Method of manufacturing hydrophobic antifouling coating material and method of forming hydrophobic antifouling coating film

An antifouling paint, a technology for a manufacturing method, applied in the formation of a hydrophobic antifouling coating film, and the manufacturing field of a hydrophobic antifouling paint, can solve the problems of incompatibility, inability to be used as a good hydrophobic antifouling paint, difficult to maintain good hydrophobic properties, and the like, To achieve the effect of reducing VOC value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

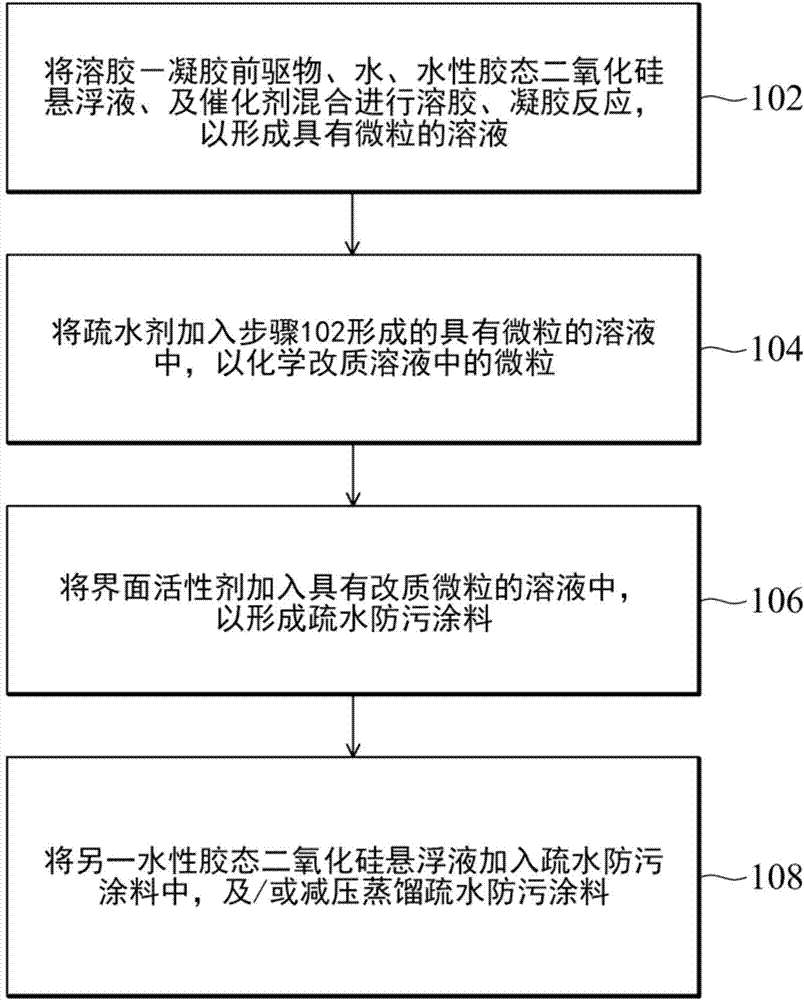

Method used

Image

Examples

Embodiment 1

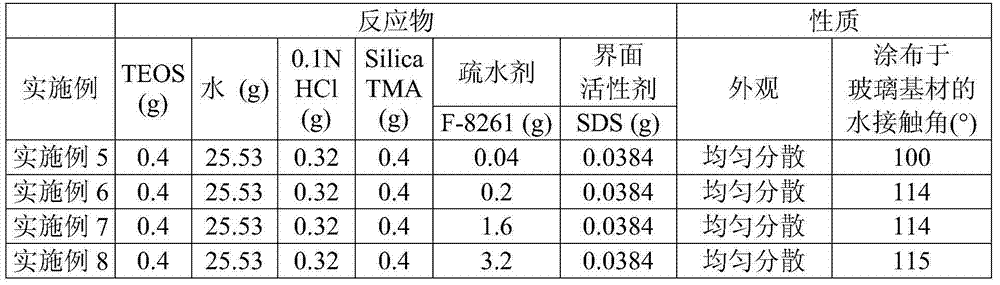

[0031] With 0.4 gram of tetraethoxysilane (Tetraethyl orthosilicate; TEOS), 0.277 gram of water, 0.4 g of aqueous colloidal silica suspension (purchased from Aldrich TMA colloidal silica suspension) and 0.32 g of 0.1N HCl were mixed and reacted at room temperature for 3 hours to obtain a solution containing microparticles. Then 0.8 grams of hydrophobic agent 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane (1H, 1H, 2H, 2H-Perfluorodecyltriethoxysilane, F-8261 available from Degussa) was added to the above-mentioned microparticle-containing solution, React at room temperature for 2 hours to modify the microparticles. Finally, the anionic surfactant sodium dodecylsulfonate (Sodium dodecyl (ester) sulfate; SDS) of 0.0384g was dissolved in 24.94 grams of water, and then it was added to the solution of modified particles, and reacted at room temperature for 12 Hours, a stable hydrophobic antifouling coating in the aqueous phase is obtained. The appearance of the above-mentioned hydr...

Embodiment 2

[0033] Similar to Example 1, the difference is that the amount of aqueous colloidal silica suspension used in the step of forming microparticles was increased to 0.8 g. The appearance of the hydrophobic antifouling paint of this embodiment is also uniformly dispersed, and it has not gelled after being placed at 60° C. for 14 days. The solid content of the above-mentioned hydrophobic antifouling coating is 3.43%, and VOC≥300g / L (VOC calculation method is ISO11890-2 (10.3Method2). Finally, the above-mentioned hydrophobic antifouling coating is coated on the glass substrate, and in After baking at 120°C for 30 minutes and then cooling, the water contact angle was measured to be 112°. In addition, the hydrophobic antifouling coating after 14 days at 60°C was coated on a glass substrate and baked at 120°C After baking for 30 minutes and then cooling, the water contact angle was measured to be 113°. As can be seen from the above, the addition of aqueous colloidal silica suspension i...

Embodiment 3

[0035] Similar to Example 1, the difference is that the amount of aqueous colloidal silica suspension used in the step of forming microparticles was increased to 1.6 g. The appearance of the hydrophobic antifouling paint of this embodiment is also uniformly dispersed, and it has not gelled after being placed at 60° C. for 14 days. The solid content of above-mentioned hydrophobic antifouling paint is 3.47%, and VOC ≥ 300g / L (the calculation method of VOC is ISO11890-2 (10.3Method2). Finally, above-mentioned hydrophobic antifouling paint is coated on the glass substrate, and in After baking at 120°C for 30 minutes and then cooling, the water contact angle was measured to be 101°. In addition, the hydrophobic antifouling coating after 14 days at 60°C was coated on a glass substrate and baked at 120°C After baking for 30 minutes and then cooling, the water contact angle was measured to be 111°. As can be seen from the above, the addition of aqueous colloidal silica suspension in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com