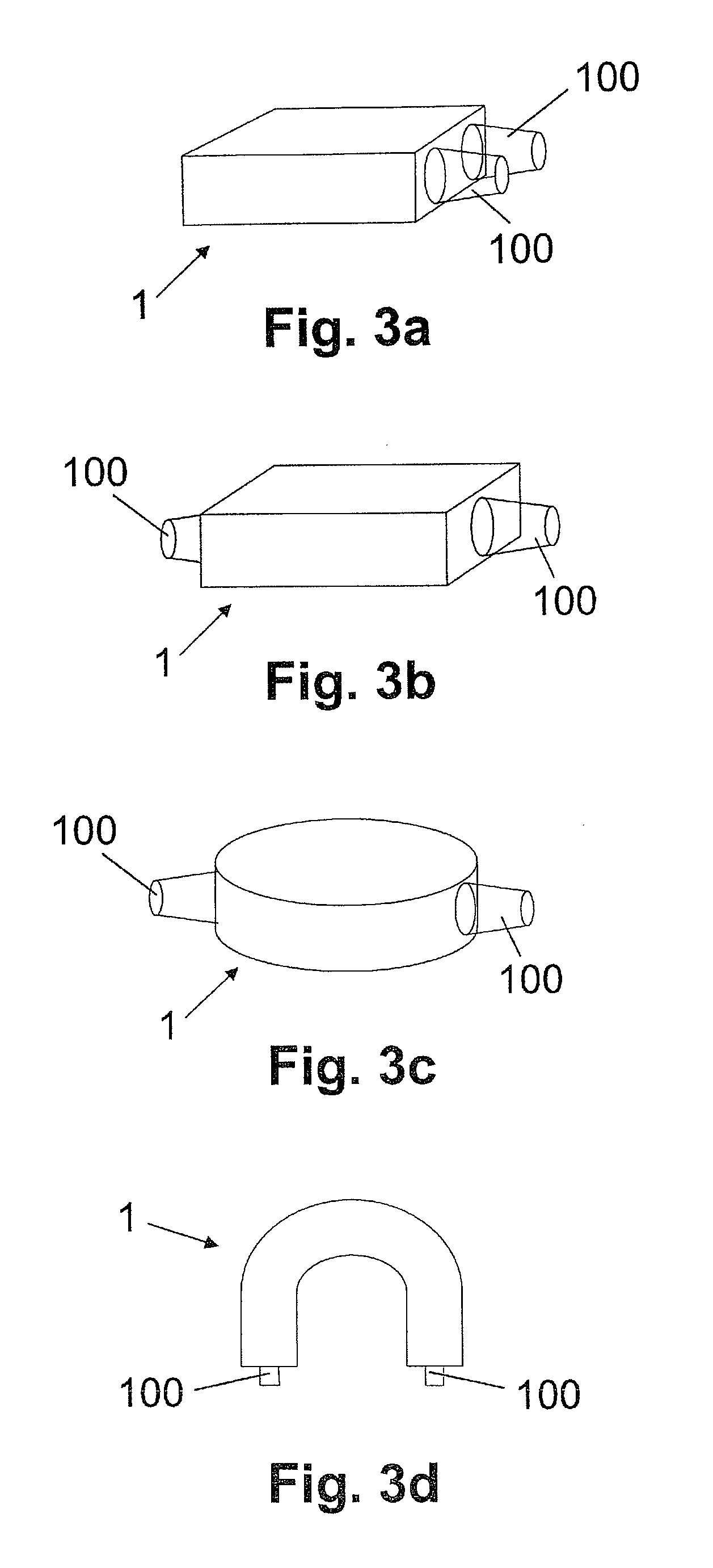

Method and equipment for quantum vacuum energy extraction

InactiveUS20140158906A1Economical and viable commercializationProduced inexpensively and efficientlyPV power plantsHollow article cleaningPolymerMaterials science

Embodiments of the present invention comprise different methods and equipment for efficiently and relatively inexpensively producing Casimir cavities for use in quantum vacuum energy extraction. The methods include without limitation, sintering; submicron porous filter materials; web roll-to-roll produced mesh or foil layers; nanotube arrays; web roll-to-roll produced porous membranes such as graphene, metallically doped; web roll-to-roll produced metallic crystals with self assembling arrays of nano-channels; three-dimensional prototyping; charged particle deposition; metal wire bundles; metal tube bundles; and metallically doped or metallically coated glass or polymer wire bundles.

Owner:ROSENDORF CHARLES HILLEL

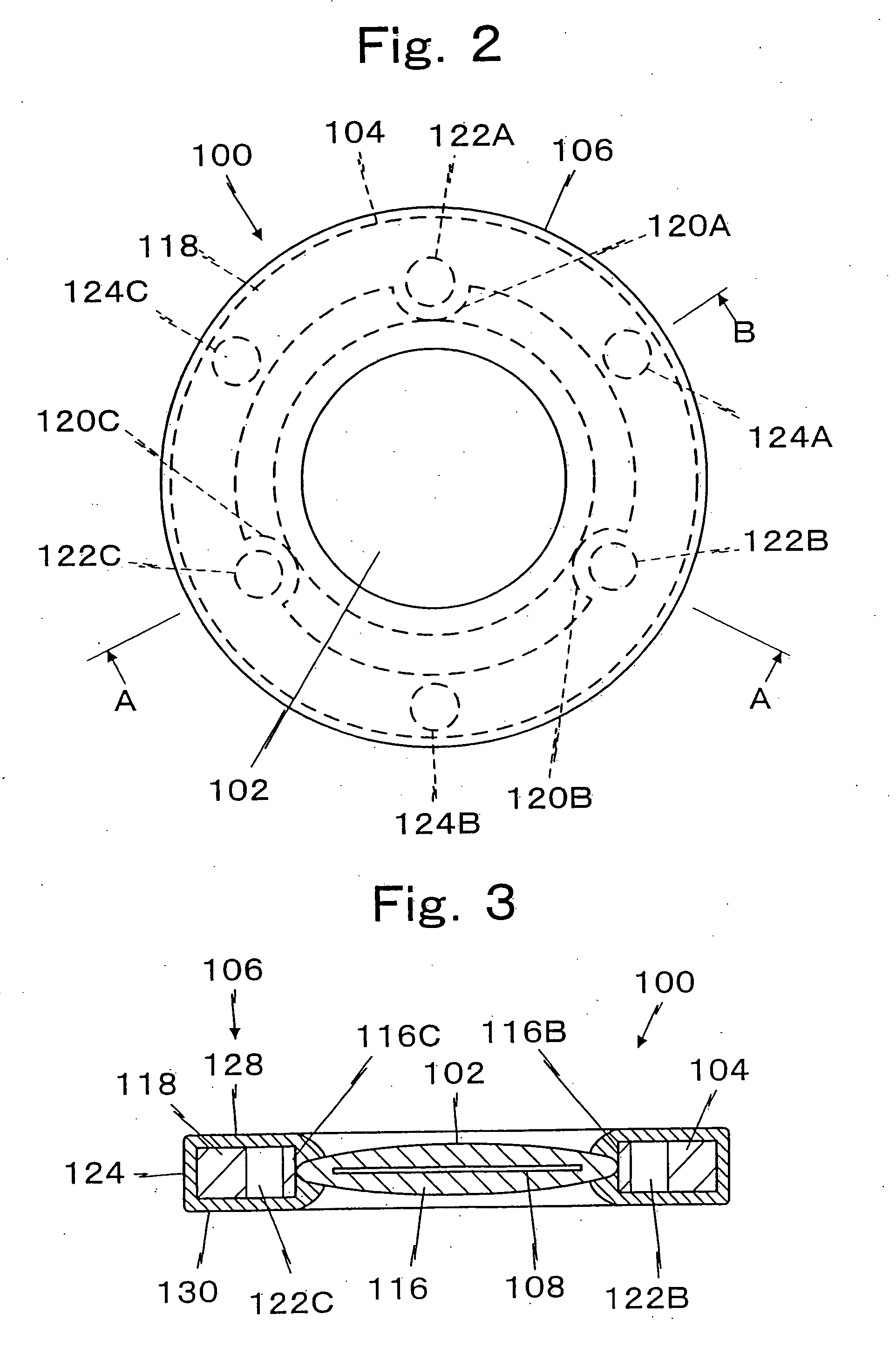

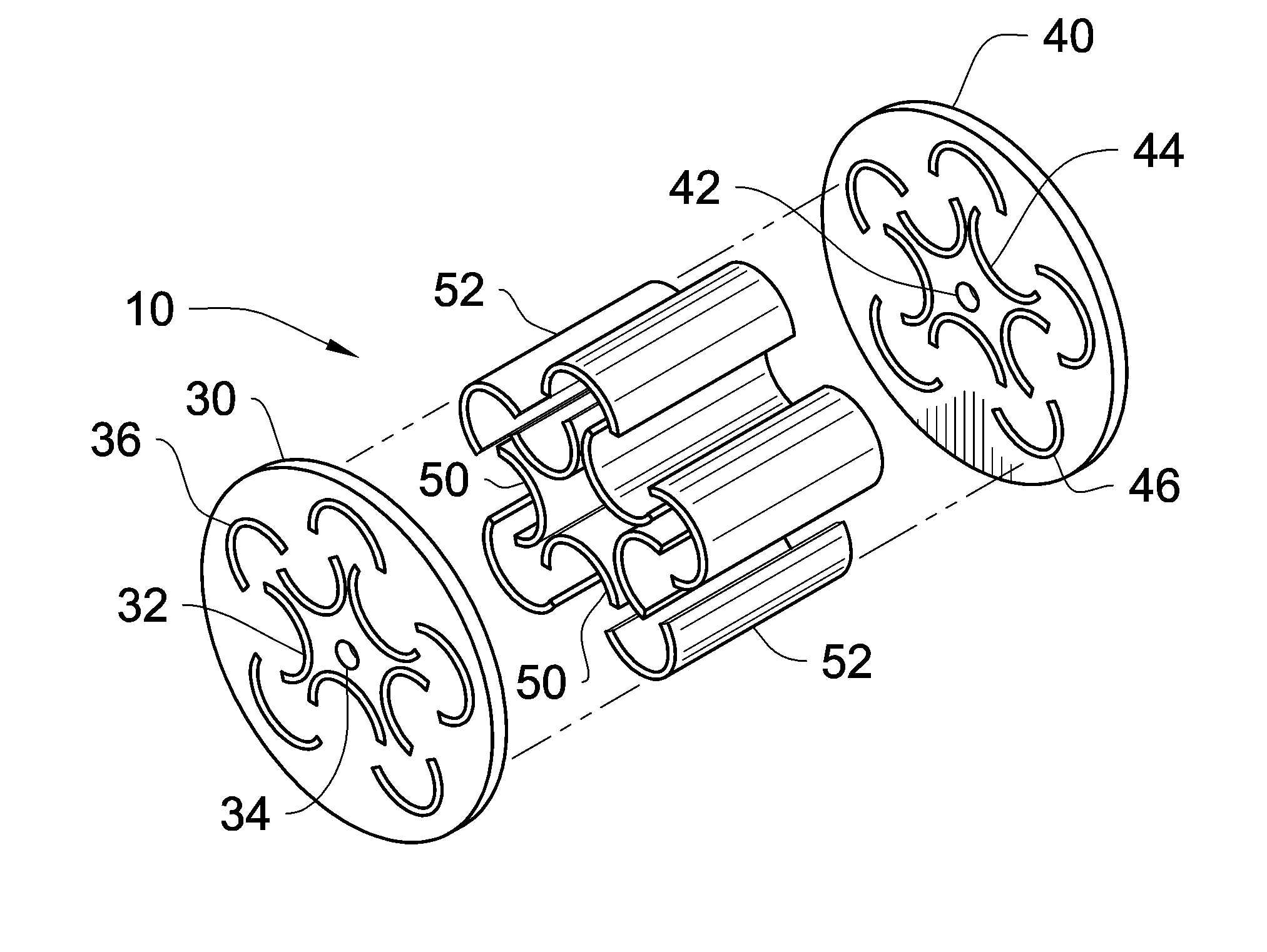

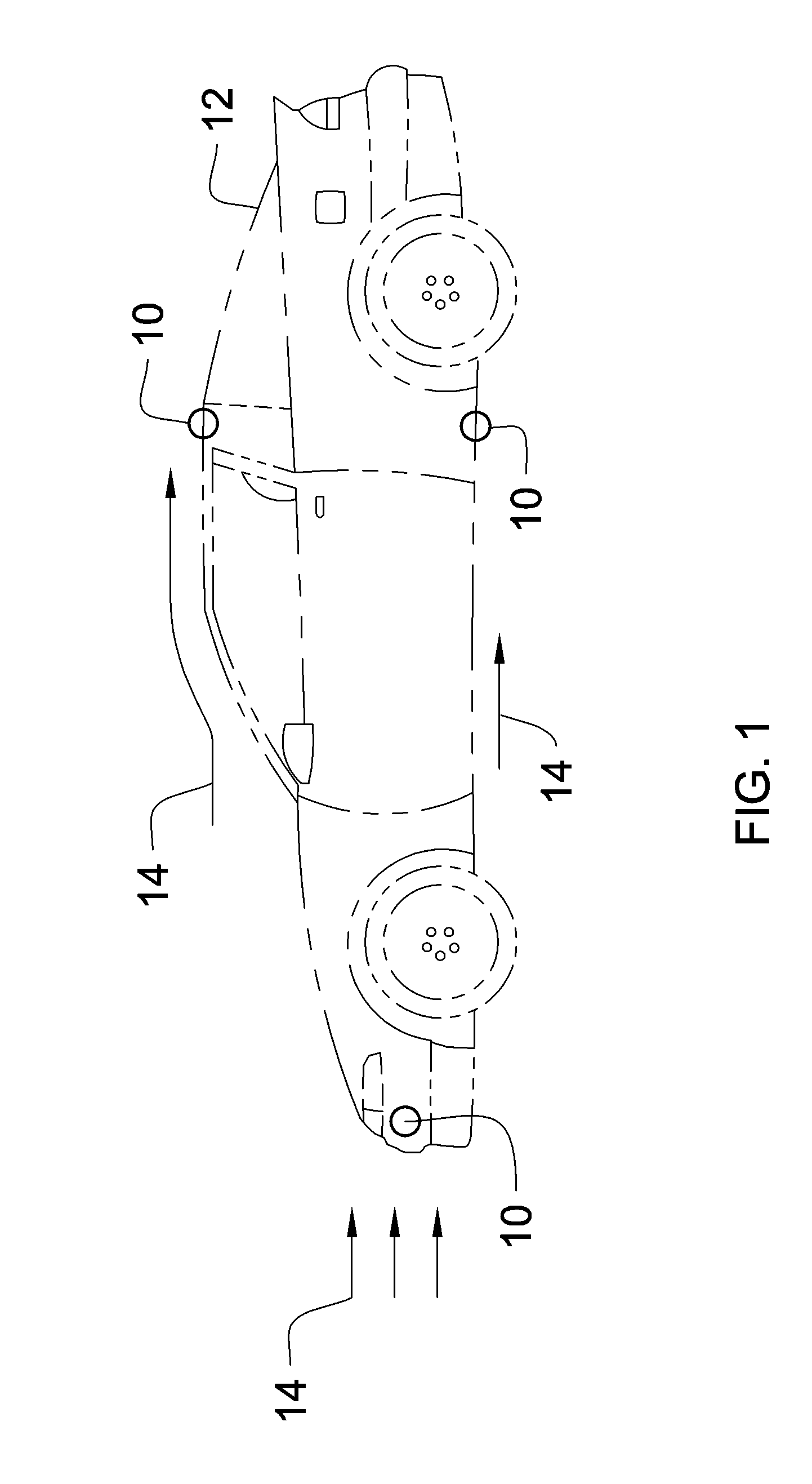

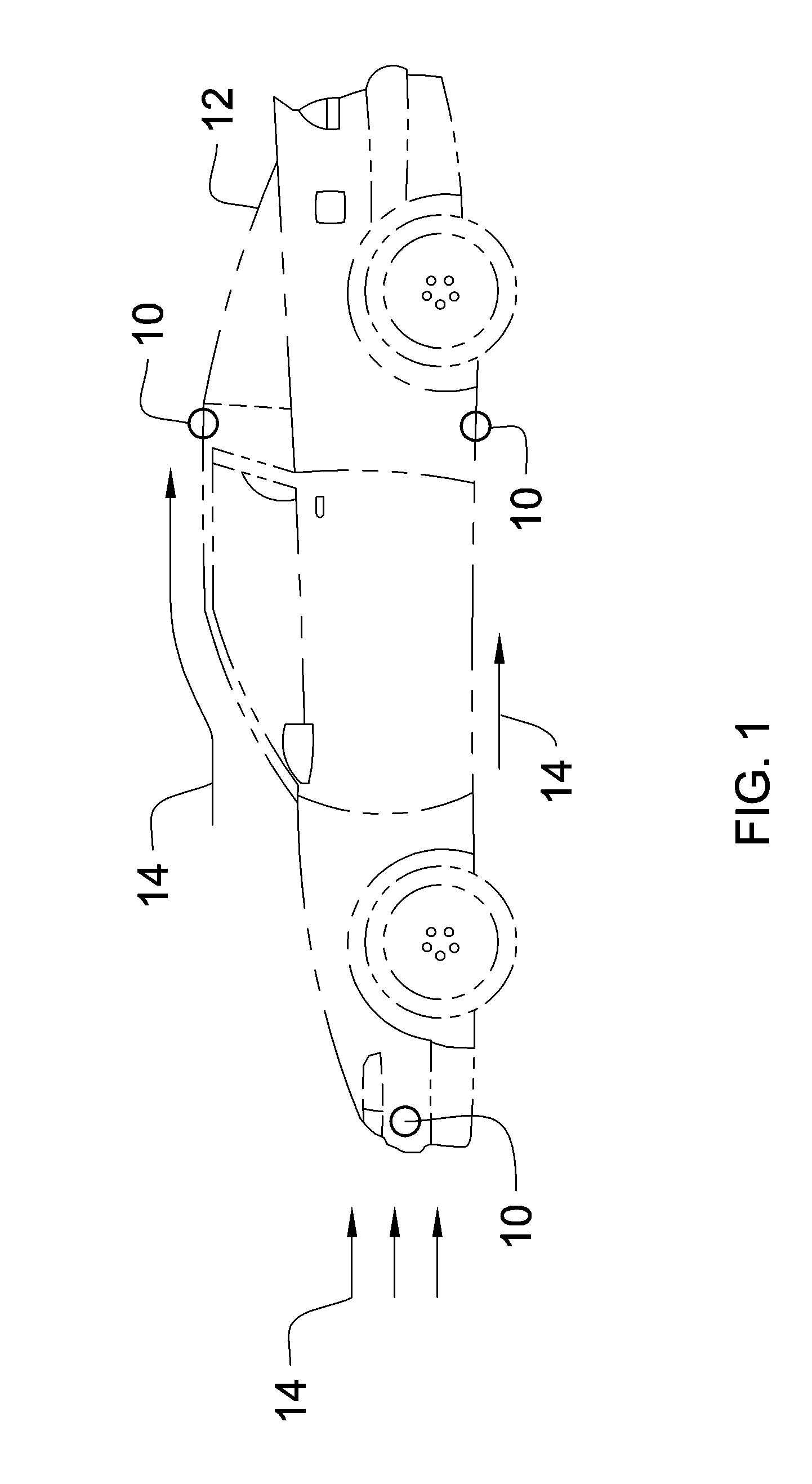

Moving fluid energy recovery system

ActiveUS8162589B2Easily and efficiently manufactured and marketedLow pricePropellersWind motor controlMobile vehicleElectricity

A moving fluid energy recovery system for generating electricity through rotational motion produced by positioning the present invention in a fluid flow produced by nature or a moving vehicle. The moving fluid energy recovery system has first and second end plates, a plurality of elongated inner vanes, a plurality of elongated outer vanes, and shaft to drive an electricity generating device. The inner and outer vanes each have a substantially curved profile featuring a curve side and an open side. The first and second end plates each has a central bore defined therethrough, a plurality of inner vane slots each shaped to receive a corresponding inner vane, and a plurality of outer vane slots each shaped to receive a corresponding outer vane. The inner vane slots are orientated with the curve side toward the central bore, and the outer vane slots are orientated with the open side toward the central bore with the free ends of adjacent inner vanes positioned in the open side of the outer vane slots.

Owner:PENTA POWER TURBINES INC

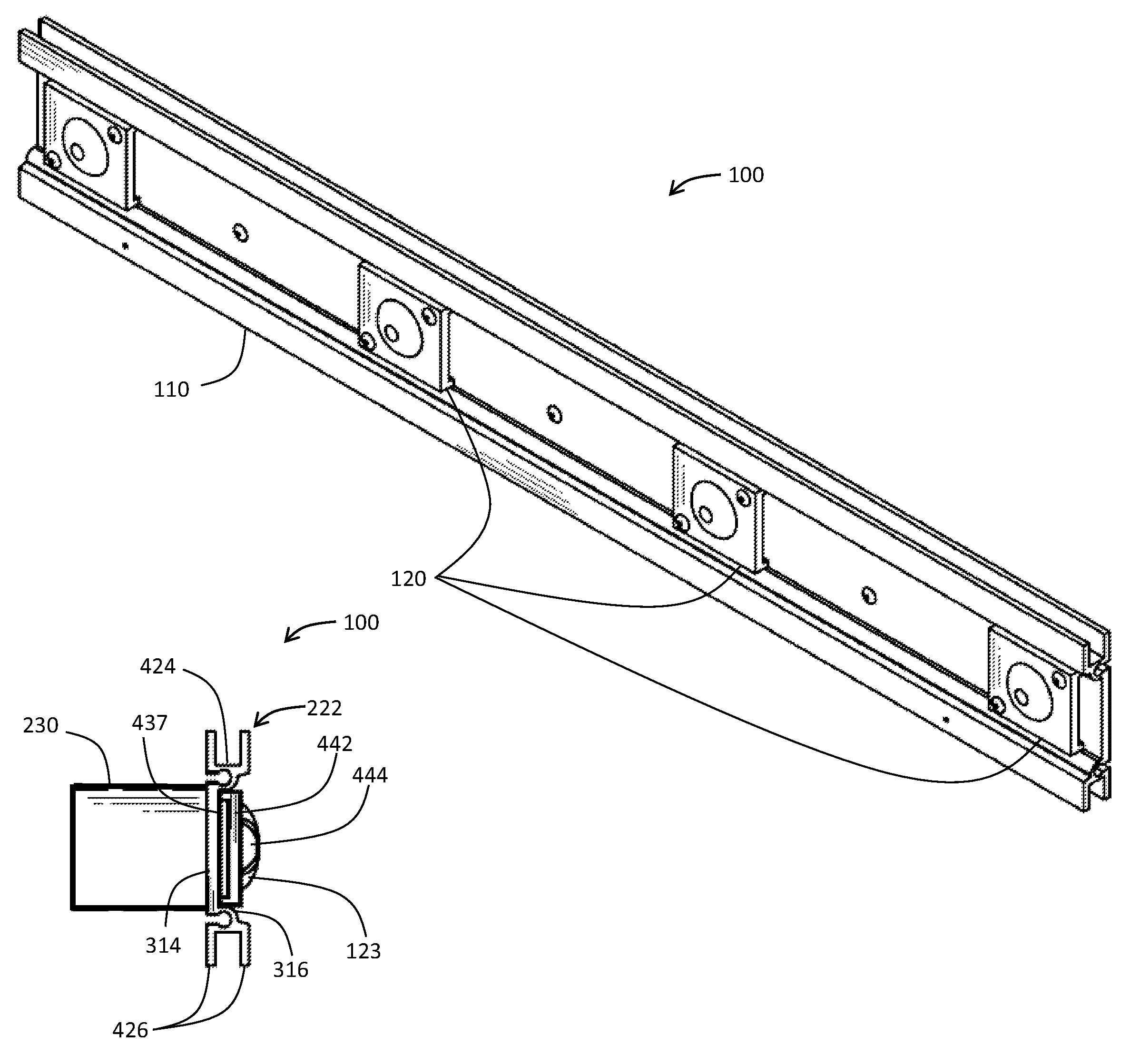

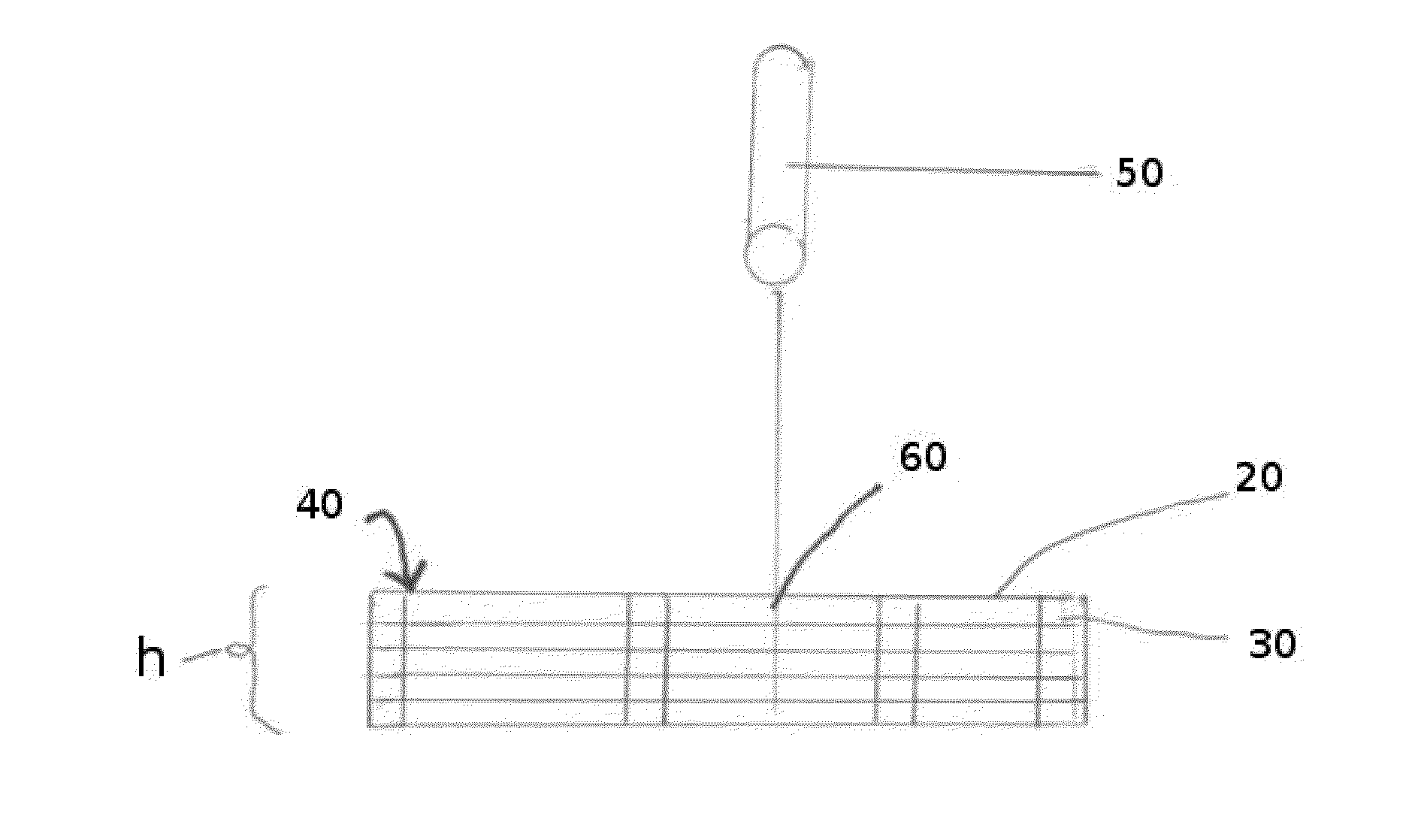

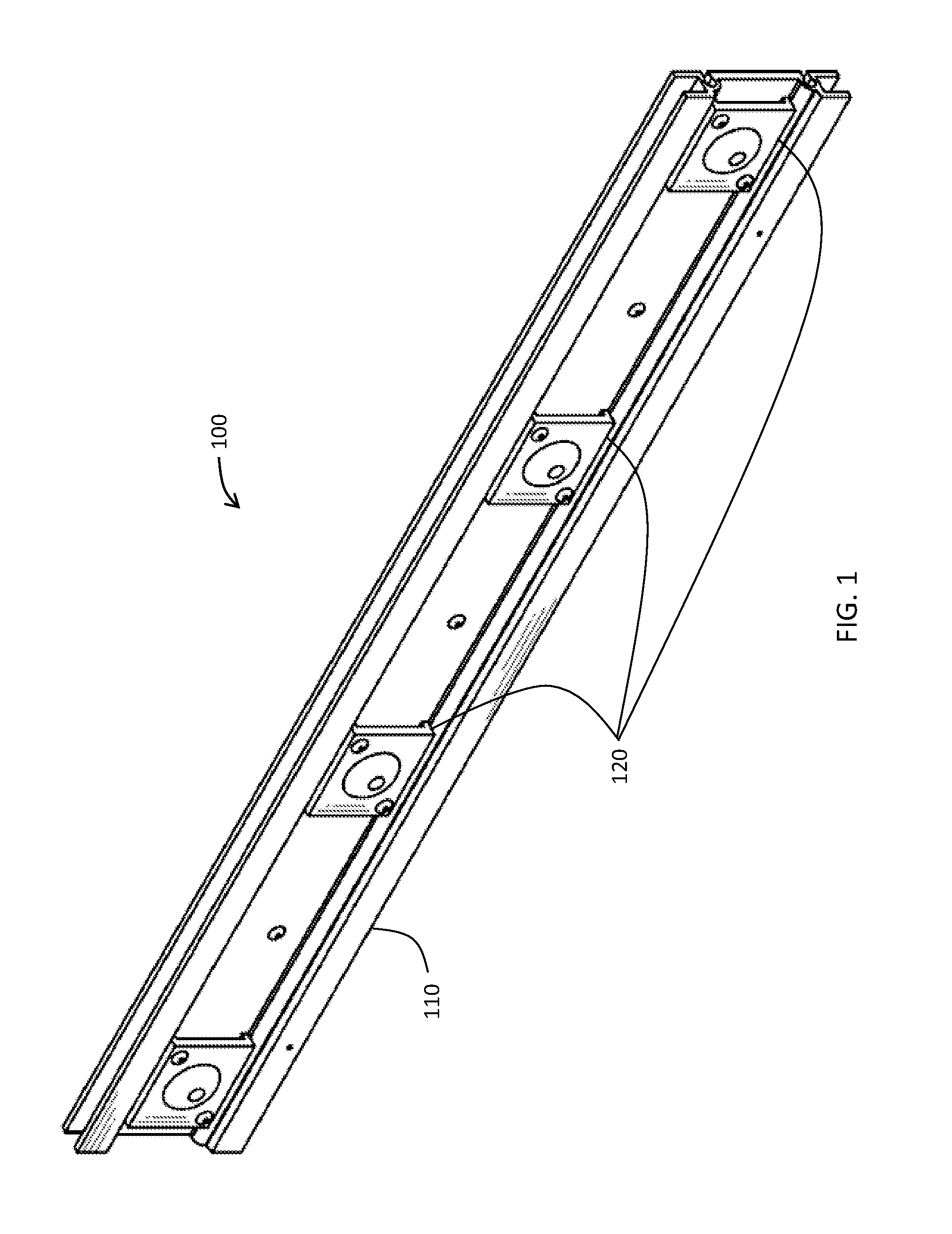

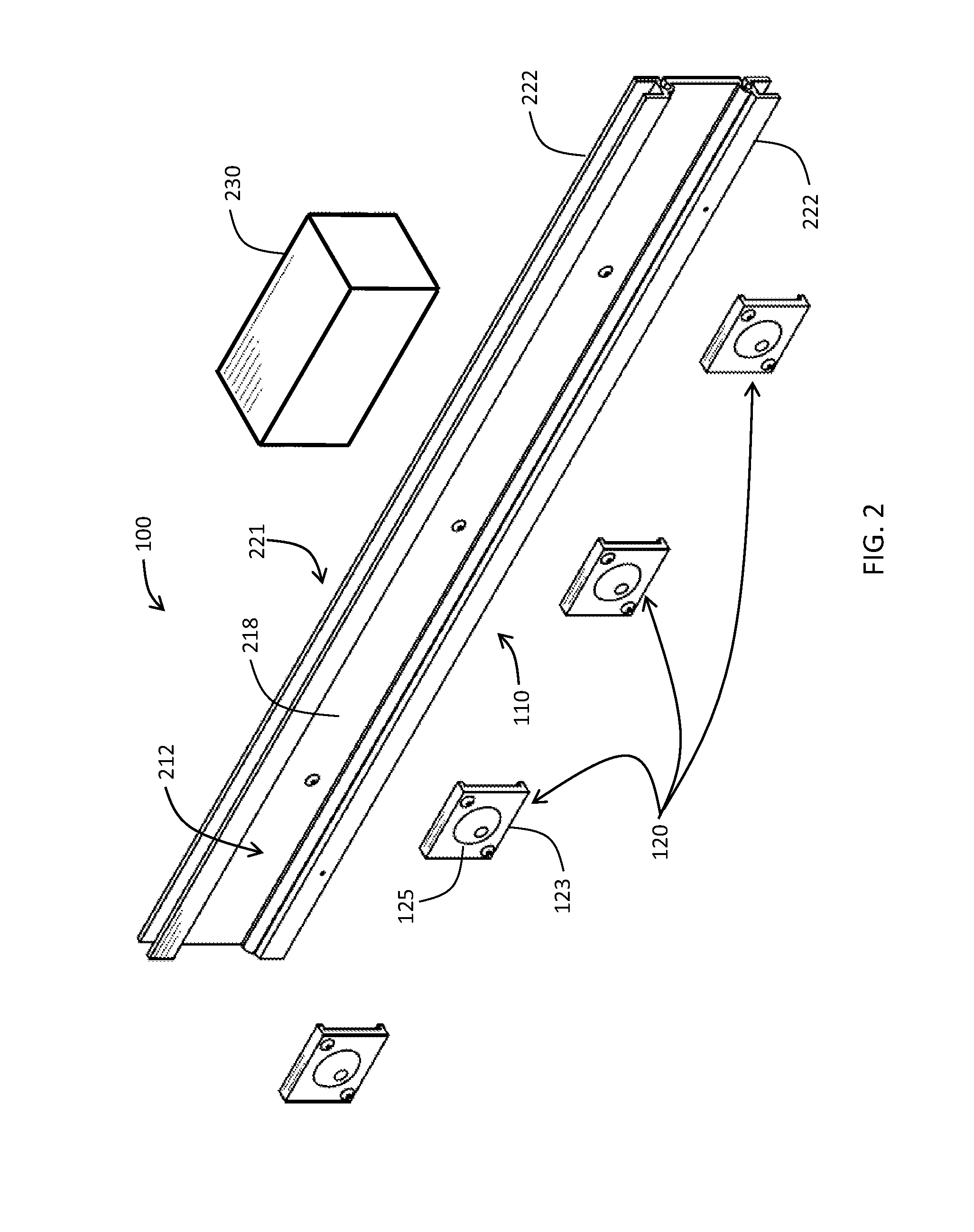

Configurable linear light assembly and associated methods

ActiveUS8899780B2Less complex in designLess-expensive to manufactureLight source combinationsLighting support devicesEngineeringLight emitting device

A linear light assembly having an elongate tray and a plurality of moveable lighting packages. The elongate tray may provide both mechanical support and thermal management for the plurality of moveable lighting packages. The elongate tray may comprise a medial channel portion with a planar track member and two opposing rim members projecting perpendicularly outward therefrom. Each flange portion may have a U-shaped cross-section. Each moveable package may comprise an assembly tray and an optical assembly having at least one light-emitting device (LED). Each moveable lighting package may be adjustably positioned along and independently removed from the front side of the track member of the elongate tray. Any segmentation of the elongate tray may be characterized by a heat dissipation rate not less than a combined heat generation rate of all moveable lighting packages carried by the segment. A method aspect includes installation of the linear light assembly.

Owner:LIGHTING SCI GROUP

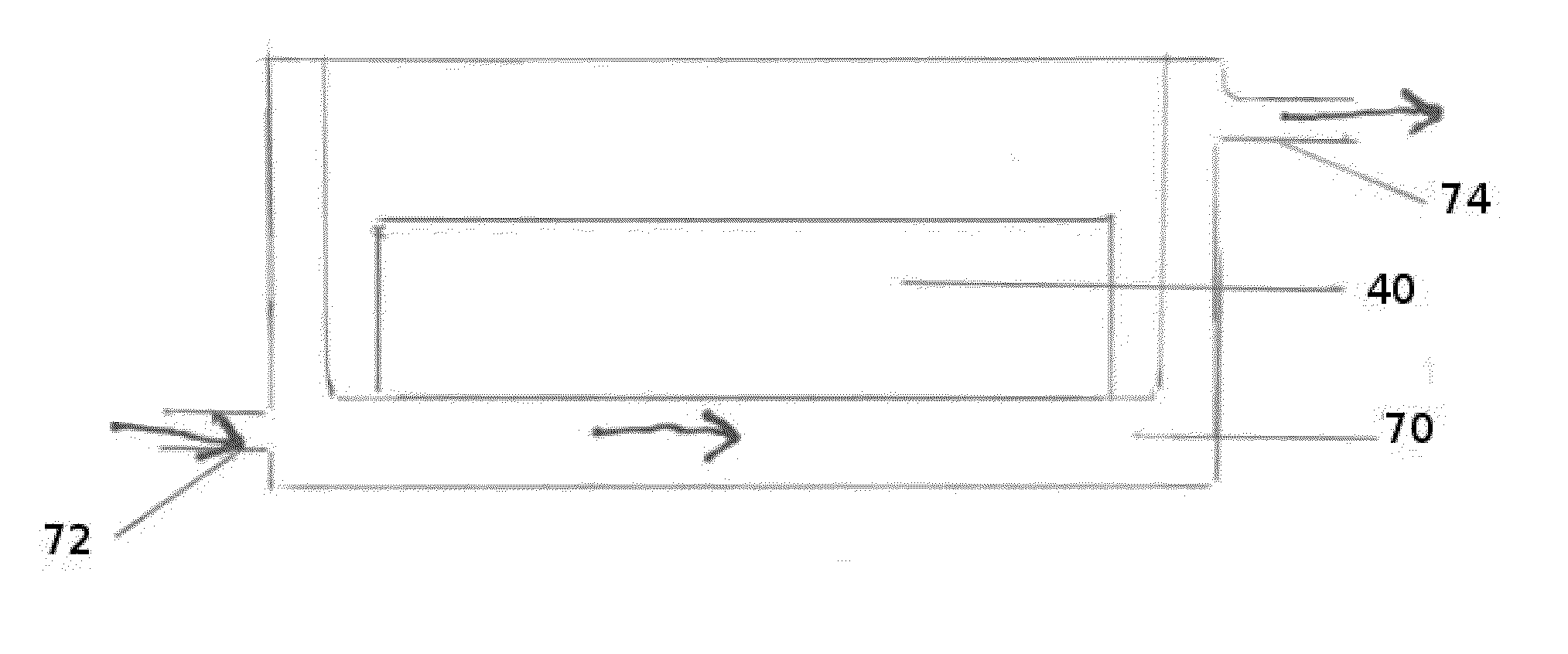

Flow sensor and production method thereof

ActiveUS20110036162A1Large lengthGood laminar flowVolume/mass flow by thermal effectsLaboratory glasswaresEngineeringMechanical engineering

In a flow sensor (1) comprising a flow channel (14) embedded in a base body (1′), a flow sensor element (13) adjacent to the flow channel (14) and a cover plate (12) covering the flow channel (14) and arranged on the base body (1′), the flow channel (14) is formed by an elastic sealing lip which delimits said channel (14), running on and around an upper side of the base body (1′) lying opposite the cover plate (12) and is pressed against the cover plate (12) such that a seal is formed. The design of the flow channel (14) by means of the sealing lip (5) allows the flow channel (14) to be sealed off from possible gaps between the base body (1′) and the cover plate (12) and in relation to the cover plate (12), such that a flow channel with a level channel bed (14) is formed by the sealing lip (15) and the cover plate (12) which channel bed has smooth peripheral areas and a uniform cross-section, and which if possible avoids the depositing and collection of dirt particles and thus prevents undesirable turbulence in the flow channel (14) and guarantees a laminar current through the flow channel (14).

Owner:BELIMO HOLDING AG

Cup containers having advertising media

InactiveUS20080142394A1Extensive and sophisticated advertising messageEnhanced size packageStampsOther accessoriesNumbering systemEngineering

Improved cup containers for products, especially single serve products, are provided for. The novel containers comprise a cup accommodating a product and lidding for the cup. The lidding comprises one or more imprintable substrate sheets which collectively provide a lid section and a message section connected to the lid section. The lid section is sealed to the cup and thereby defines a sealed volume accommodating the product therein. The message section provides a substrate on which a message may be imprinted. The lid section is provided on one of the lidding substrate sheets. The message section is provided either on the same substrate sheet as the lid section or on a separate substrate sheet. Although connected to the lid section, the message section is separable therefrom so that the message, such as an advertising message, may be removed from the container and viewed by a consumer. Preferably, the message section is separable from said lid section without compromising the integrity of the sealed volume. The novel cup containers also include preferred embodiments having a manufacturer coupon imprinted on the message section that is redeemable by a consumer of the packaged product and that has imprinted thereon machine readable indicia to facilitate automated processing of the coupon. Preferably the machine readable indicia are a UPC bar code utilizing the UCC / EAN-128 Article Numbering System or another bar code.

Owner:2204ADPLOY

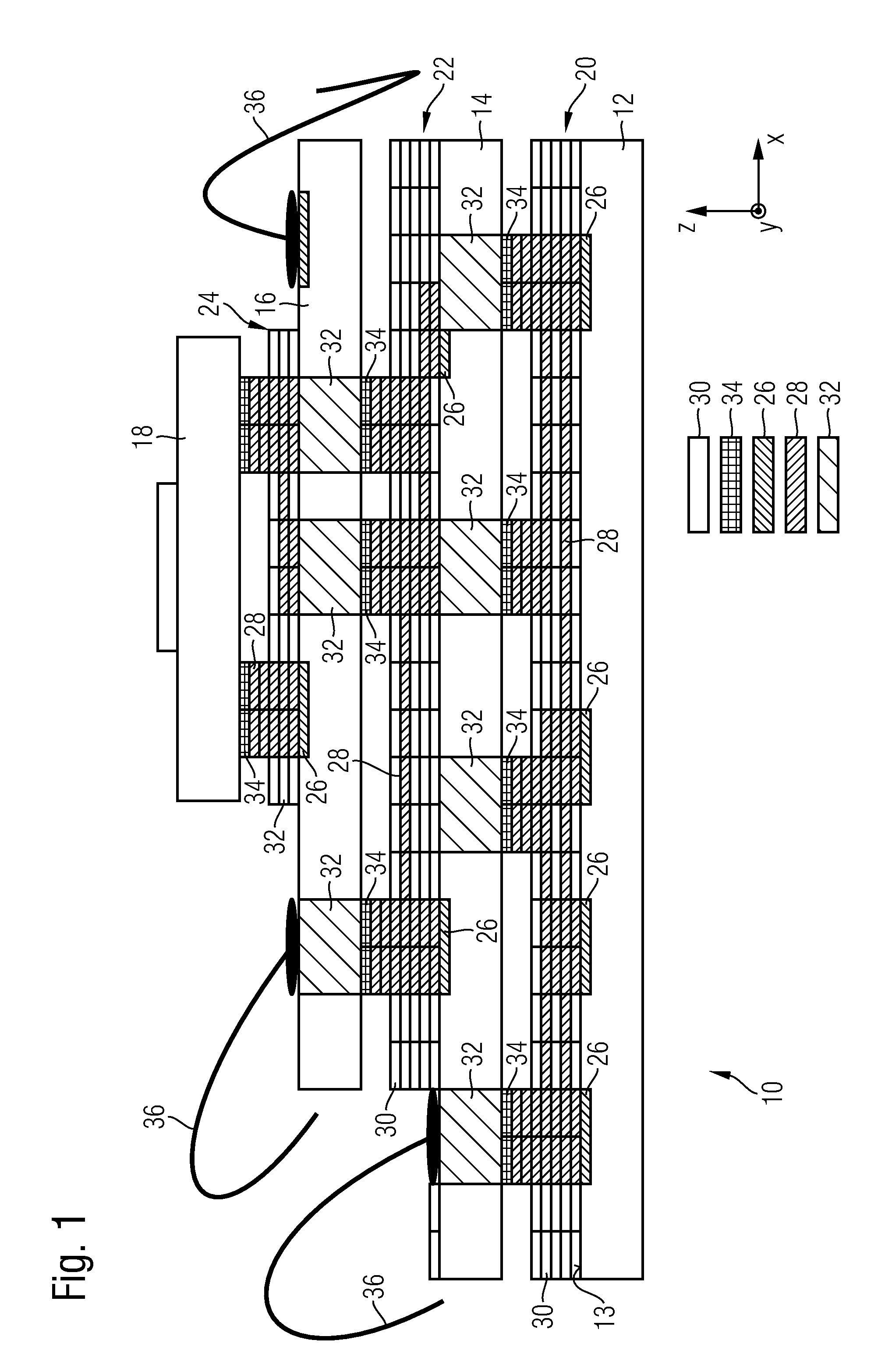

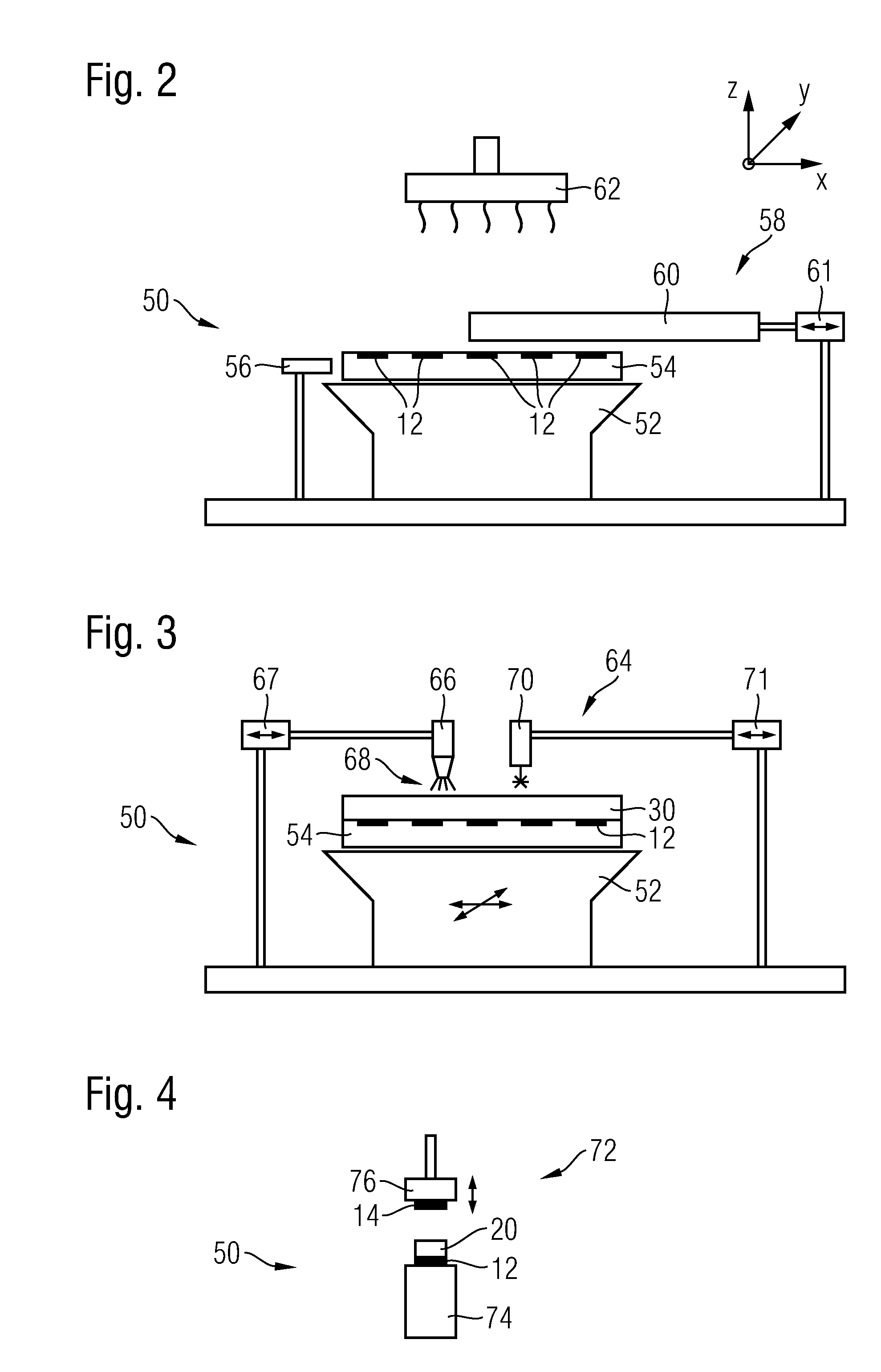

Method and A System for Producing a Semi-Conductor Module

ActiveUS20130059402A1Produced efficiently and inexpensivelyEfficient and inexpensive productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInterposerSemiconductor chip

In a method for producing a semi-conductor module (10) comprising at least two semi-conductor chips (12, 14) and an interposer (20) which has electrically conductive structures (28) connecting the semi-conductor chips (12, 14) to one another, the interposer (20) is printed directly onto a first (12) of the semi-conductor chips. When the interposer (20) is printed on, the electrically conductive structures (28) are produced by means of electrically conductive ink (68). The second semi-conductor chip (14) is mounted on the interposer (20) such that the two semi-conductor chips (12, 14) are arranged one above the other and that the interposer (20) forms an intermediate layer between the two semi-conductor chips (12, 14).

Owner:SWISS TECH ENTERPRISE GMBH

Method for production of l-amino acid

ActiveUS20110117613A1High efficiencyProduced inexpensively and efficientlyFermentationDNA/RNA fragmentationCarbon sourceAmino acid

An L-amino acid can be produced by culturing a bacterium which belongs to the Enterobacteriaceae family, and has an enhanced ability to use a fatty acid. The bacterium is capable of producing the L-amino acid in a culture medium containing a fatty acid or a hydrolysate of an oil-and-fat as a carbon source, thereby producing and accumulating the L-amino acid in a culture.

Owner:AJINOMOTO CO INC

Equipment for quantum vacuum energy extraction

InactiveUS20140092520A1Economical and viable commercializationProduced inexpensively and efficientlyAdditive manufacturing apparatusNanotechnologyFilter materialVacuum energy

Embodiments of the present invention comprise different equipment for efficiently and relatively inexpensively producing Casimir cavities for use in quantum vacuum energy extraction. The equipment includes without limitation, sintered materials; submicron porous filter materials; web roll-to-roll produced mesh or foil layers; nanotube arrays; web roll-to-roll produced porous membranes such as graphene, metallically doped; web roll-to-roll produced metallic crystals with self assembling arrays of nano-channels; materials produced by three-dimensional prototyping; materials produced by charged particle deposition; metal wire bundles; metal tube bundles; and metallically doped or metallically coated glass or polymer wire bundles.

Owner:ROSENDORF CHARLES HILLEL

Equipment for quantum vacuum energy extraction

InactiveUS20140158887A1Economical and viable commercializationProduced inexpensively and efficientlyMaterial nanotechnologyRadiation pyrometryPolymerMaterials science

Embodiments of the present invention comprise different equipment for efficiently and relatively inexpensively producing Casimir cavities for use in quantum vacuum energy extraction. The equipment includes without limitation, sintered materials; submicron porous filter materials; web roll-to-roll produced mesh or foil layers; nanotube arrays; web roll-to-roll produced porous membranes such as graphene, metallically doped; web roll-to-roll produced metallic crystals with self assembling arrays of nano-channels; materials produced by three-dimensional prototyping; materials produced by charged particle deposition; metal wire bundles; metal tube bundles; and metallically doped or metallically coated glass or polymer wire bundles.

Owner:ROSENDORF CHARLES HILLEL

Light emitting diode light source modules

InactiveUS9303861B2Produced inexpensively and efficientlySimple structurePoint-like light sourceVehicle interior lightingComputer moduleInterconnection

The present invention provides a highly-protective, heat dissipating LED light source module that may be waterproof or non-waterproof. In an embodiment, the present invention provides an LED light source module comprising: a waterproof housing comprising a metal substrate and a plastic cover integrally disposed on one or more surfaces of the metal substrate; and at least one light emitting diode, electronic component, and power line disposed on and operably connected with the metal substrate and encapsulated thereon by the plastic cover. In other embodiments are provided LED light source modules comprising: a circuit board with at least two through holes disposed at selected positions; at least one light emitting diode, electronic component, and power line disposed on the circuit board and operably connected therewith; and a plastic cover comprising at least two pins disposed and shaped for interconnection with corresponding through holes of the circuit board. The simple LED light source models disclosed may be efficiently and inexpensively produced and are capable of withstanding the harsh environments in which they are sometimes used.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD +1

Method and equipment for quantum vacuum energy extraction

InactiveUS20140092521A1Economical and viable commercializationProduced inexpensively and efficientlyAdditive manufacturing apparatusWave amplification devicesVacuum energyFilter material

Embodiments of the present invention comprise different methods and equipment for efficiently and relatively inexpensively producing Casimir cavities for use in quantum vacuum energy extraction. The methods include without limitation, sintering; submicron porous filter materials; web roll-to-roll produced mesh or foil layers; nanotube arrays; web roll-to-roll produced porous membranes such as graphene, metallically doped; web roll-to-roll produced metallic crystals with self assembling arrays of nano-channels; three-dimensional prototyping; charged particle deposition; metal wire bundles; metal tube bundles; and metallically doped or metallically coated glass or polymer wire bundles.

Owner:ROSENDORF CHARLES HILLEL

Method for production of L-amino acid

ActiveUS8389249B2Produced inexpensively and efficientlyImprove abilitiesFermentationDNA/RNA fragmentationHydrolysateFatty acid

An L-amino acid can be produced by culturing a bacterium which belongs to the Enterobacteriaceae family, and has an enhanced ability to use a fatty acid. The bacterium is capable of producing the L-amino acid in a culture medium containing a fatty acid or a hydrolysate of an oil-and-fat as a carbon source, thereby producing and accumulating the L-amino acid in a culture.

Owner:AJINOMOTO CO INC

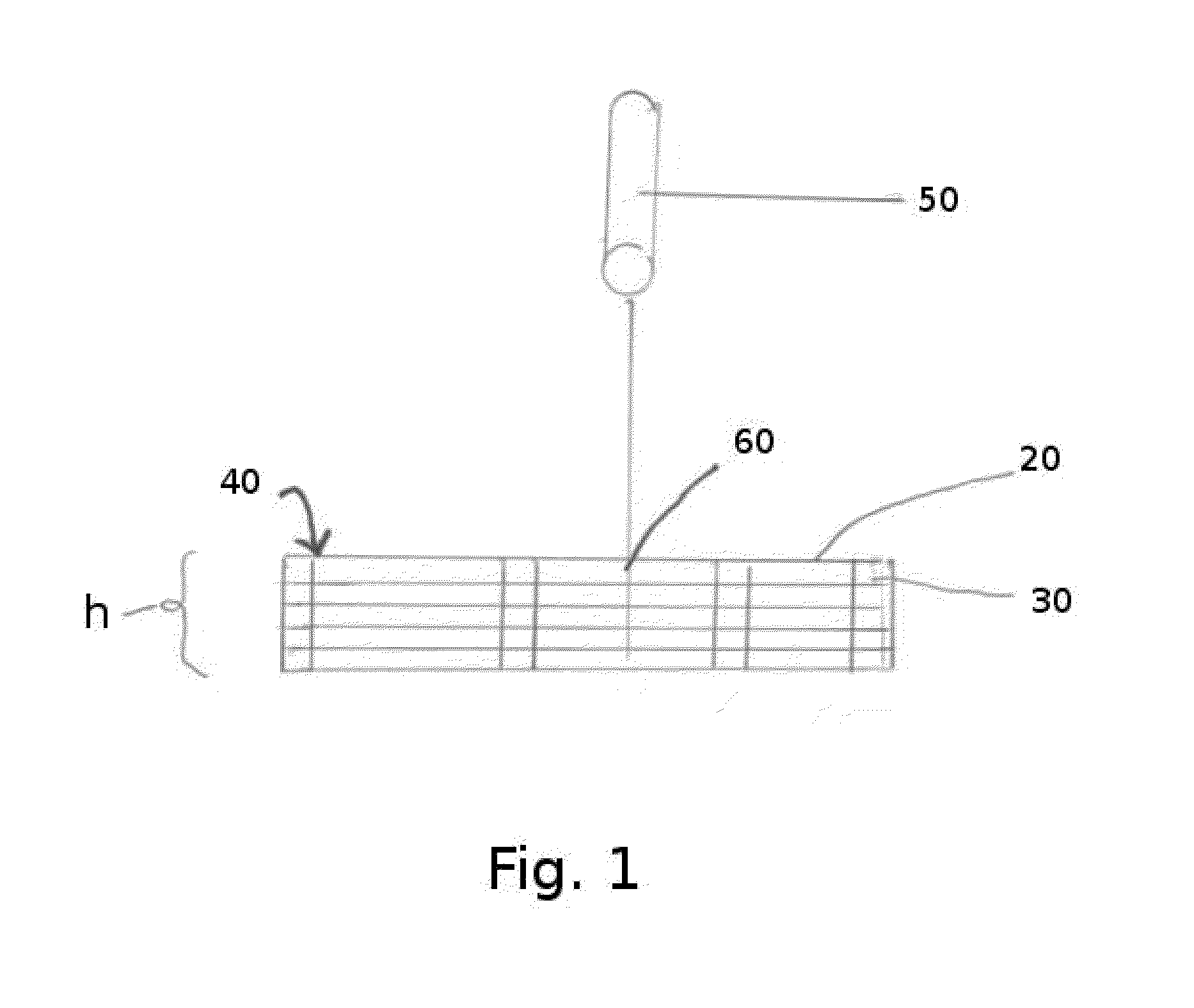

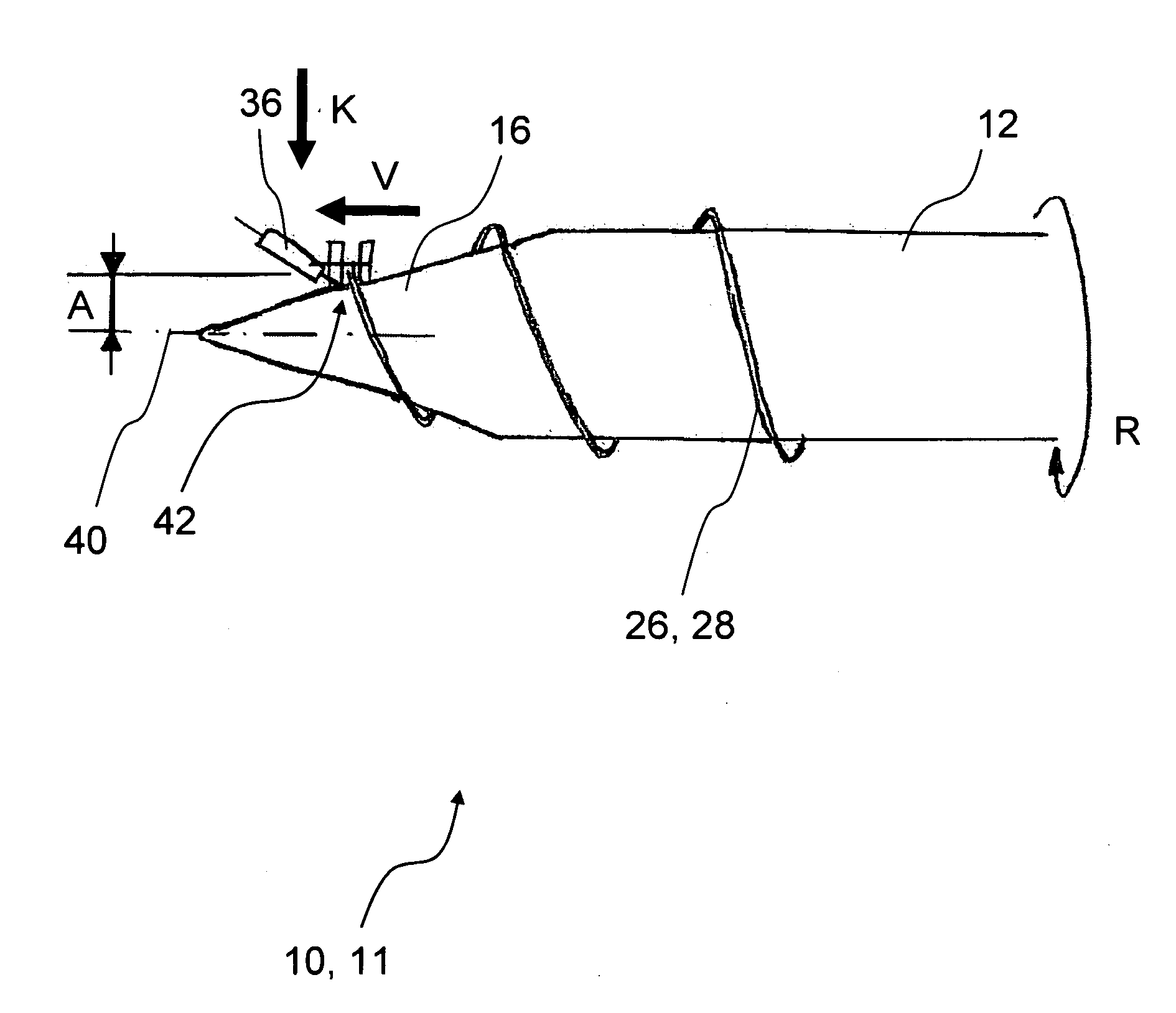

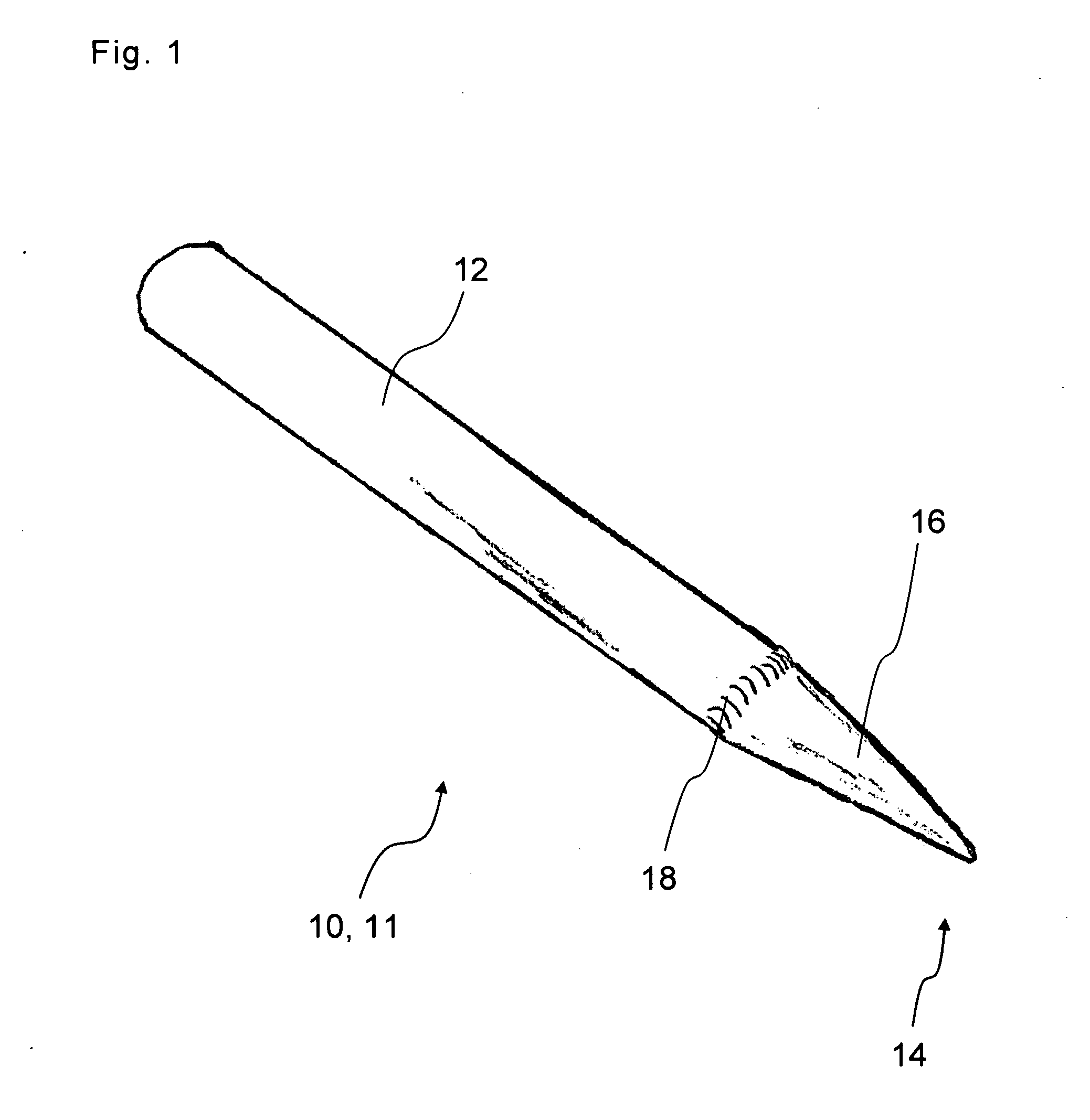

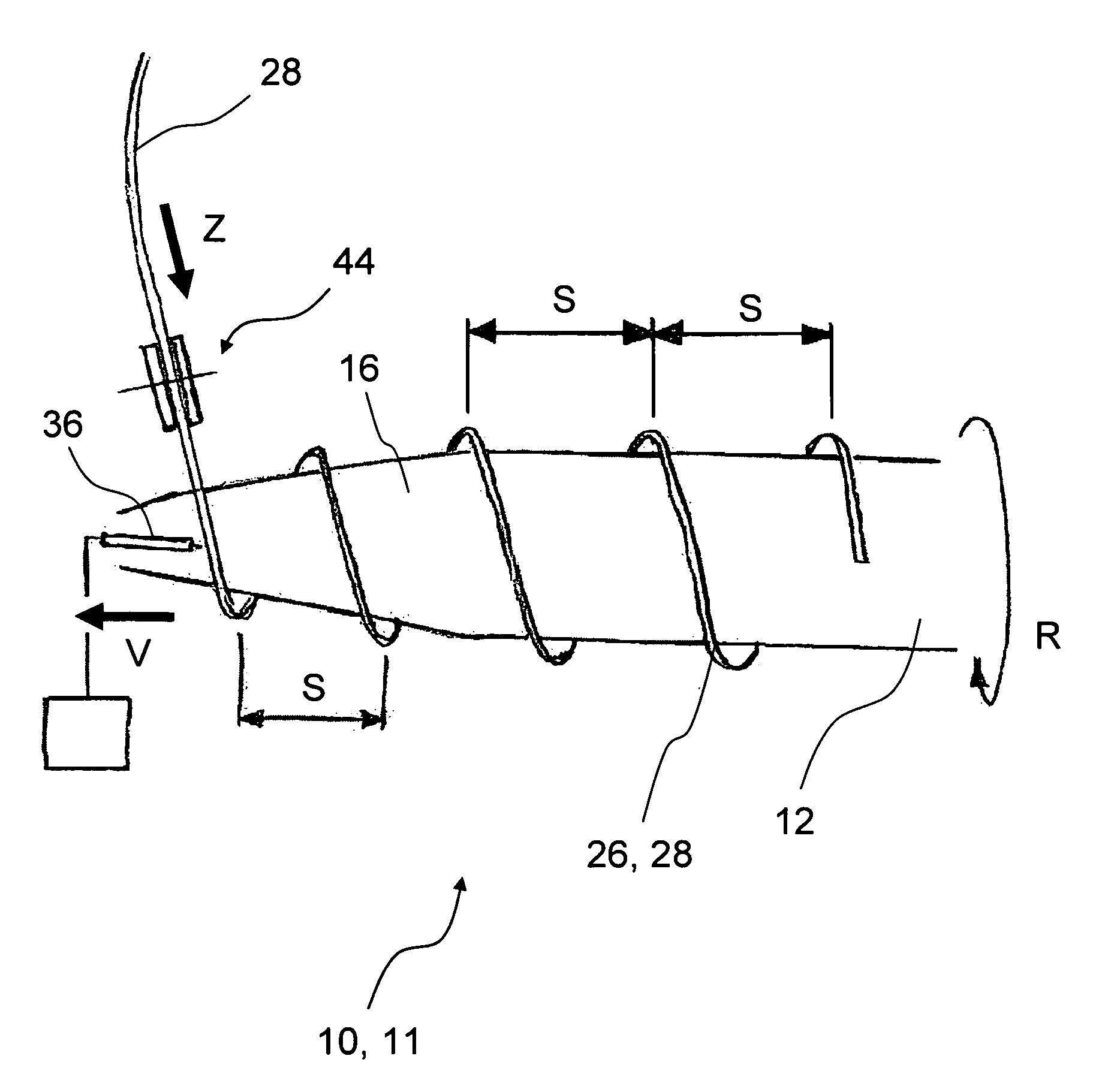

Ground peg, and device and method for the production thereof

ActiveUS20110127313A1Produced efficiently and inexpensivelyManufactured quickly and inexpensivelyCooking-vessel materialsSoldering apparatusFillet weldMechanical engineering

The invention relates to a ground peg (10) which is made from a steel tube (11) and comprises an upper cylindrical section (12), a lower section (16) that tapers towards the bottom to form a tip (14), and an external thread (26) that extends along at least part of the lower section (16) and is formed from a continuous sheet metal strip (28) welded onto an external surface (32) of the ground peg (10) by means of a continuous or regularly interrupted fillet weld (34). The external thread (26) has a nearly constant pitch (S) and slope (a) relative to a longitudinal axis (40) of the ground peg (10) along the entire length of the external thread (26). The invention further relates to a method or producing such a ground peg (10). In said method, the external thread (26) is laterally fed to the external surface (32) of the rotating steel tube as an elongate sheet metal strip (28) and is welded onto said external surface (32), the steel tube (11) being moved relative to the feeding point of the sheet metal strip (28) at a regular advance (V) in the longitudinal direction of the steel tube (11). The invention finally relates to a device for producing such a ground peg (10). Said device comprises a mechanism for clamping and rotating the steel tube as well as a mechanism (44) for feeding the sheet metal strip (28) to the external surface (32) of the steel tube (11) such that the sheet metal strip (28) tangentially rests there against.

Owner:KRINNER INNOVATION

Ground peg, and device and method for the production thereof

ActiveUS8367961B2Produced efficiently and inexpensivelyManufactured quickly and inexpensivelySoldering apparatusArc welding apparatusFillet weldMetal strips

The invention relates to a ground peg (10) which is made from a steel tube (11) and comprises an upper cylindrical section (12), a lower section (16) that tapers towards the bottom to form a tip (14), and an external thread (26) that extends along at least part of the lower section (16) and is formed from a continuous sheet metal strip (28) welded onto an external surface (32) of the ground peg (10) by means of a continuous or regularly interrupted fillet weld (34). The external thread (26) has a nearly constant pitch (S) and slope (a) relative to a longitudinal axis (40) of the ground peg (10) along the entire length of the external thread (26). The invention further relates to a method or producing such a ground peg (10). In said method, the external thread (26) is laterally fed to the external surface (32) of the rotating steel tube as an elongate sheet metal strip (28) and is welded onto said external surface (32), the steel tube (11) being moved relative to the feeding point of the sheet metal strip (28) at a regular advance (V) in the longitudinal direction of the steel tube (11). The invention finally relates to a device for producing such a ground peg (10). Said device comprises a mechanism for clamping and rotating the steel tube as well as a mechanism (44) for feeding the sheet metal strip (28) to the external surface (32) of the steel tube (11) such that the sheet metal strip (28) tangentially rests there against.

Owner:KRINNER INNOVATION

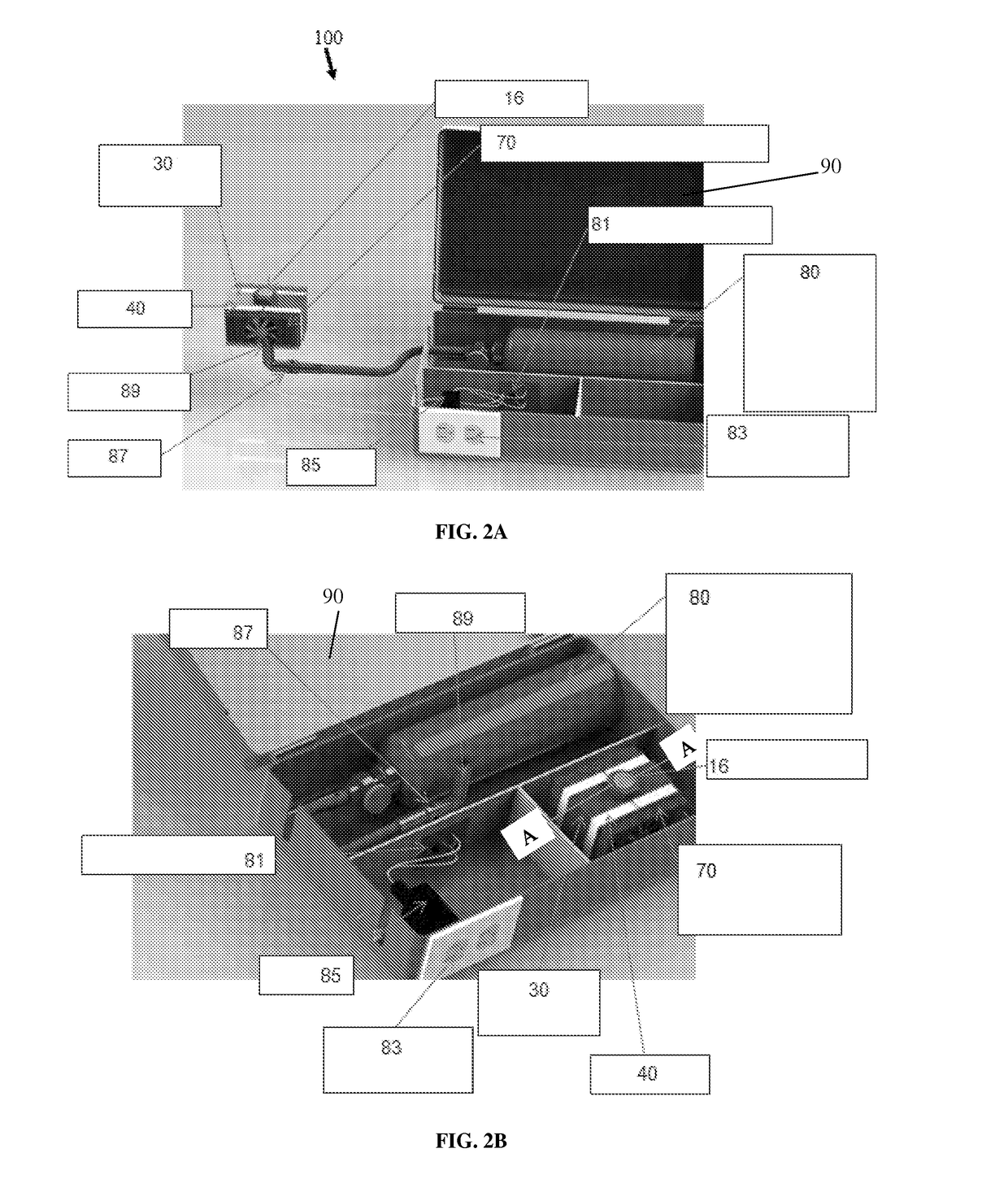

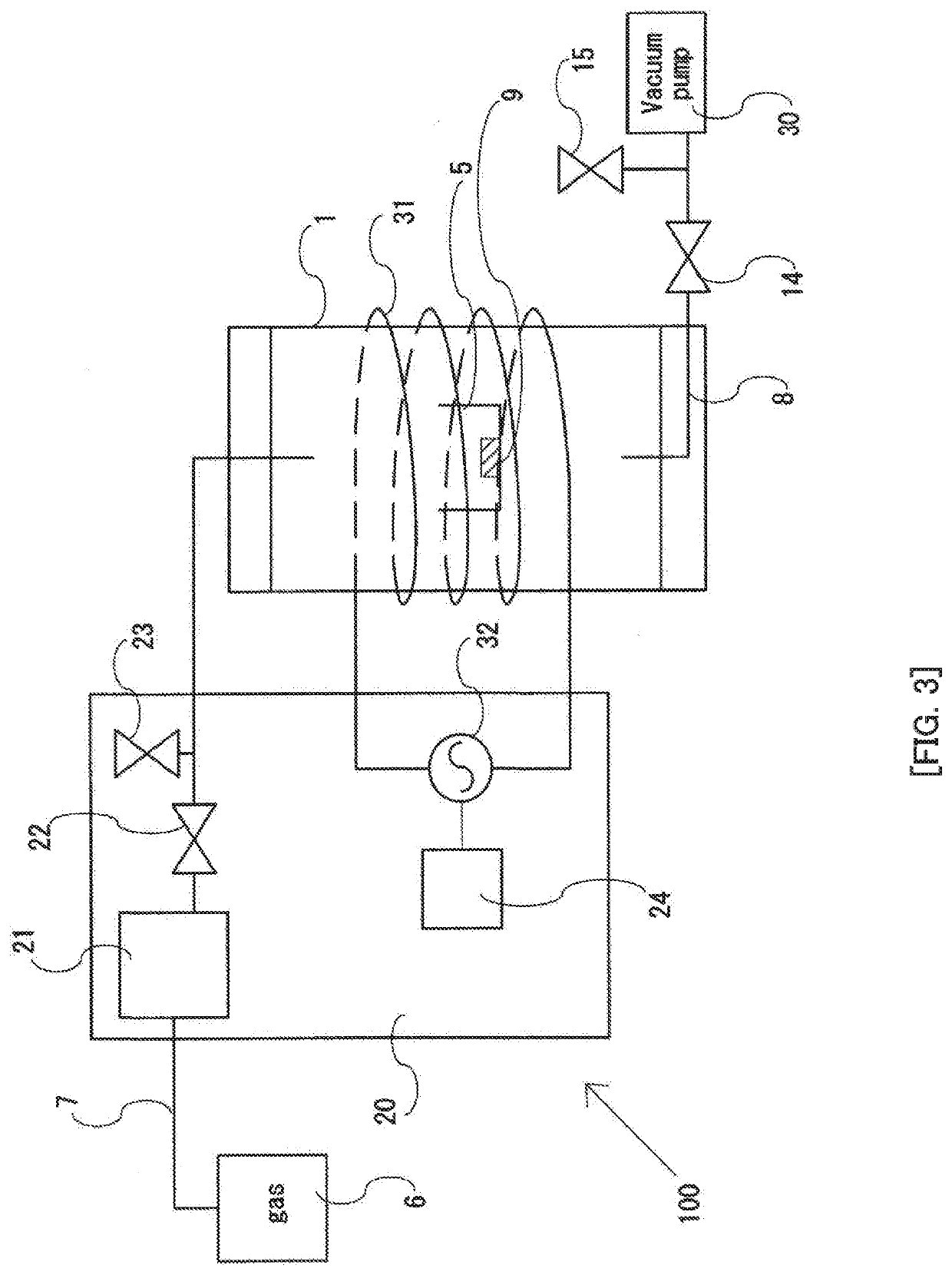

Thermoelectric power generator and combustion apparatus

ActiveUS20170077376A1Effective utilitarian valueReduce long-term operating costsFluid heatersThermoelectric device with peltier/seeback effectCombustion chamberCombustor

A small-scale thermoelectric power generator and combustion apparatus, components thereof, methods for making the same, and applications thereof. The thermoelectric power generator can include a burner including a matrix stabilized combustion chamber comprising a catalytically enhanced, porous flame containment portion. The combustion apparatus can include components connected in a loop configuration including a vaporization chamber; a mixing chamber connected to the vaporization chamber; a combustion chamber connected to the vaporization chamber; and a heat exchanger connected to the combustion chamber. The combustion chamber can include a porous combustion material which can include a unique catalytic material.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Method and a system for producing a semi-conductor module

ActiveUS9165907B2Produced efficiently and inexpensivelyEfficient and inexpensive productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipComputer module

In a method for producing a semi-conductor module (10) comprising at least two semi-conductor chips (12, 14) and an interposer (20) which has electrically conductive structures (28) connecting the semi-conductor chips (12, 14) to one another, the interposer (20) is printed directly onto a first (12) of the semi-conductor chips. When the interposer (20) is printed on, the electrically conductive structures (28) are produced by means of electrically conductive ink (68). The second semi-conductor chip (14) is mounted on the interposer (20) such that the two semi-conductor chips (12, 14) are arranged one above the other and that the interposer (20) forms an intermediate layer between the two semi-conductor chips (12, 14).

Owner:SWISS TECH ENTERPRISE GMBH

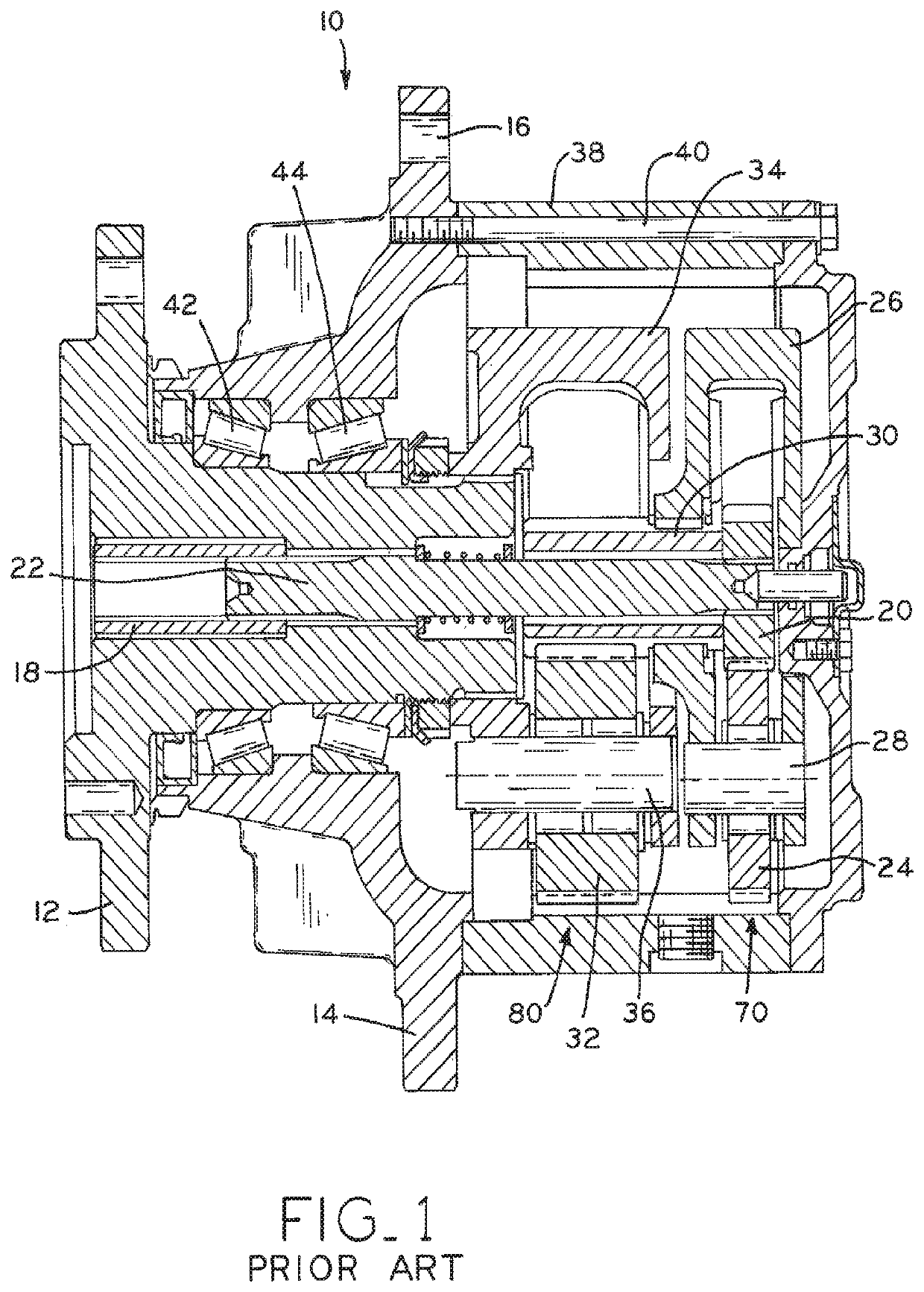

Wheel drive transmission

ActiveUS10766361B2Produced efficiently and inexpensivelyEnsure concentricityToothed gearingsCouplings for rigid shaftsGear wheelEngineering

A multistage wheel drive includes primary and secondary planetary stages, in which the ring gear of the primary (i.e., input-side) planetary stage is formed from a single machined part which also includes the planet gear carrier of the secondary (i.e., output-side) planetary stage. This dual-function “combination” component includes a splined exterior surface which interfaces with a correspondingly splined interior surface on the spindle in order to rotationally fix the combination component to the spindle. This arrangement ensures concentricity between the primary and secondary planetary stages, while allowing a desired amount of radial tolerance between the spindle, the combination component, and the hub of the wheel drive. In addition, the present arrangement can be produced efficiently and inexpensively.

Owner:AUBURN GEAR

Processes for Producing 3-Methyl-2-Butenyl Acetate

InactiveUS20080275268A1Produced inexpensively and efficientlyOrganic compound preparationPreparation by transesterificationAcetic acidAcetic anhydride

The present invention relates to a method for producing 3-methyl-2-butenyl acetate which comprises reacting 3-methyl-2-buten-1-ol with acetic anhydride in the presence of an inorganic base catalyst and a method for producing purified 3-methyl-2-butenyl acetate which comprises subjecting crude 3-methyl-2-butenyl acetate to a step (A) of contacting it with an aqueous solution of an alkali metal hydrogen sulfite, or a step (B) of contacting it with an aqueous solution of a base, or both steps (A) and (B).

Owner:SUMITOMO CHEM CO LTD

Method and a System for Producing a Semi-Conductor Module

ActiveUS20160086904A1Produced efficiently and inexpensivelyEfficient and inexpensive productionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipInterposer

In a method for producing a semi-conductor module (10) comprising at least two semi-conductor chips (12, 14) and an interposer (20) which has electrically conductive structures (28) connecting the semi-conductor chips (12, 14) to one another, the interposer (20) is printed directly onto a first (12) of the semi-conductor chips. When the interposer (20) is printed on, the electrically conductive structures (28) are produced by means of electrically conductive ink (68). The second semi-conductor chip (14) is mounted on the interposer (20) such that the two semi-conductor chips (12, 14) are arranged one above the other and that the interposer (20) forms an intermediate layer between the two semi-conductor chips (12, 14).

Owner:SWISS TECH ENTERPRISE GMBH

Amorphous silica, device for producing amorphous silica, method for producing amorphous silica, silicon produced from amorphous silica, and method for producing silicon

InactiveUS20200095130A1Produced inexpensively and efficientlyShort timeHalogenated silanesPhysical chemistrySilicon oxide

A method for producing amorphous silica includes: a pretreatment process of pulverizing vegetable material to obtain a silica source; a burning process of burning the silica source and extracting silica; and a purification process of removing carbon from burning material obtained in the burning process. The burning process includes a heating process of supplying an inert gas into a chamber and heating the silica source in the chamber in a plasma atmosphere.

Owner:LU NAO CO LTD +3

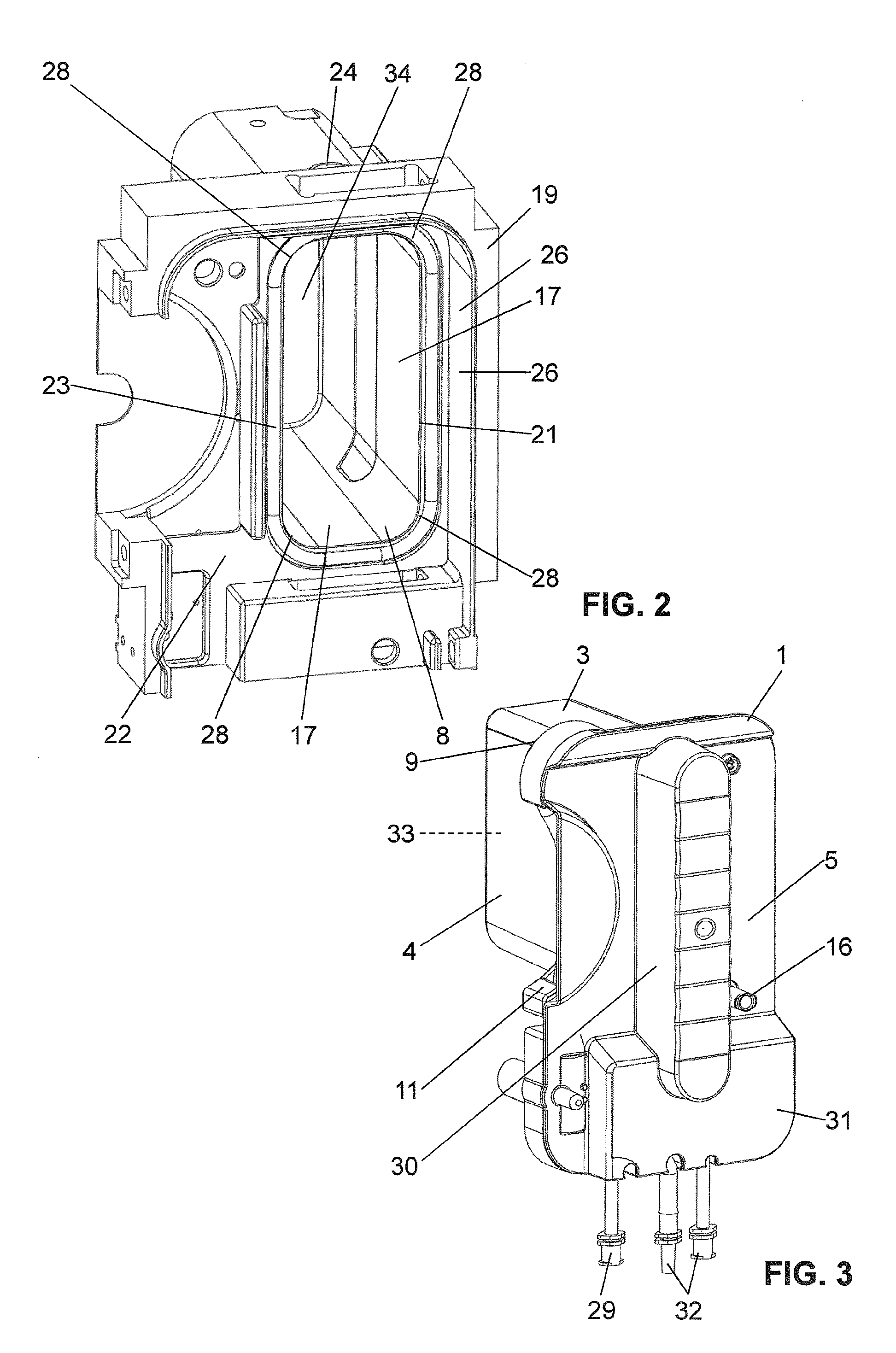

Cassette Module

ActiveUS20150258255A1Reduce weightInherent stabilityEye surgeryMedical devicesEngineeringMechanical engineering

A cassette module (1), in particular an ophthalmological cassette module (1), serves for receiving material and / or liquids aspirated during an operation and for insertion into a container chamber (8) of a suction module (19). The cassette module (1) comprises a container (4) with a container wall (3) that delimits a receiving space (33) for receiving the liquids, wherein the container (4) can be inserted into the container chamber (8), wherein the container (4) has at least one inlet opening (36) extending through the container wall (3), through which inlet opening (36) the material and / or the liquid can be delivered to the receiving space (33) of the container (4), and wherein the container (4) has at least one vacuum opening (25) which extends through the container wall (3) and by way of which the receiving space (33) can be subjected to an underpressure built up in the container chamber (8).

Owner:OERTLI INSTR

Processes for producing 3-methyl-2-butenyl acetate

InactiveUS7612227B2Produced inexpensively and efficientlyOrganic compound preparationPreparation by transesterificationAcetic anhydridePtru catalyst

The present invention relates to a method for producing 3-methyl-2-butenyl acetate which comprises reacting 3-methyl-2-buten-1-ol with acetic anhydride in the presence of an inorganic base catalyst and a method for producing purified 3-methyl-2-butenyl acetate which comprises subjecting crude 3-methyl-2-butenyl acetate to a step (A) of contacting it with an aqueous solution of an alkali metal hydrogen sulfite, or a step (B) of contacting it with an aqueous solution of a base, or both steps (A) and (B).

Owner:SUMITOMO CHEM CO LTD

Solar panel

InactiveUS20100206299A1Produced inexpensively and efficientlyEasy to mass produceSolar heating energySolar heat devicesEngineeringThermal water

A solar panel that utilizes the sun's rays to heat a liquid to be used for providing heat or hot water includes front and rear parallel clear plastic panels. The front panel is intended to face the sun and is substantially transparent so that the sun's rays can pass there through The rear panel has a reflective coating thereon wherein rays from the sun are reflected back toward the space between the panels. Located within the space are a plurality of conduits formed by a plurality of internal walls that extend between the panels and the left and right side edges. Within the conduits is a darkened oily liquid that is heated by the incoming rays of the sun and the rays reflected by the rear panel. In a preferred embodiment, the front and rear panels and the internal walls are extruded as a single unit.

Owner:HELIOS PRODS

Moving fluid energy recovery system

ActiveUS20100133845A1Easily and efficiently manufactured and marketedLow priceWind motor controlWind motor supports/mountsElectricityMobile vehicle

A moving fluid energy recovery system for generating electricity through rotational motion produced by positioning the present invention in a fluid flow produced by nature or a moving vehicle. The moving fluid energy recovery system has first and second end plates, a plurality of elongated inner vanes, a plurality of elongated outer vanes, and shaft to drive an electricity generating device. The inner and outer vanes each have a substantially curved profile featuring a curve side and an open side. The first and second end plates each has a central bore defined therethrough, a plurality of inner vane slots each shaped to receive a corresponding inner vane, and a plurality of outer vane slots each shaped to receive a corresponding outer vane. The inner vane slots are orientated with the curve side toward the central bore, and the outer vane slots are orientated with the open side toward the central bore with the free ends of adjacent inner vanes positioned in the open side of the outer vane slots.

Owner:PENTA POWER TURBINES INC

Method of producing optically active N-(halopropyl) amino acid derivative

ActiveUS8242303B2Efficient productionProduced inexpensively and efficientlyCarbamic acid derivatives preparationOrganic compound preparationProtecting groupMedicinal chemistry

The present invention provides a method for producing an optically active N-(halopropyl)amino acid derivative, wherein the method comprises the steps of obtaining a compound represented by formula (III) by reacting an optically active alanine ester represented by formula (I) or a salt thereof (hereinafter sometimes simply referred to as an “alanine ester”) with a halogenated propane represented by formula (II); and obtaining an optically active N-(halopropyl)amino acid derivative represented by formula (IV) by introducing a protecting group onto the nitrogen atom of the compound represented by formula (III). The present invention provides a method for efficiently producing an optically active N-(halopropyl)amino acid derivative.

Owner:KISHIDA CHEM

Configurable linear light assembly and associated methods

ActiveUS20140328055A1Less complex in designLess-expensive to manufactureLight source combinationsLighting support devicesEngineeringHeat generation

A linear light assembly having an elongate tray and a plurality of moveable lighting packages. The elongate tray may provide both mechanical support and thermal management for the plurality of moveable lighting packages. The elongate tray may comprise a medial channel portion with a planar track member and two opposing rim members projecting perpendicularly outward therefrom. Each flange portion may have a U-shaped cross-section. Each moveable package may comprise an assembly tray and an optical assembly having at least one light-emitting device (LED). Each moveable lighting package may be adjustably positioned along and independently removed from the front side of the track member of the elongate tray. Any segmentation of the elongate tray may be characterized by a heat dissipation rate not less than a combined heat generation rate of all moveable lighting packages carried by the segment. A method aspect includes installation of the linear light assembly.

Owner:LIGHTING SCI GROUP

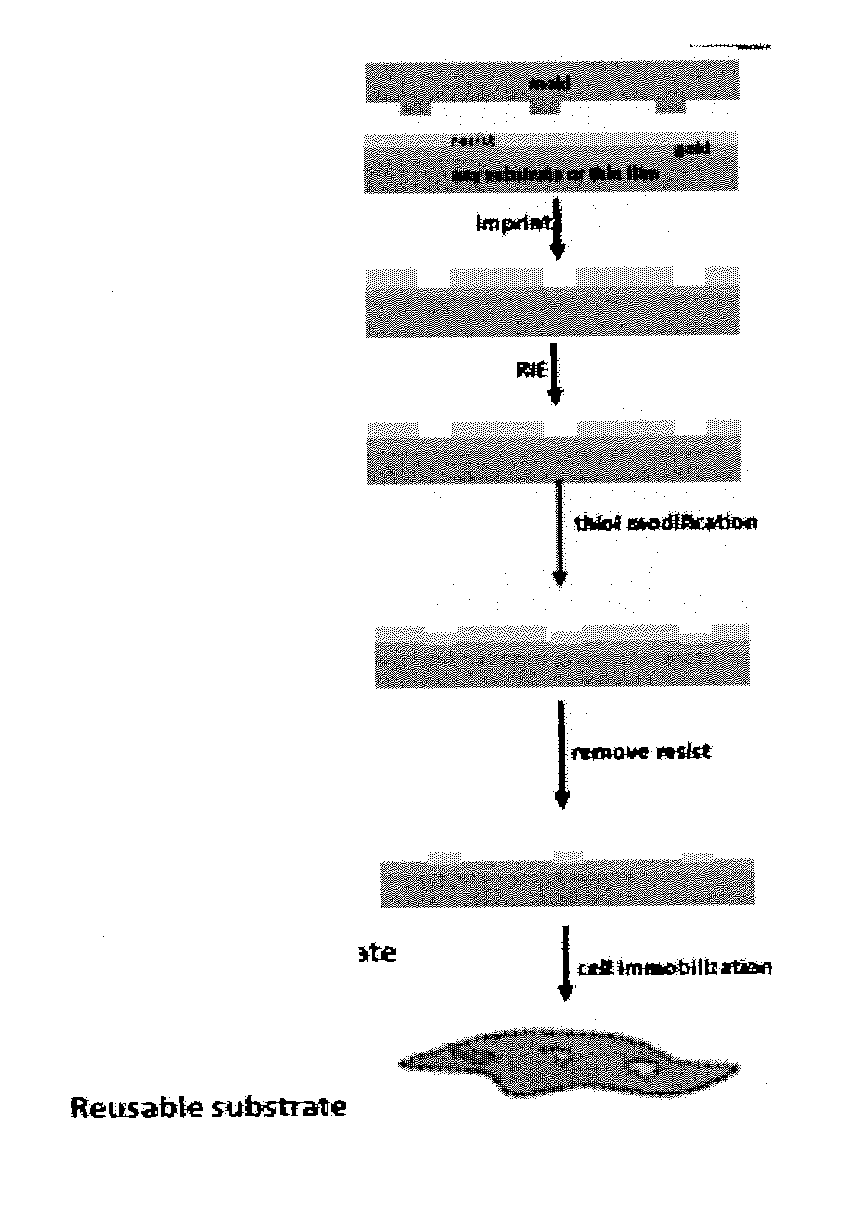

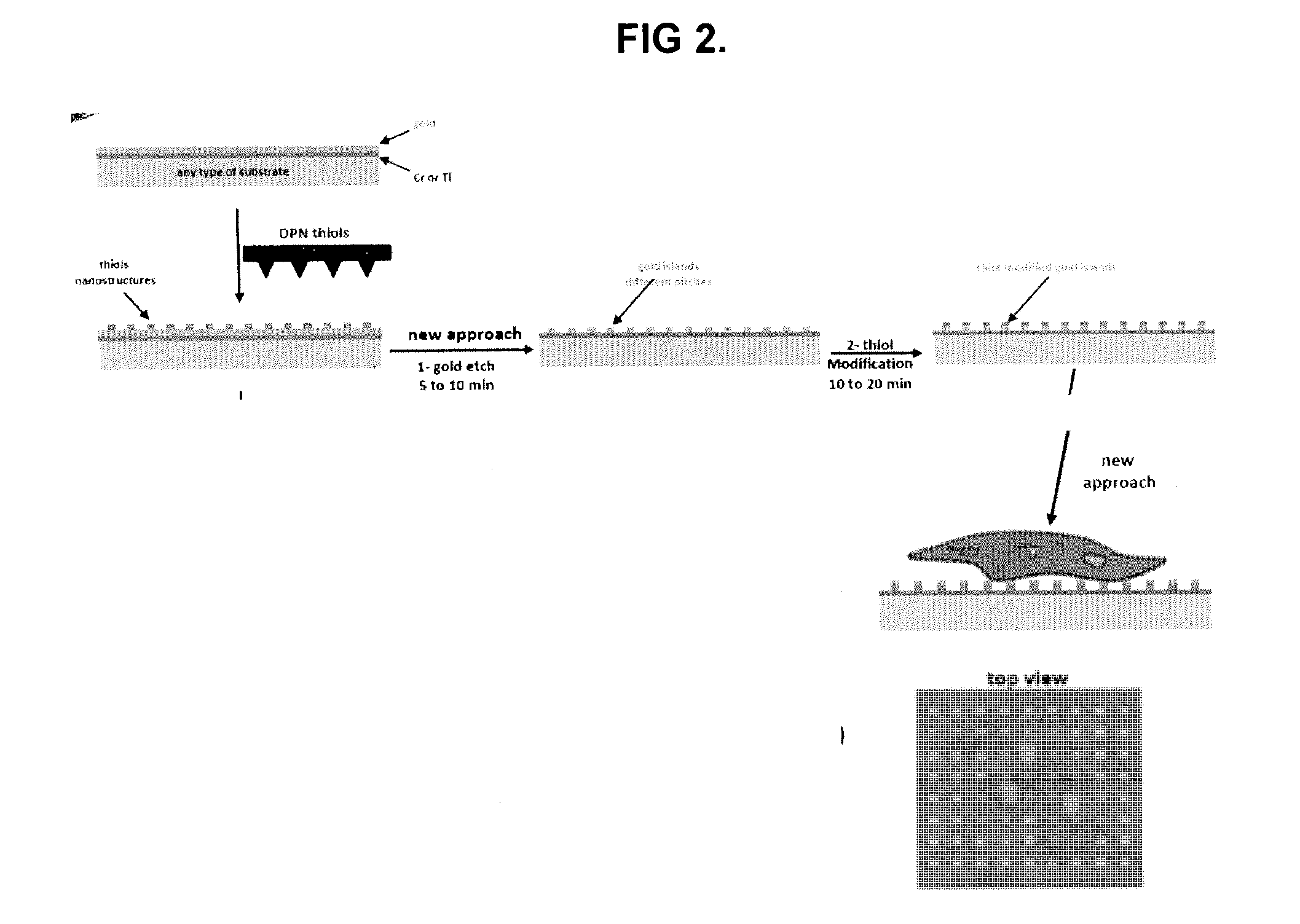

Cell growth

InactiveUS20110244571A1Improve versatilitySimple methodNanomedicineNervous system cellsNanolithographyCell growth

Methods of preparing pre-engineered surfaces using various nanolithography techniques to generate, isolate, and multiply homogeneous cell populations. Surfaces can be treated by etching before exposure to biological systems like cells. Stem cell applications are described.

Owner:NANOINK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com