Non-sparking wear-resisting concrete and method for carrying out floor construction through concrete

A technology for concrete and floor, applied in the field of building concrete, can solve the problems of complex floor concrete construction method, unable to meet various production needs, single function of floor concrete, etc., achieve high strength, low friction, prevent electrostatic sparks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

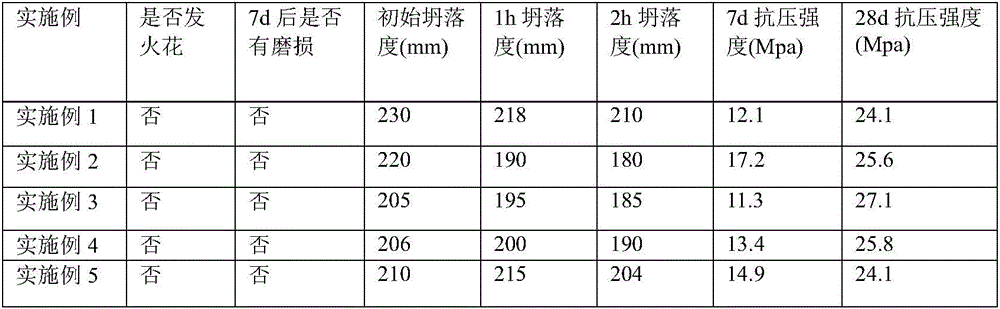

Examples

Embodiment 1

[0029] Conductive powder 3.42 parts, ordinary sand 0.5 parts, coarse aggregate 3.2 parts, SBS polymer modified emulsified asphalt 2 parts, cement 0.5 parts, water 1 part, admixture 0.4 parts. The admixture is a combination of flame retardant, anti-wear agent, foaming agent, carbon forming agent, carbon catalyst, water reducing agent and pumping agent. The conductive powder is spherical silicon-based conductive powder, the ordinary sand is quartz sand, the flame retardant is aramid fiber, the coarse aggregate is limestone, and the wear-resistant agent is α-crystalline SiO 2 Powder and cement are ordinary Portland cement with a grade strength of 42.5.

Embodiment 2

[0031] 4.45 parts of conductive powder, 2.5 parts of ordinary sand, 4.88 parts of coarse aggregate, 2.2 parts of SBS polymer modified emulsified asphalt, 1.2 parts of cement, 1 part of water, and 0.8 parts of admixture. The admixture is a combination of flame retardant, anti-wear agent and blowing agent. The conductive powder is a combination of spherical silicon-based conductive powder, electric mica powder, conductive titanium dioxide and conductive barium sulfate. Spherical silicon-based conductive powder is made of powdered quartz mineral, polymer dispersant, crystalline SnCl 4 and SbCl 3 Made of superfine spherical composite conductive powder. Ordinary sand is quartz sand with a fineness modulus of 2.2 to 2.8. The flame retardant is a combination of aramid fibers, carbon fibers, chlorinated paraffin particles, chlorinated rubber particles, aluminum hydroxide particles and magnesium hydroxide particles. The coarse aggregate is marble, and the diameter of the coarse agg...

Embodiment 3

[0033] 3.42 parts of conductive powder, 0.78 parts of ordinary sand, 4.2 parts of coarse aggregate, 2.1 parts of SBS polymer modified emulsified asphalt, 1.11 parts of cement, 1 part of water, and 0.66 parts of admixture. The admixture is a combination of flame retardant, anti-wear agent and foaming agent. Conductive powder is a combination of spherical silicon-based conductive powder and electric mica powder. Spherical silicon-based conductive powder is made of powdered quartz mineral, polymer dispersant, crystalline SnCl 4 and SbCl 3 Made of superfine spherical composite conductive powder. Ordinary sand is corundum with a fineness modulus of 2.2 to 2.8. The flame retardant is a combination of aramid fibers, carbon fibers, chlorinated paraffin particles, chlorinated rubber particles, phosphorus-containing resin particles, polyethylene particles, aluminum hydroxide particles and magnesium hydroxide particles. The coarse aggregate is dolomite. The wear agent is α-crystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com