A kind of environment-friendly modified polyphenylene ether material for automotive interior parts

A technology of automotive interior parts and polyphenylene ether, applied in the field of plastic materials, can solve the problems of difficult processing and molding, poor impact resistance, poor melt fluidity, etc., and achieve excellent antistatic, excellent scratch resistance, and not easy to fade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

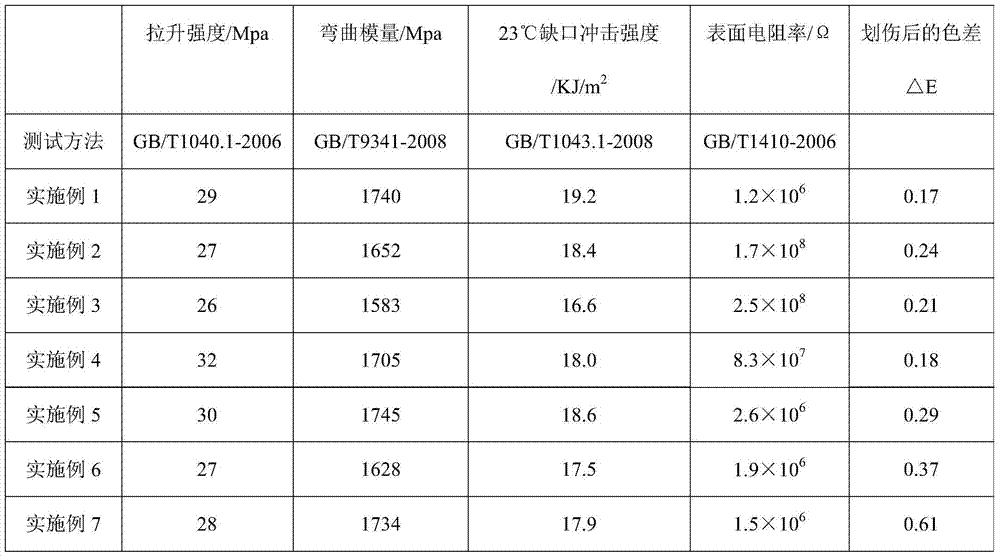

Examples

Embodiment 1

[0042] After weighing each raw material according to the data corresponding to Example 1 in Table 1, add it to a high-speed mixer for stirring, control the rotating speed at 600r / min, stir at a temperature of 90°C, and stir for 10 minutes, and then extrude and granulate through a screw extruder. Extrude at a temperature of 220° C., cool to obtain plastic granules; put the above plastic granules into an injection molding machine for injection molding to obtain the environmentally-friendly modified polyphenylene ether material for automotive interior parts.

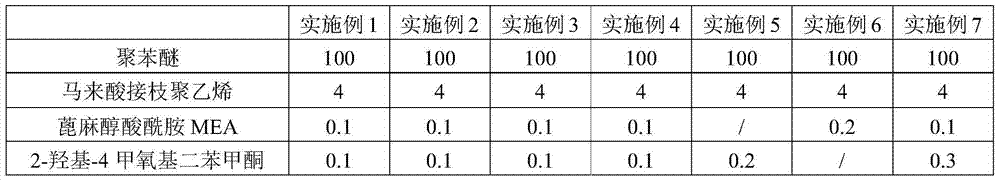

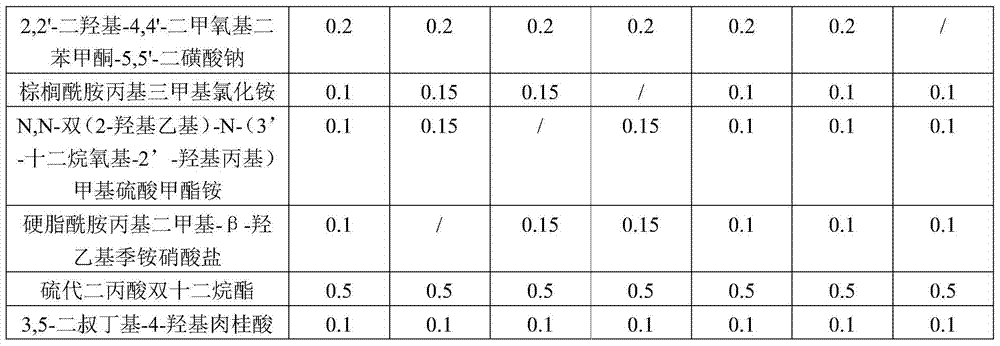

[0043] Table 1: Formulation of environmentally friendly modified polyphenylene ether materials for automotive interior parts Unit: kg

[0044]

[0045]

Embodiment 2

[0047] Each raw material was weighed according to the data corresponding to Example 2 in Table 1. The method described in Example 1 was used to prepare the environmentally friendly modified polyphenylene ether material for automotive interior parts.

Embodiment 3

[0049] Each raw material was weighed according to the data corresponding to Example 3 in Table 1. The method described in Example 1 was used to prepare the environmentally friendly modified polyphenylene ether material for automotive interior parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com