Pomegranate-like structured composite material preparation method

A composite material, pomegranate technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve the problems of consumption of silicon materials and electrolytes, complex preparation methods, etc., to achieve good mechanical support, preparation Simple method and easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

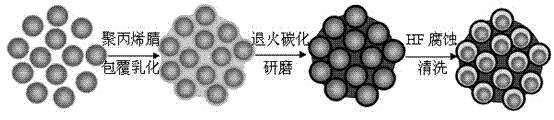

[0050] Example 1 Preparation of pomegranate-like structure composite material

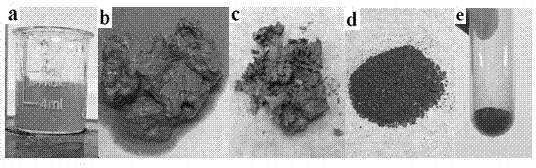

[0051] The experimental steps are as follows: Dissolve 100mg of polyacrylonitrile (PAN) in 4ml of N,N-dimethylformamide (DMF), stir and heat to dissolve to form a polyacrylonitrile solution. After the polyacrylonitrile is completely dissolved, weigh 60 mg of silicon nanoparticles and pour them into the polyacrylonitrile solution, ultrasonically disperse for 10 minutes, and then magnetically stir for 6 hours ( image 3 a). After the silicon powder is fully dispersed in the polyacrylonitrile solution, add excess deionized water while stirring, the polyacrylonitrile solution will emulsify when it meets water, and form a cement-like solid together with the silicon powder. Remove the cement-like precursor ( image 3 b), into a ceramic crucible.

[0052] In a vacuum atmosphere, use a tube furnace at a heating rate of 10°C / min to heat the obtained precursor at 1000°C for 2 hours, then cool down natural...

Embodiment 2

[0054] Example 2 Battery Preparation and Battery Assembly

[0055] Stir the pomegranate-like structure composite material in Example 1, conductive agent (Super P carbon black) and binder (sodium alginate water-based binder) according to the ratio of 8:1:1 and then coat it on the copper foil , with a thickness of 50 μm. Put it into a vacuum drying oven and dry it at 100°C (about 2h). After taking it out, cut the copper foil coated with the electrode material into pieces. The diameter of the punch of the cutting machine is 11.6mm. After pressing the pieces, put them into a vacuum drying oven and dry them at 100°C (about 3h). Prepare the working electrode.

[0056] Assembly of the battery: a metal lithium sheet is used as the counter electrode, a porous polypropylene film is used as the separator, and a 1 mol L -1 The mixed solution of ethylene carbonate and dimethyl carbonate of lithium hexafluorophosphate was used as the electrolyte (volume ratio 1:1), and a 2032 button bat...

Embodiment 3

[0058] Example 3 Structural characterization of pomegranate-like structure composites

[0059] Figure 4 It is a low-magnification scanning electron microscope (SEM) photo of the prepared pomegranate-like structure silicon-carbon lithium-ion battery electrode material. The particle morphology of hollow pomegranate-like structure composite samples can be seen from the low-magnification SEM images. Figure 4 b shows the distribution of sample particles in a certain range. It can be seen from the figure that the ground sample particles are not regular, but the particle size has a certain span. In addition to some sample particles with larger diameters, there are some fine particles at the bottom. Generally, the size of the sample particles is between 1-50 μm. Figure 4 a is a slightly higher magnification scanning electron microscope image, showing the whole picture of a single sample particle. As can be seen from this figure, the particle diameter of this sample is about 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com