Polyether-ether-ketone modified polytetrafluoroethylene composite material, bearing retainer and making method of bearing retainer

A technology of bearing cage and polytetrafluoroethylene, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of not meeting the requirements of long service life cage materials, low mechanical strength, wear resistance and poor bearing capacity, etc. problems, to achieve low friction coefficient, long service life and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

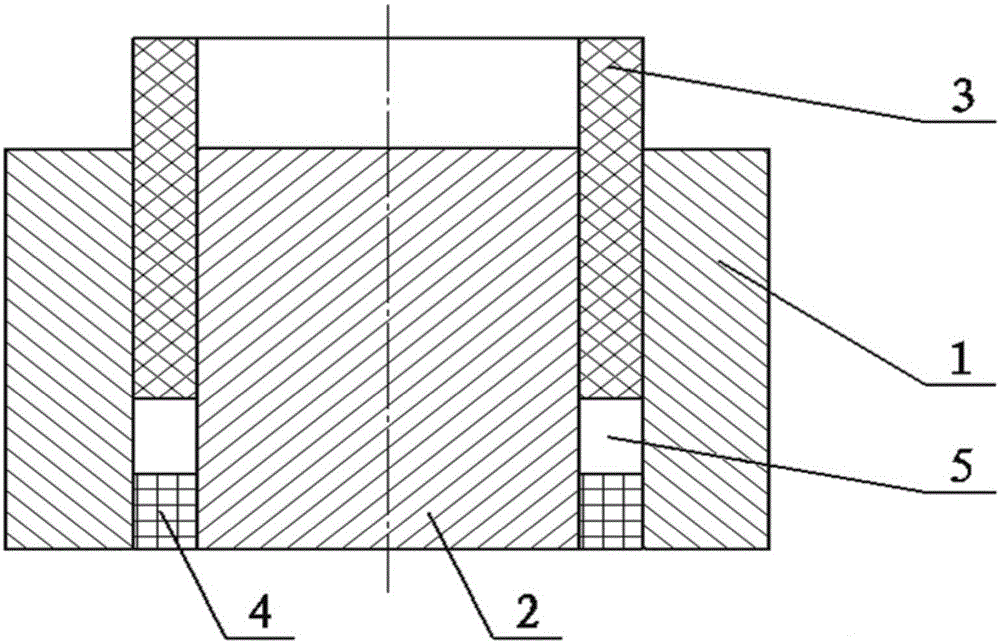

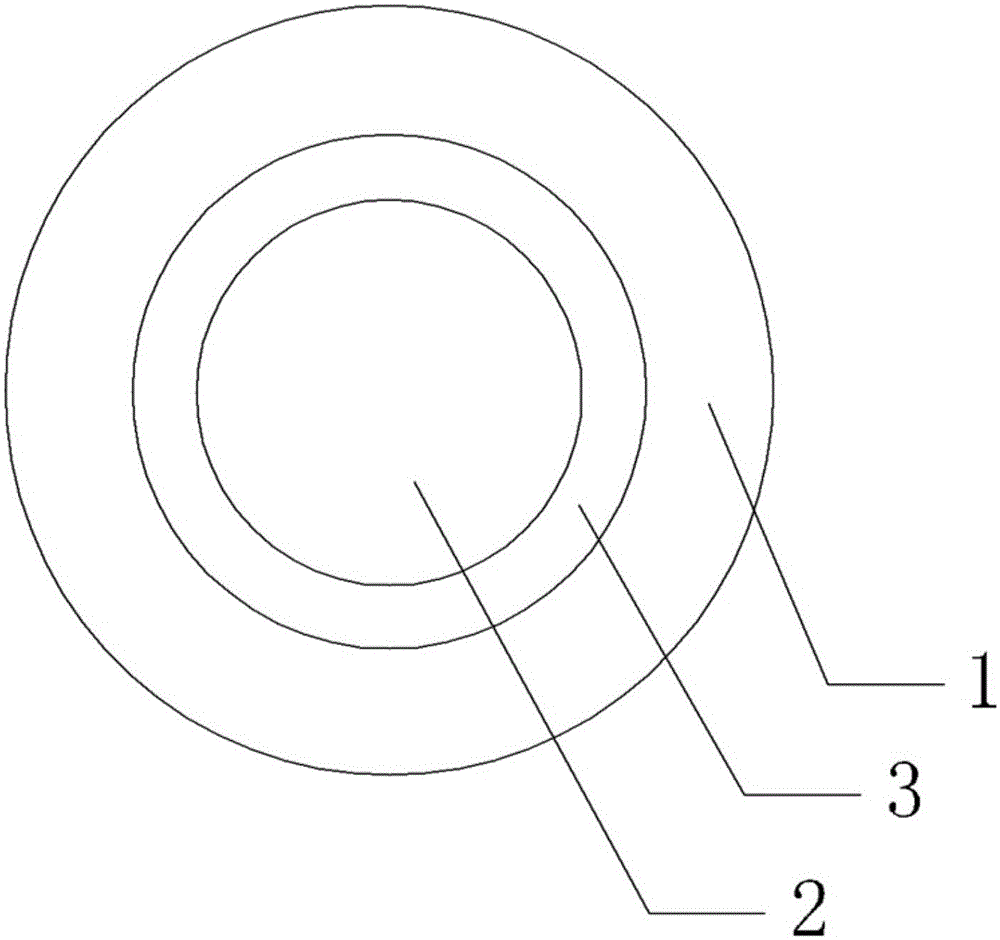

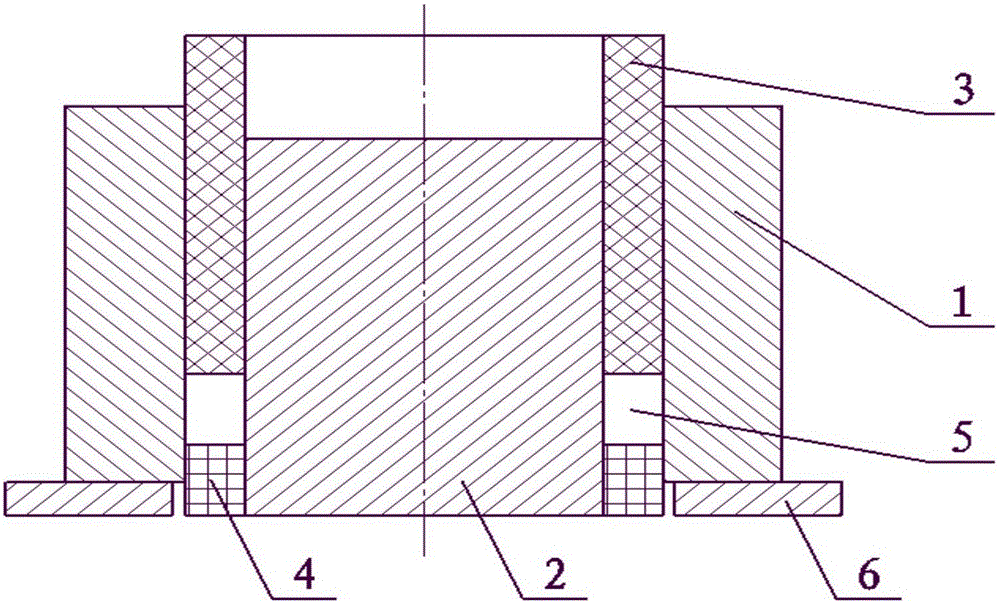

Image

Examples

Embodiment 1

[0043] The polyether ether ketone modified polytetrafluoroethylene composite material in this embodiment is composed of the following components in mass percentage: 20% polyetheretherketone, 8% tungsten disulfide, and the rest is polytetrafluoroethylene.

[0044] The bearing cage of this embodiment is composed of the following components in mass percentage: 20% of polyether ether ketone, 8% of tungsten disulfide, and the rest is polytetrafluoroethylene. That is, the bearing cage of this embodiment adopts the above-mentioned polyether ether ketone modified polytetrafluoroethylene composite material.

[0045] The preparation method of the bearing cage of the present embodiment comprises the following steps:

[0046] 1) Put the polyether ether ketone powder and tungsten disulfide powder in a vacuum drying oven for vacuum drying. During the drying process, the raw materials are spread in the vacuum drying oven, and the thickness of the laying does not exceed 25mm; the vacuum degre...

Embodiment 2

[0055] The polyether ether ketone modified polytetrafluoroethylene composite material in this embodiment is composed of the following components in mass percentage: polyetheretherketone 18%, tungsten disulfide 5%, and the rest is polytetrafluoroethylene.

[0056] The bearing cage of this embodiment is composed of the following components in mass percentage: 18% of polyether ether ketone, 5% of tungsten disulfide, and the rest is polytetrafluoroethylene. That is, the bearing cage of this embodiment adopts the above-mentioned polyether ether ketone modified polytetrafluoroethylene composite material.

[0057] The preparation method of the bearing cage of the present embodiment comprises the following steps:

[0058] 1) Put polyether ether ketone powder and tungsten disulfide powder in a vacuum drying oven for vacuum drying. During the drying process, the raw materials are tiled in the vacuum drying oven, and the tile thickness does not exceed 25mm; the vacuum degree of vacuum dr...

Embodiment 3

[0066] The polyether ether ketone modified polytetrafluoroethylene composite material in this embodiment is composed of the following components in mass percentage: 20% polyetheretherketone, 5% tungsten disulfide, and the rest is polytetrafluoroethylene.

[0067] The bearing cage of this embodiment is composed of the following components in mass percentage: 20% of polyether ether ketone, 5% of tungsten disulfide, and the rest is polytetrafluoroethylene. That is, the bearing cage of this embodiment adopts the above-mentioned polyether ether ketone modified polytetrafluoroethylene composite material.

[0068] The preparation method of the bearing cage of the present embodiment comprises the following steps:

[0069] 1) Put the polyether ether ketone powder and tungsten disulfide powder in a vacuum drying oven for vacuum drying. During the drying process, the raw materials are spread in the vacuum drying oven, and the thickness of the laying does not exceed 25mm; the vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com