Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Reduce VOC value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

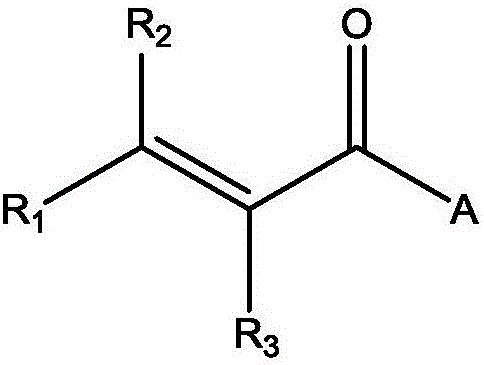

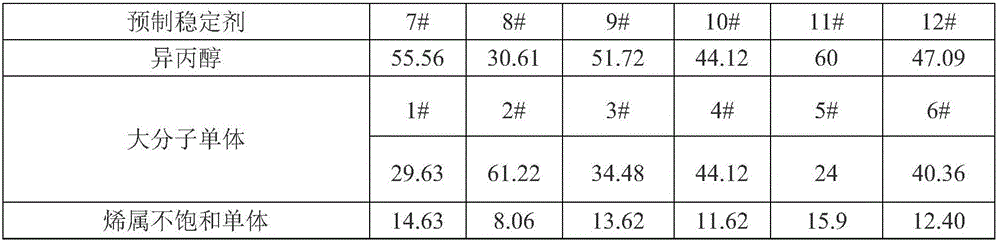

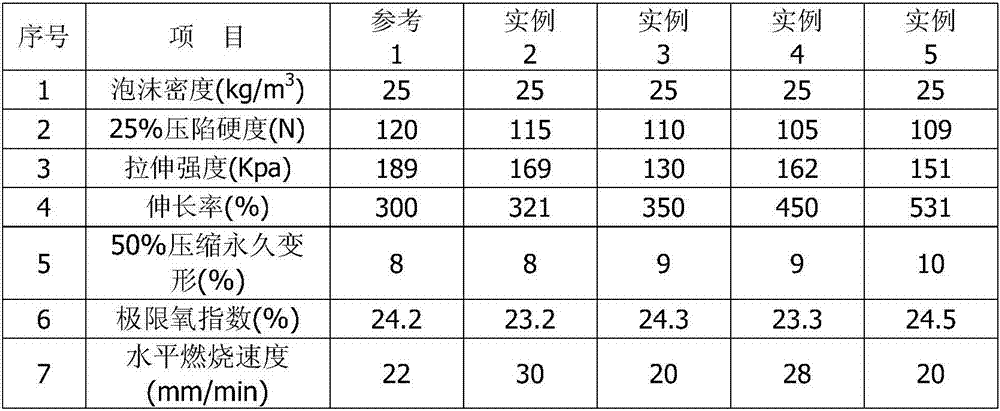

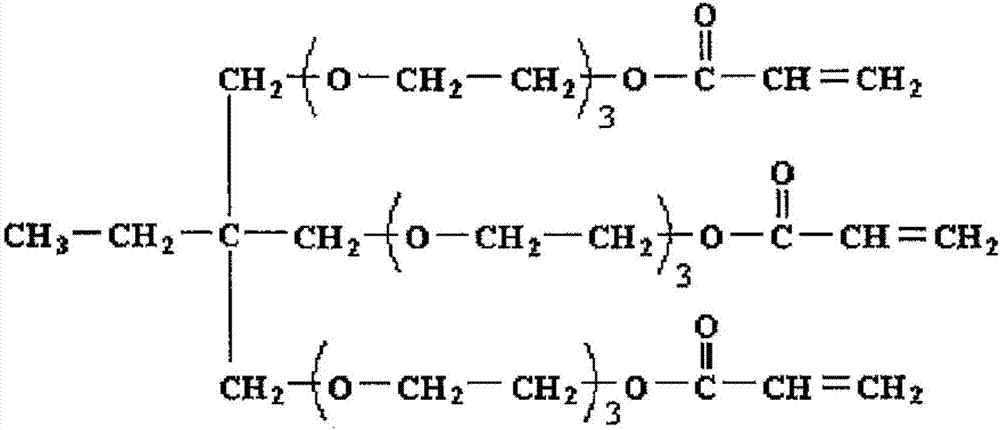

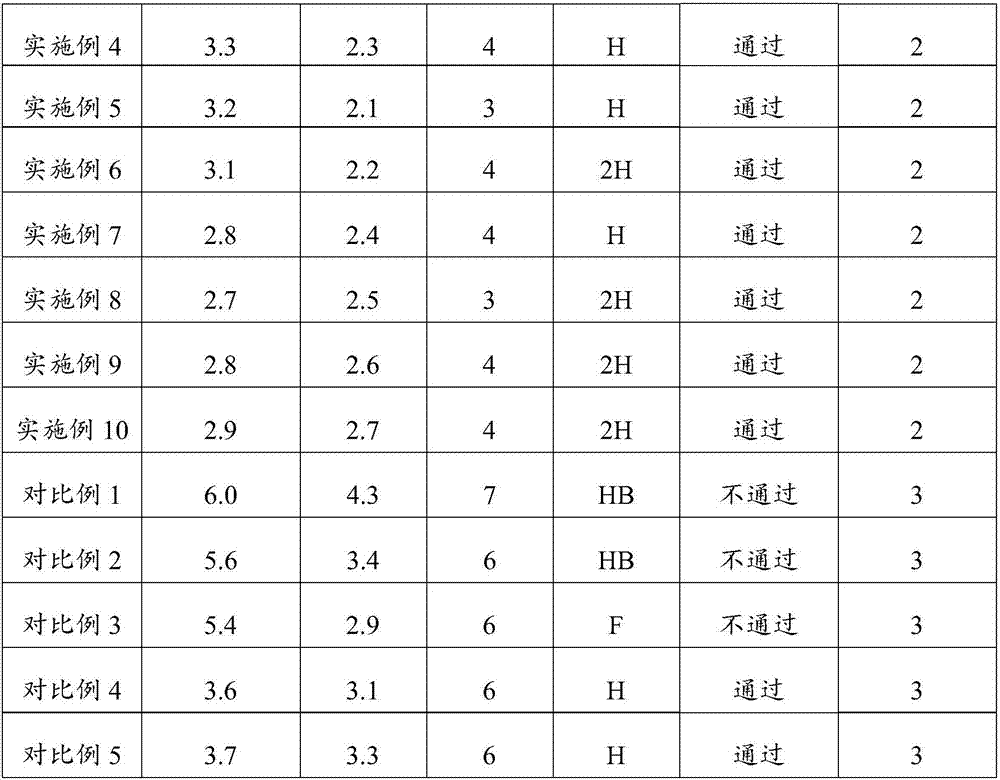

Combtype macro monomer and preparation method thereof, polymer polyol and polyurethane foam

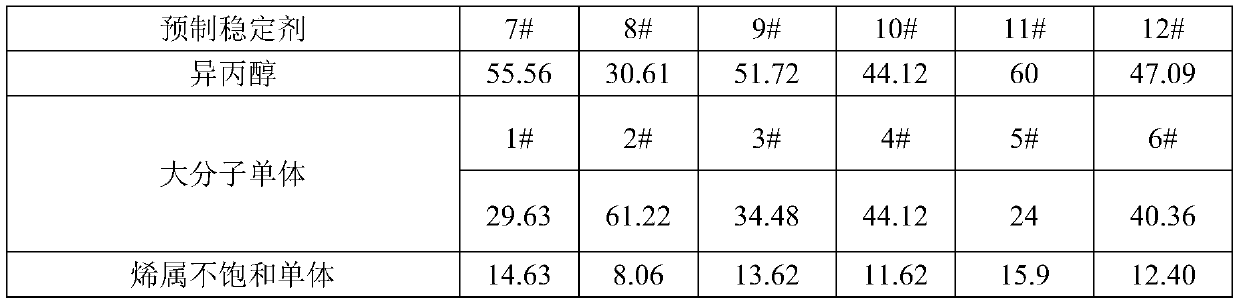

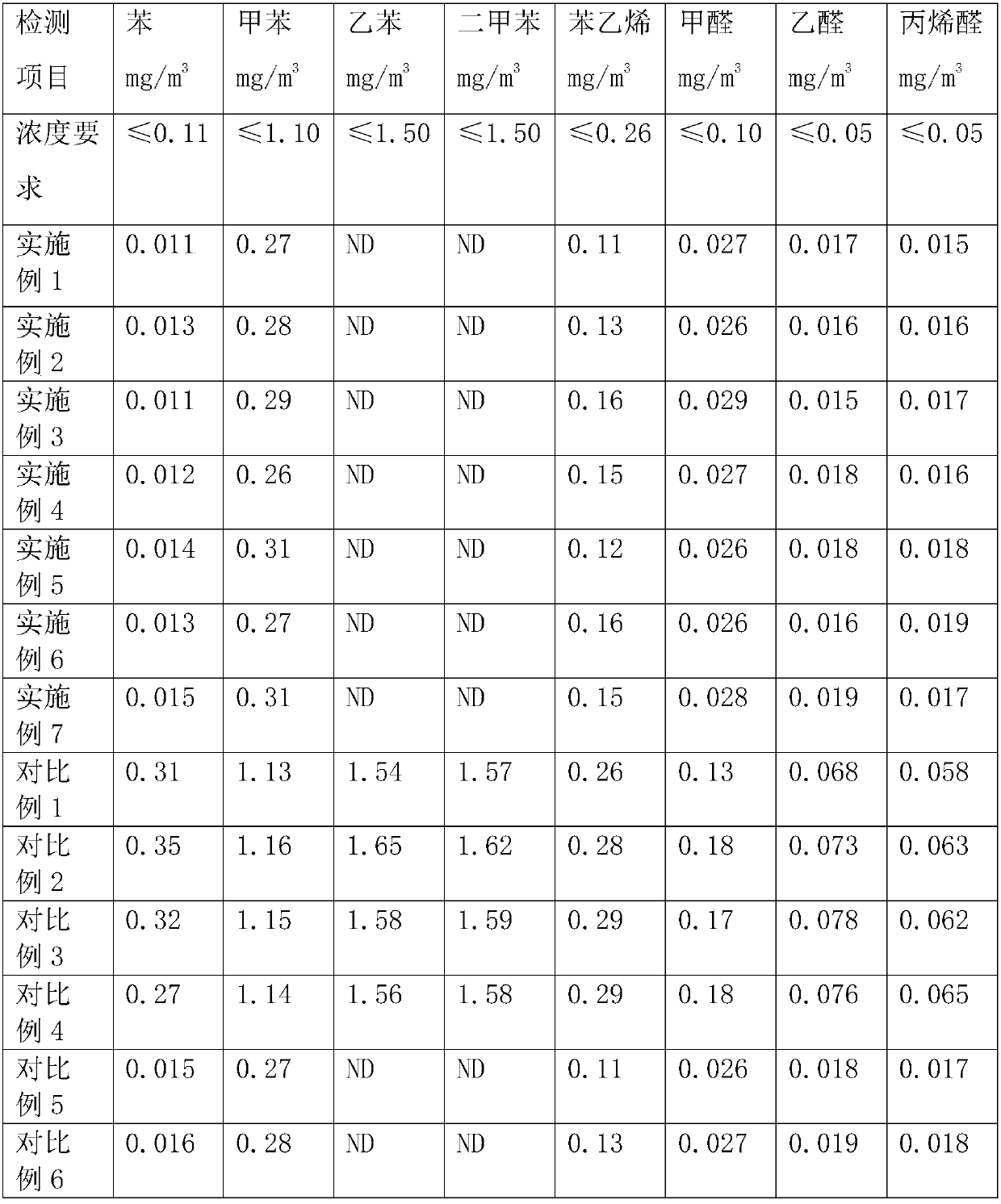

The invention discloses a combtype macro monomer and a preparation method thereof, and polymer polyol prepared according to the combtype macro monomer. The preparation method includes the steps that a compound containing double bonds is reacted with dihydric alcohol at first; and then in the existence of an optional initiator, the monomer containing conjugated double bonds is added for carrying out a polymerization reaction, and accordingly the combtype macro monomer can be obtained. The combtype macro monomer is suitable for being used as a dispersion stabilizer of the polymer polyol, the viscosity is lowered, and the stability performance is excellent. Soft polyurethane foam prepared through the polymer polyol is high in performance, the VOC and odors are low, and the elongation at break and tensile strength are excellent.

Owner:WANHUA CHEM GRP CO LTD

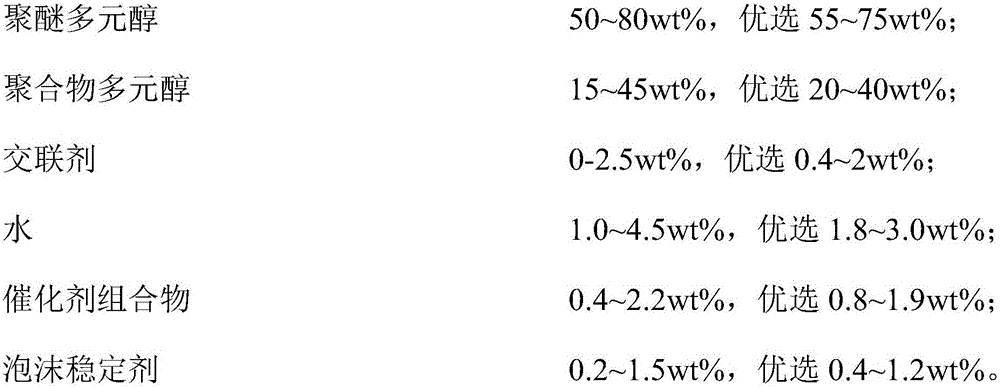

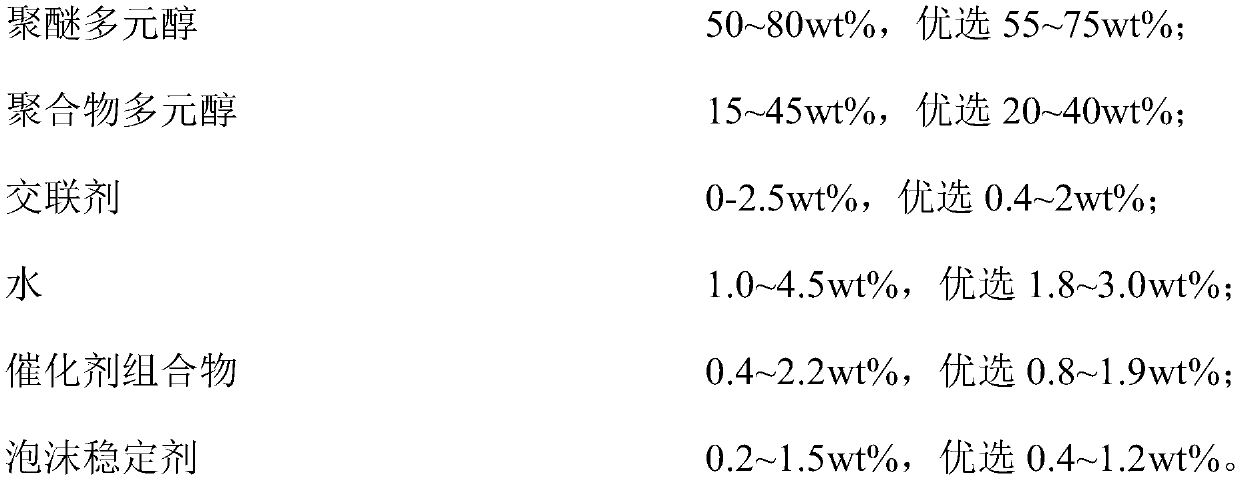

Low-fogging polyurethane composition and preparation method thereof

The invention discloses a low-fogging polyurethane composition, which consists of a component A and a component B, wherein the component A consists of polyether polyol, polymer polyol, a cross-linking agent, a foaming agent, a foam stabilizer and a catalyst; and the component B consists of polyether polyol, isocyanate and a prepolymer made from a storage stabilizer. When the low-fogging polyurethane composition is used, the component A and the component B are mixed according to the isocyanate index of 1.05 for injection molding, and mold opening is performed within 4-6 minutes. A product produced from the polyurethane composition is widely applied to the industries of automobiles, furniture, toys and the like by virtue of the advantages of high environmental friendliness, low VOC (Volatile Organic Compound) value and comfortableness.

Owner:SHANDONG INOV POLYURETHANE

Preparation of aqueous epoxy resin

The invention provides a preparation method of water-dilutable epoxide resin, comprising two steps as follows: epoxide resin and polyether dihydric alcohol react under the action of Lewis acid catalyst to prepare a reactivity emulsifier which is a polymerized substance with terminal groups of an epoxy group and a hydroxyl group; and then different epoxide resins react with the reactivity emulsifier prepared in the first step to obtain the water-dilutable epoxide resin. The water-dilutable epoxide resin can be applied to the fields of dope, cement enhancement, terrace, and the like through mixing with matched a firming agent and taking water as a diluting agent.

Owner:CHINA PETROCHEMICAL CORP

High-solid-content high-temperature-resistant organic-silicone pressure-sensitive adhesive and preparation method thereof

The invention discloses a high-solid-content high-temperature-resistant organic-silicone pressure-sensitive adhesive which is prepared by reacting the following components in percentage by weight: 25.0-40.0% of organic silicone rubber, 25.0-40.0% of MQ organic silicone resin, 0.05-5.00% of catalyst and 30.0-40.0% of solvent. The organic-silicone pressure-sensitive adhesive disclosed by the invention can resist high temperature (250-280 DEG C), and the solid content of the organic-silicone pressure-sensitive adhesive is up to 65-70%; and compared with the silanol condensed type high-temperature-resistant organic-silicone pressure-sensitive adhesive system in the existing market, the VOC (volatile organic compound) content of the organic-silicone pressure-sensitive adhesive disclosed by the invention is obviously lowered, and the organic-silicone pressure-sensitive adhesive disclosed by the invention has better environmental protection performance.

Owner:无锡达美新材料有限公司

Terrace water borne coating

InactiveCN101186776AGood osmotic wettabilitySealing and strong adhesionEmulsion paintsWater basedTitanium

The invention relates to a water-based paint for terrace. The ingredient and the weight percentage of the materials formula of the paint are as follows, 34-46% organosiloxane-acrylate core-shell polymer emulsion, 1.0-2.5% dispersant, 3-8% for titanium pigment, 36-48% stuffing material, 2-5% pigment or color paste, 2-5% film forming addition agent, 0.3-0.6% defoamer proportion, 0.2-15 pH modifying agent, and the rest is water. Compared with the existing technique, the paint of the invention has the advantages that the invention is environment-friendly, energy-saving, safe and reliable, and fast-dried, maintenance time of the invention is short, the repainting work is easy, and the like.

Owner:上海德锐环保材料科技有限公司

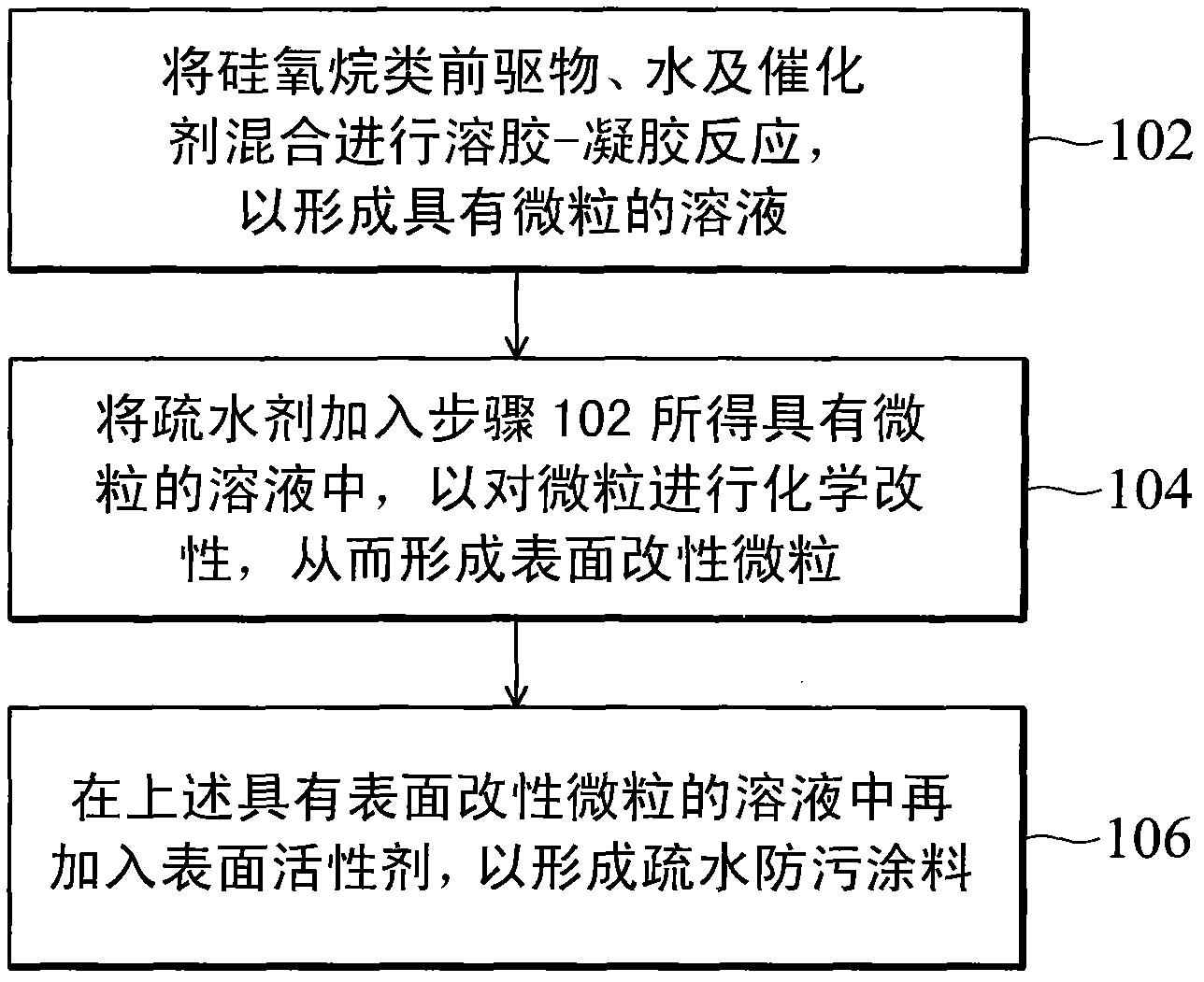

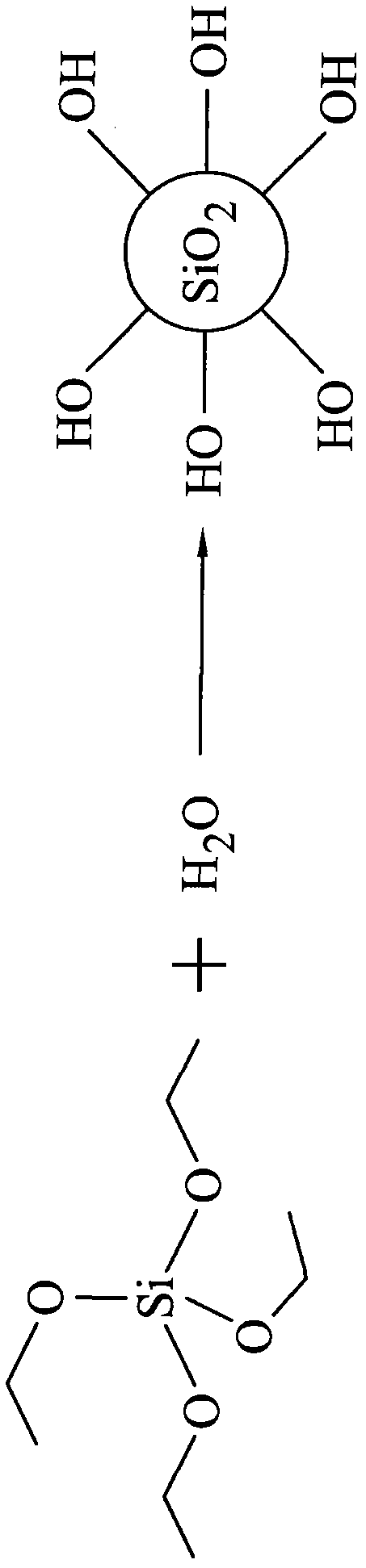

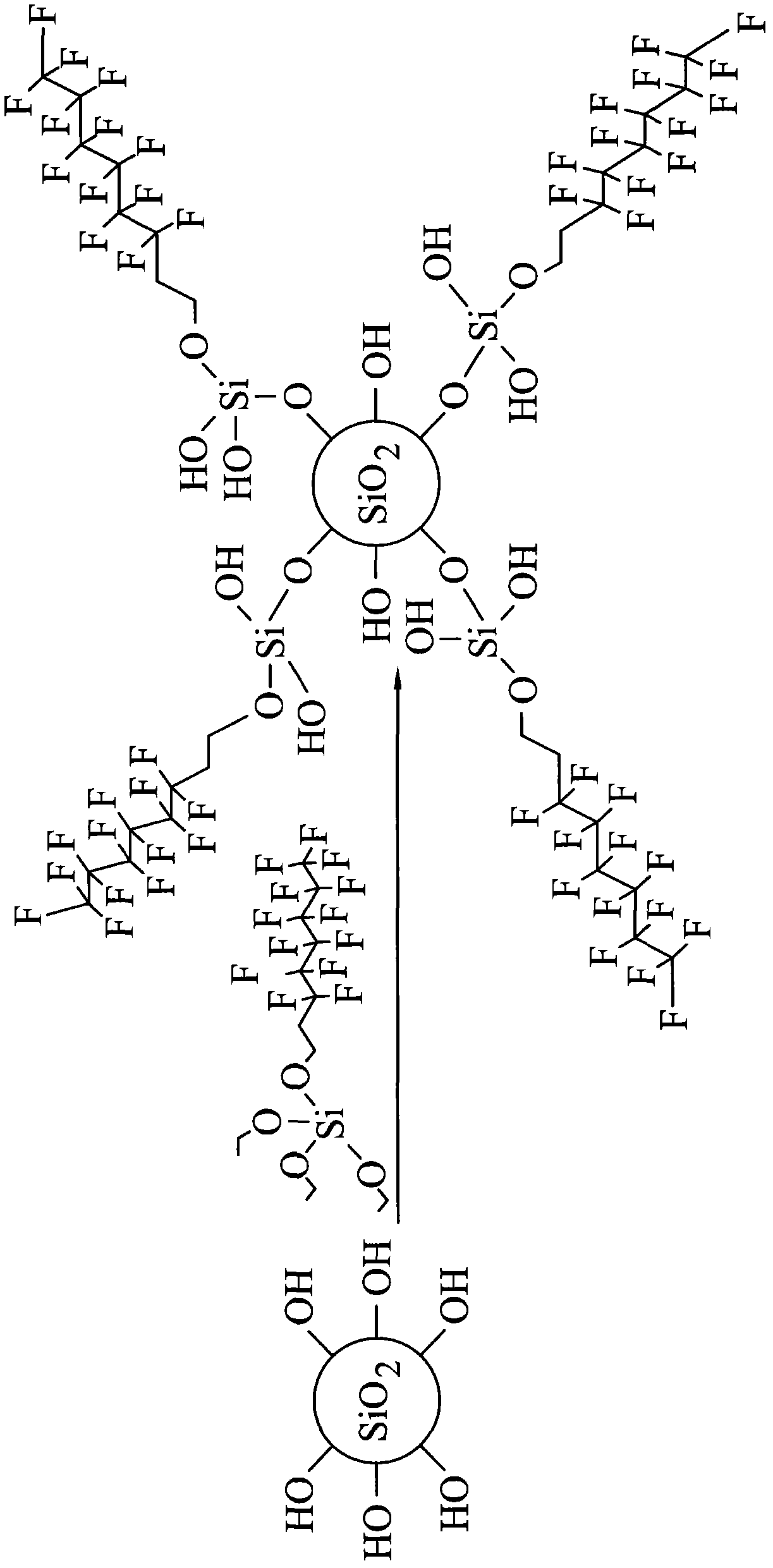

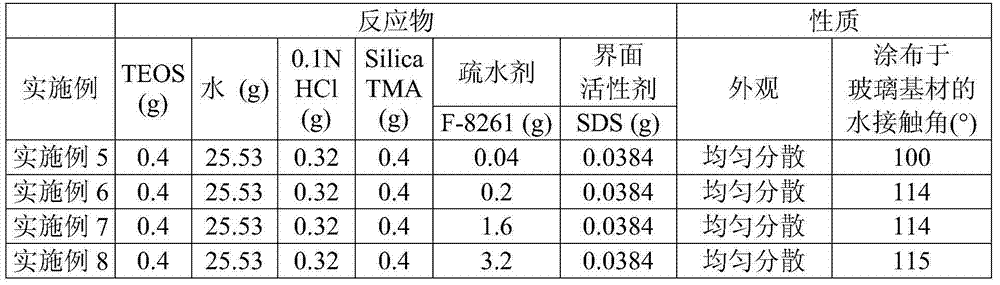

Hydrophobic coating material and method for manufacturing the same

ActiveCN103044973AGood spreadabilityGood adhesionAntifouling/underwater paintsPaints with biocidesOrganic solventActive agent

A method of manufacturing a hydrophobic coating material, including: (a) mixing a siloxane precursor, water, and a catalyst to proceed with a sol-gel reaction to form a solution having particles therein, wherein the sol-gel reaction is performed without using any organic solvent; (b) chemically modifying the particles with a hydrophobic agent to form surface-modified particles; and (c) adding a surfactant to the solution containing the surface-modified particles to form a hydrophobic coating material. A hydrophobic coating material and a hydrophobic coating formed by the hydrophobic coating material are also provided. The hydrophobic coating material may preferably have a low VOC (Volatile organic compound) value, and may disperse in a water phase solution.

Owner:IND TECH RES INST

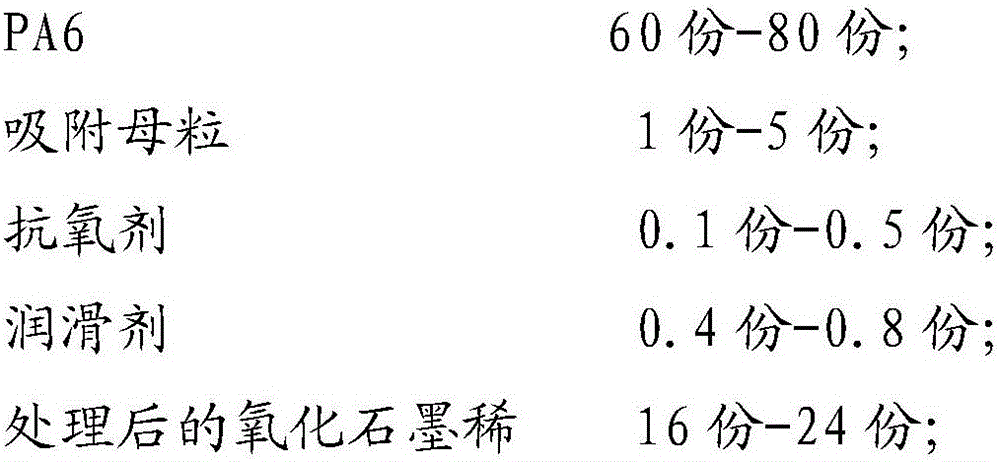

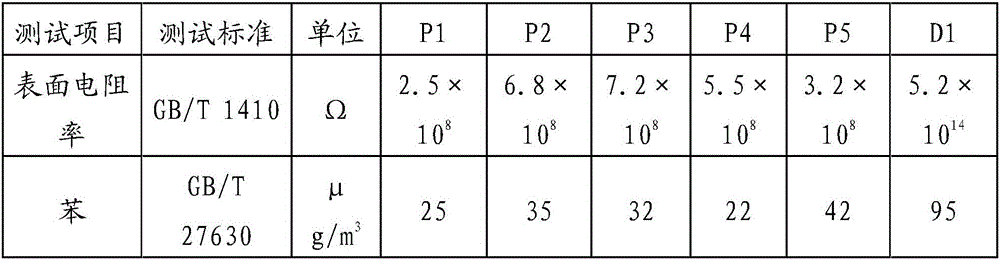

Antistatic low-VOC (volatile organic compound) polyamide 6 composite material and method for preparing same

The invention relates to an antistatic low-VOC (volatile organic compound) polyamide 6 composite material. The antistatic low-VOC polyamide 6 composite material comprises, by weight, 60-80 parts of PA6, 1-5 parts of adsorption master batch, 0.1-0.5 part of antioxidants, 0.4-0.8 part of lubricants and 16-24 parts of treated graphene oxide. The adsorption master batch comprises polypropylene and mica. According to the technical scheme, the antistatic low-VOC polyamide 6 composite material has the advantages that appropriate long-chain alkane is grafted on the surfaces of the antistatic low-VOC polyamide 6 composite material in chemical bonding modes by the aid of oxygen-containing functional groups on the surfaces of the graphene oxide, agglomeration of graphene can be effectively prevented by the long-chain alkane, and accordingly the graphene can be effectively dispersed in the antistatic low-VOC PA 6 composite material; diversified volatile small-molecular and organic compounds generated in processing procedures can be effectively removed by the added adsorption master batch, and accordingly VOC numerical values can be lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

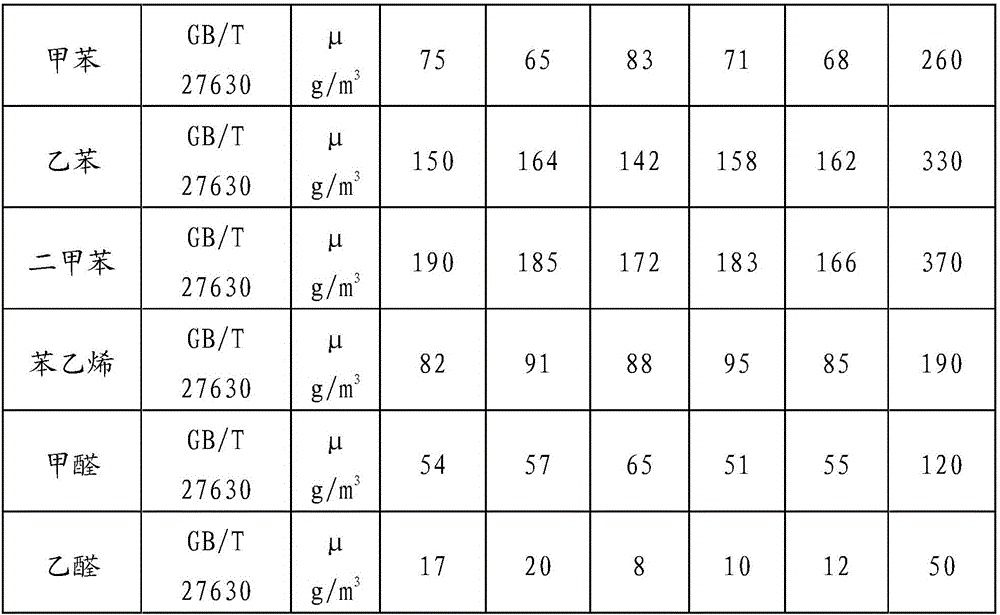

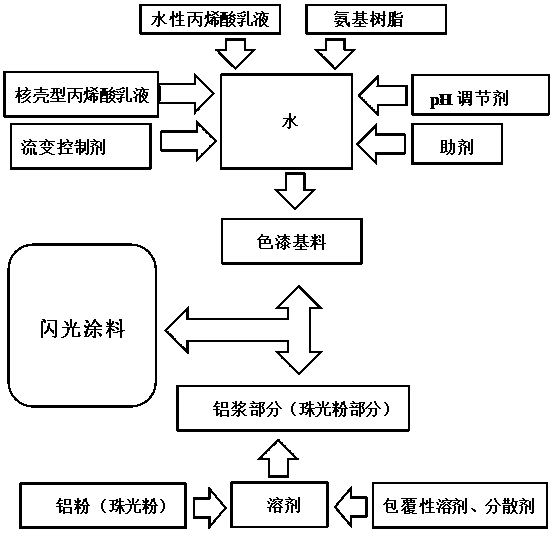

Water-based flash colored paint and preparation method thereof

InactiveCN110229574AGood storage stabilityReduce VOC valueAnti-corrosive paintsPaints with free metalsWater basedEmulsion

The invention belongs to the technical field of chemical materials, and particularly relates to water-based flashing colored paint and a preparation method thereof. According to the invention, directionally arranged aluminum powder or pearl powder provides a flashing effect, an acrylic emulsion is a main film-forming substance, and an appropriate amount of a rheological control agent, a wetting leveling auxiliary agent, a defoaming agent, an aluminum powder wrapping agent, a dispersing agent and the like are added. The invention solves the problem that construction difficulty is large and reworking easily occurs in an existing water emulsion system due to the fact that the directional arrangement method of aluminum powder (pearl powder) is single and difficult and has a poor effect. A coating film of the coating has good flashing and optically variable decorative effect, storage stability of the paint is prolonged, no sediment, layering or floating phenomenon occurs after long-time placement, and the paint has the advantages of low volatile organic compound (VOC) value, safety and environmental protection. Meanwhile, mechanical performance and chemical resistance of the paint filmare superior to mechanical performance and chemical resistance of oily products of the same type.

Owner:FUDAN UNIV

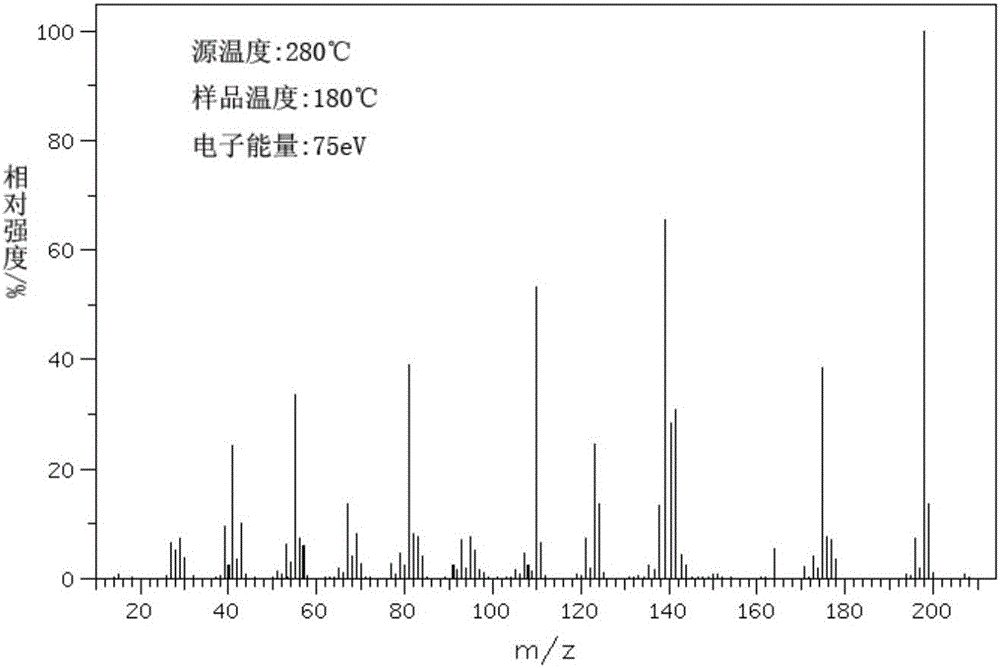

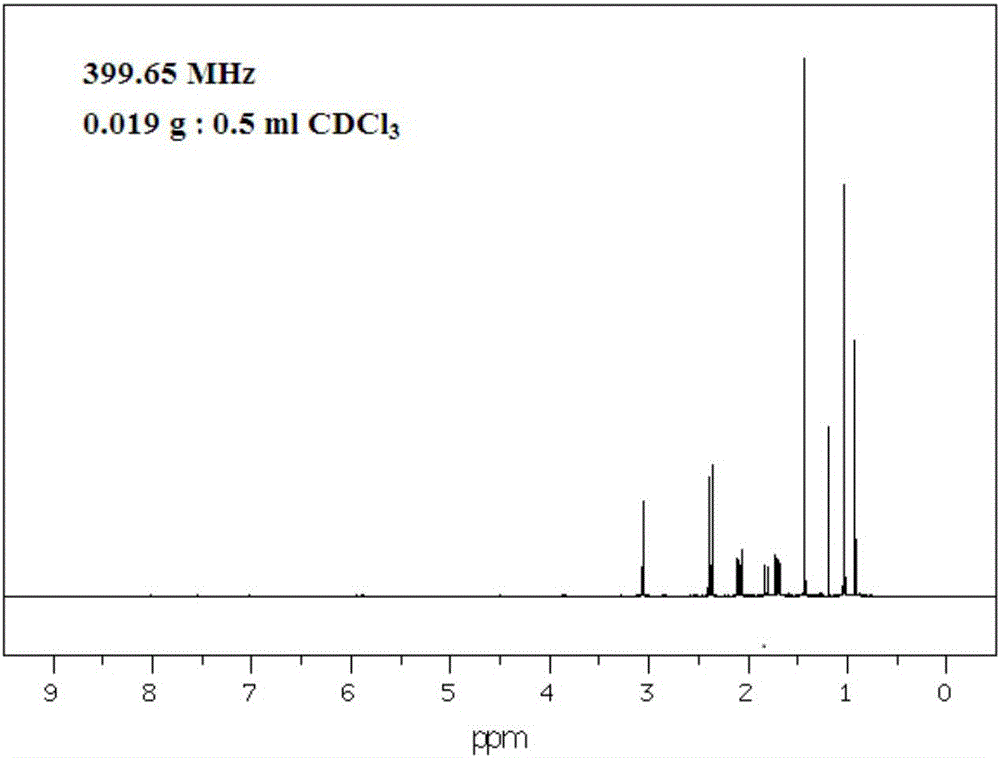

Preparation method and application of 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol

ActiveCN105001099AHigh catalytic activityLow costOrganic compound preparationAmino-hyroxy compound preparationHydrogenOil phase

The invention relates to a preparation method and application of 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol, and polyurethane foam prepared therefrom. The preparation method comprises: in the presence of a catalyst and acidic substance and under certain temperature and pressure, subjecting 3-aminomethyl-3, 5, 5-trimethylcyclohexanol, formaldehyde and hydrogen to aminomethylation reaction to obtain a reaction mixture containing an aqueous phase and an oil phase, separating the aqueous phase from the oil phase, wherein the oil phase mainly contains 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol, and the aqueous phase mainly contains formaldehyde; and optionally, purifying the oil phase so as to obtain 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol. The method provided by the invention realizes effective utilization of IPDA byproduct, and the polyurethane foam material prepared therefrom has the advantages of low smell, excellent physical performance and the like.

Owner:WANHUA CHEM GRP CO LTD

Heat-insulation fireproof water-based paint and preparation method thereof

InactiveCN104371524AImprove fire performanceGood heat insulationFireproof paintsPolyurea/polyurethane coatingsCarbon fibersMeth-

The invention discloses a heat-insulation fireproof water-based paint. The invention is characterized in that the paint is prepared from the following raw materials in parts by weight: 20-25 parts of silicone-acrylic emulsion, 1-2 parts of aluminum potassium sulfate, 1-2 parts of polyethyleneglycol, 2-4 parts of barite powder, 14-18 parts of silica sol, 20-25 parts of water-based polyurethane, 0.3-0.5 part of sodium caseinate, 2-4 parts of propanediol tert-butyl ether, 1-2 parts of benzotriazole, 1-2 parts of dioctyl adipate, 0.2-0.4 part of mineral oil defoaming agent, 1-2 parts of aluminum tripolyphosphate, 1-2 parts of potassium methylsilanolate, 2-3 parts of borax, 2-3 parts of water glass, 1-2 parts of trisodium phosphate, 2-3 parts of pulverized asbestos, 7-9 parts of heat-insulation slurry, 2-3 parts of carbon fiber and 14-20 parts of deionized water. The paint has excellent fire resistance, heat-insulation property, aging resistance, water resistance and the like. The added silica sol enhances the hardness and wear resistance of the paint film. By using the safe and nontoxic raw materials and using water as the diluter, the paint has the advantages of low cost and low VOC (volatile organic compound) value, is free of heavy metals and benzene organic solvents, is convenient for construction and application and harmless to the body of the workers, has wide application range, and is worthy of popularization.

Owner:ANHUI LENCAQI BUILDING MATERIAL

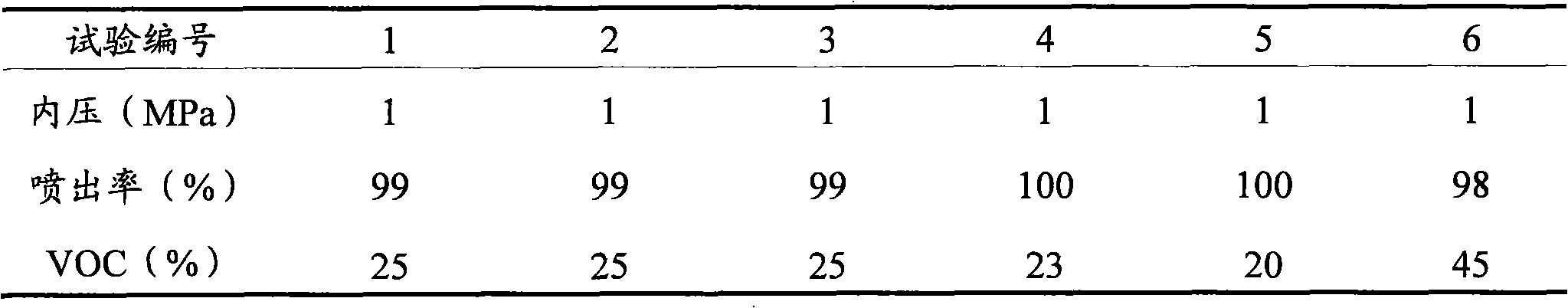

Insecticide aerosol and preparation method thereof

ActiveCN101940220ALow VOC contentReduce stimulationBiocideAnimal repellantsOrganic solventAdditive ingredient

The invention relates to an insecticide aerosol and a preparation method thereof. The insecticide aerosol comprises the following components in percentage by weight: 60-80 wt% of organic solvent, 10-30 wt% of propellent, 1-5 wt% of potentiating agent, 1-5 wt% of accessory ingredient, 0.2-1 wt% of synthetic pyrethroid and 1-5 wt% of essence. The insecticide aerosol has better atomization and desinsection effect and low VOC content. The preparation method of the insecticide aerosol comprises the following steps: mixing the organic solvent, the potentiating agent, the accessory ingredient, the synthetic pyrethroid and the essence at ratio to prepare a liquid medicine; filling the liquid medicine into a filling container, and sealing; filling the propellent into the filling container; and pressing an aerosol cover on the container to obtain the insecticide aerosol.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

Water-based baking varnish and preparation method thereof

InactiveCN101701121AImprove adhesionAccelerated corrosionAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention relates to the technical field of the baking varnish, in particular to a water-based baking varnish and a preparation method thereof. The water-based baking varnish comprises the following raw materials by weight percent: 40-60% of acrylic resin, 11-17% of amino resin, 6-10% of ethanol, 3-7% of normal butanol, 2-5% of neutralizer, 0.1-0.4% of flatting agent, 0.1-0.3% of defoaming agent, 15-25% of water and 1-2.5% of adhesive agent. The water-based baking varnish of the invention contains no pollutant and harmful material such as benzene and aldehyde, has low VOC, uses water as diluent instead of organic solvent, and is non-toxic, odourless and environmentally friendly, thus improving the working environment of constructors and protecting the health condition of constructors; acrylic resin using edible ethanol as additive is selected to be the main base stock so that in processing process, the baking varnish has the functions of sterilization and disinfection; and the adhesive force of the baking varnish of the invention can reach 2-3h, no unusual change appears on the baking varnish in the water after 72h and the baking varnish has the advantages of strong adhesive force and good water resistance.

Owner:XINDA INK & PRINTING

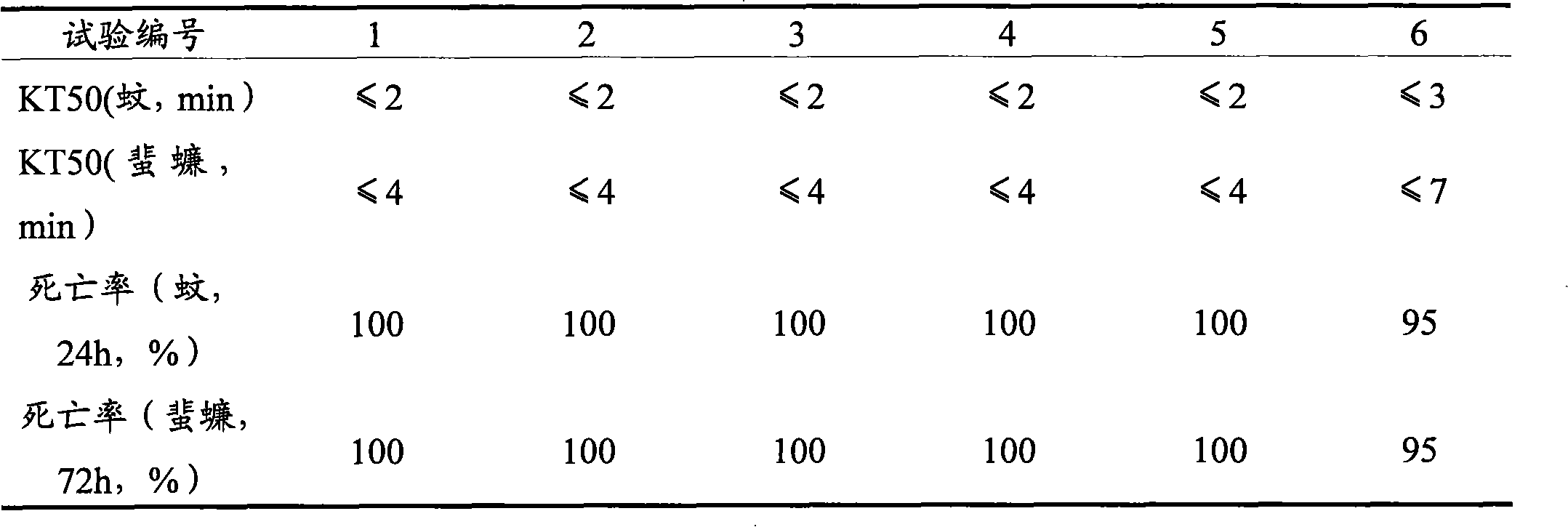

Efficient flame-retardant environment-friendly polyurethane flexible foam plastic for interior part of passenger car and preparation method of efficient flame-retardant environment-friendly polyurethane flexible foam plastic

InactiveCN107254029AImprove composite effectGood physical propertiesPolyesterEnvironmental resistance

The invention discloses an efficient flame-retardant environment-friendly polyurethane flexible foam plastic for an interior part of a passenger car and a preparation method of the efficient flame-retardant environment-friendly polyurethane flexible foam plastic. The efficient flame-retardant environment-friendly polyurethane flexible foam plastic takes polyester polyol and structural type flame-retardant polyether polyol as the main raw materials, and the main raw materials are mixed, foamed and polymerized with an isocyanate component under the actions of a reaction type or low-odor catalyst, a physical and / or chemical foaming agent and a foam stabilizer and / or a fire retardant to generate the polyurethane flexible foam plastic. The flame retardance and the environmentally friendliness of the product both meet the application requirements of a composite material, and the polyurethane flexible foam plastic is convenient to prepare.

Owner:JIANGSU LVYUAN NEW MATERIALS

Insulation anti-fouling self-cleaning paint and preparation method thereof

InactiveCN104403449AImprove insulation performanceGood antifoulingAntifouling/underwater paintsCellulose coatingsTripropylene glycolPhosphate

The invention discloses an insulation anti-fouling self-cleaning paint which is prepared from the following raw materials, by weight: 30-36 parts of acrylic resin emulsion, 10-15 parts of elastic emulsion, 20-26 parts of polytetrafluoroethylene emulsion, 1-2 parts of lignocellulose, 1-2 parts of hydroxyethyl cellulose sodium, 0.2-0.4 parts of dimethicone, 2-3 parts of silicon carbide, 0.5-0.8 parts of polyvinyl isobutyl ether, 2-3 parts of triethylene glycol monobutyl ether, 0.3-0.5 parts of a leveling agent BYK-56, 0.3-0.5 parts of polyoxyethylene monooleate, 0.2-0.4 parts of azobisisobutyronitrile heptanenitrile, 2-3 parts of nano-scale antimony-doped tin dioxide, 2-3 parts of silicon phosphate, 1-2 parts of micrometer-scale matting powder, 6-9 parts of self-cleaning slurry, and 14-20 parts of deionized water. The paint provided by the invention has the characteristics of good insulation property, good anti-static property, good self-cleaning property, and the like. The paint is safe and environment-friendly, and does not contain heavy metal and toxic organic solvent. The VOC value of the paint is extremely low. The paint is simple to apply, and does not harm human health. The paint satisfies the requirements of a green and environment-friendly paint.

Owner:ANHUI LENCAQI BUILDING MATERIAL

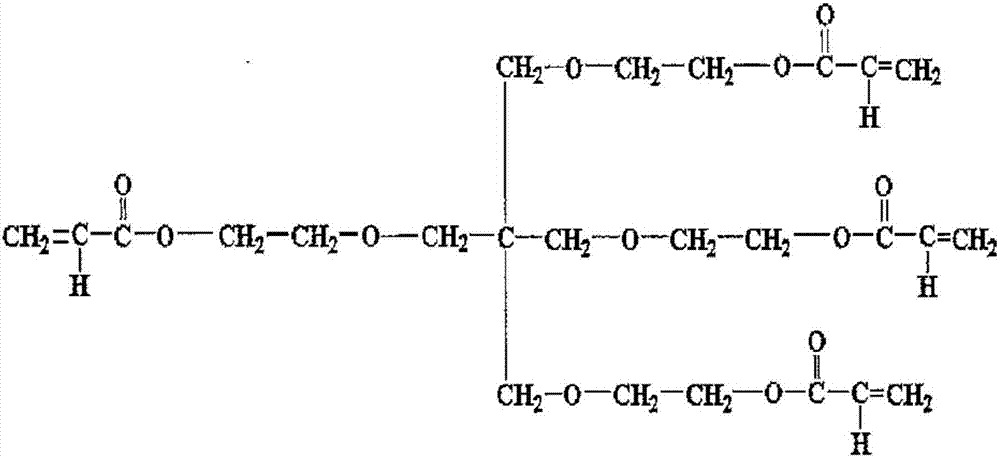

Two-part anti-fouling paint composition, anti-fouling paint film, anti-fouling base member, and method for manufacturing anti-fouling base member

ActiveCN107109082ASufficiently curableHigh film strengthAntifouling/underwater paintsSynthetic resin layered productsChemical compoundEther

Provided is a two-part anti-fouling paint composition which can exhibit excellent wastage sustainability and long-term anti-fouling properties against marine organisms. The two-part anti-fouling paint composition according to the present invention is characterized by comprising (A) a first component comprising a (meth)acrylic ester component, (B) a second component comprising an amino-group-containing compound, and (C) an anti-fouling agent contained in either the first component or the second component, wherein the (meth)acrylic ester component (A) and / or the amino-group-containing compound (B) has an ether structure, a trifunctional or higher (meth)acrylic ester is contained in an amount of 50% by weigh or more relative to the total weight of the (meth)acrylic ester component (A), and the amino-group-containing compound (B) is contained in an amount of 20 to 100 parts by weight relative to 100 parts by weight of the (meth)acrylic ester component (A).

Owner:CHUGOKU MARINE PAINTS

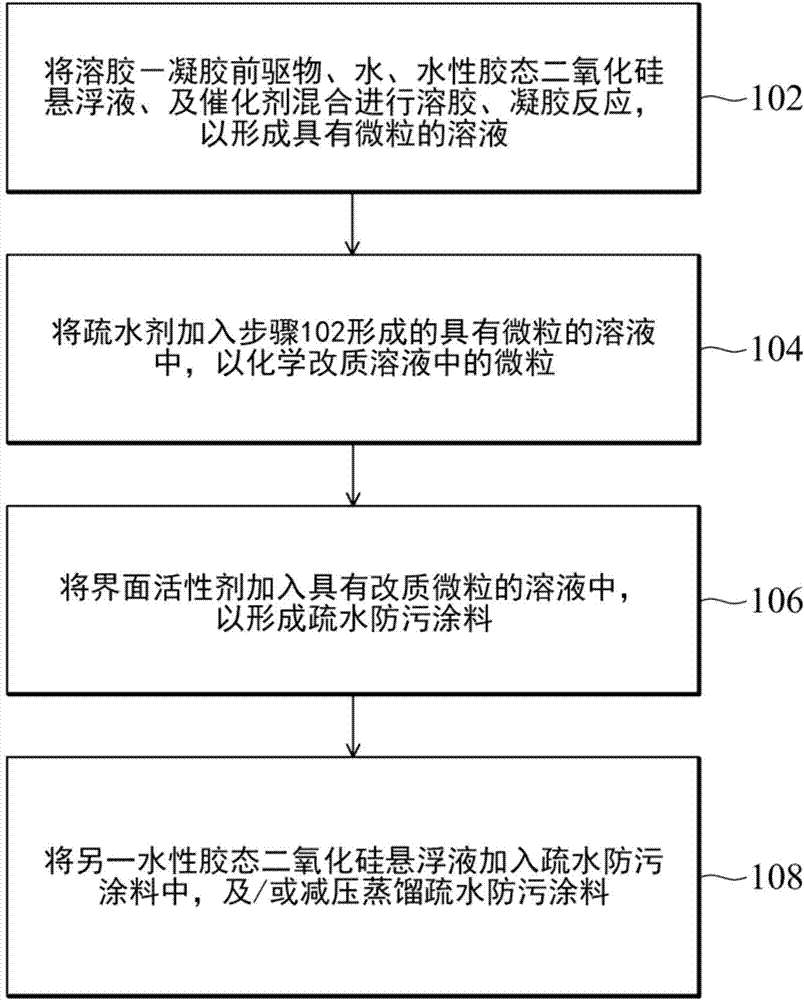

Method of manufacturing hydrophobic antifouling coating material and method of forming hydrophobic antifouling coating film

ActiveCN104744985AReduce VOC valueMeet the needs of environmental protectionAntifouling/underwater paintsPaints with biocidesColloidal silicaOrganic solvent

A method of manufacturing a hydrophobic antifouling coating material, including: (a) mixing a sol-gel precursor, water, an aqueous colloidal silica suspension, and a catalyst to perform a sol-gel reaction to form a solution having particles therein, wherein the sol-gel reaction is performed without addition of any organic solvent; (b) chemically modifying the particles with a hydrophobic agent to form surface-modified particles; and (c) adding a surfactant to the solution containing the surface-modified particles to form a hydrophobic antifouling coating material. The hydrophobic antifouling coating material can be dispersed in an aqueous solution, and has properties such as low VOC (Volatile organic compound) value, high solid content, and high stability.

Owner:IND TECH RES INST +1

Catalyst compound capable of degrading formaldehyde, dry-powdered emulsion paint and preparation method thereof

InactiveCN106179518AEvenly dispersedAvoid stickingAntifouling/underwater paintsOrganic-compounds/hydrides/coordination-complexes catalystsEmulsionPreservative

The invention discloses a catalyst compound capable of degrading formaldehyde, dry-powdered emulsion paint and a preparation method thereof. The compound is prepared from organic emulsion particles, noble metal catalyst particles and inorganic solid protective agent particles, and is prepared by a spray drying method; the noble metal catalyst particles and the inorganic solid protective agent particles can be embedded into the organic emulsion particles to a certain extent and cannot be separated from the organic emulsion particles so as to form protection layers on the surfaces of the organic emulsion particles; therefore, adhesion of the organic emulsion particles during spray drying is avoided, uniform dispersion of the catalyst particles in a paint film forming process is facilitated, and the catalysis efficiency is improved. By means of the spray drying method, volatilizable components in the organic emulsion particles can be removed; meanwhile, the emulsion paint disclosed by the invention is in a solid state, so that no preservatives or antifreezing agents is added, the VOC value of the system is reduced, and packing and transportation are facilitated.

Owner:QINGHAI PERSPECTIVE NEW ENERGY TECH +1

Silane-modified waterborne epoxy double-component zinc-rich paint composition and preparation method thereof

InactiveCN107523186AImprove water resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

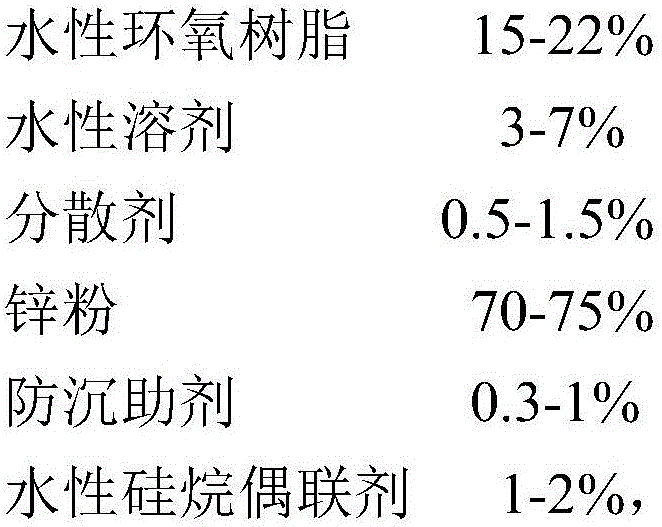

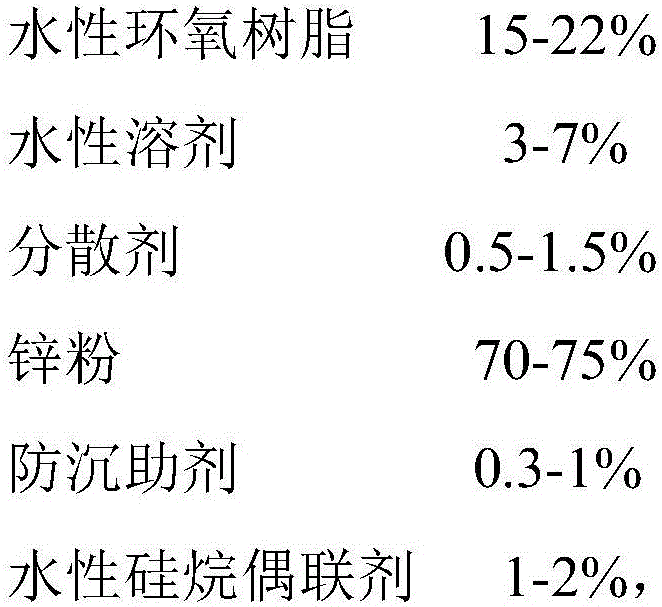

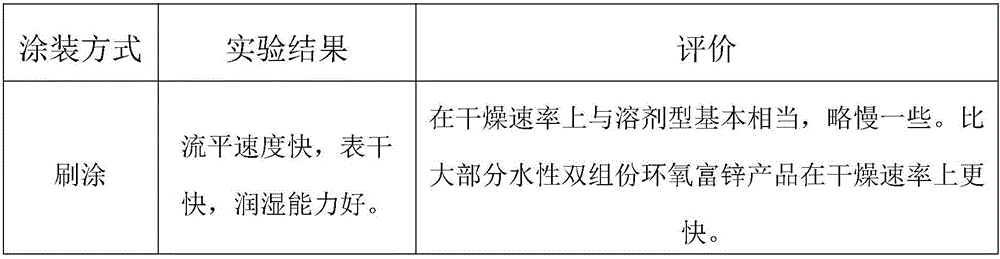

The invention relates to silane-modified waterborne epoxy double-component zinc-rich paint composition and a preparation method thereof. The composition is used for solving the problems that current like products in the market have poor water resistance and attachment and relatively high VOC value and can realize the performance of a solvent-type zinc-rich product. A main agent of the composition is prepared from components in percentage by weight as follows: 15-22% of waterborne epoxy resin, 3%-7% of a waterborne solvent, 0.2%-1% of a defoaming agent, 0.5%-1.5% of a dispersant, 70%-75% of zinc powder, 0.3%-1% of an anti-settling aid and 1%-2% of a waterborne silane coupling agent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

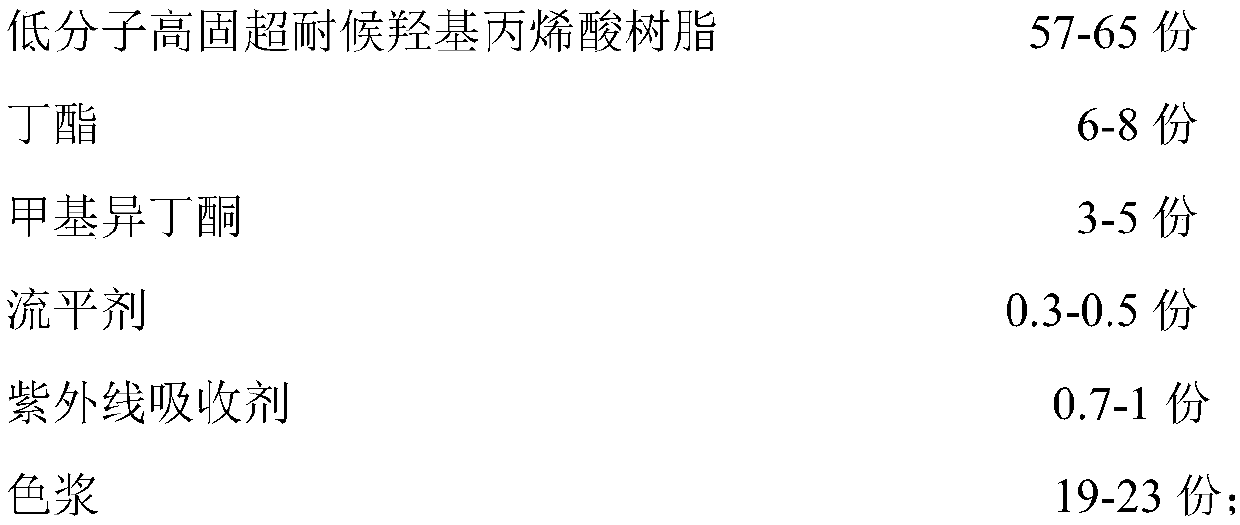

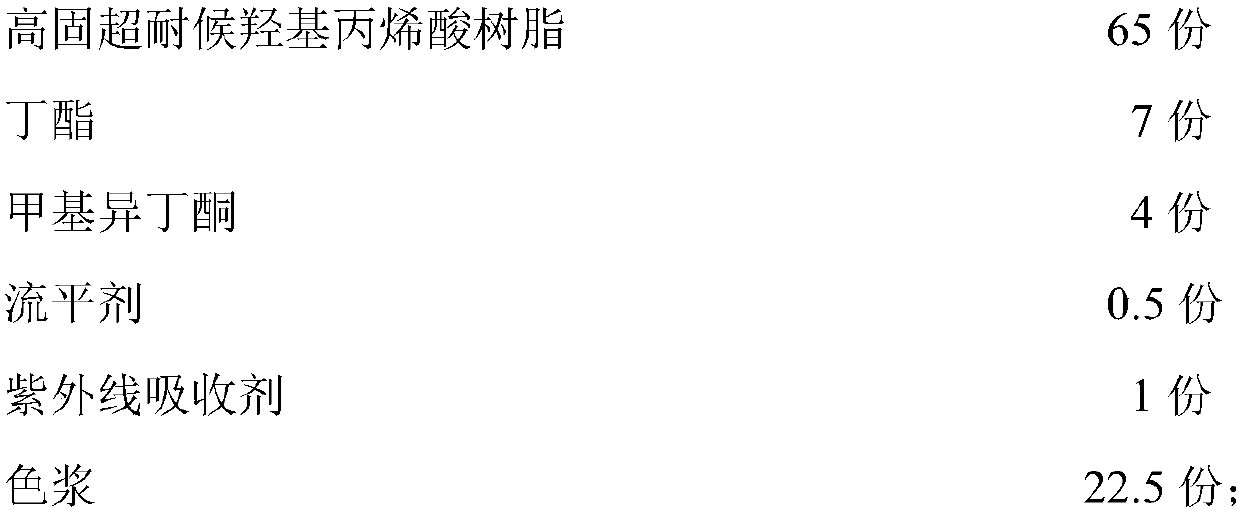

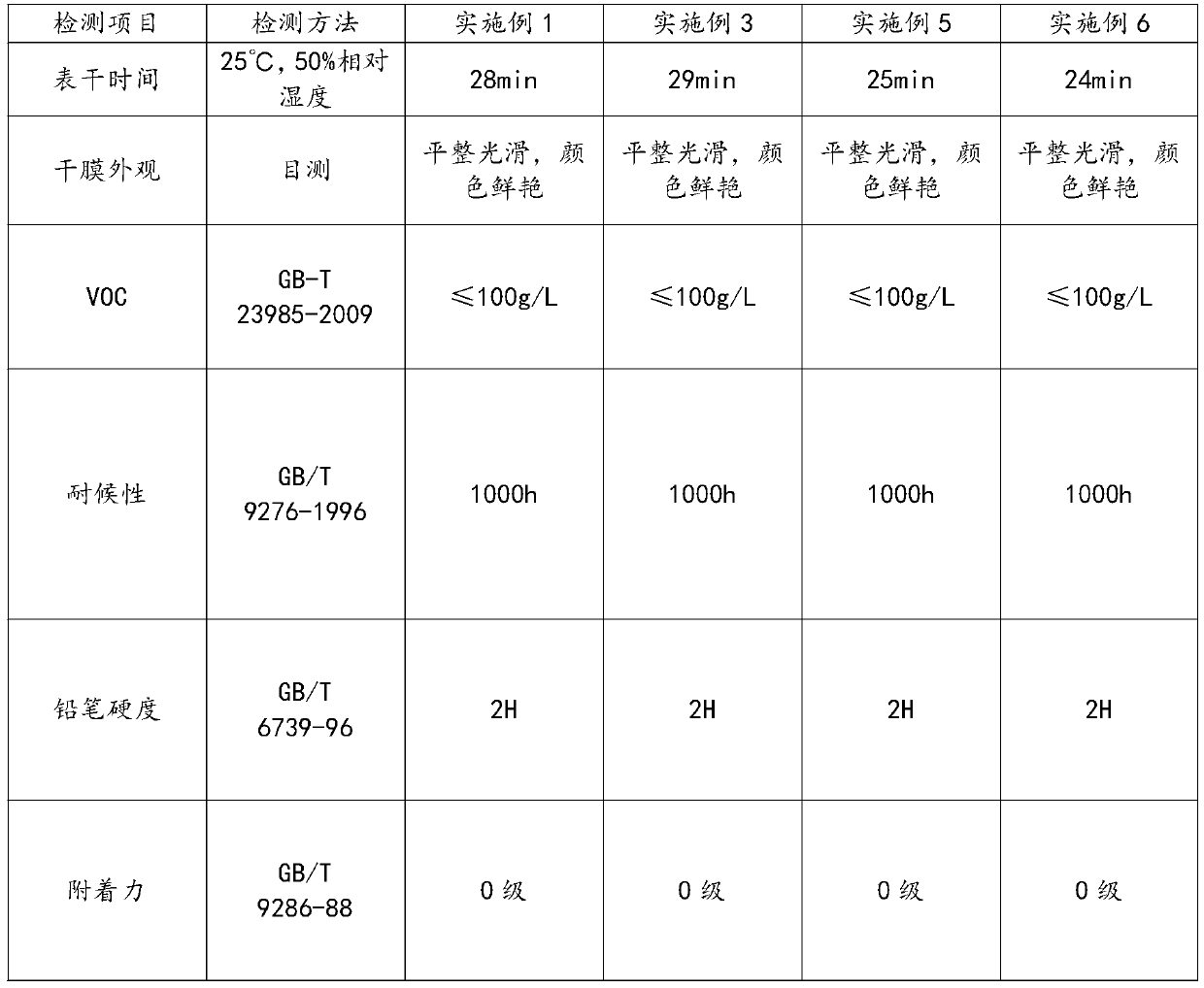

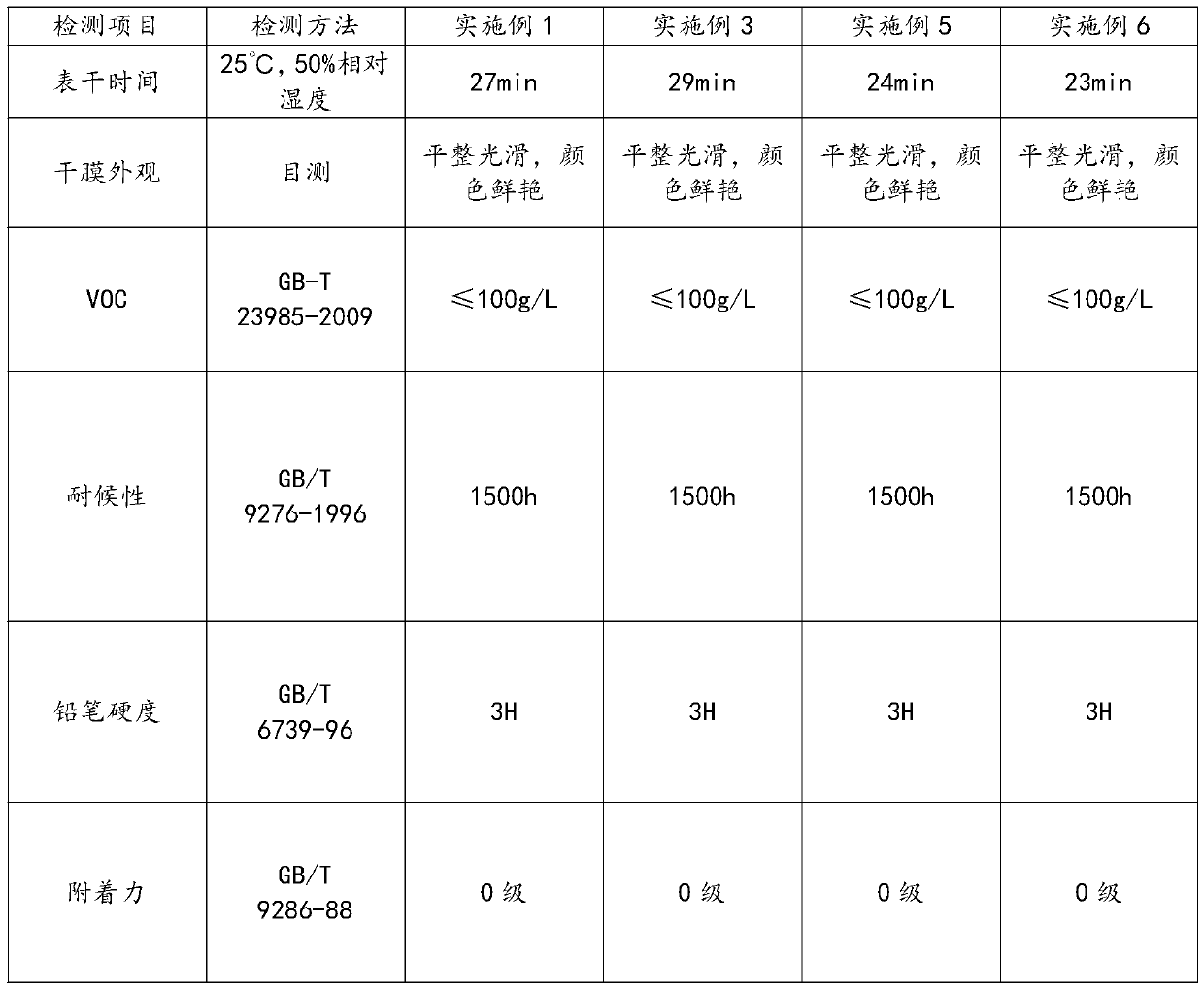

Super-weather-resistant low-VOC bus paint and preparation method thereof

ActiveCN108047912APowder freeChalking notAntifouling/underwater paintsPaints with biocidesWeather resistanceAcrylic resin

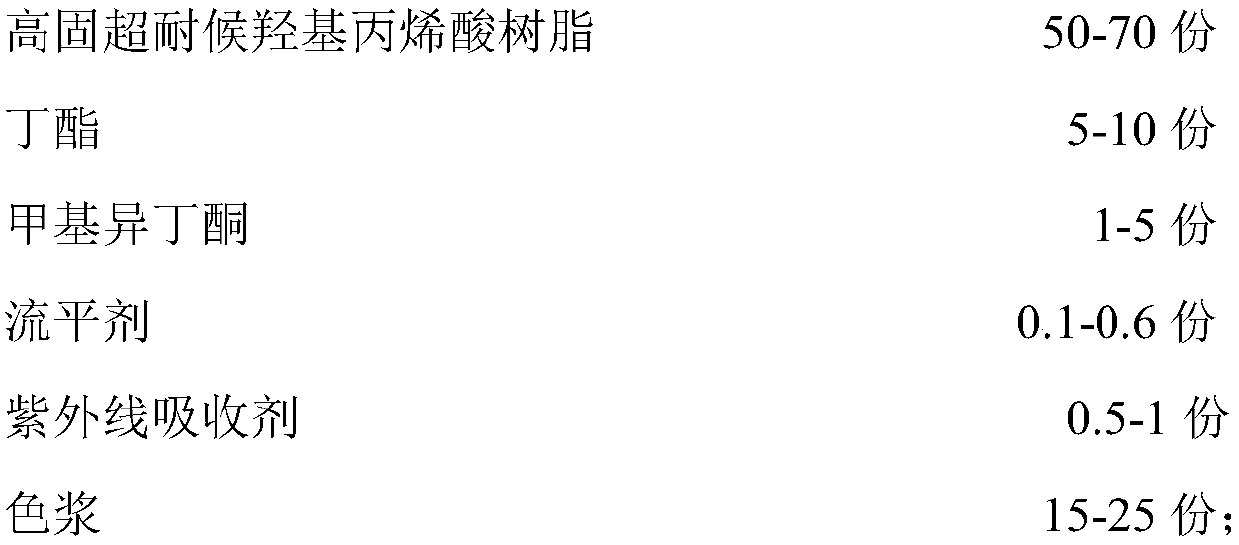

The invention discloses super-weather-resistant low-VOC bus paint and a preparation method thereof. The super-weather-resistant low-VOC bus paint is obtained by mixing a component A and a component Baccording to the mass ratio being (1.5-2.5):1, wherein the component A comprises, by weight, 50-70 parts of hydroxylated acrylic resin, 5-10 parts of diluent, 1-5 parts of solvent, 0.1-0.6 part of a flatting agent, 0.5-1 part of ultraviolet light absorber and 15-25 parts of a colorant, and the component B comprises, by weight, 50-65 parts of a curing agent, 15-30 parts of diluent and 10-30 parts of solvent. The VOC value of the super-weather-resistant low-VOC bus paint is lower than 415 g / L, water resistance is kept for 25 days or above, and good weather resistance is achieved.

Owner:GUANGDONG YATU CHEM

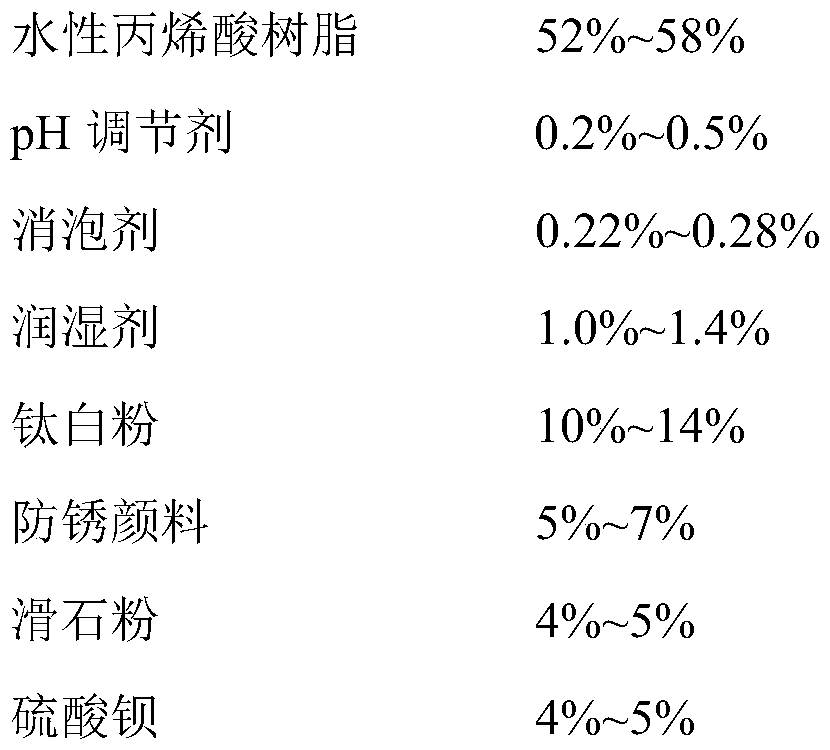

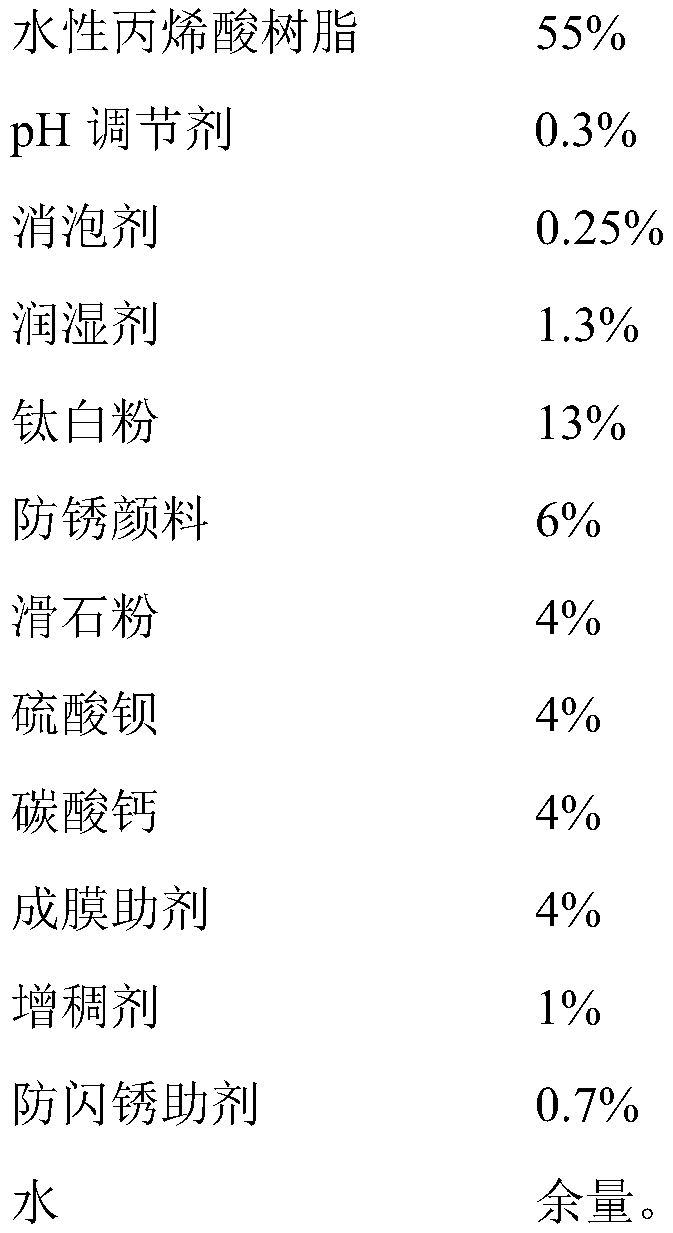

Water-based single-component air-dry paint used for machines and production method of water-based single-component air-dry paint used for machines

InactiveCN110272672APrevent electrochemical flash corrosionAvoid erosionAnti-corrosive paintsWater basedAcrylic resin

The invention relates to the technical field of paint, in particular to water-based single-component air-dry paint used for machines and a production method of the water-based single-component air-dry paint used for the machines. The water-based single-component air-dry paint used for the machines is produced from water-based acrylic resin, a pH regulator, a defoaming agent, a wetting agent, titanium dioxide, anti-rust pigment, talcum powder, barium sulfate, calcium carbonate, a coalescing agent, a thickener, an anti-flash-rust assistant and water, wherein the anti-rust pigment is one or a composition of any two or more of zinc phosphate, aluminum tripolyphosphate, zinc aluminum phosphate, zinc molybdate and zinc borate. The selected anti-rust pigment not only can conduct charge migration on metal surfaces to prevent the metal surfaces from rusting, but also can conduct passivation and isolation on rusty metal surfaces to prevent the rusty metal surfaces from continuous oxidation and rusting. Moreover, due to the fact that no raw materials which contain heavy metal are used in a formula of the water-based single-component air-dry paint used for the machines, the water-based single-component air-dry paint used for the machines has the characters that the water-based single-component air-dry paint used for the machines is safe and environmentally friendly, and a VOC value is low. The production method has the characters that the process is simple, the production cost is low, and the production method can be suitable for large-scale production.

Owner:东莞大宝化工制品有限公司

Modified styrene acrylic emulsion water-based adhesive and preparation method thereof

InactiveCN107779138ANo demulsification and no delaminationImprove high and low temperature storage effectAmide/imide polymer adhesivesEster polymer adhesivesWater basedFunctional monomer

The invention relates to the field of adhesives and particularly relates to a preparation method of a modified styrene acrylic emulsion water-based adhesive. The preparation method comprises the following steps: (1) pre-emulsification: mixing hard monomers, soft monomers, functional monomers and an emulsifying agent in deionized water, and heating to 45-55 DEG C, so as to form a stable pre-emulsion; (2) pre-polymerization reaction: adding 20wt%-30wt% of the pre-emulsion into a reactor, introducing nitrogen, heating to 70-75 DEG C, and dropwise adding an initiator for reacting for 10-30 minutes; and (3) polymerization reaction: dropwise adding the residue pre-emulsion, a proper amount of the initiator and a proper amount of a chain transfer agent into the reactor at a constant temperature for 30-60 minutes, after the dropwise adding is finished, carrying out constant-temperature reaction for 1-2 hours, heating to 80-85 DEG C, and adding a proper amount of the initiator once so as to remove residual monomers. The invention aims at providing the stable-performance modified styrene acrylic emulsion water-based adhesive capable of resisting the changes of high and low temperatures and the preparation method of the modified styrene acrylic emulsion water-based adhesive.

Owner:SHENZHEN TAIQIANG CHEM

Waterborne protective paint for container car and preparation method of waterborne protective paint

InactiveCN110003748AReduce VOC valueEasy constructionEpoxy resin coatingsVolatile organic compoundEmulsion

The invention provides waterborne protective paint for a container car. The waterborne protective paint selects a mixed system of waterborne acrylic emulsion and waterborne epoxy ester resin and has the advantages of fast drying and good weather fastness; meanwhile, due to environment-friendly raw materials and low VOC (volatile organic compound) value, the waterborne protective paint has a low VOC value, is environmentally friendly and easy to construct and has the advantages of higher weather fastness and aging resistance. Compared with traditional paint, the waterborne protective paint is easy to construct, production efficiency of workers can be greatly improved, and construction cost is saved. A preparation method of the waterborne protective paint is provided, a special production technology process is designed according to physicochemical properties of different raw materials, with the adoption of the preparation method, properties of the components can be played to a better level, and the waterborne protective paint which has low VOC value, is environmentally friendly and easy to construct and has higher weather fastness and aging resistance is obtained finally.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

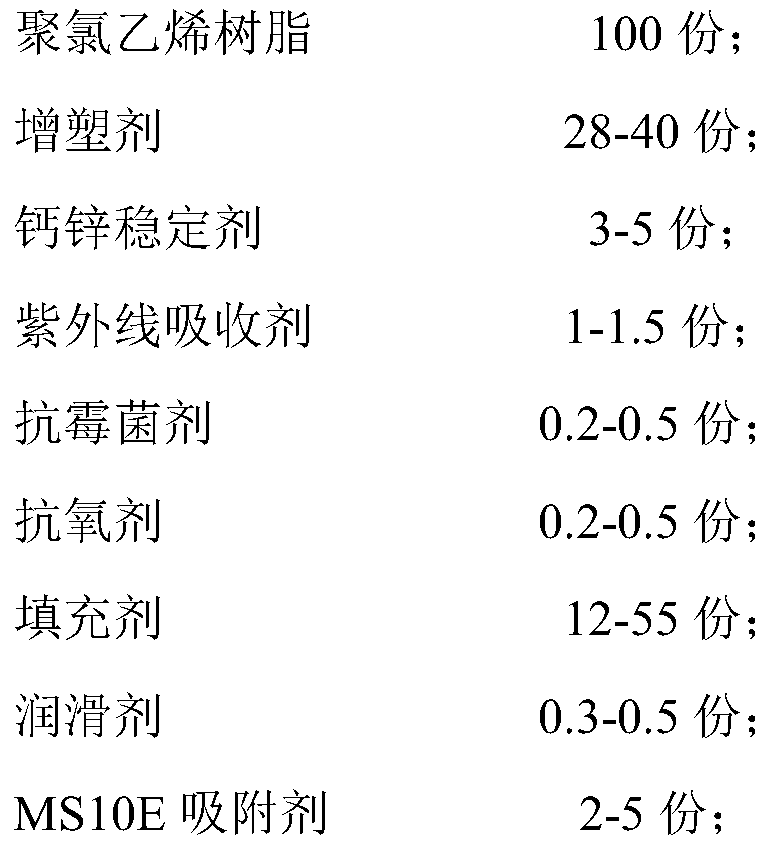

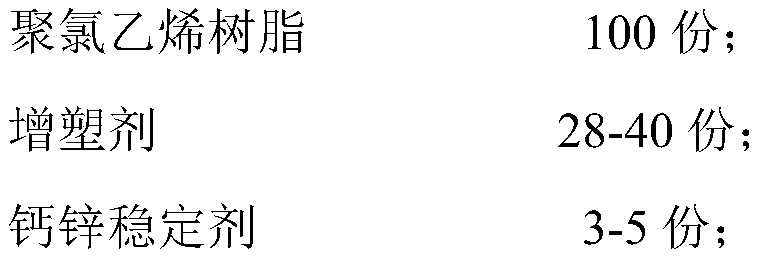

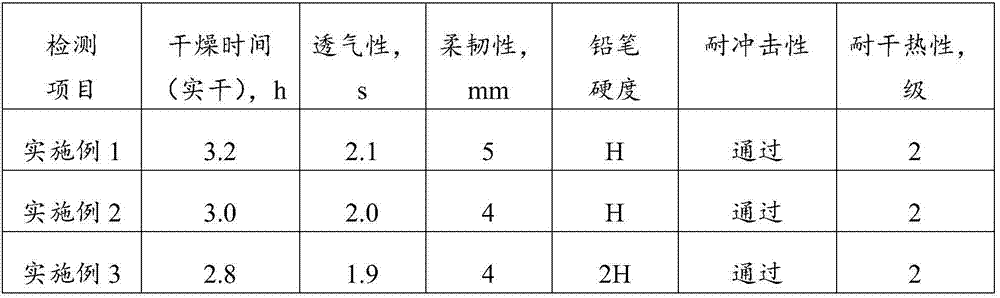

Environment-friendly PVC material for textilene dinner pad and preparation method of environment-friendly PVC material

PendingCN110437562AIncrease wear resistance and scratch resistanceSmall smellAntioxidantPolyvinyl chloride

The invention discloses an environment-friendly PVC material for a textilene dinner pad. The environment-friendly PVC material for the textilene dinner pad comprises the following components in partsby weight: 100 parts of polyvinyl chloride resin, 28-40 parts of a plasticizer, 3-5 parts of a calcium zinc stabilizer, 1-1.5 parts of an ultraviolet absorber, 0.2-0.5 part of an antimycotic agent, 0.2-0.5 part of an antioxidant, 12-55 parts of a filler, 0.3-0.5 part of a lubricant and 2-5 parts of an MS10E adsorbent, wherein the filler comprises transparent powder and calcium carbonate, the transparent powder is aluminosilicate crystals, and the MS10E adsorbent is a magnesium silicate adsorbent. According to the environment-friendly PVC material for the textilene dinner pad, a proper amount of the transparent powder is added into the polyvinyl chloride resin, so that the wear resistance and scratch resistance of a PVC coating layer are improved, meanwhile, the MS10E adsorbent is added, the odor of a product is reduced, and the VOC value is low; and meanwhile, a preparation process is simple, the yield is high, and the environment-friendly PVC material for the textilene dinner pad is simple and easy to obtain.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL

Waterborne alkyd resin coating for wooden product surface

InactiveCN107955504AHigh hardnessImprove toughnessPolyester coatingsResin coatingAntibacterial agent

The invention discloses a waterborne alkyd resin coating for a wooden product surface, which is prepared from, by weight, 80-90 parts of film forming substance, 1-2 parts of tetraethylenepentamine, 0.2-0.6 part of phenylenediamine, 1-5 parts of microcrystalline cellulose composite, 2-8 parts of calcined kaolin, 1-5 parts of vermiculite powder, 1-5 parts of glass fiber, 4-10 parts of pigment, 1-2 parts of magnesium oxide, 1-2 parts of antibacterial agent, 1-2 parts of mildew preventive, 1-2 parts of antifoaming agent, 1-2 parts of wetting agent, 15-22 parts of oxidized polyethlene wax, and 80-160 parts of water. The waterborne alkyd resin coating for the wooden product surface has good coating fullness, high hardness, good flexibility, and good waterproof and anti-scratching performance; moreover, the coating is featured by low VOC value and sticky resistance; meanwhile, the cost is low.

Owner:合肥林邦门业有限公司

Aqueous wood wax oil as well as preparation method and application thereof

ActiveCN107418438AFast dryingImprove breathabilityWax coatingsPolyurea/polyurethane coatingsNano siliconCellulose

The invention provides aqueous wood wax oil as well as a preparation method and application thereof, relating to the technical field of coatings. The aqueous wood wax oil is prepared by taking a natural wood wax emulsion and a polyurethane modified acrylic emulsion as main raw materials and adding lignocelluloses and nano silicon sol in a compounding manner, the lignocelluloses can infiltrate into a filming substance to form a staggered net-shaped structure, the nano silicon sol enters gaps among the lignocelluloses, the raw materials act together to form a dense three-dimensional net-shaped structure, then a formed coating film is good in hardness, air permeability, toughness and impact resistance, and the defects that aqueous wood wax oil is poor in air permeability, easy to crack, easy to deform and easy in tendon exposure are alleviated. The invention further provides a preparation method of the aqueous wood wax oil. According to the preparation method, the process is simple, the operation is easy and the industrial production can be realized.

Owner:苏州市金能高新材料有限公司

Water-based protective paint for protective fence of residential quarter and preparation method of water-based protective paint

InactiveCN110041778AReduce VOC valueEasy constructionPolyurea/polyurethane coatingsPolyester coatingsWater basedEmulsion

The invention provides water-based protective paint for a protective fence of a residential quarter. The water-based protective paint uses a water-based acrylic emulsion and water-based alkyd resin mixed system and has the advantages of being fast in drying and good in weather fastness; besides, raw materials are environmentally friendly and the VOC value is low, so that the water-based protectivepaint has the advantages of being low in VOC value, environmentally friendly, easy to construct and higher weather fastness and ageing resistance. Compared with conventional paint, the water-based protective paint is easier to construct, the production efficiency of workers can be greatly improved, and the construction cost is saved. According to the preparation method of the water-based protective paint, a special production technological procedure is designed according to physical and chemical properties of different raw materials. With the adoption of the preparation method, properties ofall components can be played to a better level, and finally, the water-based protective paint which is low in VOC value, environmentally friendly, easy to construct and higher weather fastness and ageing resistance is obtained.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

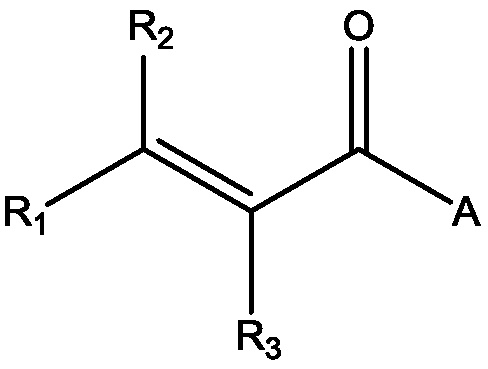

A kind of comb type macromonomer and preparation method thereof, a kind of polymer polyol and polyurethane foam

The invention discloses a comb-shaped macromolecular monomer, a preparation method thereof and a polymer polyol prepared therefrom. The comb-shaped macromonomer is prepared by first reacting a compound containing a double bond with a dihydric alcohol, and then adding a monomer containing a conjugated double bond in the presence of an optional initiator for polymerization. The comb-shaped macromonomer is suitable as a dispersion stabilizer for polymer polyol, reduces its viscosity, and has excellent stabilizing properties. The flexible polyurethane foam prepared by using the polymer polyol has excellent properties, low VOC and low odor, and excellent elongation at break and tensile strength.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing polyurethane adhesive in use for rubber tiles

InactiveCN1696232AHigh tensile strengthImproved elongation at break propertiesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

A process for preparing the polyurethane adhesive used for rubber floor tile is disclosed. Said polyurethane adhesive features high tension strength and elongation at break, low content of VOC and no phenol.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Nano antibacterial aqueous woodenware paint and preparing method thereof

InactiveCN100503753CLow costEasy to useLiquid surface applicatorsAntifouling/underwater paintsPolymer scienceEmulsion

The invention relates to a paint, in particular to a single-component nanometer antibacterial water-based wood paint and a preparation method thereof. In the present invention, three different water-based polyurethane resin emulsions, water-based acrylic modified polyurethane resin emulsions and nanometer water-based acrylic resin emulsions are mixed in different proportions as a film-forming material, and while successfully reducing product costs, it also has a low VOC value , anti-adhesion, scratch resistance, pollution resistance, yellowing resistance and good sealing characteristics. The composite inorganic antibacterial agent used in the present invention uses organic expansive soil prefabricated sol as a carrier, contains a variety of inorganic nano-components, not only has the advantages of environmental protection, broad-spectrum antibacterial and strong antibacterial function durability, but also is easy to mix and process, solving the problem of ordinary inorganic antibacterial agents. The technical problems of easy sedimentation, easy discoloration and easy agglomeration during the production and processing of antibacterial agents.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

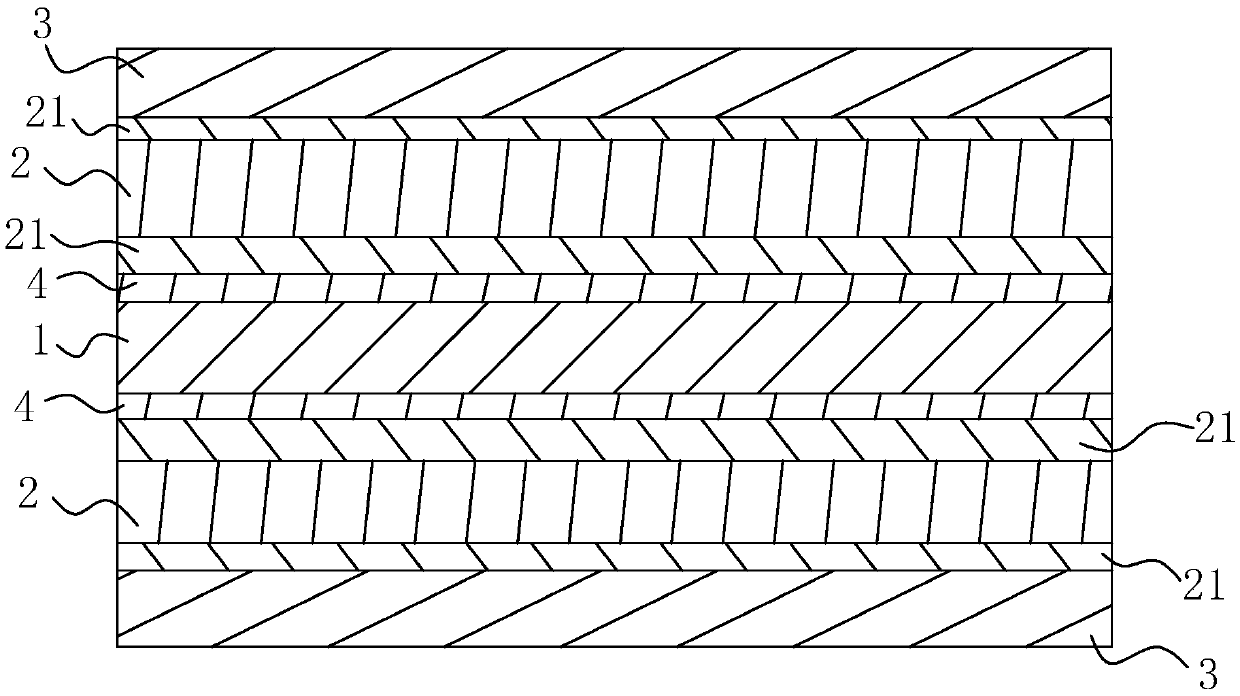

Automobile ceiling and manufacturing method thereof

ActiveCN109517366AReduce VOC valueFresh airNon-macromolecular adhesive additivesSynthetic resin layered productsGlass fiberEngineering

The invention discloses an automobile ceiling and a manufacturing method thereof. The automobile ceiling comprises a ceiling substrate layer, glass fiber felt layers located on the upper and lower sides of the ceiling substrate layer and glue layers attached to the upper and lower sides of the glass fiber felt layers, wherein the glue layer located on the side, close to the ceiling substrate, of the glass fiber felt layer is in contact with the ceiling substrate and a non-woven fabric is attached to the glue layer, far away from the ceiling substrate, of the glass fiber felt layer. The manufacturing method comprises the following steps: S1, preparing the ceiling substrate layer; S2, spraying softening water; S3, preparing an auxiliary layer; S4, pressing and forming; S5, cooling and sizing; and S6, cutting with a water knife. The automobile ceiling has the advantage of low VOC content. In addition, the preparation method has the advantages of being simple in process and capable of preparing the automobile ceiling uniform in density.

Owner:天津华翔车顶系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com