Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Powder free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

Downconversion frequency shift infrared radiation enhanced coating and preparation method thereof

InactiveCN101712816AHigh heat conversion efficiencyImprove absorption rateCoatingsEmissivityFrequency shift

The invention relates to an infrared radiation enhanced coating and a preparation method thereof. The downconversion frequency shift infrared radiation enhanced coating is characterized by consisting of the following components in percentage by mass: 20 to 50 percent of radiation synergistic enhancer, 1 to 7 percent of downconversion frequency shift additive, 15 to 45 percent of high-temperature resistant base stock, 32 to 50 percent of high-temperature binder, 1 to 4 percent of flexibilizer and 1 to 4 percent of coating auxiliary agent, and the sum of the mass percentage of the components is 100 percent. The coating not only has high emissivity and good thermal shock resistance, but also can convert visible light into infrared radiation; and the thermal conversion efficiency of the coating is effectively improved.

Owner:WUHAN YINFURUI NEW MATERIAL

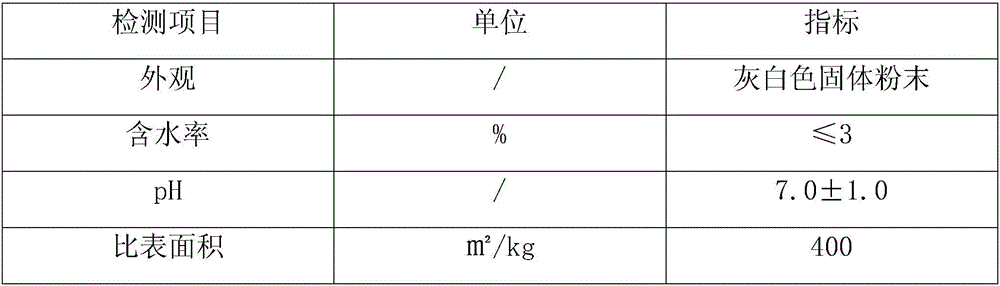

Pomegranate-like structured composite material preparation method

InactiveCN104300125AEasy to prepareThe preparation method is safeMaterial nanotechnologyCell electrodesMaterials preparationSilica particle

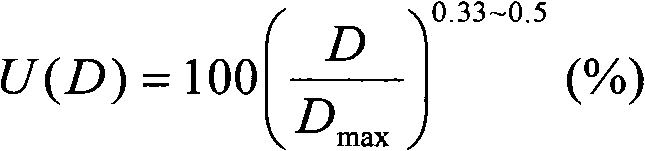

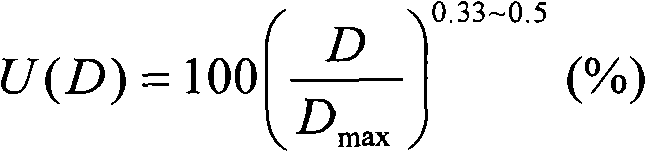

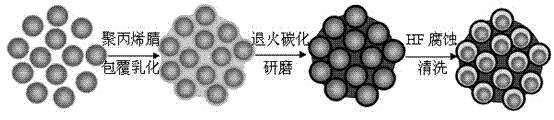

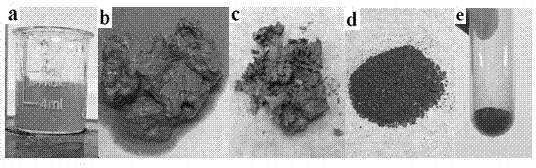

The invention discloses a pomegranate-like structured composite material preparation method which comprises the following steps: S1, taking a polyacrylonitrile solution, adding silica nanoparticles, and fully dispersing; S2, adding deionized water after stirring for emulsification to obtain a mud like precursor; S3, heating the mud like precursor obtained in the S2, and annealing to obtain a solid composite; and S4, grinding the solid composite obtained in the S3 into micron particles, adding a hydrogen fluoride solution for corrosion for a certain period of time, washing hydrogen fluoride, and drying to obtain a pomegranate-like structured composite material. According to the method, polyacrylonitrile is used for coating the silica particle surface, the polyacrylonitrile is emulsified when meeting water, so that the coated silicon particles are agglomerated, the coated silicon particles are carbonized and ground for formation of the pomegranate shaped structured silicon carbon composite material, HF is used for direct corrosion of the silicon nanoparticles in the material for preparation of the hollow pomegranate-like structured composite material, and detailed structure characterization and electrochemical performance testing of the material show that the material is good in performances.

Owner:SUN YAT SEN UNIV

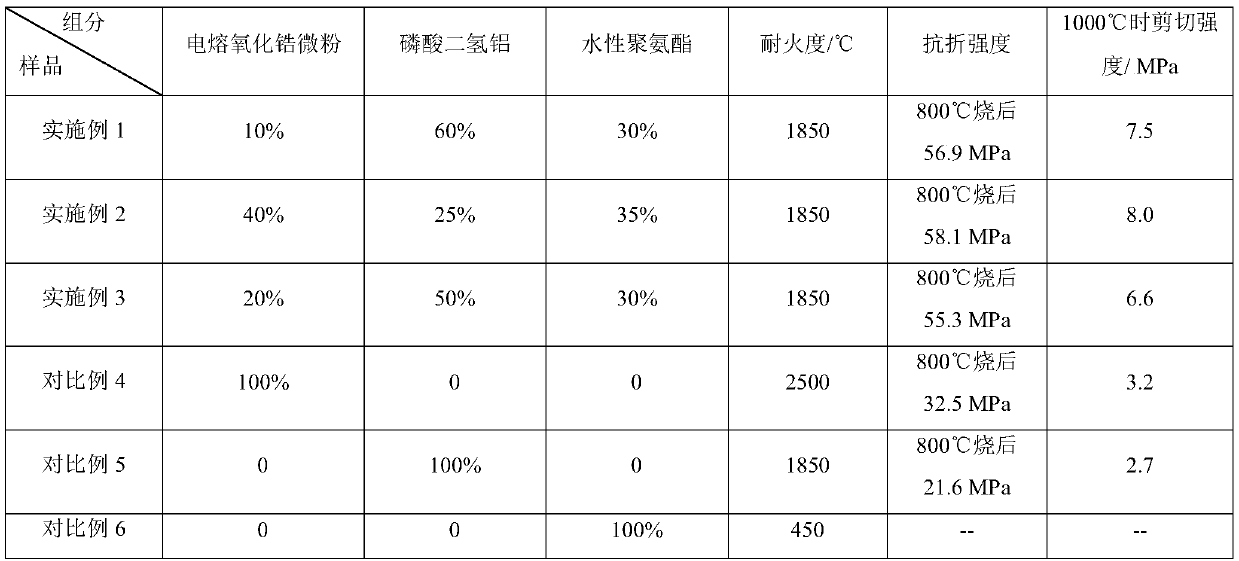

Preparation process for anticorrosion saggar for calcination of lithium battery cathode material

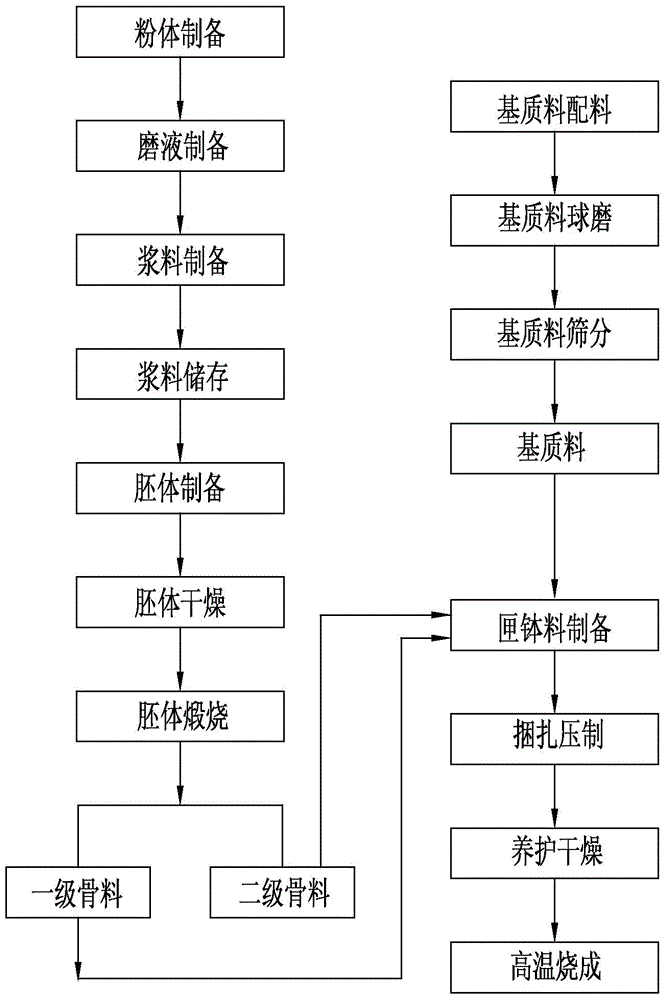

The invention discloses a preparation process for an anticorrosion saggar for calcination of a lithium battery cathode material. The preparation process includes the steps of primary aggregate preparation, secondary aggregate preparation, matrix material preparation and saggar preparation. The steps of primary aggregate preparation and secondary aggregate preparation sequentially comprise the procedures of powder preparation, ball milling slurry preparation, slurry preparation, slurry storage, blank preparation, blank drying and blank calcination. The step of matrix material preparation sequentially includes the procedures of matrix material burdening, matrix material ball milling and matrix material screening. The step of saggar preparation sequentially includes the procedures of saggar material preparation, bundling pressing, maintenance drying and high-temperature firing. Primary aggregates, secondary aggregates and a matrix material are mixed according to the process ratio to form a saggar material. The anticorrosion saggar has the alkali-resistant and anti-corrosion functions, and pure magnesium hydrate, aluminum oxide and silicon dioxide are calcinated to obtain high-purity cordierite material aggregates; magnesium-aluminum-rich spinel powder is added for preparing the matrix material, and the saggar is small in heat expansion coefficient, high in heat impact resistance and long in service life.

Owner:SUZHOU RUIBANG CERAMIC NEW MATERIAL

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Preparation of carbonaceous composite pellet containing manganese

The invention discloses a preparation method of a composite pellet, which includes the working procedures of preparing materials, measuring, mulling, pressing and drying. Compared with the prior art, the preparation method is simple to be operated and has the advantages that: (1) the composite conception is broad; the pellet not only has a manganese material, but also has a reducer needed by smelting and takes coal for replacing tar and reducing the production cost; the material containing manganese not only includes the powder of a manganese ore (molybdenum concentrate, imported fine ore, slag rich in manganese, sintering fine ore and baking fine ore), but also includes manganese soot and improves the operating factor of resources; (2) the materials adopted by the composite pellet are broad in granularity; the granularity of the manganese ore (molybdenum concentrate, slag rich in manganese, sintering fine ore and baking fine ore) is between 0 and -3mm, the granularity of the coal is between 0 and -5mm, and the production technique is simplified; (3) drying is carried out under lower temperature, thus saving energy resources; and (4) a dry power sintering agent is used and the operation is simple and convenient. The composite pellet is applied to smelting manganese series iron alloys by electric furnaces and the smelting effect of the electric furnaces is good.

Owner:云南文山斗南锰业股份有限公司 +1

Building heat preservation material

InactiveCN106588108AReduce weightImprove insulation effectCeramicwareCelluloseEnvironmental resistance

The invention discloses a building heat preservation material. The building heat preservation material is mainly prepared from, by weight, 15-30 parts of bentonite, 15-30 parts of coal ash, 10-20 parts of mica, 2-5 parts of polyacrylamide, 12-27 parts of kaolin, 11-25 parts of expanded perlite, 7-15 parts of phenolic resin, 0.5-2 parts of calcium stearate, 1-3 parts of foaming agent, 6-13 parts of soapstone, 35-55 parts of modified environment-friendly adhesive, 3-6 parts of starch ether, 6-13 parts of centrifugal glass fibers, 2-8 parts of hydroxymethyl propyl cellulose, 15-25 parts of cement, 8-17 parts of ceramsite and 11-23 parts of diatomite. The building heat preservation material is low in weight, can replace a traditional building heat preservation material, and can be used for coating protection of building side walls. The heat conductivity coefficient of the material is tested based on the GB / T10297-1998 standard, the heat conductivity coefficient is only 0.038-0.040, the heat preservation performance is extremely excellent, high acid-base corrosion resistance is achieved, no abnormities exist after the experimental test is carried out for 150 h, superhigh weather fastness is achieved, and no discoloring or pulverization or bubbles or stripping or cracks are generated 420 h later.

Owner:南宁市大江保温材料有限公司

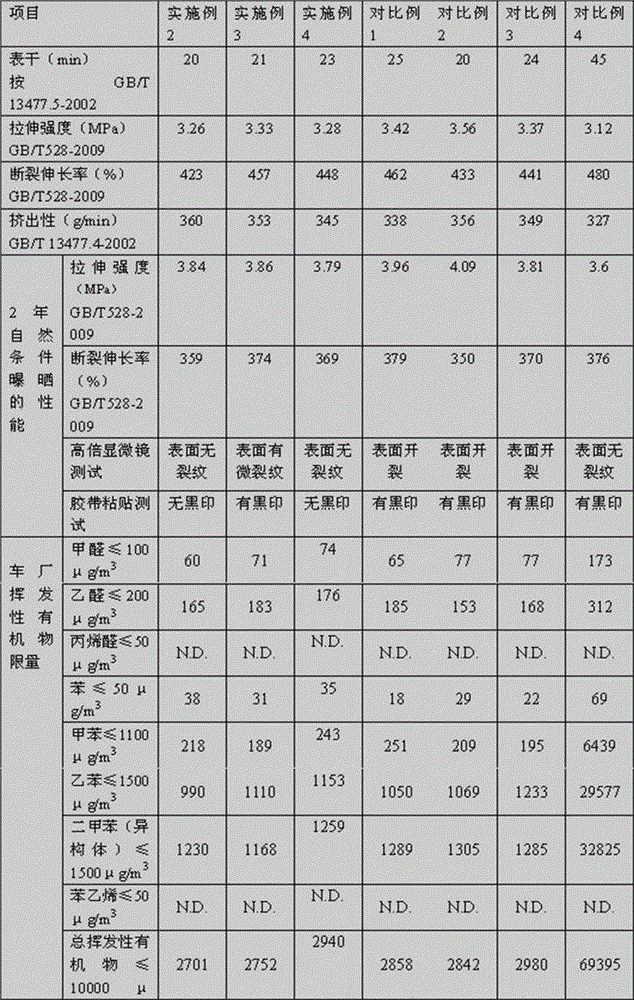

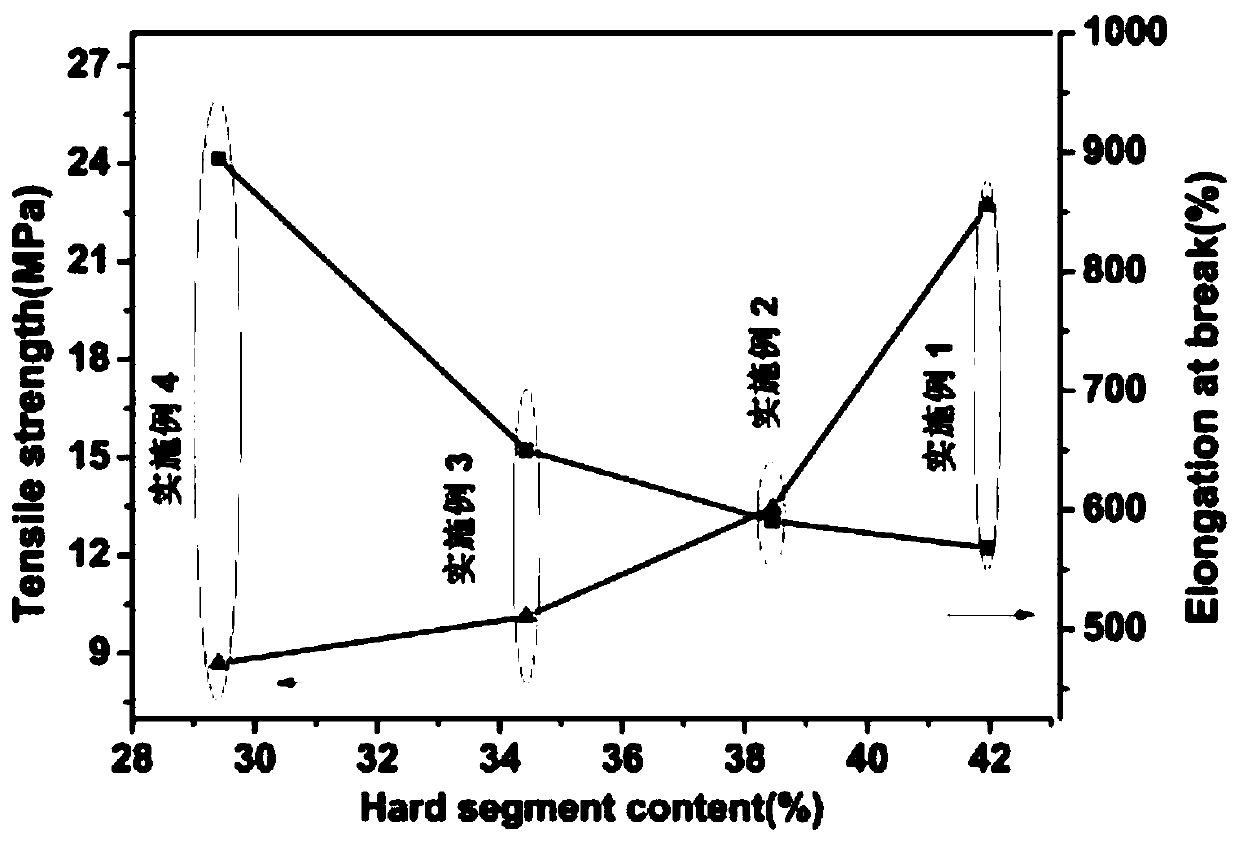

Low-TVOC polyurethane weather-proof sealant and preparation method thereof

InactiveCN105733491AGood construction performanceFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolWater flow

The invention relates to the technical field of sealant, in particular to low-TVOC polyurethane weather-proof sealant and a preparation method thereof.The low-TVOC polyurethane weather-proof sealant is prepared from polyurethane prepolymer, environment-friendly diluent, compound stabilizer, filler, solidification accelerant, bonding accelerant, a water removal agent and a thixotropic agent.The polyurethane prepolymer is prepared from polyether polyol, isocyanate, a catalyst and environment-friendly diluent.The low-TVOC polyurethane weather-proof sealant has the advantages of being low in TVOC, good in application property, quick in solidification, outstanding in weather-proof effect, free of rainwater flushing print and good in mechanical performance.After the low-TVOC polyurethane weather-proof sealant is applied, the phenomena of fracturing, pulverization and black water flowing happen in one year in the atmosphere environment, and the mechanical performance retention rate of the low-TVOC polyurethane weather-proof sealant ranges from about 80% to about 120%.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

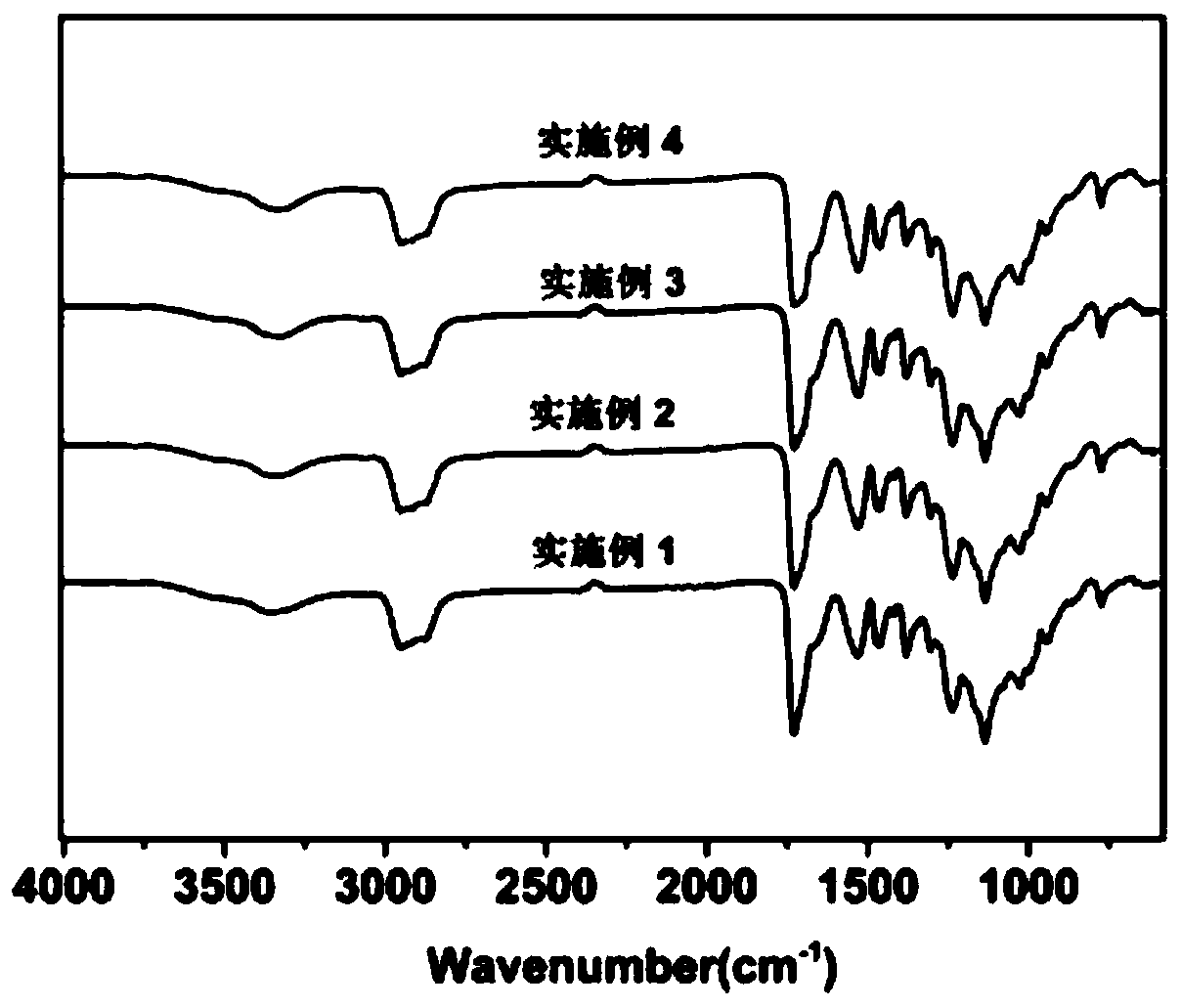

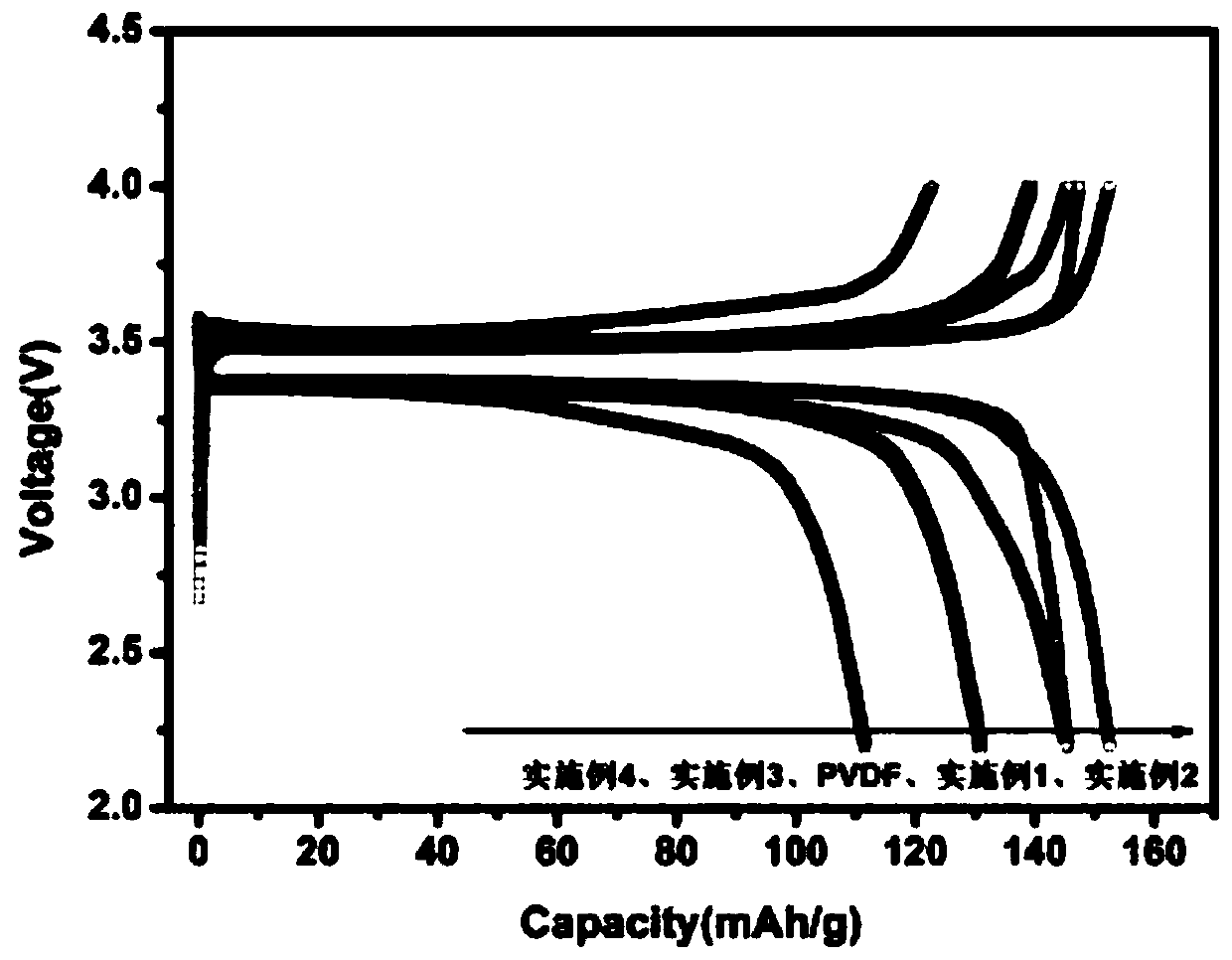

Preparation method for waterborne polyurethane binder and lithium-ion battery anode slurry containing waterborne polyurethane binder

InactiveCN110144033AImprove flexibilityNo demulsificationCell electrodesSecondary cellsHydrophilic monomerDistillation

The invention discloses a preparation method for a waterborne polyurethane binder and a lithium-ion battery anode slurry containing the waterborne polyurethane binder, and relates to the technical field of lithium ions. The preparation method for the waterborne polyurethane binder comprises the following steps: subjecting macromolecular dihydric alcohol to dehydration treatment, mixing dehydratedmacromolecular dihydric alcohol with diisocyanate, carrying out a reaction under heating, then carrying out cooling, adding a side-chain type nonionic hydrophilic monomer, carrying out a reaction under heating, then carrying out cooling, adding a micromolecular chain extender, a catalyst and a solvent, carrying out a reaction under heating, and carrying out cooling and discharging so as to obtaina prepolymer emulsion; and adding water into the prepolymer emulsion, carrying out emulsification under high-speed dispersion, then adding a diamine chain extender, and carrying out pressure-reduced distillation to remove the solvent so as to obtain a waterborne polyurethane emulsion with a side-chain structure. The polyurethane binder prepared by using the preparation method provided by the invention has good flexibility and excellent bonding performance, and is used in an anode slurry; and a button type lithium-ion battery assembled by using the anode slurry has large first discharge capacity and good cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

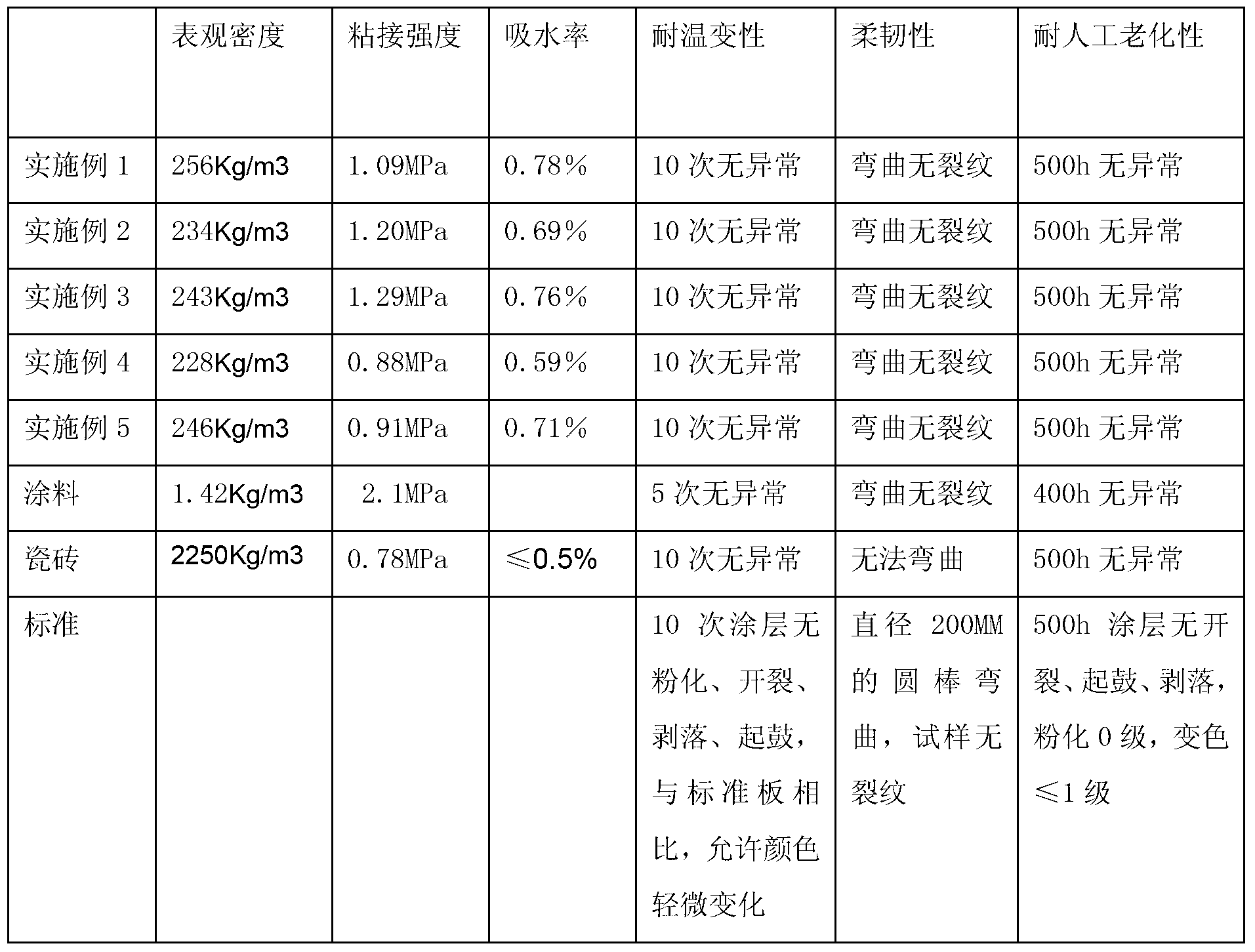

Inorganic composite flexible decorative coiled materials and producing method thereof

InactiveCN103266734ASolve empty drumSolve crackingCovering/liningsWater-setting substance layered productCelluloseGlass fiber

The invention belongs to the field of building, and discloses inorganic composite flexible decorative coiled materials. The thickness of the inorganic composite flexible decorative coiled materials is 2mm to 10mm, the inorganic composite flexible decorative coiled materials comprise an inorganic coiled material mortar layer, a decorative mortar layer is combined on the inorganic coiled material mortar layer, and reinforcing materials formed by alkali-resisting glass fiber gridding cloth or glass fiber roofing felts are arranged in the inorganic coiled material mortar layer or on the boundary of the inorganic coiled material mortar layer and the decorative mortar layer. The inorganic coiled material mortar layer is mainly formed by the following materials, by weight: 100 parts of portland cement with intensity no less than 42.5, 1.2 to 2.0 parts of cellulose, 350 to 450 parts of 50 to 100-mesh silica sand, 180 to 220 parts of coarse whiting, 1.8 to 2.2 parts of water reducing agent and 120 to 160 parts of 707 emulsion or cement-based elastic emulsion. The decorative mortar layer is mainly formed by the following materials, by weight: 150 parts of synthetic resin emulsion for maishi paint, 4 to 6 parts of coalescing agent, 8 to 12 parts of ethylene glycol, 1 to 2 parts of cellulose and 700 to 800 parts of natural color sand. The inorganic composite flexible decorative coiled materials are good in toughness, small in thickness, light in weight, good in application property, not prone to peeling off and good in weather fastness, and different decorative styles can be formed easily.

Owner:BEIJING SOLID BUILDING ENG

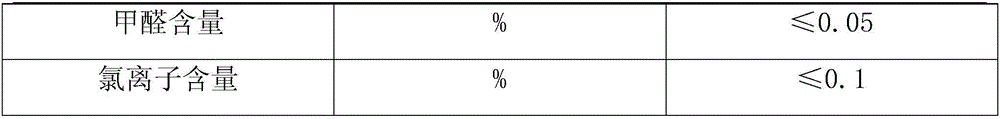

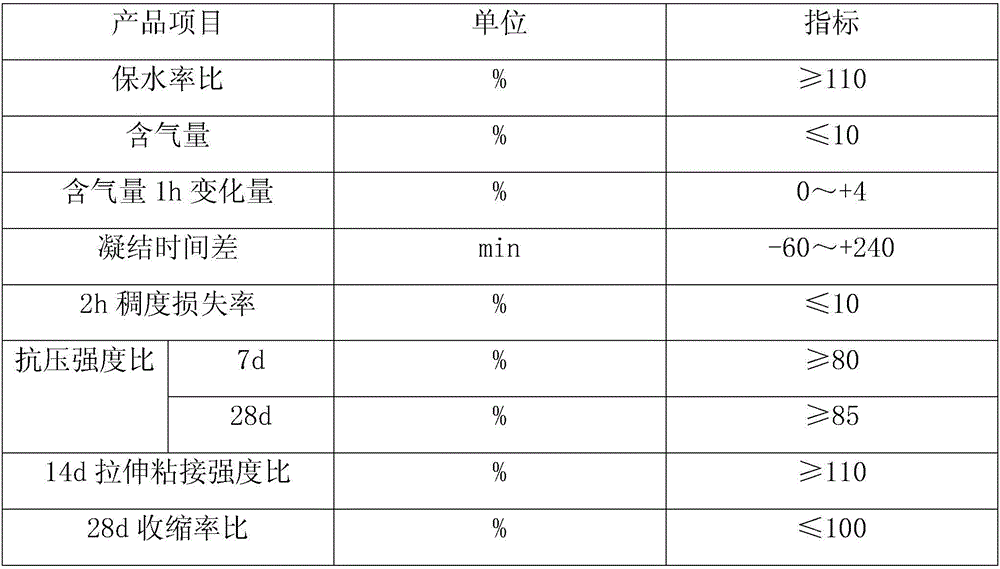

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

Elastic fluorocarbon paint and formula thereof

The invention relates to a formula of elastic fluorocarbon paint. The formula comprises the following ingredients: 40-50% of fluorocarbon resin, 15-20% of elastic resin, 0.3-0.5% of a wetting agent, 0.3-0.5% of a dispersant, 0.5-1% of a leveling agent, 15-20% of aluminium powder, 0.1-0.2% of an antifoaming agent, 0.1-0.5% of an anti-settling agent, 0-0.5% of a drier and 15-20% of a solvent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

Slag modifier and preparation method and application thereof

ActiveCN102534116AHard textureSave resourcesManufacturing convertersElectric furnaceSlagAluminum industry

The invention discloses a slag modifier which comprises the following components by weight percentage: 40-70% of aluminium dross, 10-35% of aluminium skimmings, 10-40% of active lime, 0.5-10% of fluorite, and 0-35% of calcium carbide, wherein the Al content in the aluminium dross is 15-50%, and the Al content in the aluminium skimmings is 75-95%. The slag modifier prepared by the invention is hard in quality, is not cracked, has no powder, cannot cause dust when molten steel is fed, and is beneficial to environment protection. As a large amount of aluminium dross is used, a new effective utilization way can be provided for the industrial slag, and simultaneously, the aluminium skimmings adopt leftover bits and pieces produced during processing in aluminum industry, so that the situation that regenerative aluminum processing is performed again is avoided, resources are saved, and economic benefits are outstanding.

Owner:大连环球矿产股份有限公司

Nano fluorocarbon exterior wall heat-insulating paint

The invention relates to nanometer fluorocarbon exterior wall heat insulation paint, which is prepared from ingredients according to the following weight proportion: the ratio of acrylics to fluorocarbon resin to nanometer SiO2 to titanium pigment to silicon acrylate latex to calcium carbonate to foam suppressor is 100-220 to 100-200 to 20-50 to 10-18 to 80-150 to 20-50 to 10-20. The invention makes the structure and the chemical composition part of transparent paint regulated to the most scientific and most reasonable state, and adds a few nanometer grade materials, so that the exterior wall paint is non-toxic and odorless, and accords with the requirement of environmental protection; a paint film resists water, has quite strong performances of acid and alkali resistance and mildew resistance; and the paint film can cover fine cracks. The nanometer fluorocarbon exterior wall heat insulation paint has the advantages of strong adhesive force, good heat insulation performance and low cost.

Owner:孙恒玉

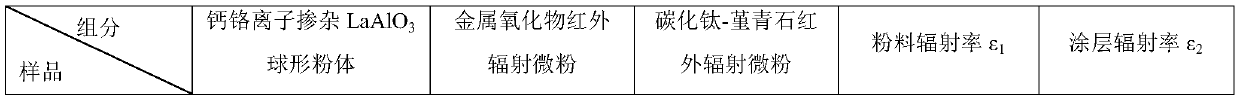

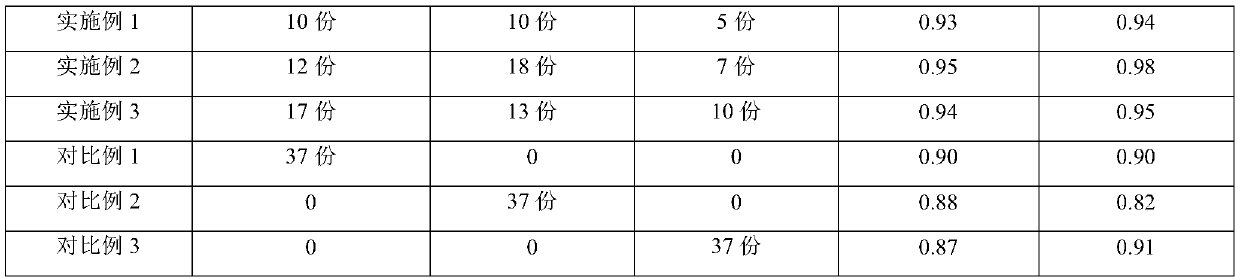

High-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating

InactiveCN110117457AImprove mechanical propertiesSolve crackingFireproof paintsChemical industryFull waveAdhesive

The invention discloses a high-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating. The coating is prepared from, by weight, 10-20 parts of LaAlO3 spherical powder doped with calcium and chromium ions, 10-20 parts of metallic oxide infrared radiation micro powder, 5-10 parts of titanium carbide-cordierite infrared radiation micro powder, 15-25 parts of filler, 0.1-0.2 part of a retardant, 30-50 parts of an adhesive, 10-20 parts of a solvent, 0.15-0.25 part of a dispersion agent, 0.1-0.35 part of a coupling agent and 0.05-0.15 part of a defoaming agent. The invention further discloses a preparation method of the coating. The coating comprises the following steps of step one, raw material preparation; step two, high temperature treatment; step three, high shearing dispersion; step four, coating preparation. The infrared radiation rate of the full-wave band of the provided energy-saving coating is 0.94-0.98, infrared radiation attenuation can be effectively prevented, after long-time using of the coating, the phenomena of cracking and coating shedding cannot occur, and the thermal shock resistance is high.

Owner:河南嘉和节能科技有限公司

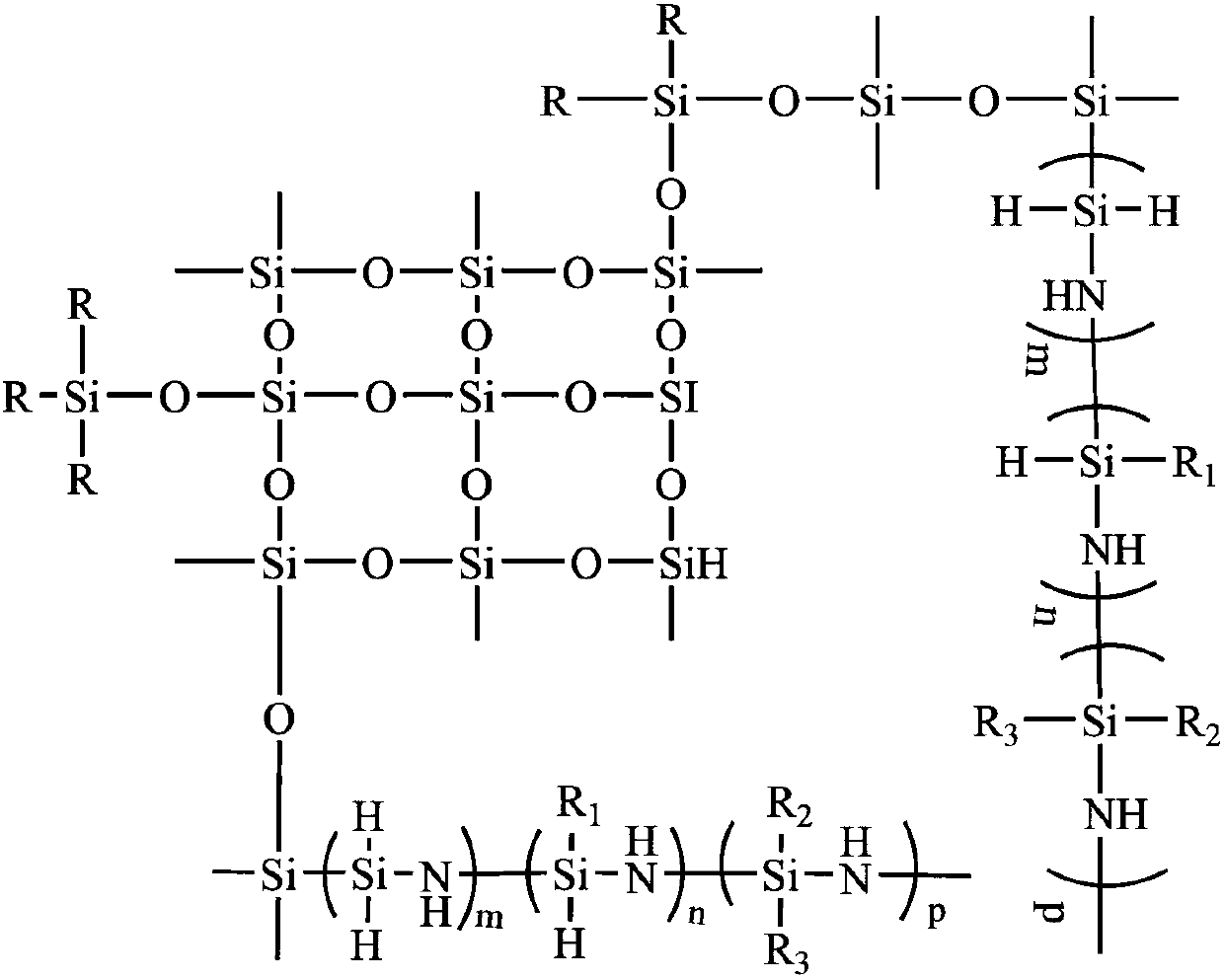

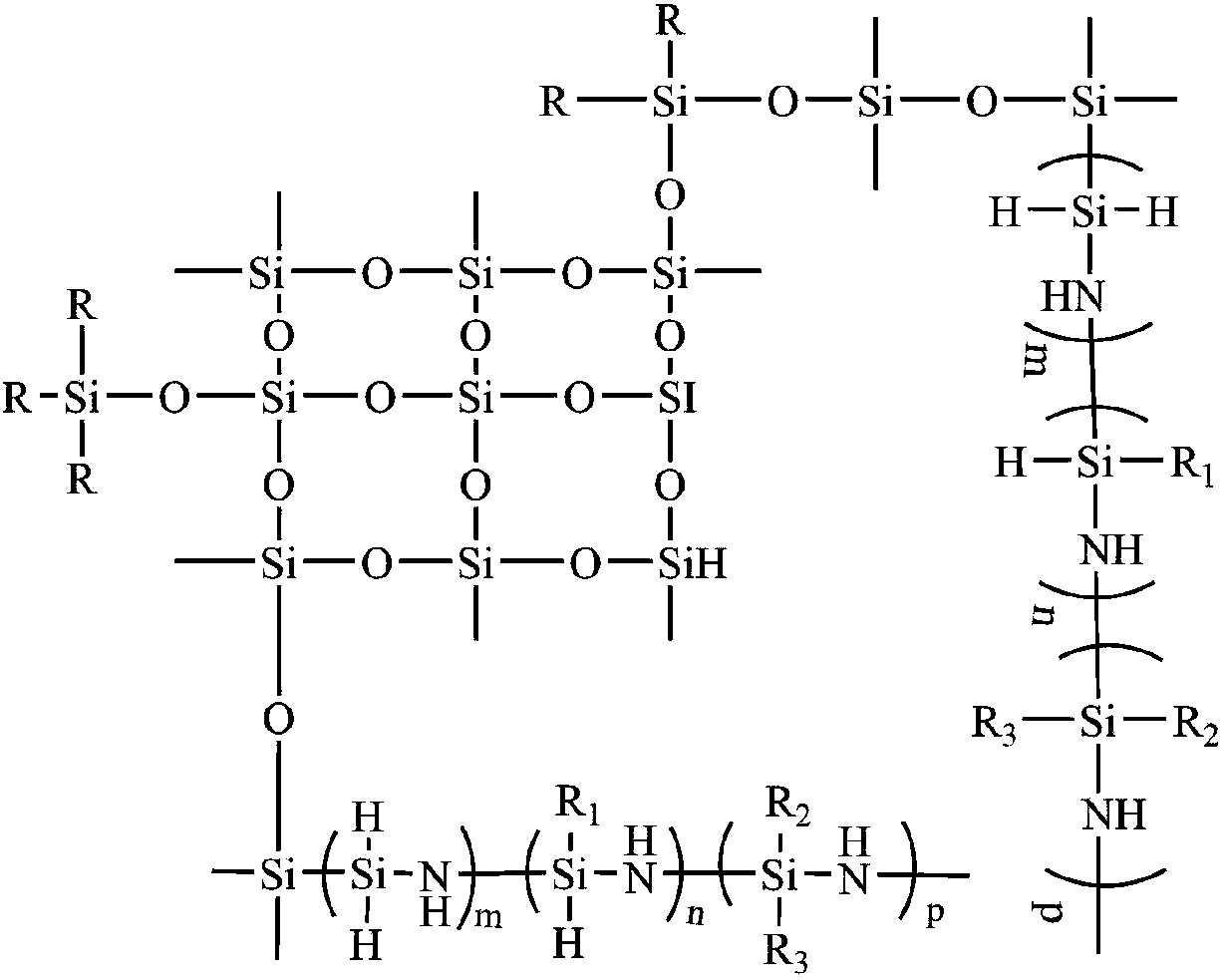

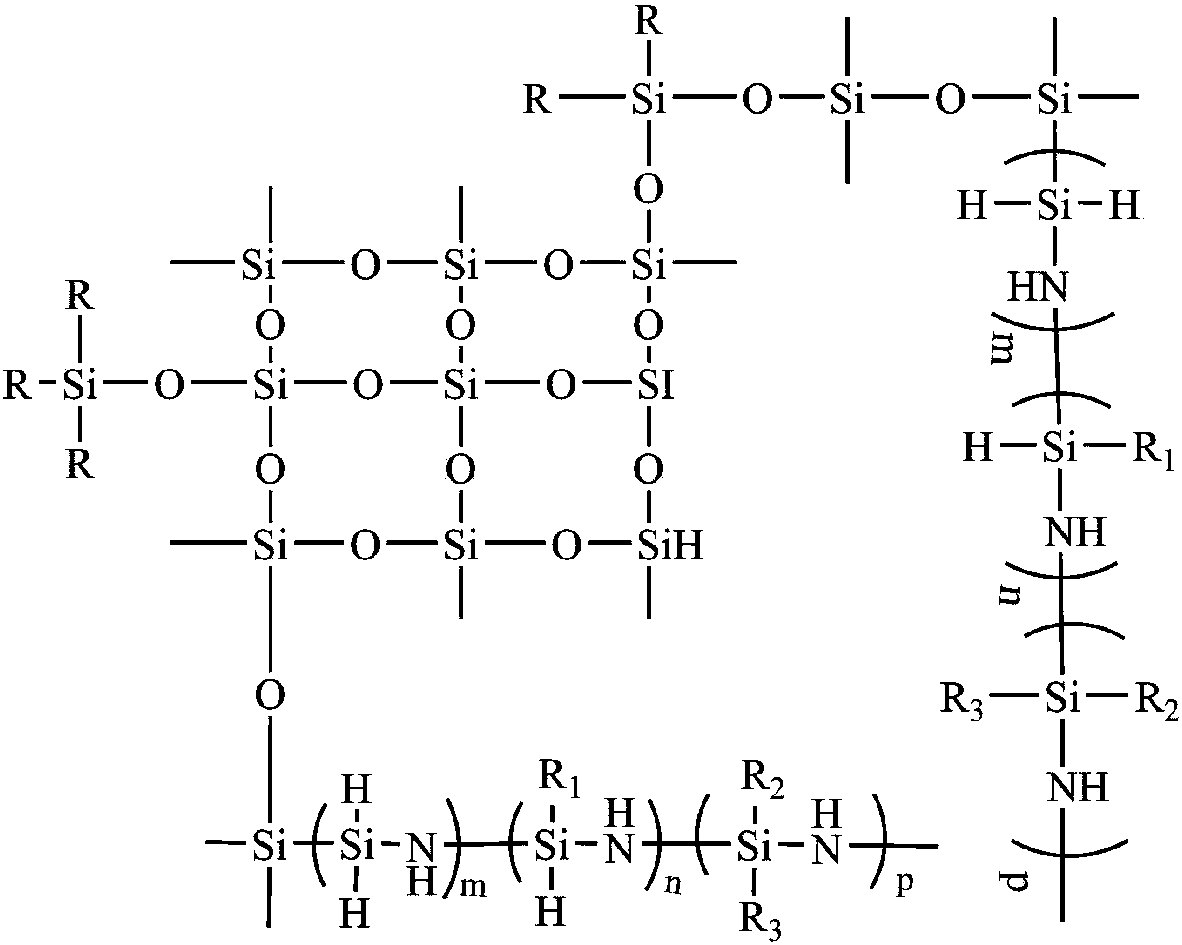

Super-hard organic silicone hydrophobic glass resin and preparation method thereof

The invention relates to super-hard organic silicone hydrophobic glass resin and a preparation method thereof. Under the catalysis of a Karsted catalyst, active silicon-hydrogen bonds and carbon-carbon double bonds in hydrogen-containing polymethylhydrogensiloxane, vinyl MQ silicone resin, polyhydroxy polysiloxane, and amino silicone oil are crosslinked, and active silicon-hydrogen bonds and hydroxyl or amino in the hydrogen-containing polymethylhydrogensiloxane, the vinyl MQ silicone resin, the polyhydroxy polysiloxane, and the amino silicone oil are crosslinked, so that three-dimensional network-shaped organic silicone resin is formed, and then in the presence of a catalyst, polysilazane reacts with hydroxyl, amino or carbon-carbon double bonds in the organic silicone resin through active -Si-H to be grafted on the molecular chain of the organic silicone resin. The glass resin provided by the invention can be self-catalyzed and cured at a room temperature, and has uniform film formation without cracking or powdering; the film has good water resistance and stain resistance, and the contact angle of water and the film formed after the glass resin coats the surface of a tile can reach 130 degrees; the transparency is good, and the light transmittance is up to 80%; and the hardness of the film is high, the pencil hardness is up to 7H or above, and the film can withstand the hightemperature of 300 DEG C.

Owner:HUNAN QIWEI TECH CO LTD

Heat-insulating material

The invention discloses a heat-insulating material which comprises the following raw materials in parts by mass: 10-25 parts of volcanic ash and 75-90 parts of environment-friendly adhesive; and the environment-friendly adhesive is prepared by mixing 100 parts of water and 6-10 parts of polyvinyl alcohol. The heat conductivity coefficient of the heat-insulating material is only 0.036; the heat-insulating material has the advantages of favorable heat-insulating property, high acid / alkali corrosion resistance and high weather resistance; the volcanic ash raw material has abundant sources, so the cost is lower; and therefore the heat-insulating material disclosed by the invention can substitute the traditional heat-insulating material, and has unique advantages in the application field of architectural coating for industrial and mining enterprises.

Owner:珠海市联达环保科技有限公司

Far infrared interior wall painting

InactiveCN101709190AGood health effectPromote circulationAntifouling/underwater paintsPaints with biocidesCelluloseAdhesive

The invention discloses a far infrared interior wall painting, which comprises the following raw materials in part by weight: dispersant 15-25, thickener 8-12, defoamer 1.5-2.5, titanium oxide 100-150, nano silicon dioxide 1-3, neutralizer 1.5-2.5, zinc oxide 1-3, soybean cellulose 1.5-2.5, kaolin 40-60, polyacrylic emulsion 150-250, film-forming agent 8-12, titanium dioxide 2-6, silicon carbide 1-2, calcium carbonate 1-3, glycol 10-30, tourmaline 160-180, triple superphosphate 200-340 and water 100-140. The preparation method of the far infrared interior wall painting comprises the following steps: 1, putting the raw materials in a reaction kettle and stirring the raw materials till the raw materials are fully and uniformly mixed for later use; 2, crushing the tourmaline by nanometer for later use; and 3, putting the mixed raw materials obtained by the step 1 into the nanometer tourmaline raw material, adding water into the resulting mixture and stirring the resulting mixture by using a stirring machine to obtain the painting of the invention. The painting of the invention has a good health-care effect on human bodies and a bacteriostatic action, avoids generating mildews when applied on an interior wall and has good wall adhesive attraction and high stability.

Owner:吴尚泉

High-temperature resistant toxicity-reducing release agent and its preparation method

ActiveCN103600446ASolve pollutionImprove protectionFoundry mouldsFoundry coresAcetic acidChemical industry

A high-temperature resistant toxicity-reducing release agent and its preparation method relate to a release agent and its preparation method. According to the invention, the problem that preparation and application processes of a present release agent pollute the environment, are harmful to the health and require high preparation cost and complex preparation method and a present release agent has poor demoulding effects is solved. The high-temperature resistant toxicity-reducing release agent is prepared from A, B, C and D, wherein A is silicone rubber; B is tetraethyl orthosilicate; C is any one of dibutyltindilaurate and dibutyltin dilaurate or a mixture of the above two compounds according to any ratio; D is ethyl acetate; and the mass ratio of A to B to C to D is 100:1-50:1-50:1-50. The method comprises the following steps: 1, mixing A, B, C and D; and 2, preparing the high-temperature resistant toxicity-reducing release agent. The method is benefit for environmental protection, minimizes harm to human body, and requires low cost and simple technology. The prepared release agent has high temperature resistance and good demoulding effect. The release agent provided by the invention can be used in the fields of national defense, aerospace, chemical industry and civilian use.

Owner:HARBIN FRP INST

Method for producing converter coolant by Bayer red mud

ActiveCN103352099AImprove cooling efficiencyDoes not take up smelting timeManufacturing convertersWater contentSodium fluosilicate

The invention discloses a method for producing converter coolant by Bayer red mud, and relates to the field of converter steelmaking. The method comprises steps of preparing Bayer red mud by using 30-40% of Fe2O3, 25-30% of SiO, 10-20% of Al2O3, 1-7% of CaO, 5-10% of Na2O and 2-5% of TiO in percentage by weight; carrying out wet magnetic separation on the Bayer red mud, to obtain 45-75% of Fe2O3, 5-15% of SiO2, 6-16% of Al2O3, 0.2-5% of CaO, 3-10% of Na2O and 1-3% of TiO2; filter-pressing the red mud after the magnetic separation to obtain 5-8% of water, adding 4-6% of water glass and 0.5-1% of sodium fluosilicate, mixing and shaping in a ball press machine, and drying until water content is 2-4%, thus obtaining the converter coolant. The converter coolant prepared by the method is high in cooling efficiency, free from smelting time occupation, convenient to regulate temperature, low in production cost, uniform in granularity, good in ball press effect, high in strength and small in dust; the converter coolant protects environment and saves resource.

Owner:武汉振海科技有限公司

Liquid aqueous multi-color granite coating and preparation method thereof

The invention discloses a liquid aqueous multi-color granite coating and a preparation method thereof, for solving the problems that a conventional aqueous granite coating is severely thickened after a multi-color coating is stored, and is large in viscosity and has easily damaged constructed multi-color particles. The liquid aqueous multi-color granite coating is prepared from the following raw materials in parts by weight: 23.0-27.0 parts of silicone acrylic emulsion, 1.0-2.0 parts of propylene glycol, 1.0-2.0 parts of filming agent, 0.1-0.3 part of defoaming agent, 8.0-14.8 parts of water, 0.1-0.3 part of preservative, 0.1-0.3 part of thickening agent and 58.0-62.0 parts of multi-color particles. According to the coating, multi-color paint protecting glue is used together with special resins, elastic emulsion and silicone acrylic emulsion special for multi-color paint, the reaction gel degrees of different components are controlled to achieve relative balance of a system, the coating is free of color bleeding phenomenon after being stored for a long time and is clear and definite in color particle after being sprayed, the later thickening phenomenon of the stored liquid aqueous multi-color granite coating is effectively solved, and the storage and construction stability is improved.

Owner:西北永新涂料有限公司

Heat-insulating material

ActiveCN103555093AGood insulation performanceGood acid and alkali corrosion resistanceAnti-corrosive paintsVolcanic ashWeather resistance

The invention discloses a heat-insulating material which comprises the following raw materials in parts by mass: 10-25 parts of volcanic ash, 75-90 parts of environment-friendly adhesive and white latex accounting for 10-30 parts on the basis of 100 parts of volcanic ash and environment-friendly adhesive; and the environment-friendly adhesive is prepared by mixing 100 parts of water and 6-10 parts of polyvinyl alcohol. The heat conductivity coefficient of the heat-insulating material is only 0.036; the heat-insulating material has the advantages of favorable heat-insulating property, high binding strength, high acid / alkali corrosion resistance and high weather resistance; the volcanic ash raw material has abundant sources, so the cost is lower; and therefore the heat-insulating material disclosed by the invention can substitute the traditional heat-insulating material, and has unique advantages in the application field of architectural coating for industrial and mining enterprises.

Owner:珠海市澜诺新材料科技有限公司

Hot-melt splicing adhesive tape

InactiveCN106800896AGood taping effectEasy to fixNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesRaw materialChemistry

The invention discloses a hot-melt splicing adhesive tape. The hot-melt splicing adhesive tape comprises a textured paper base material, a release layer and a hot melt adhesive layer, wherein the hot melt adhesive layer is prepared from the following raw materials in parts by weight: polyacrylate pressure-sensitive adhesive, diisocyanate, tackifying resin, a plasticizer and other auxiliary agents. The hot-melt splicing adhesive tape provided by the invention is very low in initial bonding property; when being heated for use, the hot-melt splicing adhesive tape can firmly stick metal pins, and the adhesive strength is more than or equal to 75N / in; the hot-melt splicing adhesive tape is easy in sticking and good in hydrolysis resistance. The hot-melt splicing adhesive tape gives full play to the oxidation resistance and anti-aging property of acrylate, and also can reach the very excellent high temperature resistance, high humidity resistance and anti-aging property even if an antioxidant is not added into the hot-melt splicing adhesive tap. The tensile strength of the hot-melt splicing adhesive tap is more than or equal to 100N / in, and the elongation at break of the hot-melt splicing adhesive tap is more than or equal to 10%. The polyacrylate pressure-sensitive adhesive used by the hot-melt splicing adhesive tape is synthesized in a way of overall copolymerization, so that the hot-melt splicing adhesive tape is simple in synthetic process and stable in quality.

Owner:HUIZHOU XINHAOYUAN DEV

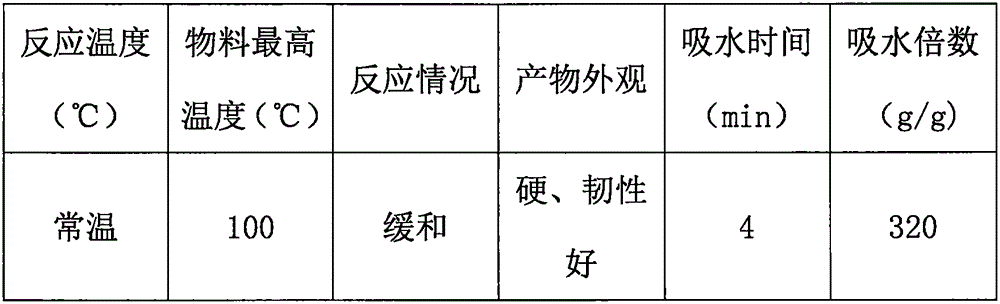

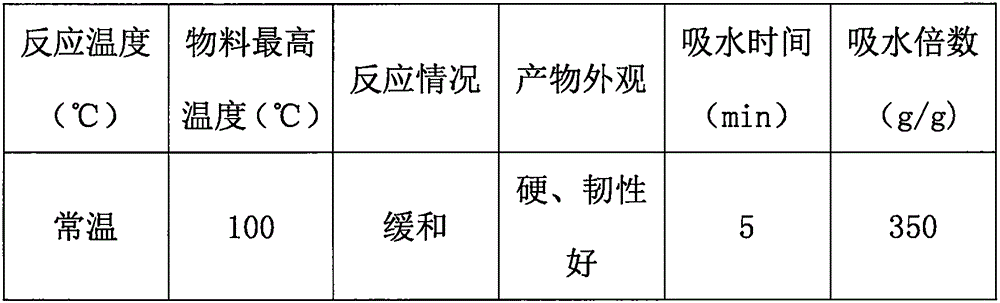

Water-retaining agent and manufacture method thereof

InactiveCN107434836AReduce heat releaseSpeed up heat dissipationAgriculture tools and machinesOrganic fertilisersIonDiammonium carbonate

The invention provides a water-retaining agent and a manufacture method thereof. The method is characterized by comprising the following steps: adding a few amount of low-concentration potassium hydroxide solution into an acrylic acid aqueous solution for neutralization, neutralizing with ammonium carbonate, controlling neutralization degree of acrylic acid to 70-75%, adding acrylamide, a cross-linking agent N,N'-methylene bisacrylamide, an inducer potassium persulphate and potassium sulfite to carry out normal-temperature synthesis, mixing with a rooting agent naphthylacetic acid and an anti-bacteria agent Xitujunke and granulating, and drying. During the whole synthesis, potassium and ammonium ion compounds which are beneficial to plants are adopted; by normal-temperature synthesis, energy consumption is saved; the process is safe and reaction time is short; and the preparation method is simple, and the prepared water-retaining agent has advantages of large molecular weight, less powder, fast water absorption speed, good water retention and antibacterial and root-promoting effects.

Owner:YANGXIAN COUNTY ZHUHUAN ORGANIC IND TECH CONSULTATION CO LTD

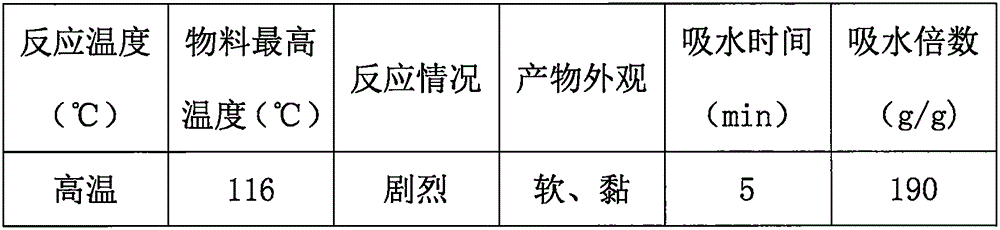

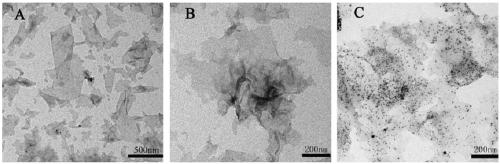

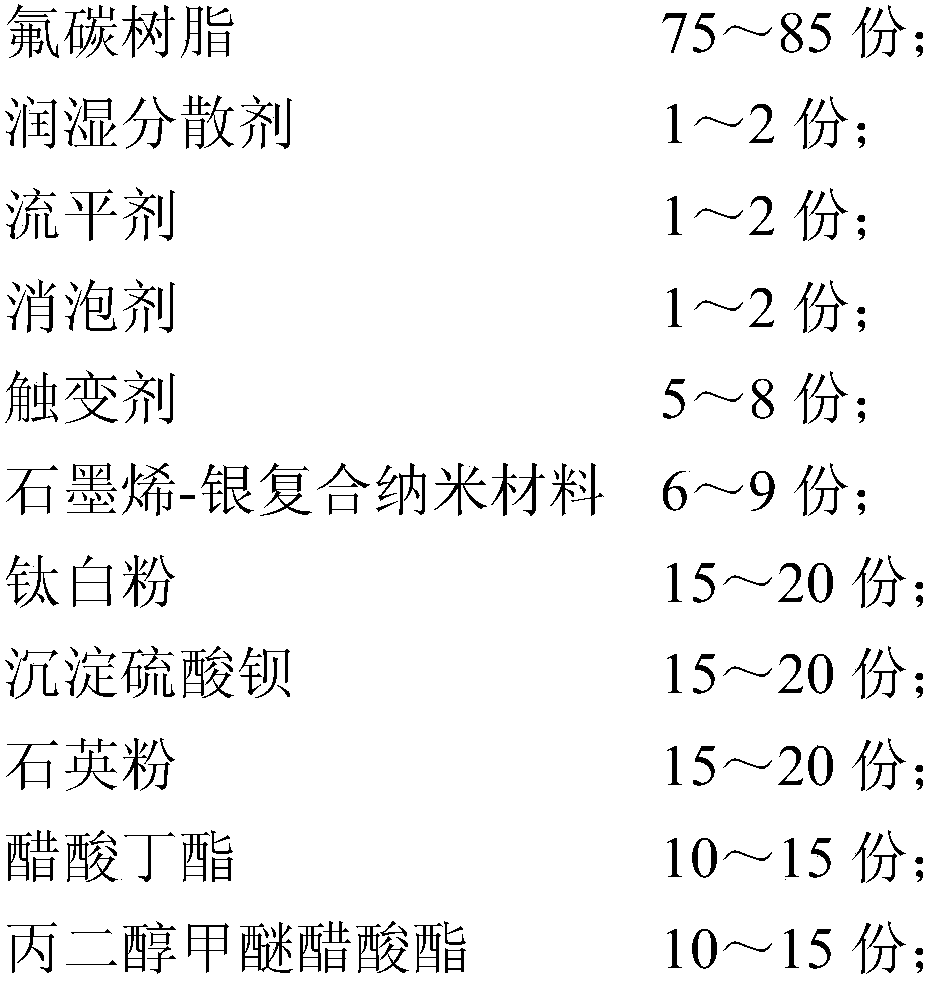

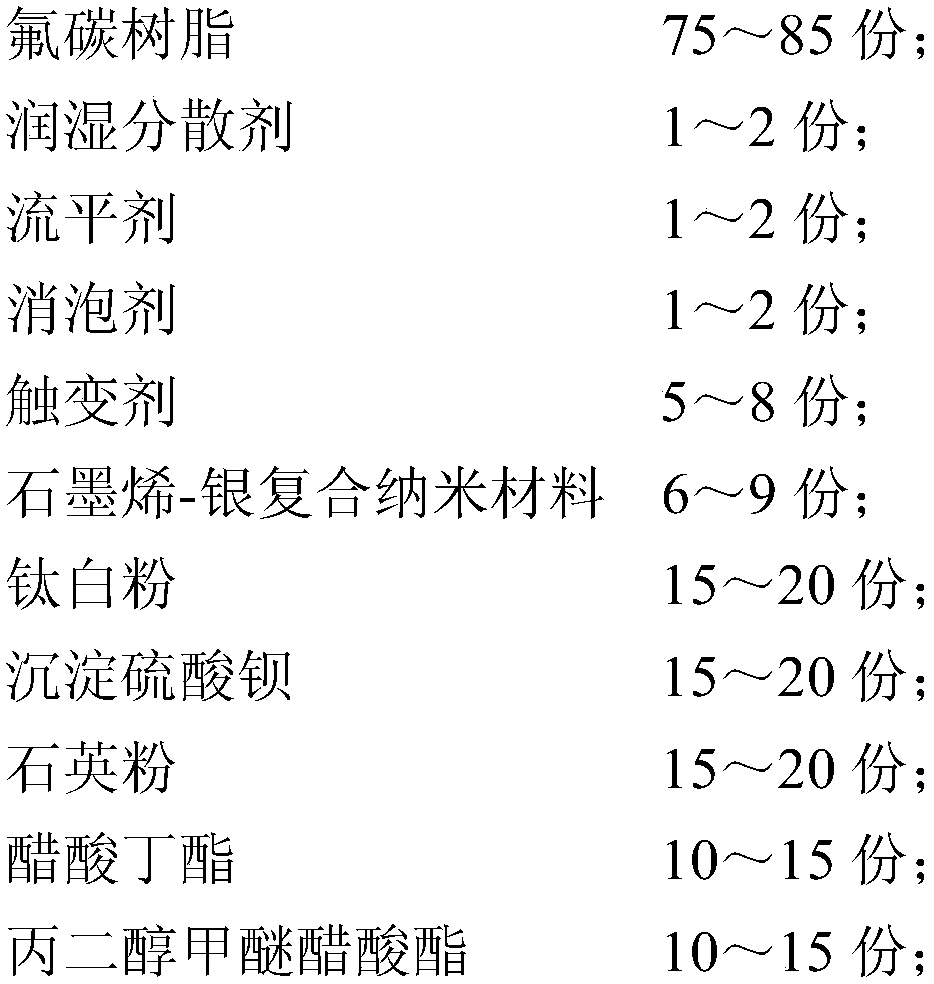

Graphene-silver antibacterial and antifouling fluorocarbon coating, and preparation method and application thereof

PendingCN108948832AStable antibacterial and antifouling propertiesSlow recoveryAntifouling/underwater paintsPaints with biocidesSurface energyFluorocarbon Resins

The invention belongs to the technical field of coatings, and specifically relates to a graphene-silver antibacterial and antifouling fluorocarbon coating, and a preparation method and an applicationthereof. The graphene-silver antibacterial and antifouling fluorocarbon coating comprises a component A and a component B, wherein the component A comprises the following components: fluorocarbon resin, a wetting dispersant, a leveling agent, an antifoaming agent, a thixotropic agent, a graphene-silver composite nanometer material, titanium dioxide, precipitated barium sulfate, quartz powder, butyl acetate and propylene glycol methyl ether acetate; and the component B comprises an isocyanate curing agent. According to the invention, due to introduction of the graphene-silver composite nanometer material, a paint film has good adhesion force, impact resistance, hydrophobicity, stable broad-spectrum antibacterial property and antifouling property; in addition, through selection of the fluorocarbon resin with a fluorine content of no less than 26%, glossiness, aging resistance and mechanical properties of the paint film are improved; meanwhile, low surface energy of the paint film is guaranteed; and the paint film prepared from the coating provided by the invention has strong hydrophobicity.

Owner:洛阳双瑞防腐工程技术有限公司

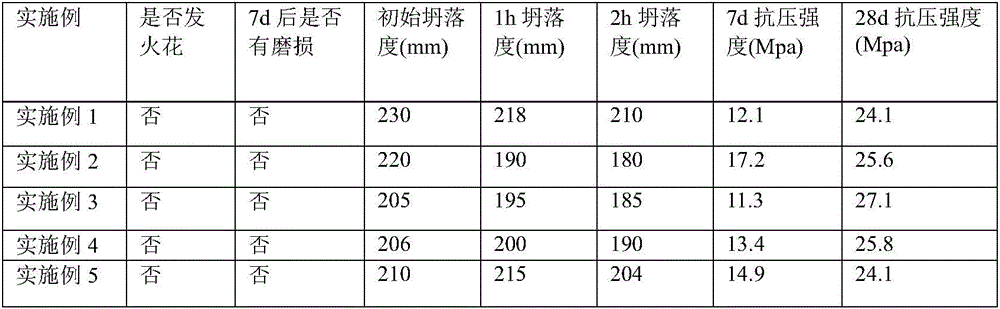

Non-sparking wear-resisting concrete and method for carrying out floor construction through concrete

InactiveCN106587823AImprove wear resistanceStrong decorationCeramicwareFlooringFire retardantHigh polymer

The invention discloses non-sparking wear-resisting concrete and a method for carrying out floor construction through the concrete. The non-sparking wear-resisting concrete is prepared from, by weight, 3.42-4.45 parts of conductive powder, 0.5-2.5 parts of common sand, 3.2-4.88 parts of coarse aggregate, 2-2.2 parts of SBS high polymer modified emulsified asphalt, 0.5-1.2 parts of cement, 1 part of water and 0.4-0.8 part of an additive. The additive is a combination of one or more of a fire retardant, a wear resisting agent, a foaming agent, a carbon forming agent, a carbon catalyst, a water reducing agent and a pumping agent. The conductive powder is a combination of one or more of spherical silicon-based conductive powder, electric mica powder, conductive titanium dioxide and conductive barium sulfate. The non-sparking wear-resisting concrete can be widely applied to ground construction of combustible product warehouses, production areas with sparks prone to being generated or explosive plants, hangars and other areas with high requirements for the fireproof degree and wear resisting degree.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG +1

Method of producing light-calcined magnesia with powdery tailings of magnesite

ActiveCN106145716AAvoid pellet pulverizationRealize industrial productionLime productionEconomic benefitsCalcination

A method of producing qualified light-calcined magnesia with powdery tailings of magnesite. In the method, the powdery tailings of magnesite, of which the content of MgO is not less than 44%, is employed as a raw material. The method includes the processes of modifying and aging the powdery tailings of magnesite, pelletizing the powdery tailings of magnesite, and performing light calcination. The method successfully maintains the strength of pellets during calcination, and effectively solves a problem of pulverization during the light calcinations of the magnesite and can produce the qualified light-calcined magnesia pellet product that satisfies the HGT 2573-2012 industrial light magnesia related grade standard. The method tightly combines a magnesite lump ore roasting process in the prior art and achieves utilization of the powdery tailings of magnesite by means of the roasting equipment that is applied for roasting the lump ore in industry at present without much transformation. The method simplifies the recycling utilization process of the powdery tailings of magnesite, greatly reduces production energy consumption and improves economic benefit.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Adhesive for preparing iron powder ball using iron ore powder and its prepared ironpowder ball

The invention relates to an iron ore powder preparing iron powder ball bonding agent and the iron powder ball. It belongs to metallurgy industry blast furnace iron making technique field. The bonding agent material and its amounts by weight are water glass saturated solution 70-80, potassium aluminum sulfate 8-9, tetra-boron oxide 10-15, sulfur 7.5-8.5, organic dispersing agent, and water 20-25. The preparing method mixing the bonding agent and the iron ore powder by weight; using ball press to form iron powder wet ball with 3-6cm diameter; naturally drying to gain iron powder ball. The bonding agent makes the iron powder ball have good high temperature sphericity and intension without agglomeration to reduce preparing cost, makes the iron powder have good oxygen permeability and diathermancy to reduce energy consumption. The invention can apply in various iron powder preparing iron powder ball and blast furnace iron making.

Owner:姜文平 +1

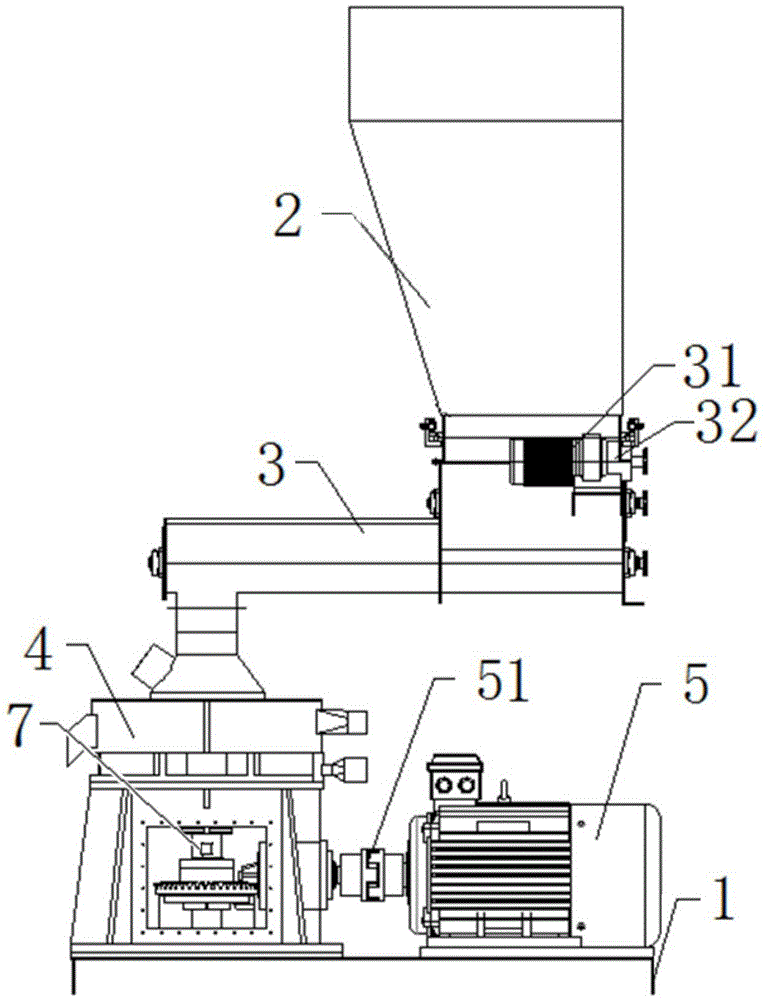

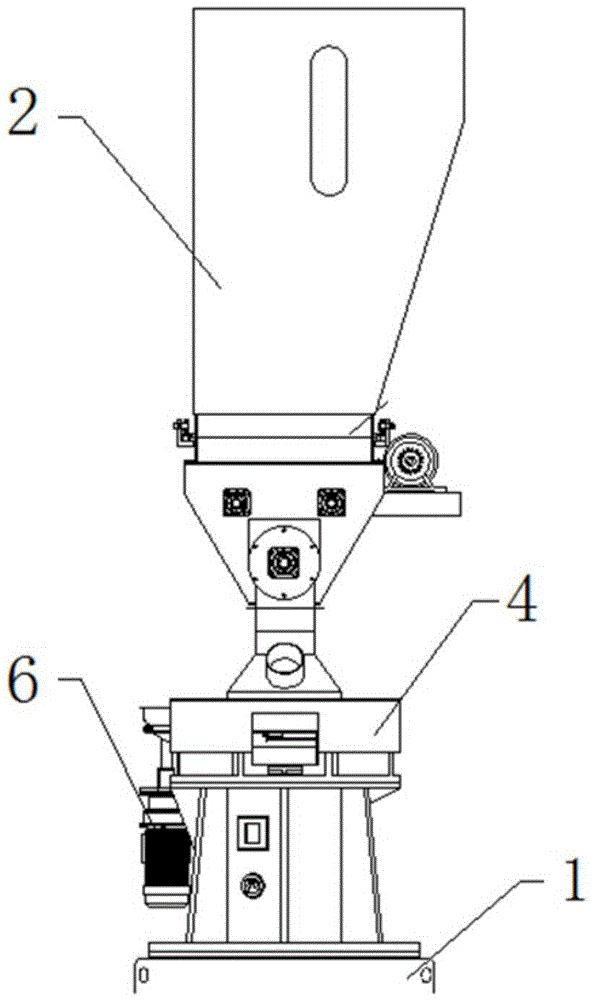

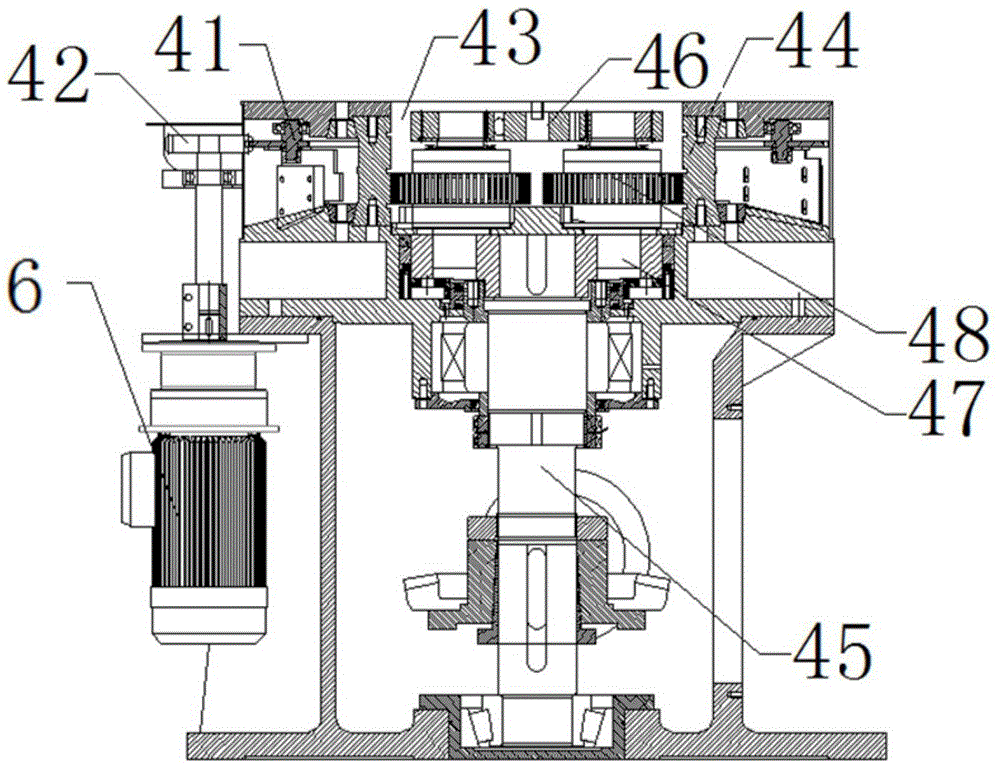

High-strength granulation machine

ActiveCN105617935AImprove carrying capacitySmall footprintGranulation by pressingElectric machineryUltimate tensile strength

The invention discloses a high-strength granulation machine which mainly comprises a support, a to-be-granulated material bin, a feeder, a pressing device, a main motor, a distributing motor and a pressure self-regulating device. The high-strength granulation machine has the technical advantages that spiral bevel gears comprise gear shafts and bevel gears which mesh with one another in pairs, accordingly, the raw material utilization rate can be increased, and the yield can be increased by 20% at least as compared with the traditional machine with identical power; the high-strength granulation machine comprises the pressure self-regulating device, accordingly, pressures of a spindle pressure plate and pressure rollers can be automatically regulated, the high-strength granulation machine is low in energy consumption and is environmentally friendly, and the service life of equipment can be prolonged; products produced by the aid of the high-strength granulation machine are high in granular forming rate and strength and basically free of cracking or powder; the high-strength granulation machine has obvious merits when used for straw materials and has a broad application prospect.

Owner:TAICANG TAIBANG ELECTRONICS TECH

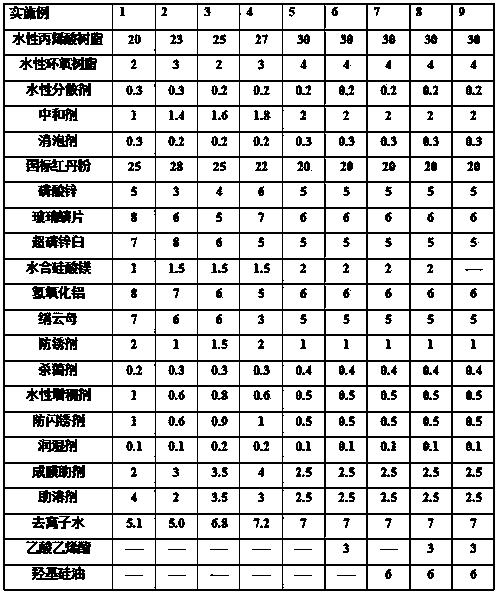

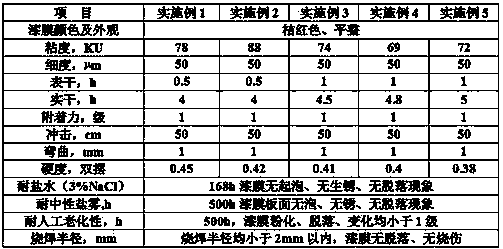

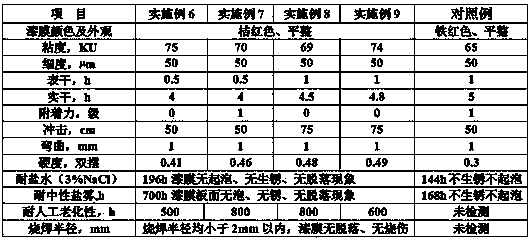

Water-based acrylic red lead rust-proof paint and preparation method thereof

The invention relates to a water-based acrylic red lead rust-proof paint and preparation method thereof, and belongs to the technical field of coatings. The water-based acrylic red lead rust-proof paint comprises the following components in parts by weight: 20-30 parts of water-based acrylic resin, 2-5 parts of water-based epoxy resin, 20-30 parts of red lead powder, 3-6 parts of zinc phosphate, 5-8 parts of super zinc phosphate, 5-8 parts of glass flake, 5-8 parts of aluminum hydroxide, 3-7 parts of sericite, 0.2-0.3 part of a water-based dispersant, 0.2-0.3 part of a defoaming agent, 0.5-1 part of hydrated magnesium silicate, 0.2-0.4 part of a sterilizing agent, 0.5-1 part of a thickener, 1-2 parts of neutralizer, 0.5-1 part of an anti-flash rust agent, 2-4 parts of a coalescing agent, 2-4 parts of cosolvent, 0.1-0.2 part of a wetting agent and 5.0-7.2 parts of deionized water. The product is high in drying speed and strong in antiseptic capacity; the salty spray resistance can be over 500h; after carrying out artificial aging resisting test for 500h, no atomization and falling are caused to the paint film.

Owner:JIANGSU HUAXIA PAINT MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com