Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Solve empty drum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

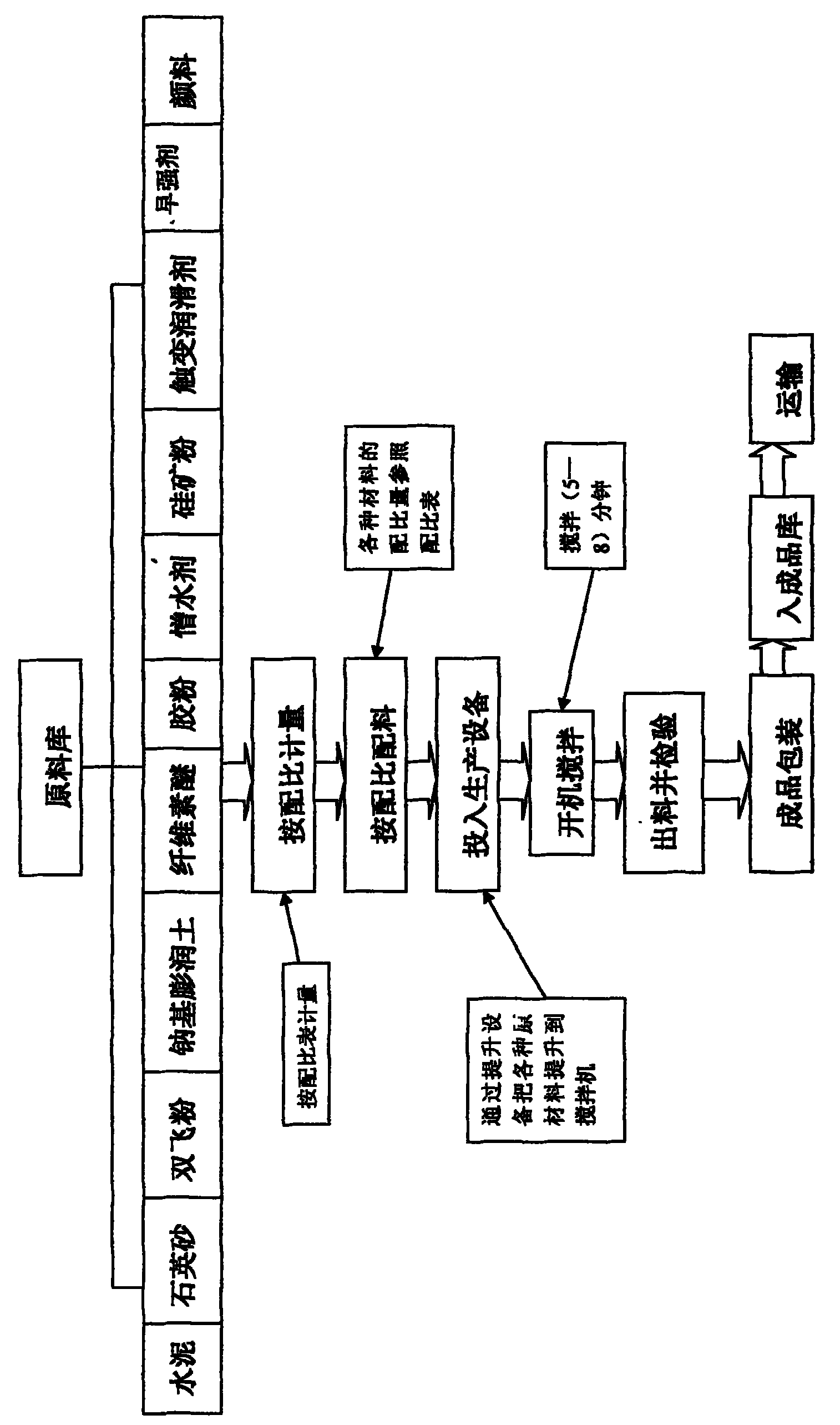

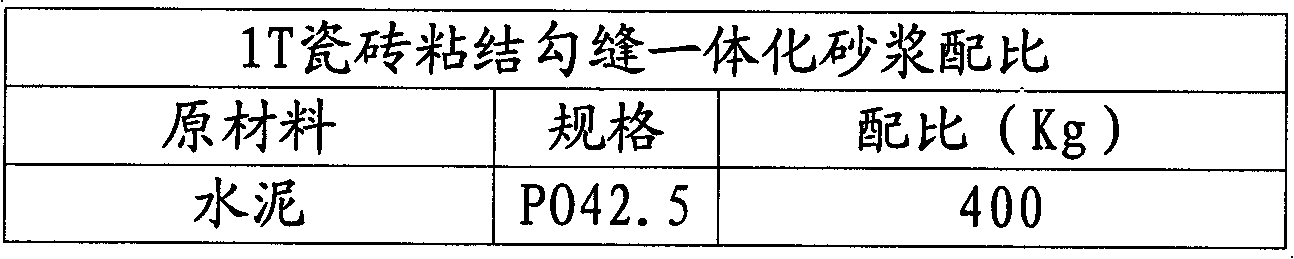

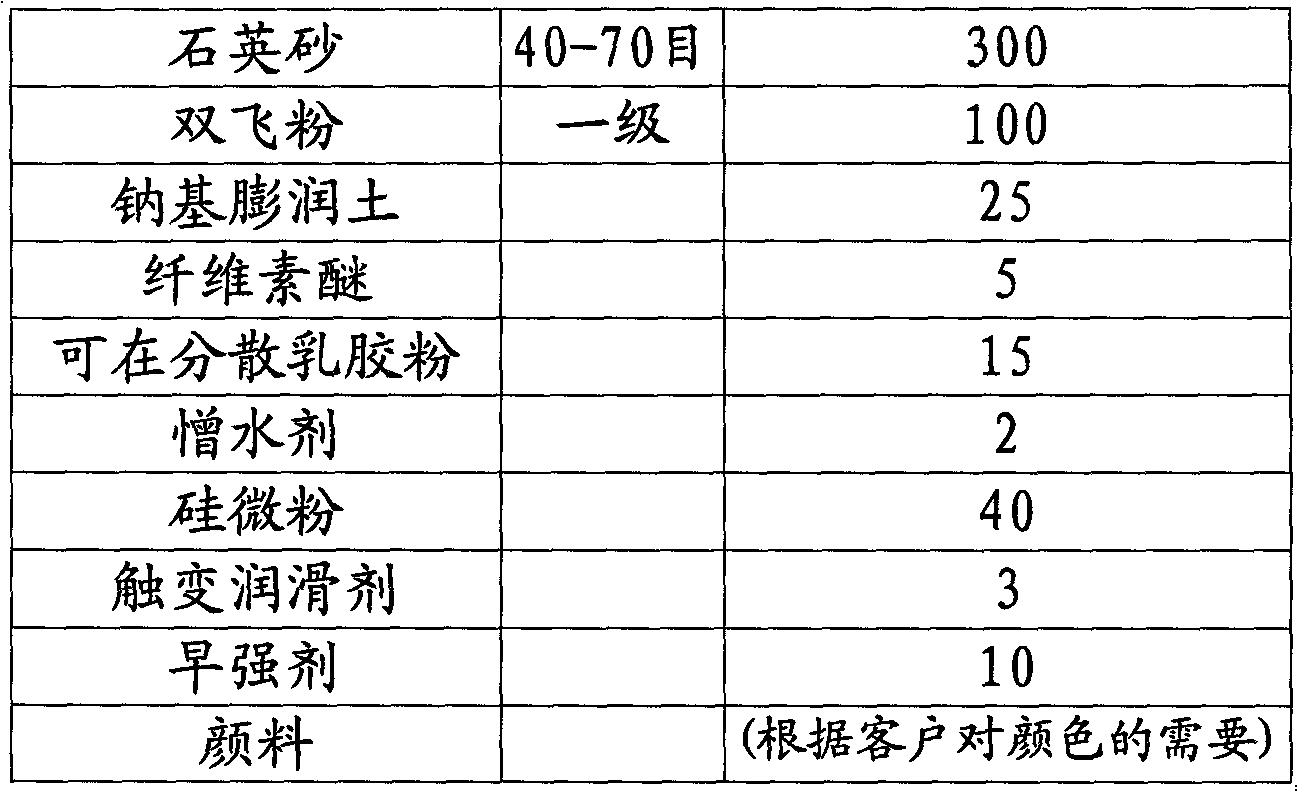

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

Bottom layer brushing gypsum and application thereof

The invention discloses a bottom layer brushing gypsum, which is prepared by mixing the following components in parts by weight: 200-500 parts of building gypsum, 485-785 parts of quartz sand, 3 parts of regulator, 5 parts of inorganic gel, 0.2-0.5 part of retarder and 2 parts of anti-cracking agent, wherein the quartz sand is one or the mixture of more than two of the quartz sands of 30 meshes, 40 meshes and 60 meshes in any proportion, the regulator is hydroxypropyl methyl cellulose, the inorganic gel is sodium bentonite, the retarder is a special retarder for polyphosphate gypsum, and the anti-cracking agent is lignocellulose; and the building gypsum is prepared by desulfurized gypsum according to the following method that the desulfurized gypsum enters a boiling calcinator after being pre-dried at the temperature of 80-90 DEG C, is calcined at the temperature of 120-130 DEG C, then is added into an impact type flour mill to be ground, and is prepared into the building gypsum after being cooled and aged. The invention has strong adhesive force, effectively inhibits the phenomenon of shrinkage cracking in plastering, and has good water resistance.

Owner:上海每天节能环保科技股份有限公司

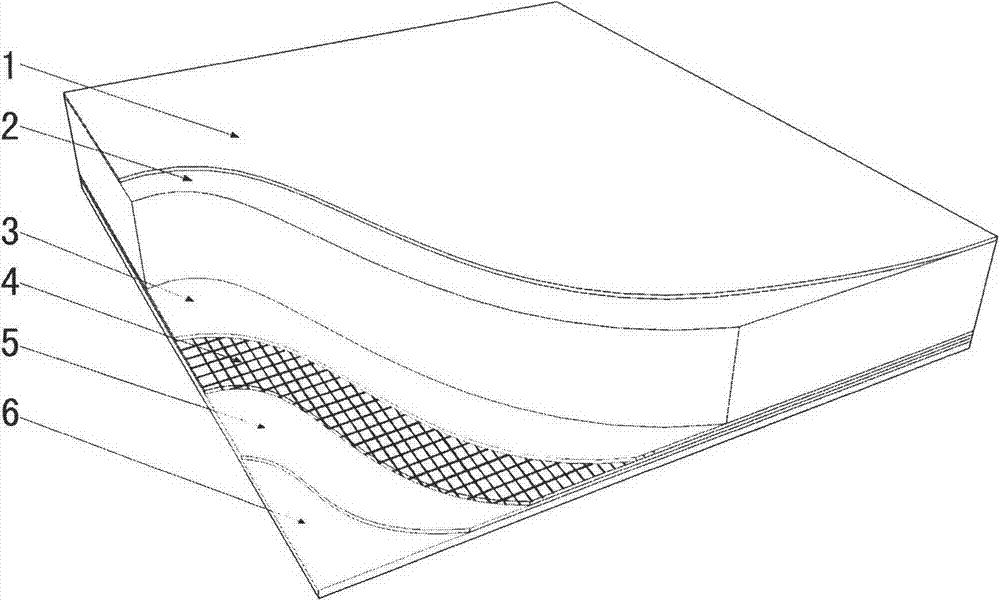

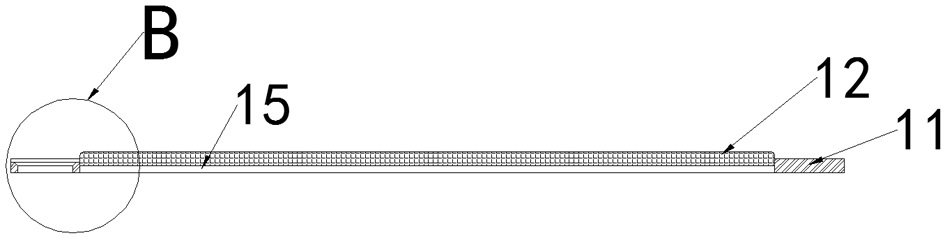

Inorganic composite flexible decorative coiled materials and producing method thereof

InactiveCN103266734ASolve empty drumSolve crackingCovering/liningsWater-setting substance layered productCelluloseGlass fiber

The invention belongs to the field of building, and discloses inorganic composite flexible decorative coiled materials. The thickness of the inorganic composite flexible decorative coiled materials is 2mm to 10mm, the inorganic composite flexible decorative coiled materials comprise an inorganic coiled material mortar layer, a decorative mortar layer is combined on the inorganic coiled material mortar layer, and reinforcing materials formed by alkali-resisting glass fiber gridding cloth or glass fiber roofing felts are arranged in the inorganic coiled material mortar layer or on the boundary of the inorganic coiled material mortar layer and the decorative mortar layer. The inorganic coiled material mortar layer is mainly formed by the following materials, by weight: 100 parts of portland cement with intensity no less than 42.5, 1.2 to 2.0 parts of cellulose, 350 to 450 parts of 50 to 100-mesh silica sand, 180 to 220 parts of coarse whiting, 1.8 to 2.2 parts of water reducing agent and 120 to 160 parts of 707 emulsion or cement-based elastic emulsion. The decorative mortar layer is mainly formed by the following materials, by weight: 150 parts of synthetic resin emulsion for maishi paint, 4 to 6 parts of coalescing agent, 8 to 12 parts of ethylene glycol, 1 to 2 parts of cellulose and 700 to 800 parts of natural color sand. The inorganic composite flexible decorative coiled materials are good in toughness, small in thickness, light in weight, good in application property, not prone to peeling off and good in weather fastness, and different decorative styles can be formed easily.

Owner:BEIJING SOLID BUILDING ENG

A-level flame-retardant modified polystyrene board heat-insulating system

InactiveCN103452195ASolve the weakness of poor fire performanceSolve empty drumHeat proofingFire proofingFoaming agentPolystyrene

The invention discloses an A-level flame-retardant modified polystyrene board heat-insulating system, which comprises a base layer, a bonding layer, a heat-insulating layer, a plastering layer and a decorative finish layer sequentially from inside to outside, wherein the heat-insulating layer, the bonding layer and the base layer are fixed through connecting pieces; the heat-insulating layer includes an A-level flame-retardant modified polystyrene board; and the A-level flame-retardant modified polystyrene board comprises the following components in parts by weight: 20 to 25 parts of flame-retardant polystyrene resin, 0.4 to 0.5 part of foaming agent, 40 to 50 parts of talcum powder, 6 to 10 parts of aluminum hydroxide, 2 to 4 parts of surfactant and 3 to 5 parts of curing agent. The fireproof performance of the system reaches level A, so the defect that the existing traditional organic heat-insulating board heat-insulating system has low fireproof performance is solved; and the heat-insulating layer of the system adopts the A-level flame-retardant modified polystyrene board and is low in heat conductivity coefficient, so various potential quality hazards in slurry heat-insulating systems that on-site construction quality is difficult to control, heat-insulating performance cannot reach to the standard, and hollowing, dropping and cracking phenomena occur easily are overcome.

Owner:ANHUI ZHONGRUI DECORATION MATERIALS GRP

Anhydrite-based light plastering mortar and preparation method thereof

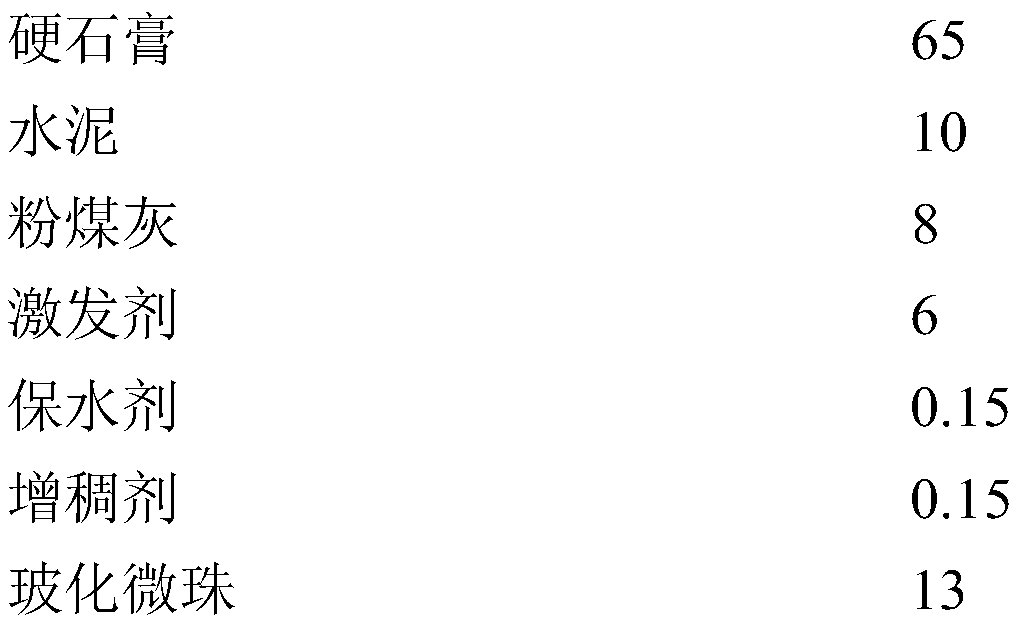

ActiveCN111410502ALow hardening strengthHigh hardening strengthSolid waste managementMining engineeringMaterials science

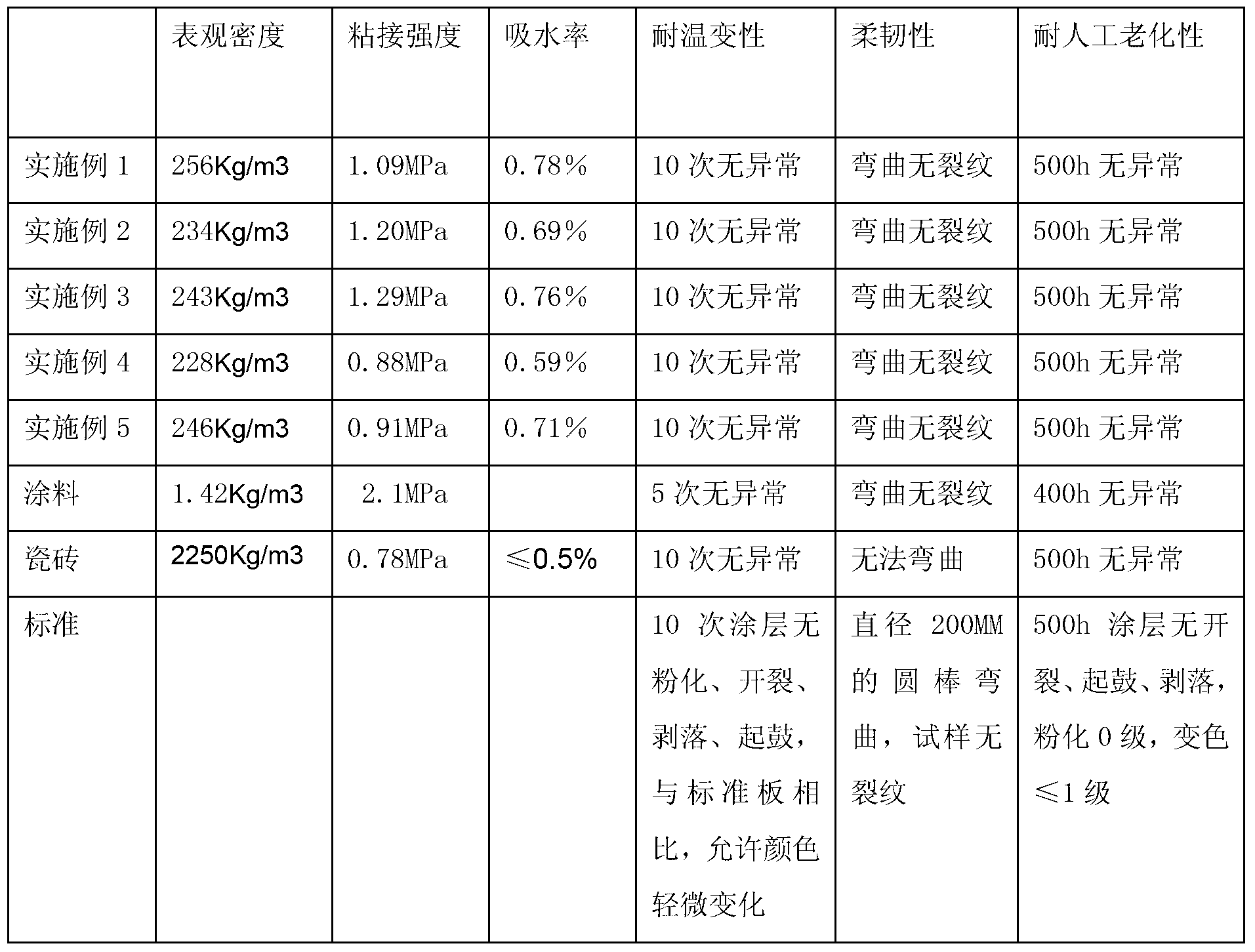

The invention discloses anhydrite-based light plastering mortar and a preparation method thereof. The anhydrite-based light plastering mortar which is light, energy-saving, good in comprehensive performance and simple in process and is prepared by taking anhydrite as a main material is researched and developed, and the anhydrite-based light plastering mortar has important practical significance. The anhydrite-based light plastering mortar is composed of anhydrite, cement, fly ash, an excitant, vitrified microbead, a thickening agent and a water-retaining agent. The concrete is composed of thefollowing components in parts by weight: 65-70 parts of the anhydrite, 8-10 parts of the cement, 4-8 parts of the fly ash, 4-6 parts of the excitant, 0.15-0.2 parts of the water-retaining agent, 0.1-0.15 part of the thickening agent, and 13-16 parts of vitrified microbead. The anhydrite-based light plastering mortar is prepared by adopting anhydrite associated in a pyrite production process as a main material, calcination treatment is not needed, only physical grinding and mixing are needed, the preparation process is simple, energy is saved, and pollution is reduced; and the problems of hollowing and cracking of the traditional mortar are fundamentally solved.

Owner:安徽合信大环保科技有限公司

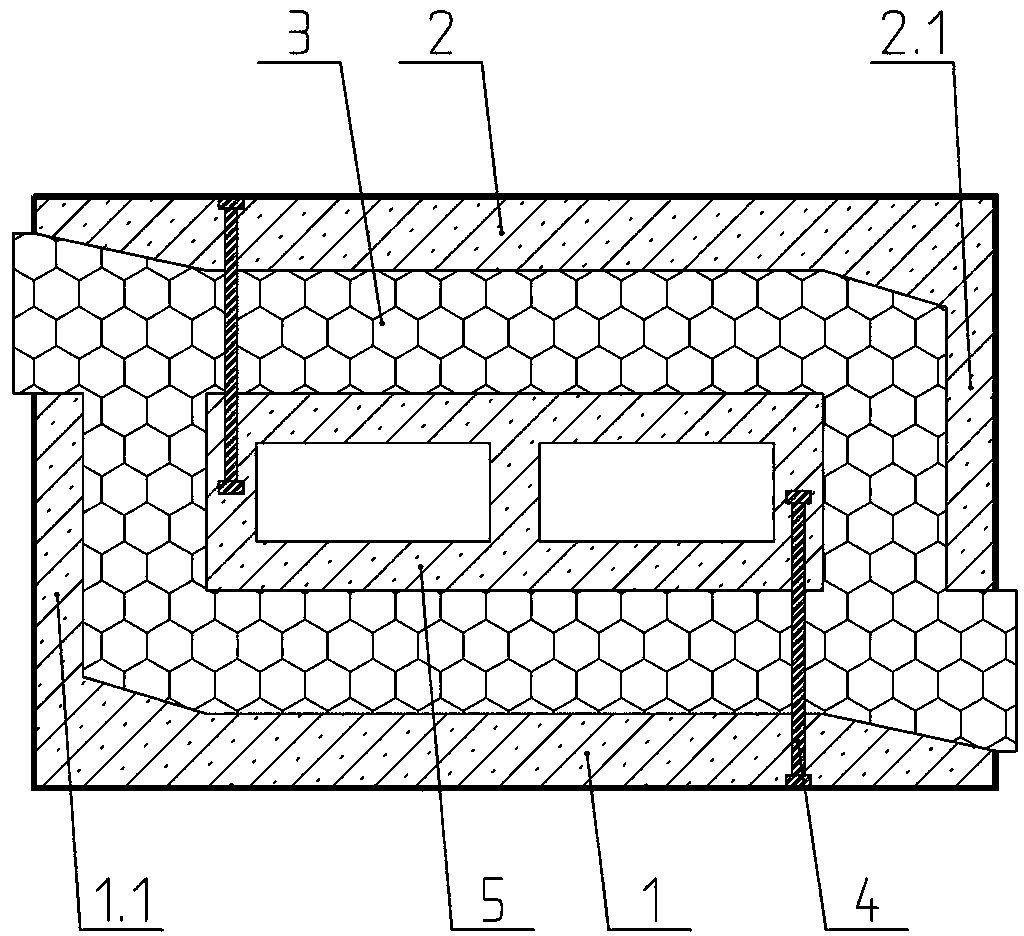

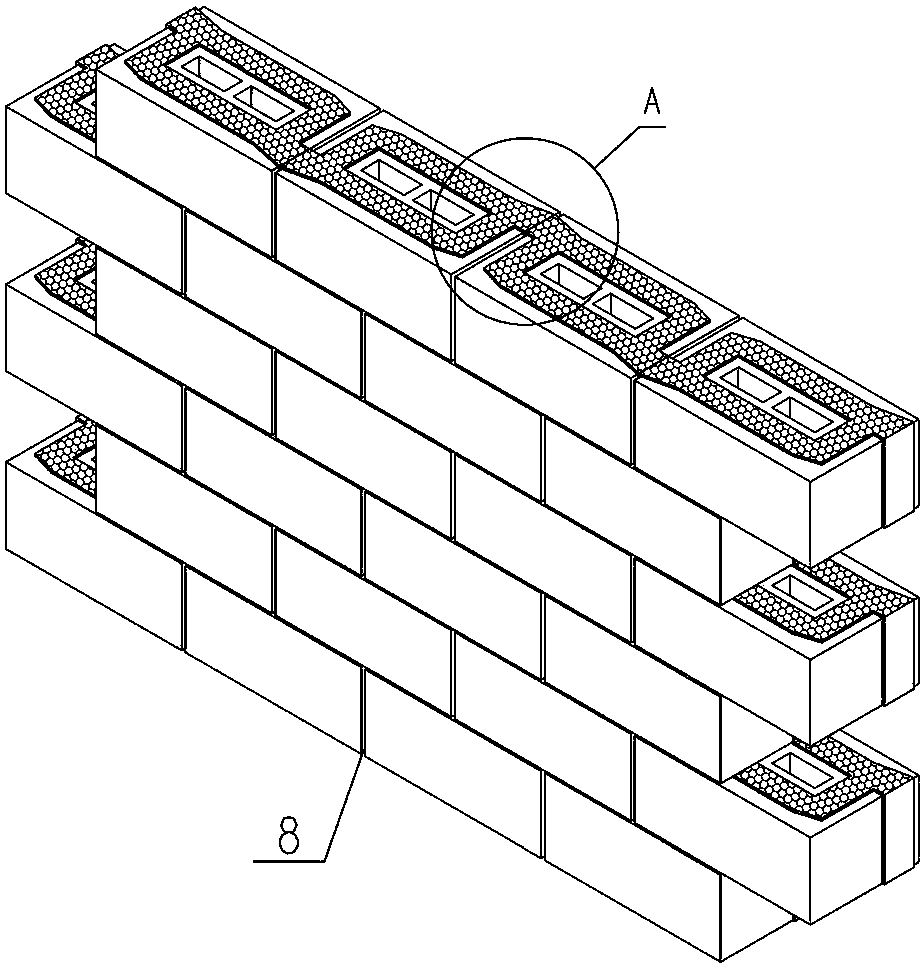

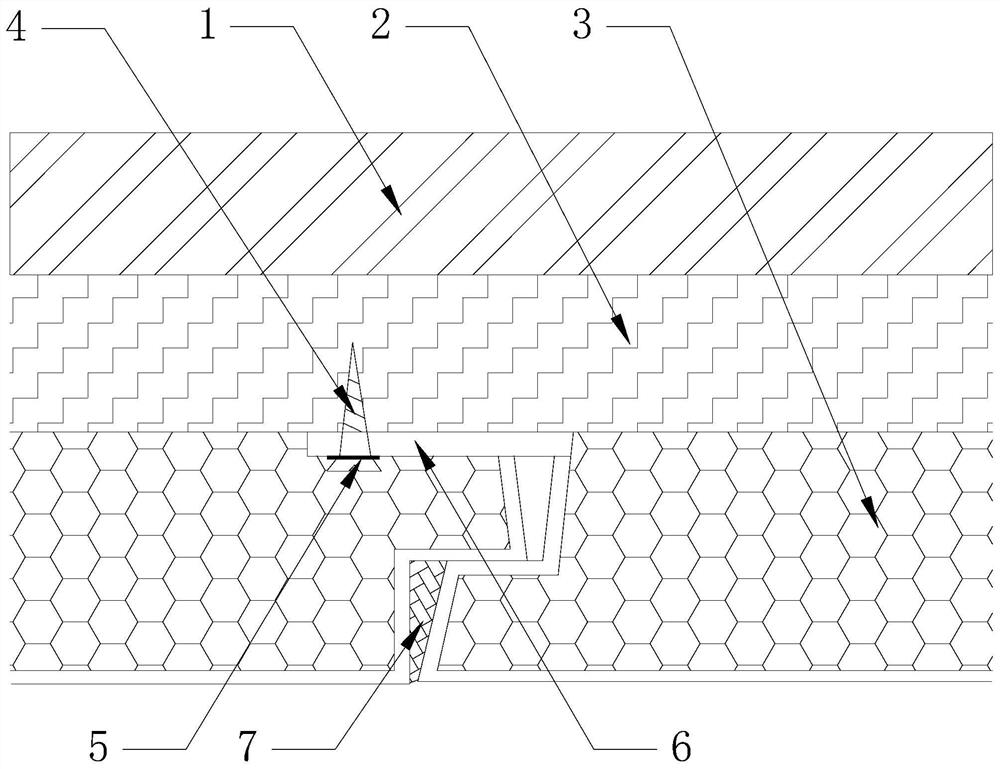

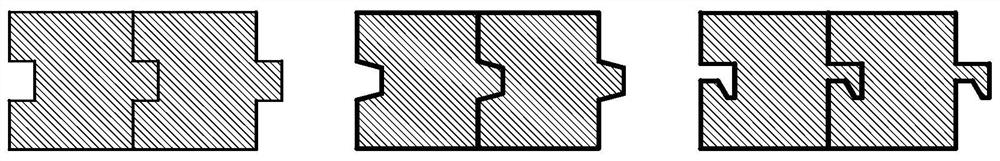

All-obstruction bridge concrete composite self-heat-preservation integrated building block

ActiveCN104278790ASynchronous lifespanLife SynchronizationConstruction materialStructural engineeringConcrete composites

Owner:刘立才

Gypsum plastering mortar suitable for mechanical spray coating construction and construction process of gypsum plastering mortar

InactiveCN110156422AReduce dependenceImprove liquidityBuilding constructionsSpray coatingUltimate tensile strength

The invention discloses gypsum plastering mortar suitable for mechanical spray coating construction and a construction process of the gypsum plastering mortar. The gypsum plastering mortar comprises the following raw materials, by weight: gypsum composite gel, fine aggregate, modified attapulgite clay, fly ash, vitrified microbeads, redispersible latex powder, an anti-cracking water retention agent, a rheological lubricant, and an air entraining agent. The gypsum plastering mortar provided by the invention adopts the composite gypsum gel instead of a single gypsum material, so that dependenceon a single gypsum species is reduced, and the mortar has good fluidity and workability, and is easy to pump; the gypsum plastering mortar adopts the composite anti-cracking water retention agent to improve water retention, fluidity and shrinkage compensation of mortar, so that the gypsum plastering mortar has the advantages of a high water retention rate, good flexibility, strong sag resistance and the like; the gypsum plastering mortar is suitable for mechanical spray coating operation, after spray coating is performed, a sodium carbonate solution is adopted for reinforcement treatment, so that strength and compact smoothness of a plastered surface are significantly improved; and the gypsum plastering mortar has good adhesion to a wall, and the hardened mortar is firmly bonded with a substrate.

Owner:浙江兆山建材科技有限公司

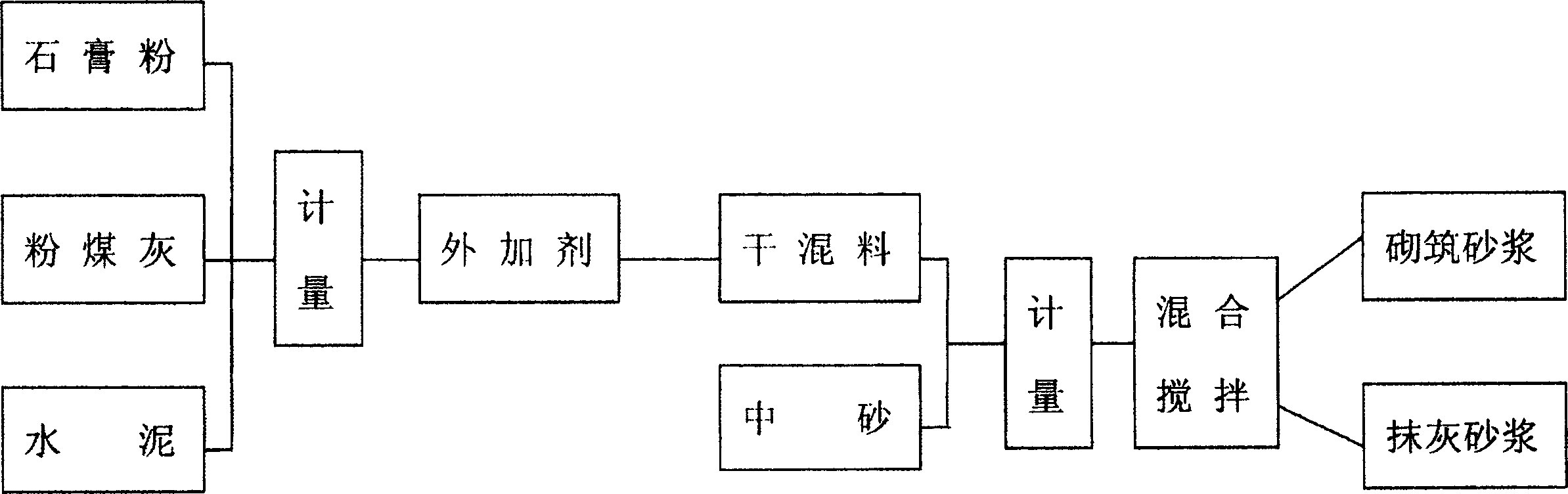

Dedicated mortar for steaming and pressing fly ash brick and aerated concrete building block

Disclosed is a dedicated mortar for steaming and pressing fly ash brick and aerated concrete building block which comprises gypsum 30-40%, comprising silicate cement 15-25%, coal ash 45-55%, water-retaining and thickening agent 0.1-0.4%, redispersable rubber powder 2-4%, crack resistant fiber 0.1-15%, wherein the content of the coal ash exciting agent is 2-4% of the total coal ash amount.

Owner:牟同升

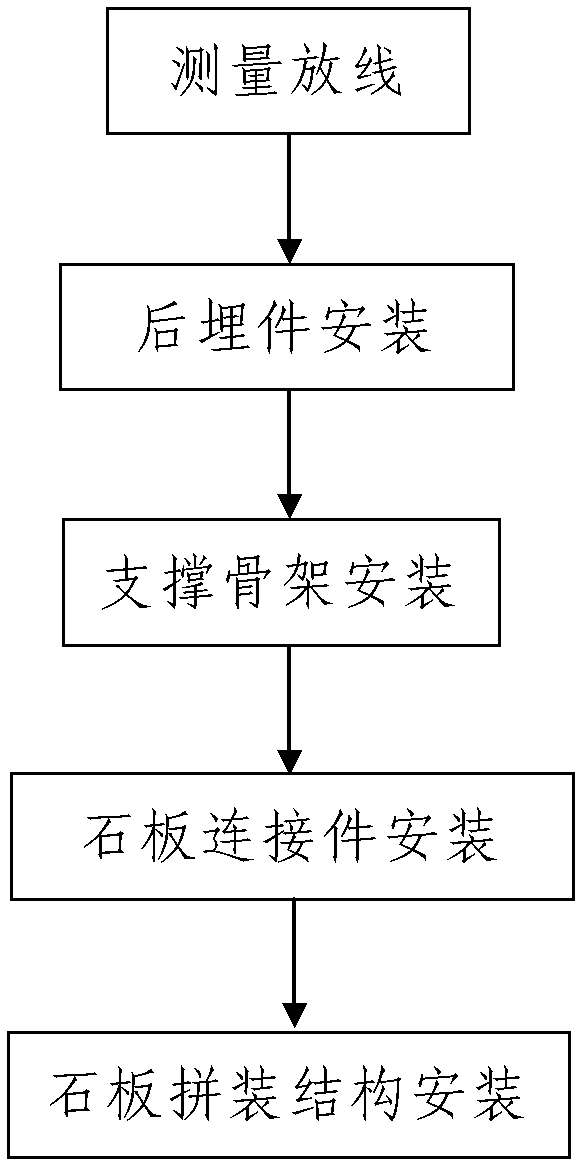

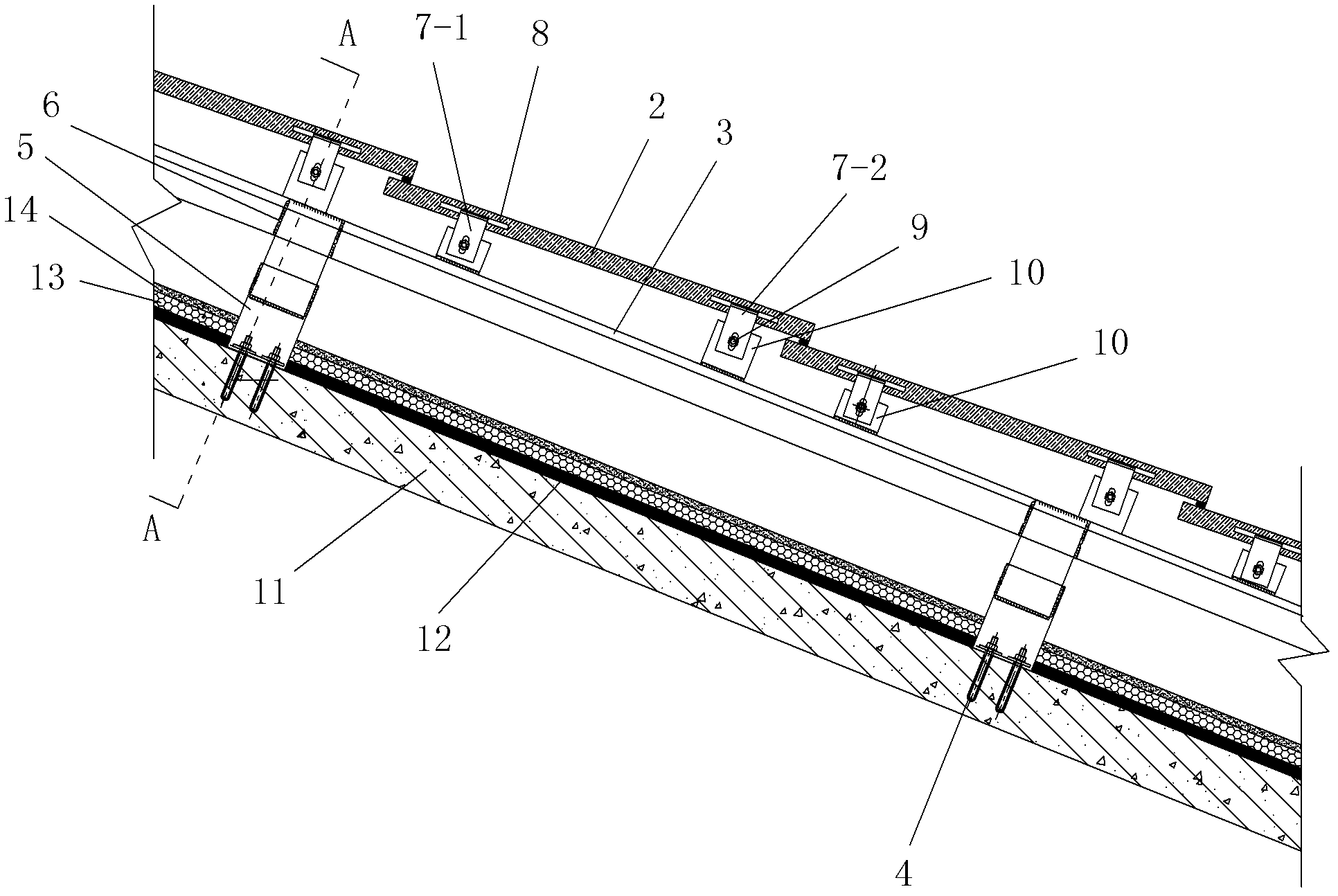

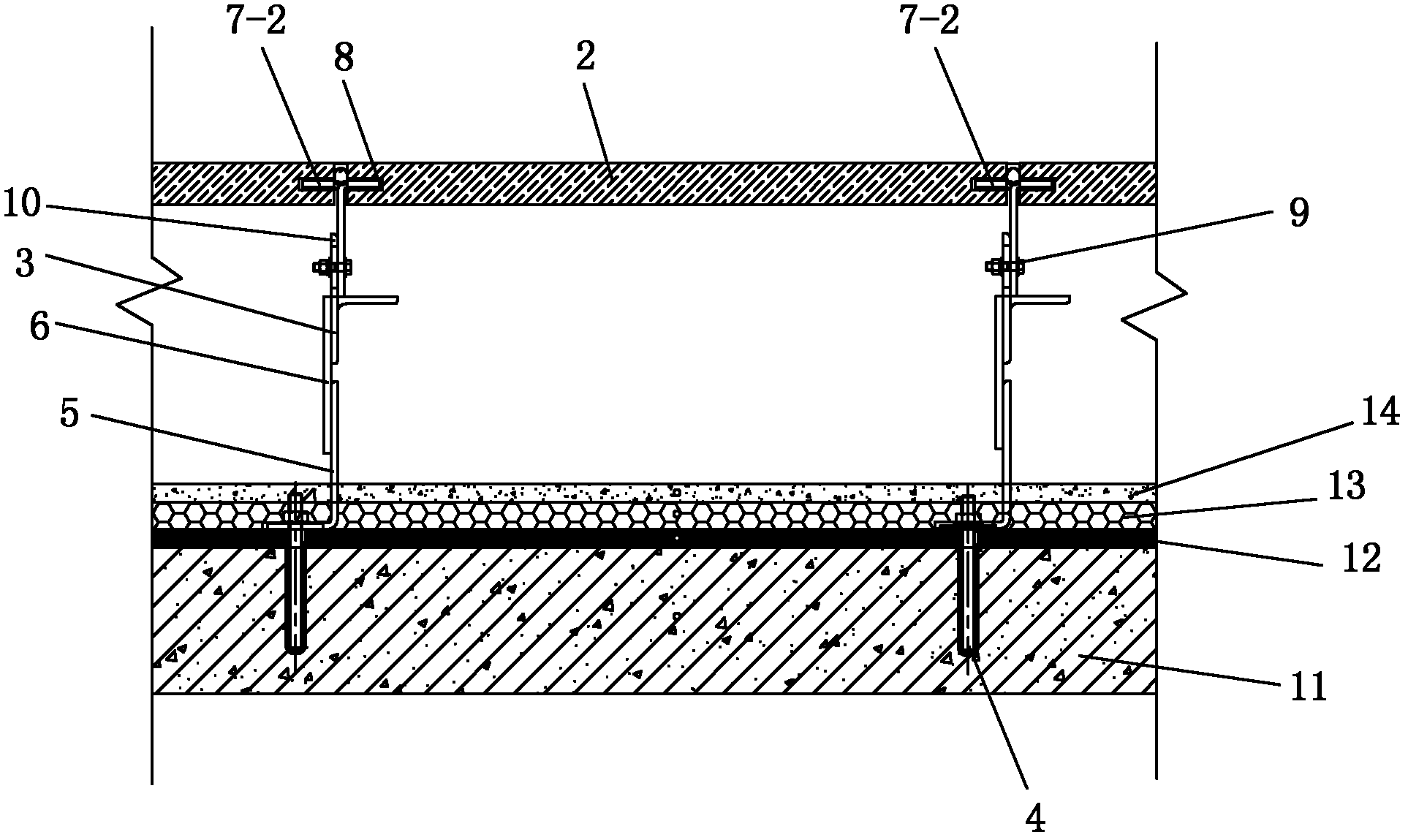

Construction method of overhead stone plate of slope roof

InactiveCN102561710ASimple stepsEasy to operateBuilding roofsBuilding material handlingAssembly structureBuilding construction

The invention discloses a construction method of an overhead stone plate of a slope roof. The overhead stone plate is arranged on the constructed slope roof and comprises a supporting framework and a plurality of stone plate assembly structures, wherein the supporting framework consists of multiple rows of supports, the stone plate assembly structures are mounted on the supporting framework from bottom to top, a plurality of rectangular stone plates which are arranged on the same plane are continuously assembled from left to right to form each stone plate assembly structure, the lap joint length between each two vertically adjacent stone plate assembly structures is not smaller than 30mm, and a plurality of groups of stone plate connectors which support the stone plate assembly structures are disposed on the supports from top to bottom. The construction process of the overhead stone plate comprises steps of 1, measuring and paying off a line; 2, mounting the supporting framework; and 3, mounting the stone plate assembly structures. The construction method is simple in step, convenient in implementation, easy to guarantee construction quality, high in construction efficiency and fine in construction effect, and can resolve problems that an existing construction method of a stone plate of a slope roof is complex in process, low in work efficiency, high in invested cost and difficult to guarantee construction quality, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

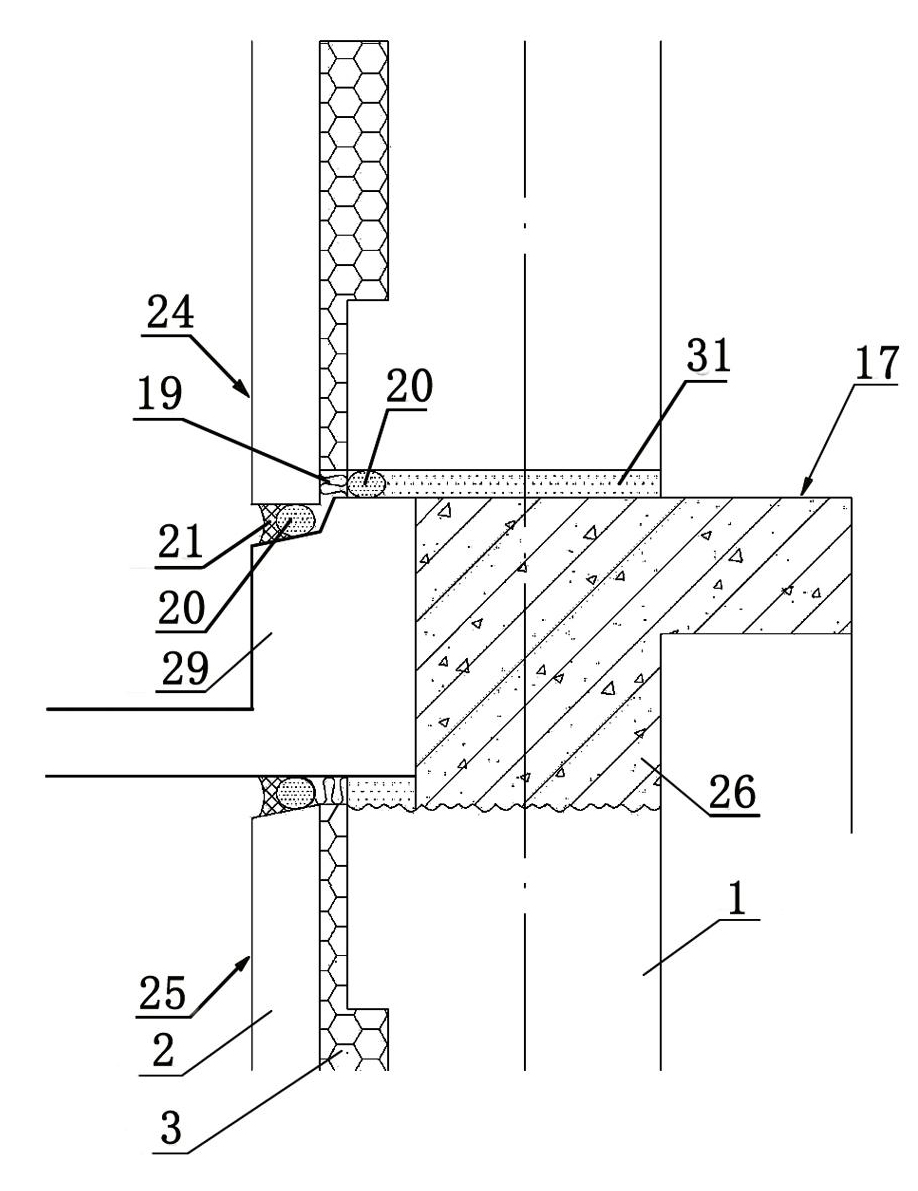

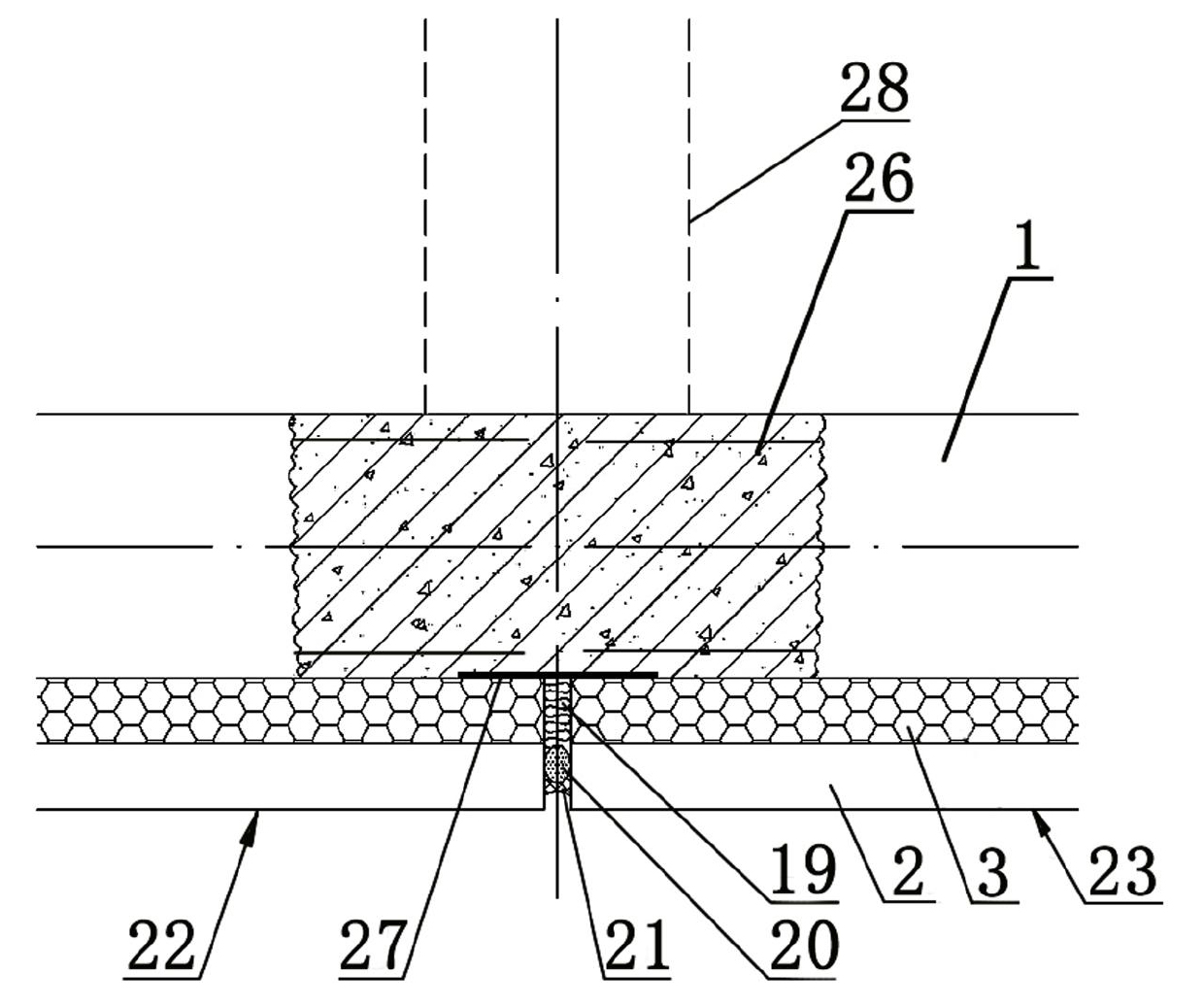

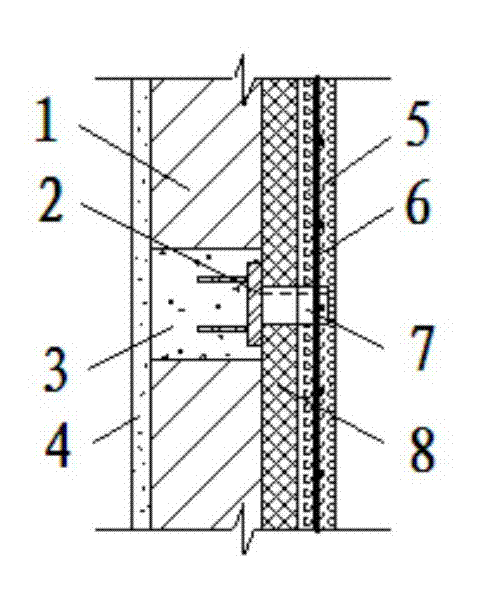

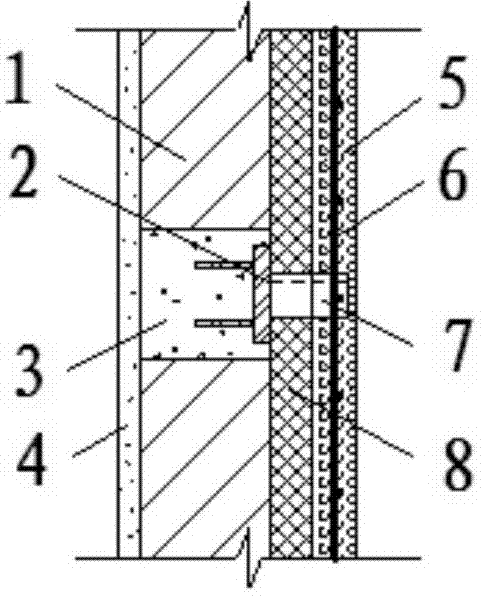

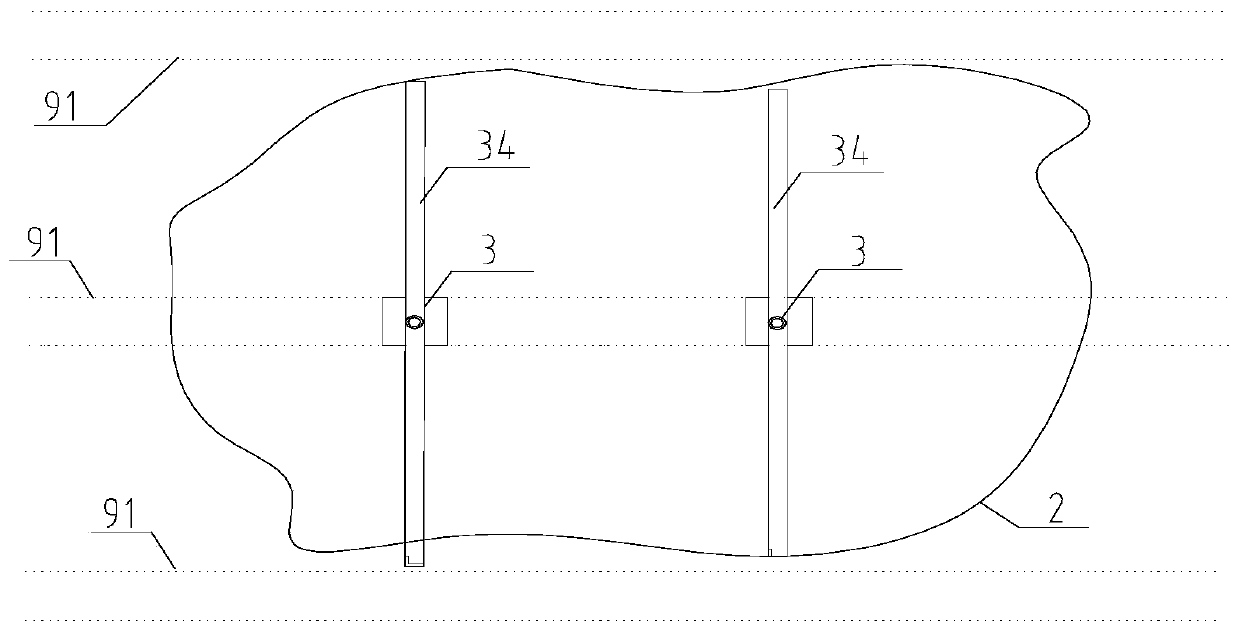

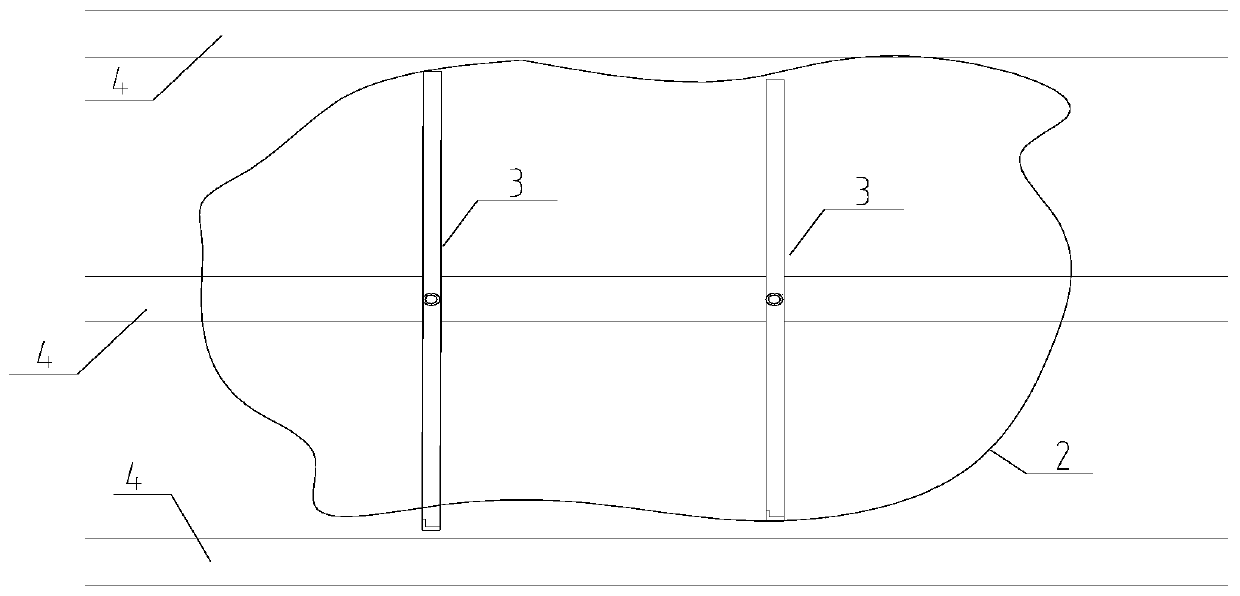

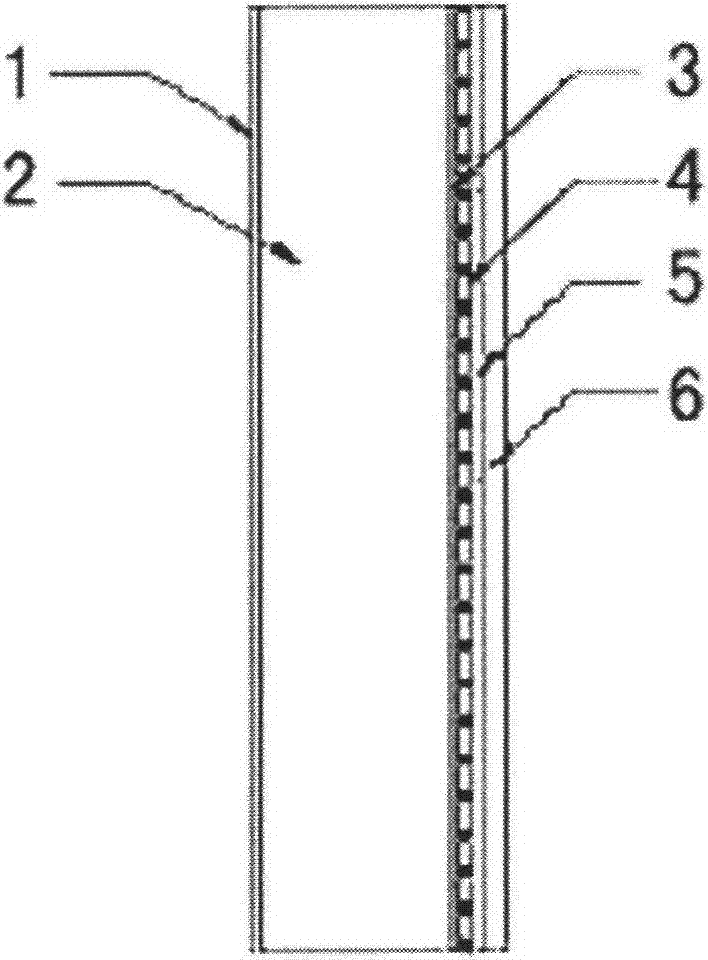

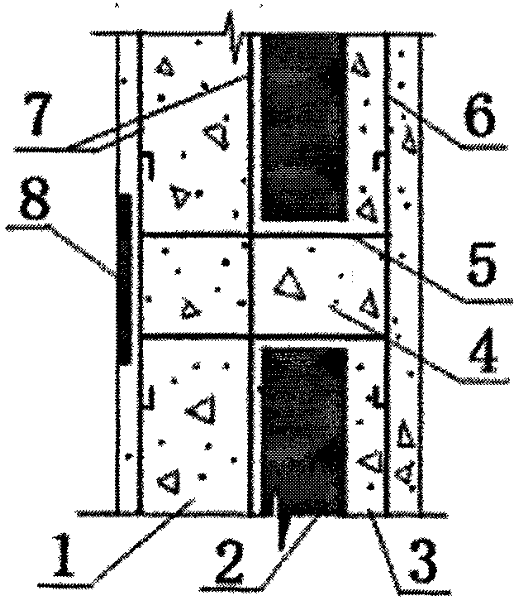

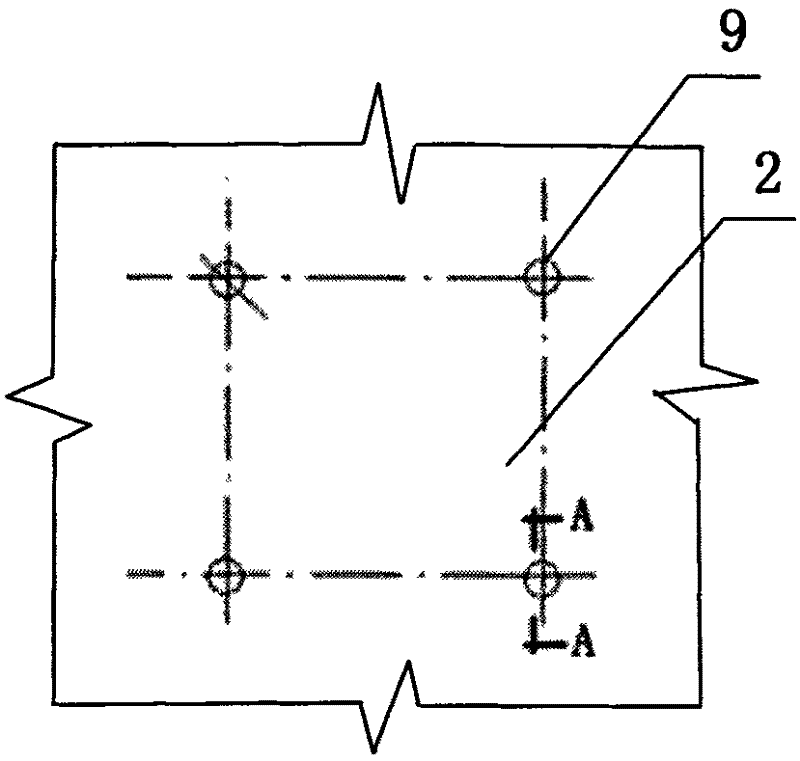

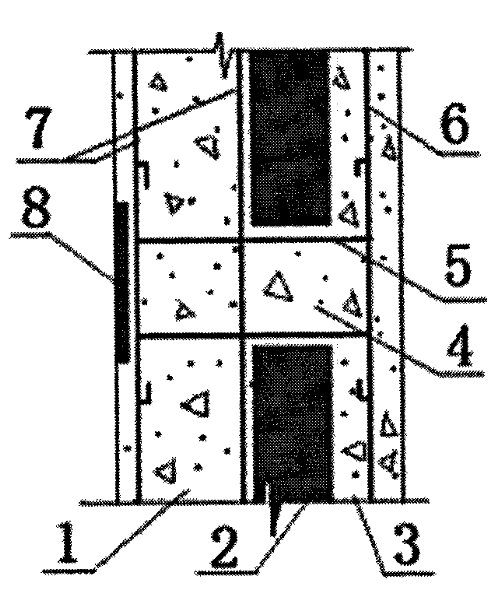

Heat insulating structural system suitable for existing building masonry and construction method thereof

InactiveCN102251592ASolve easy cracksSolve empty drumHeat proofingBuilding material handlingBrickThermal bridge

The invention relates to a heat insulating structural system suitable for an existing building masonry and a construction method thereof. The system comprises an inner decorative layer, an existing foundation wall layer, a heat insulating layer and a concrete protection layer from inside to outside; concrete anchors for anchoring embedded parts are arranged in the existing foundation wall layer at intervals; reinforcing steel bars are arranged in the concrete protection layer; and the reinforcing steel bars are anchored with the embedded parts through pulling connectors passing through the heat insulating layer. The system has long service life and good fireproof performance, and can ensure sticking safety and durability of face bricks; and a dispersed pulling bridge connecting mode is adopted between the existing foundation wall and the concrete protection layer, so that the layers are connected tightly, safely and reliably, the heat bridge effects of the pulling bridges of the inner and outer layers are dispersed, heat transfer of a building envelope is balanced, the heat transfer coefficient of each part is controlled close, uniform heat transfer of each part is ensured, and the influence of the connected heat bridges on the heat insulating effect is reduced.

Owner:河南省九建工程有限公司 +1

Construction method of integrated roof joint structure

ActiveCN113175163AIncrease profitHigh degree of industrializationRoof covering using slabs/sheetsWallsArchitectural engineeringExpansion joint

The invention discloses a construction method of an integrated roof joint structure. The construction method specifically comprises the following steps that corresponding detachable molds are customized according to the sizes of prefabricated walls, prefabricated flooding surface layers and prefabricated roof surface layers; the prefabricated walls, the prefabricated flooding surface layers and the prefabricated roof surface layers are numbered; the prefabricated walls, the prefabricated flooding surface layers and the prefabricated roof surface layers are processed; combined hanging pieces are installed at the expansion joints between the two adjacent prefabricated walls, the two prefabricated flooding surface layers and the two prefabricated roof surface layers, and expansion joint cover plates are buckled; the surface of a joint between the prefabricated walls and the concrete flange is sealed with weather-proof sealant; and completing and checking are carried out. A roof ceramic tile surface layer and a slope making layer adopt the prefabricated parts, the construction period is shortened while the project quality is guaranteed, and the cost is saved; and by integrally planning the walls, the ground and the installation project, the forming effect is attractive, and the roof leakage risk is greatly reduced.

Owner:WUHAN CONSTR ENG

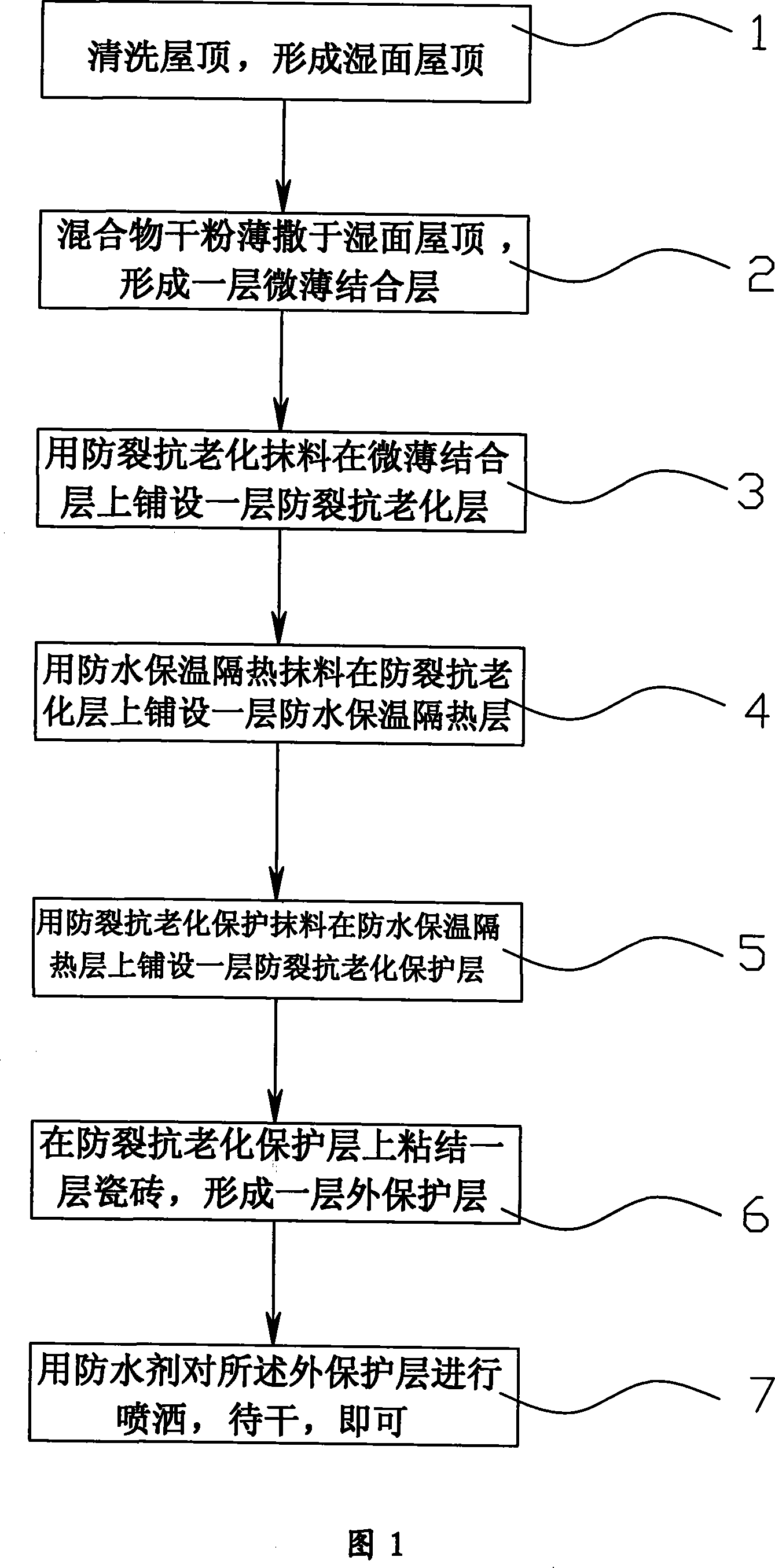

Roof water-proof thermal-insulation construction technique

The invention provides a roof water proof heat preserving and insulating construction technology, which includes the following procedures: the roof is cleaned and wetted; a thin layer of mixed dry powder is spread on the wet roof to form a thin combined layer; the crackle resistant anti-ageing soread is adopted to pave a crackle resistant anti-ageing layer on the micro thin combined layer; the water proof heat preserving and insulating soread is adopted to pave a water proof heat preserving and insulating layer on the crackle resistance anti-ageing layer; the crackle resistant anti-ageing preventive soread is adopted to pave a crackle resistant anti-ageing preventive layer on the water proof heat preserving and insulating layer; a layer of ceramic tiles is bonded on after the crackle resistant anti-ageing preventive layer is solidified, so as to form an outer protective layer; the water proof agent is adopted to sprinkle the outer protective layer and the layer is then left dry, and those are all for the procedures. With such a technology, the construction layer and the roof are firmly combined, with extremely good affinity and outstanding binding effect; in addition, the construction technology is scientific and reasonable, simple and easy, has outstanding water proof, heat preserving and insulating effects, and thoroughly solves the technical problems of roof leakage, hollowing and crackling.

Owner:韩志同

Water-repellent and breathable stone-like coating and preparation method thereof

The invention provides a water-repellent and breathable stone-like coating, which is prepared from the following raw materials in parts by weight: 90-110 parts of natural quartz sand, 10-13 parts of colloidal silicon dioxide, 6-9 parts of a pure acrylate emulsion, 0.9-1.5 parts of butyl cellosolve, 2-9 parts of an antibacterial agent, 6-111 parts of a silicone acrylic emulsion, 0.15-0.65 part of sodium silicate, 3-9 parts of a thixotropic agent, 8-19 parts of a coalescing agent, 0.3-0.6 part of calcium chloride powder, 0.5-3 parts of a magnesium chloride solution and 20-60 parts of water. The invention further provides a preparation method of the water-repellent and breathable stone-like coating. The water-repellent and breathable stone-like coating has the advantage and positive effects that the water repellency is good, the whitening resistance and the hardness of a film are effectively improved, the air permeability is good, the problems of hollowing and bubbling of the surface of the stone-like coating film can be solved, the initial cracking resistance is good, the bonding strength is high, and the preparation technology is simple and suitable for industrialization.

Owner:青岛金绮丽涂料股份有限公司

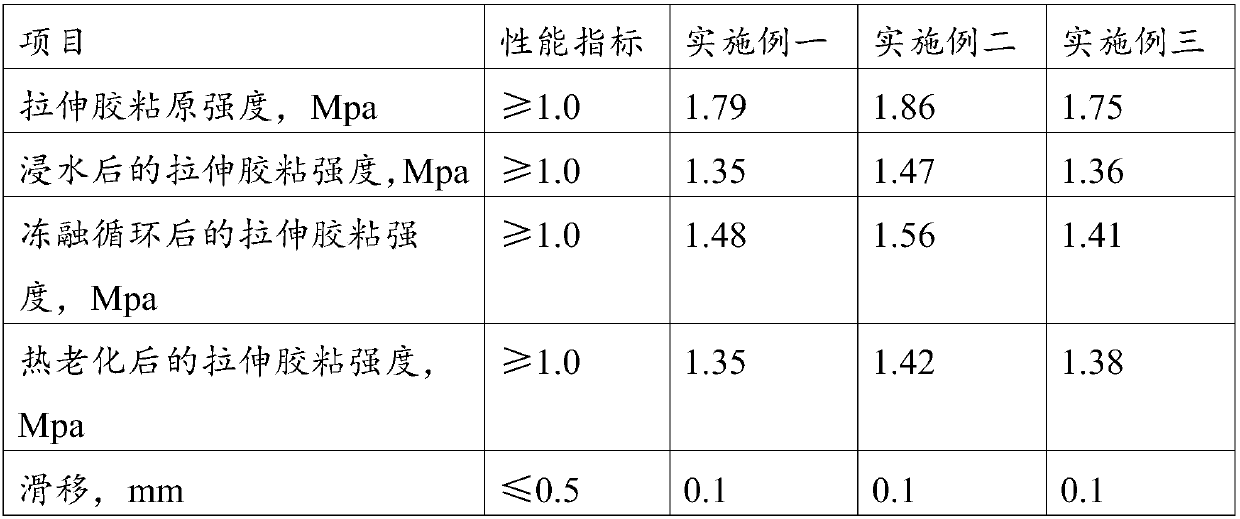

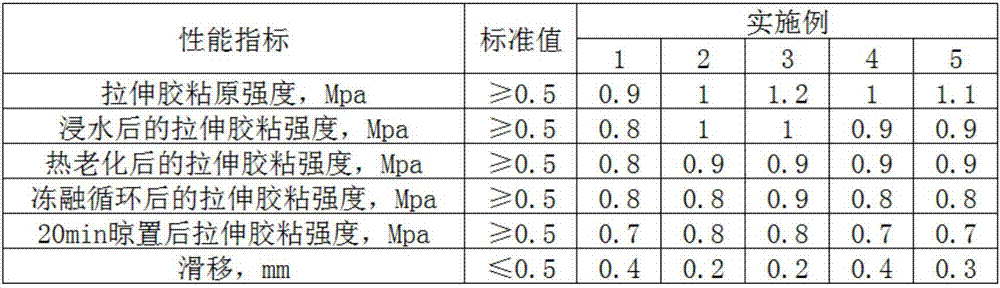

Adhesive for tiles and preparation method of adhesive

The invention relates to the technical field of building materials, in particular to an adhesive for tiles and a preparation method of the adhesive. The adhesive comprises, by weight, 25-38 parts of Yellow River sediments, 20-35 parts of dry fine sand, 10-25 parts of sludge, 12-20 parts of cement, 2-10 parts of rosin saponified products, 1-5 parts of water-soluble silicate, 1-5 parts of re-dispersible latex powder and 0.2-2 parts of micro-expansion agents. The adhesive for the tiles has high bonding strength, water resistance, corrosion resistance and thermal aging resistance (70 DEC C), and can withstand tests in which wet and dry conditions alternate or freezing and thawing conditions alternate, completely solving the problems of whiskering, hollowing and peeling of the tiles.

Owner:陈谓清

External wall insulation layer nondestructive repair method and external wall insulation structure

PendingCN110656706ASolve empty drumSolve the cracking problemBuilding repairsHeat proofingInsulation layerEngineering

The invention provides an external wall insulation layer nondestructive repair method. The external wall insulation layer nondestructive repair method comprises the following steps: (S1) original insulation layers to be repaired are pressed, and are provided with multiple transverse grooves; and then, the original insulation layers on each rows are returned and reinforced; (S2) primary plasteringglue is fully coated on the outer surfaces of one row of the original insulation layers; (S3) first transverse grid cloth is uniformly pressed into the primary plastering glue to form turning parts; (S4) new insulation plates are embedded in bottom grooves; the plastering glue is fully coated on the outer surfaces of the new insulation plates; and second transverse gird cloth is uniformly pressedinto the plastering glue to form joint parts; (S5) the steps (S2-S4) are repeated to embed the new insulation plates into the grooves from bottom to top; and (S6) secondary plastering glue is fully coated on the outer sides of all the transverse grid cloth; and the grid cloth is longitudinally bonded. The invention further provides an external wall insulation structure. The external wall insulation layer nondestructive repair method has the beneficial effects of capability of solving such problems as hollows, cracks or fall in the insulation layers and capability of preventing garbage and pollution generated during repair.

Owner:周德元

High-precision automatic tile fixing machine

The invention discloses a high-precision automatic tile fixing machine, comprising a pressure-bearing base plate, wherein a vibration motor is fixedly installed on the upper surface of the pressure-bearing base plate; an uniformly smeared rotary table is fixedly installed at the bottom of the vibration plate; a height measuring rod and a pressure rod are installed between the pressure-pressing base plate and the vibration plate; there are two pressure rods; the height measuring rod is installed between the pressure rods;a plane level is installed at the top of the height measuring rod; a tile temporary storage room is installed above the vibration motor; multiple layers of baffles are set in the tile temporary storage room; mortar boxes are fixedly installed at the two sides of the tile temporary storage room; a stirring rod is installed in the mortar box; a mortar conveying pipeline is connected with the bottom of the mortar box. The high-precision automatic tile fixing machine has quick locating, simple and convenient operation, high quality, quick speed, light weight, high product precision and wide adaptation.

Owner:陈泳东

Fabricated type non-load-bearing cast-in-situ lightweight composite wall material

InactiveCN106946516ASolve empty drumSolve the problem of cracking and dustingCellulosePortland cement

The invention relates to a fabricated type non-load-bearing cast-in-situ lightweight composite wall material. The fabricated type non-load-bearing cast-in-situ lightweight composite wall material is prepared from the following raw materials in parts by weight: 19 to 43 parts of portland cement, 0.02 to 0.14 part of polypropylene, 0.08 to 0.192 part of a water reducing agent, 0.011 to 0.037 part of cellulose ether, 0.0098 to 0.022 part of sodium dodecyl sulfate, 9 to 20 parts of second-grade fly ash, 0.31 to 0.78 part of polyphenyl particles, 2.1 to 9.7 parts of yellow sand, 0.23 to 1.21 parts of a setting accelerator and 0.91 to 2.15 parts of an expansion agent. The wall prepared from the fabricated type non-load-bearing cast-in-situ lightweight composite wall material provided by the invention is improved in bearing capacity, and the problems of cracking, peeling and falling-off of the wall are avoided.

Owner:CHANGZHI LUXINYUAN NEW WALL BUILDING MATERIALS CO LTD

Mortar glue and production method thereof

The invention provides a mortar glue. Raw materials of the mortar glue comprise, by weight, 15-30 parts of methylethyl cellulose ether, 20-45 parts of methylhydroxypropyl cellulose ether, 1-5 parts of an AC foaming agent, 10-28 parts of starch ether, 20-30 parts of acrylic glue powder and 8-12 parts of triterpenoid saponins. A weight ratio of the methylethyl cellulose ether to the methylhydroxypropyl cellulose ether is 2:3, so the requirement glue of the mortar glue for the water: cement: sand ratio is reduced.

Owner:东莞市西牛建材科技有限公司

PTB (Polytechnisch Bedrijf Bvba/Sprl) multifunctional composite board for outer wall as well as preparation method and use method thereof

InactiveCN102433971AVersatileFast constructionCovering/liningsCeramic shaping apparatusScreedReinforced concrete

The invention discloses a PTB (Polytechnisch Bedrijf Bvba / Sprl) multifunctional composite board for an outer wall as well as a preparation method and a use method thereof. The PTB composite board is formed by integrally pressing a PTB interface agent mortar layer, a waterproof anti-crack plastering layer, a rockwool slab or a foam glass plate and a PTB interface agent mortar layer from outside to inside in sequence. The preparation process comprises the steps of molding, pouring, high-frequency vibrating, demolding and curing. According to the invention, the heat insulating and energy saving difficulties and the poor quality problem of the composite plate are solved; the finished product composite plate which is waterproofing, heat-insulating, wear-resistant and corrosion-resistant and never cracks is prepared by using a thin high-strength reinforced concrete injection pressing method, adding European imported original PTB emulsion and successfully carrying out molding and pressing with a heat insulation board through difficult vacuum-pumping treatment in one step in a mechanical way, and has the obvious economic benefits and environment-friendly benefits because the traditional heat insulation method is abandoned.

Owner:福建康波力特阳光建材有限公司

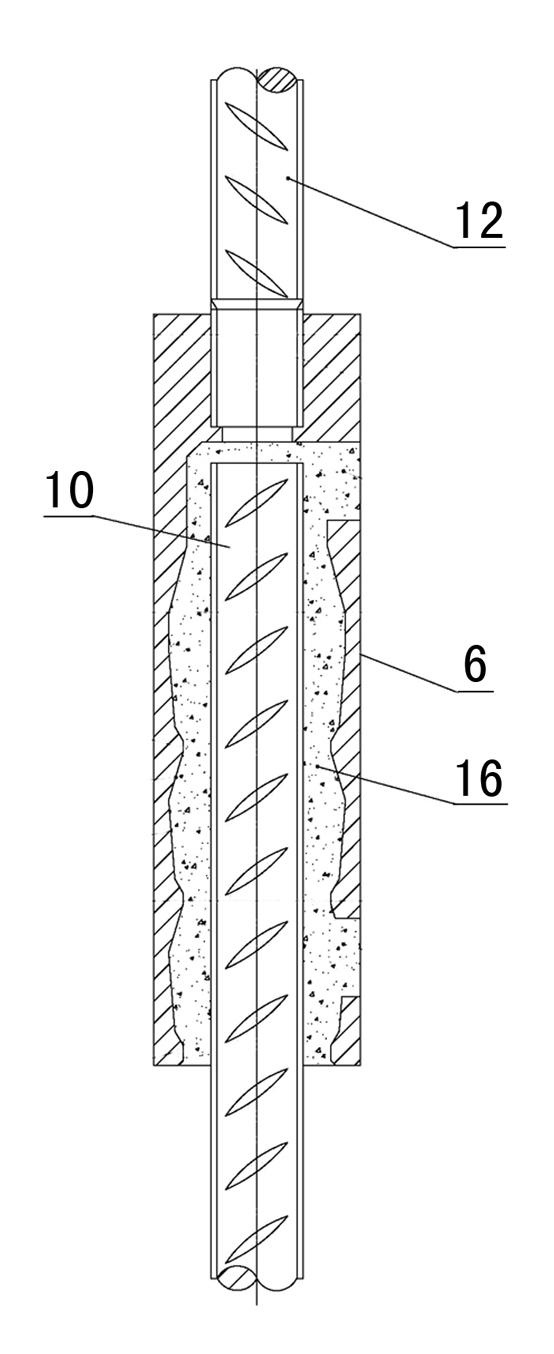

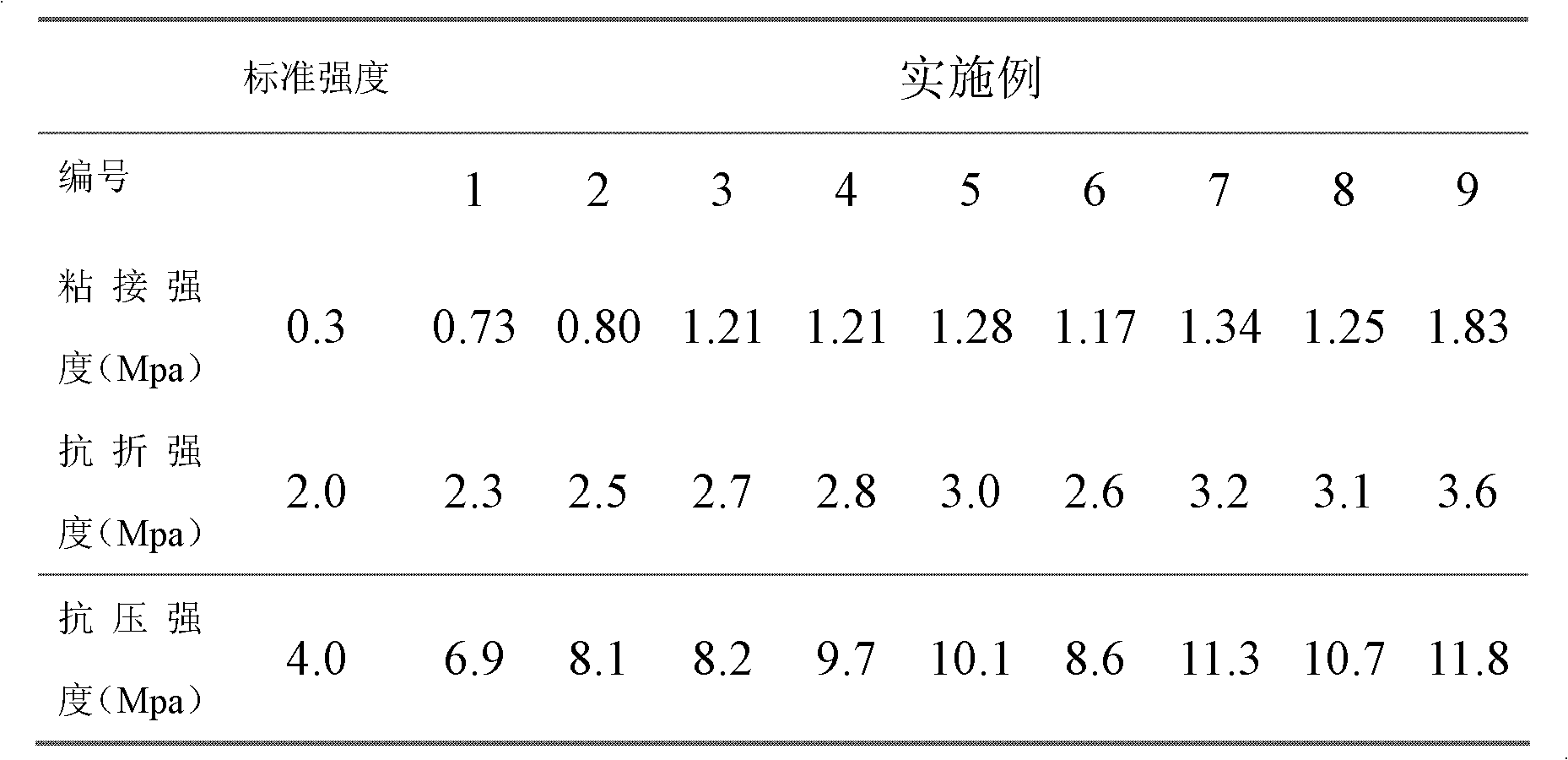

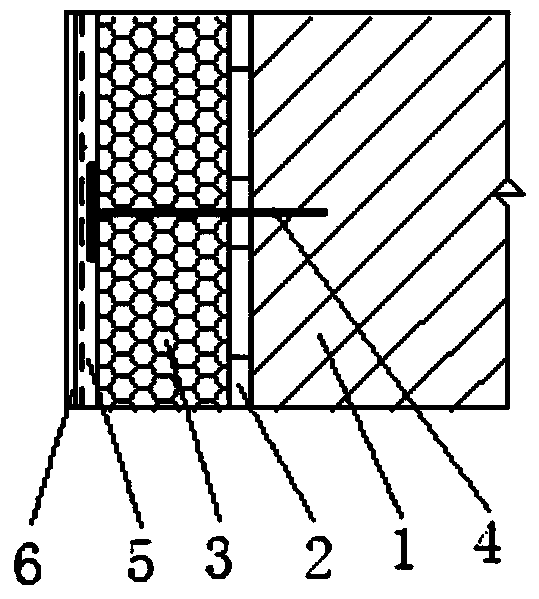

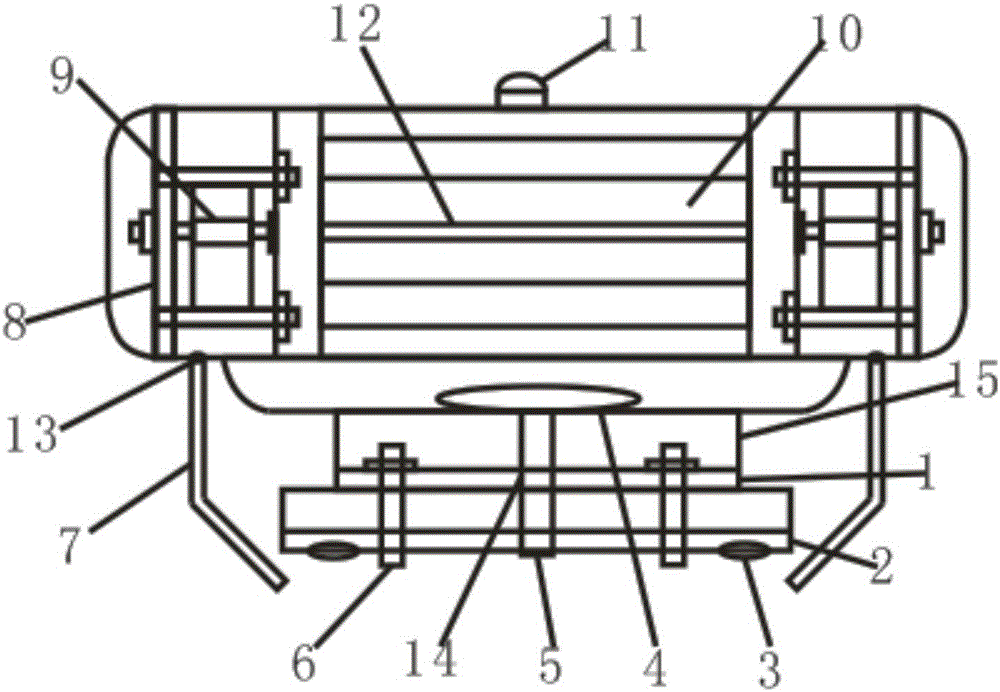

Heat-resistant fixing structure of travertine plate on floor heater

The invention discloses a heat-resistant fixing structure of a travertine plate on a floor heater. The heat-resistant fixing structure comprises a first travertine mortar permeation film layer (1), the large travertine plate (2), a second travertine mortar permeation film layer (3), a steel wire mesh (4), a travertine mortar film layer (5) and a gravelly sand layer (6) which are sequentially integrally compounded with one another in an interlayer manner. The heat-resistant fixing structure of the travertine plate on the floor heater has the advantages that problems of hollowing, peeling, damage, short service lives of crystal planes and the like due to the fact that heat stress deformation of an existing travertine plate on a floor heater occurs under long-term hot and cold cycles and dry shrinkage effects are solved; polluted black spots of surface holes and gaps are prevented, potential quality hazards of materials are eliminated, and the impression and the durability of a decorative effect are improved.

Owner:GOLD MANTIS CONSTR DECORATION

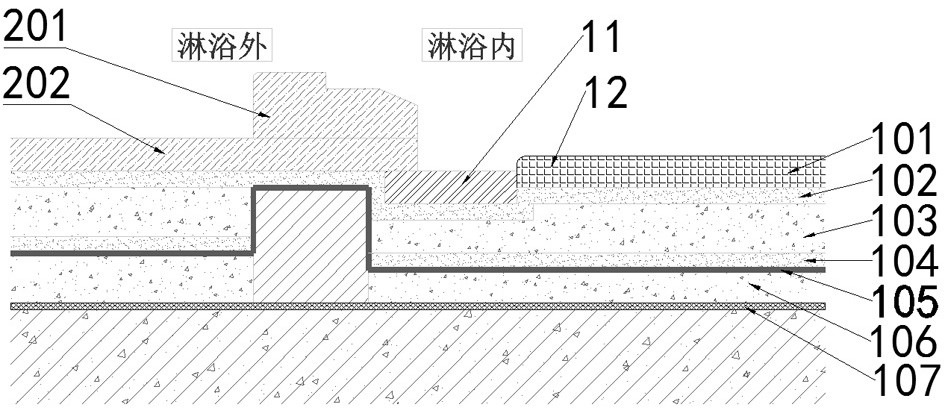

Quick-mounting type shower floor stone and paving method

PendingCN113463873AQuality improvementQuality assuranceSewerage structuresClimate change adaptationArchitectural engineeringStructural engineering

The invention relates to a quick-mounting type shower floor stone and a paving method. The paving method comprises the following steps that (1) the stone is cut, specifically, the middle of the stone is cut, the cut stone is divided into a base and a boss, the boss is lifted by a certain distance and pasted and fixed through stone glue, and a water outlet pipe mounting hole and a floor drain cover mounting groove are machined according to a floor drain; (2) a flat interface agent, a leveling layer, a waterproof layer and a protective layer are paved; and (3) a bonding layer, plain cement paste and the like which are attached to the concave surface of the stone are paved. The shower room floor stone is mainly an integral stone, after integral machining, integral forming and paving are conducted on site, the construction period is greatly shortened, the labor cost is reduced, the effect of reducing the cost is achieved, the leakage risk of a bathroom can be greatly reduced, the integral quality of bathroom floor paving is improved, the common quality problems of hollowing, cracking and the like are solved, meanwhile, material loss is small, the stone quality can be ensured, and the paving attractiveness is enhanced.

Owner:浙江中天精诚装饰集团有限公司

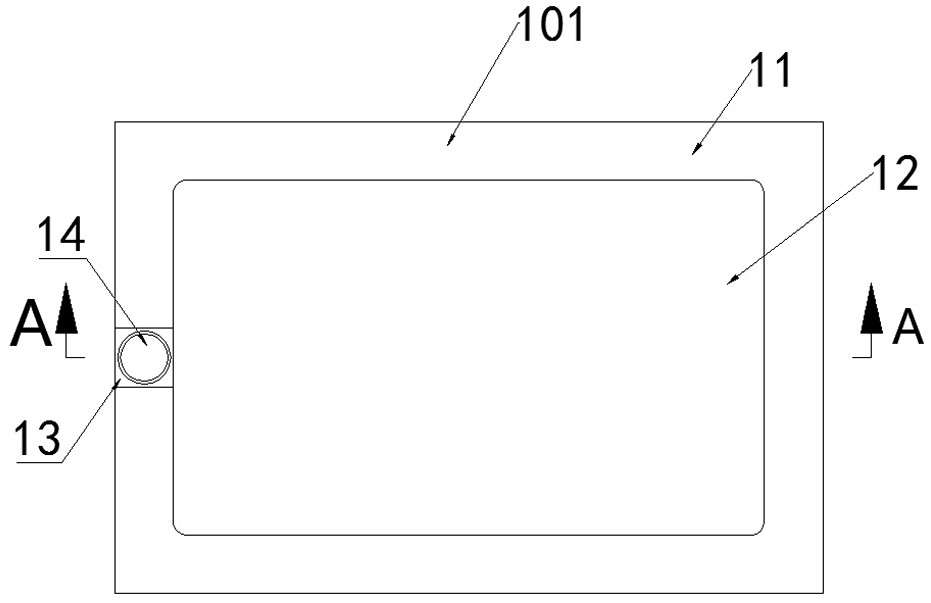

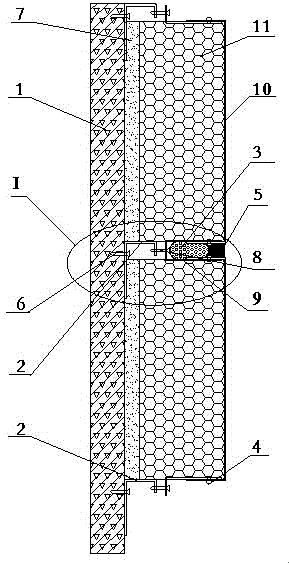

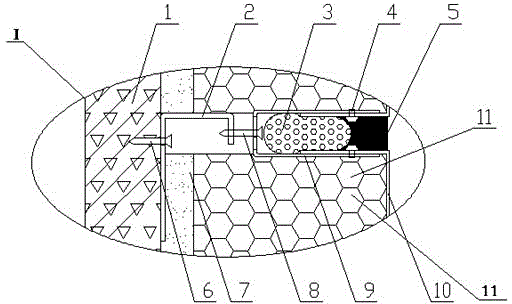

Phenolic foam insulation and decoration integration board external wall insulation system

InactiveCN104863276ASolve empty drumSolve the shedding problemHeat proofingArchitectural engineeringZinc

The invention belongs to a phenolic foam insulation and decoration integration board external wall insulation system. A phenolic foam insulation board (11) is bonded to a base course wall (1) through bonding mortar (7), and an aluminum-zinc coated steel sheet (10) is fixed on the outer surface of the phenolic foam insulation board (11) through aluminum pulling rivets (4). The phenolic foam insulation and decoration integration board external wall insulation system is characterized in that the integrated phenolic foam insulation board (11) and the aluminum-zinc coated steel sheet (10) which are adjacent to each other are fixedly connected by a U-shaped corner brace (9) through the aluminum pulling rivets (4); the U-shaped corner brace (9) is fixedly connected with an L-shaped bracket (2) through a round-head self-tapping screw (8), and the round-head self-tapping screw (8) is fixed on the base course wall (1) through a mechanical anchoring part (6). The phenolic foam insulation and decoration integration board external wall insulation system is low in self-weight and convenient to construct and thoroughly solves the problems of hollowing and falling of a building external wall insulation system; external wall insulation system fire accidents are completely eradicated.

Owner:营口象圆新材料工程技术有限公司

Novel vitrified brick gum

InactiveCN107033821AHigh bonding strengthMeet the bonding requirementsNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyEmulsion

The invention discloses a novel vitrified brick gum. The novel vitrified brick gum comprises slurry and powder. The weight percentage ratio of the slurry to the powder is 1: 3.5-4.5. The slurry comprises the following components in parts by weight: emulsion 15-55 parts, silicon modified aqueous epoxy resin 18.5-53 parts, a preservative 0.5-3.5 parts and cellulose 0.5-2 parts. The powder comprises the following components in parts by weight: titanium dioxide 1-8 parts and an inorganic filler 15-35 parts. The silicon modified aqueous epoxy resin comprises the following components in parts by weight: aqueous epoxy resins 8-20 parts, an auxiliary agent 5-15 parts, a modifying agent 5-15 parts and catalyst 0.5-3 parts. The slurry and the powder are organically combined according to a certain ratio, the adhesion strength of the vitrified brick gum is improved, adhesion requirements of vitrified bricks can be met completely, the vitrified bricks can be adhered to different base materials, the novel vitrified brick gum is simple to construct, and the problems of hollowing, breaking, dropping and the like during adhesion of the vitrified bricks are solved effectively.

Owner:湖北碱克新材料有限公司

Repair method of existing building wall thermal insulation system

ActiveCN111852067ASolve empty drumSolve crackingCovering/liningsClimate change adaptationThermal insulationKeel

The invention relates to a repair method of an existing building wall thermal insulation system. The thermal insulation decoration system comprises a keel and metal outer wall decoration plates whichare arranged outside a base layer wall. The repair method comprises the steps of keel design, base layer treatment, keel laying, metal outer wall decoration plate laying and local cavity-free treatment. Through the combination of the metal outer wall decoration plate, an anchoring part and the keel, the thermal insulation system is integrally suspended on an existing wall, and procedures such as shoveling, layer-by-layer grouting are not needed, the construction steps are simple, the influence of existing thermal insulation system defects is avoided, and the applicability is high; according todifferent heights and body type characteristics of existing buildings, the keel material and density are designed, the fixing points of the metal outer wall decoration plates and the keel are increased, combined with the tongue-and-groove design of metal outer wall decoration plates and the local cavity-free treatment, the outward pulling force of negative wind pressure on the thermal insulationsystem can be born, and the load requirement is achieved; and the effect of ventilation and waterproofing is realized by combining the local cavity structure design, and the problems such as wall hollowing, cracking caused by water seepage are fundamentally solved.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +3

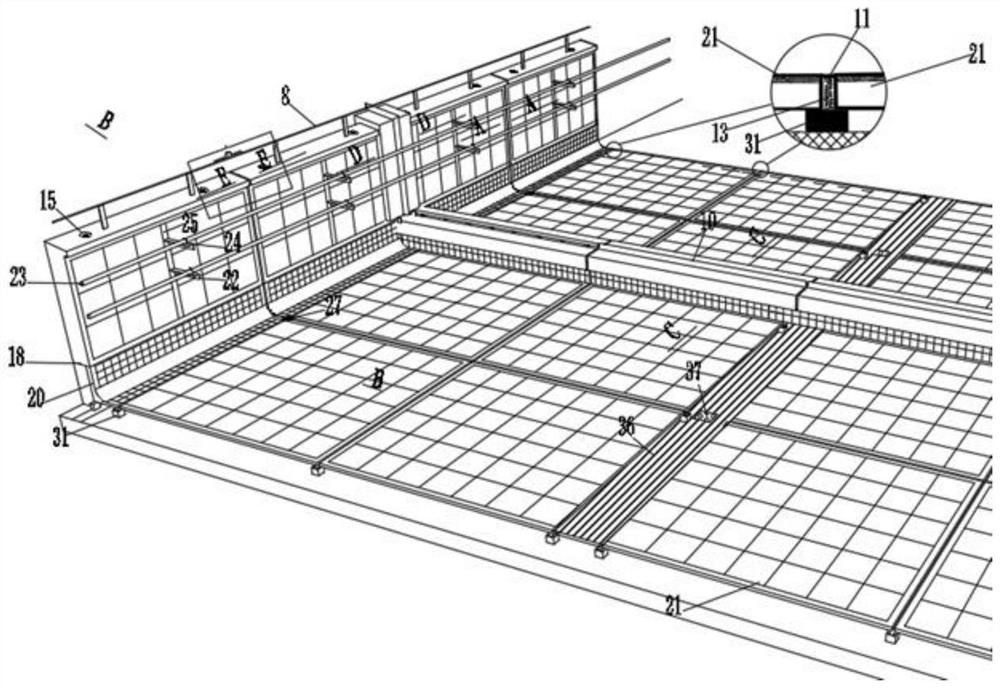

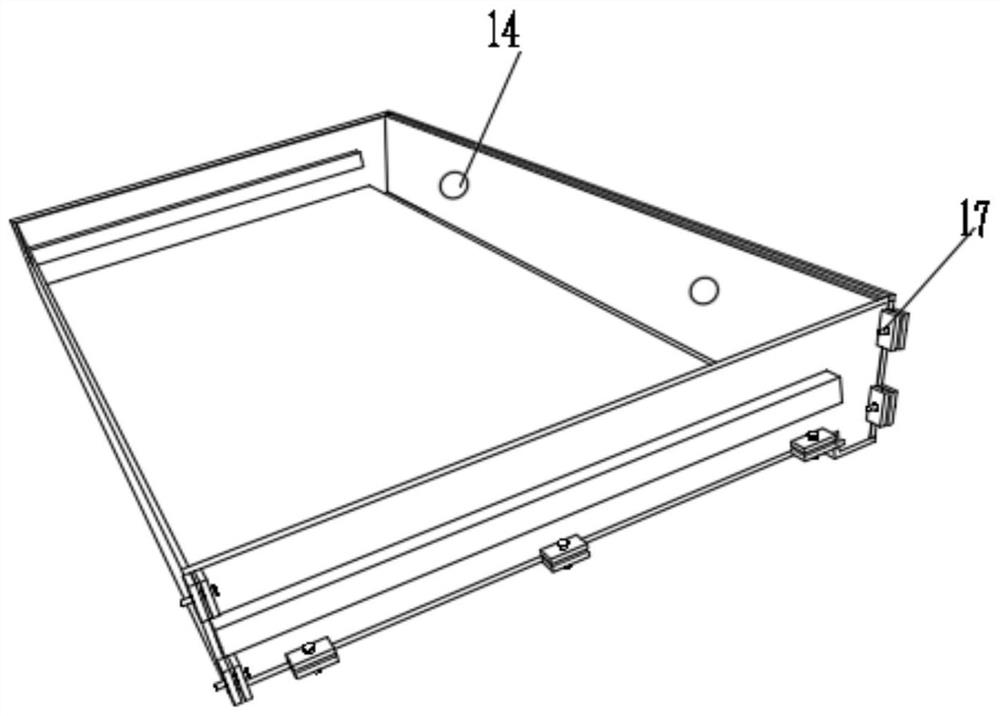

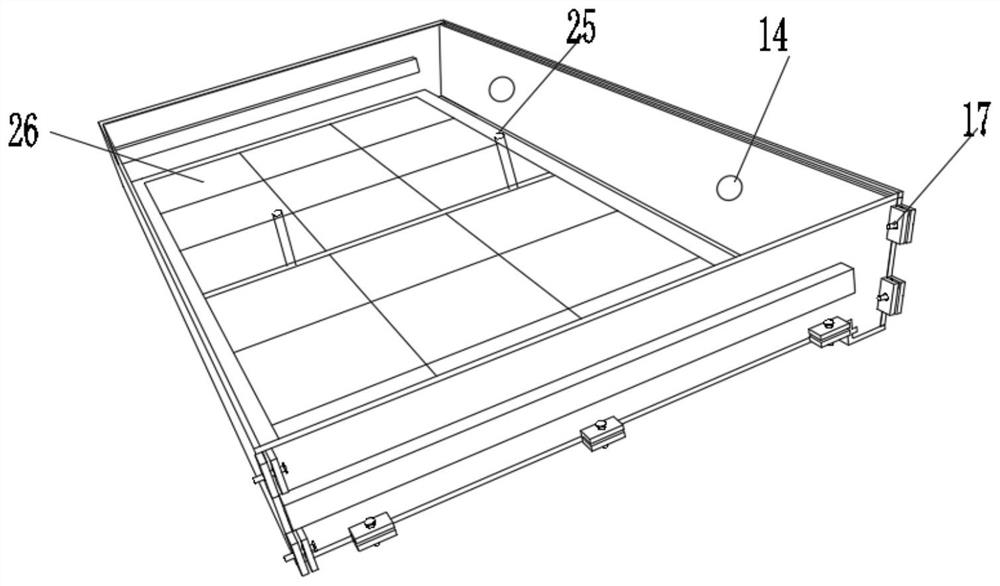

Construction method and formwork structure for structure bottom plate and ground plate of underground pipe gallery

ActiveCN107542109ASolve empty drumSolve quality problemsArtificial islandsUnderwater structuresRebarGround plate

The invention relates to a construction method for a structure bottom plate and a ground plate of an underground pipe gallery. The construction method comprises the following steps that bottom plate rebars are bound to the position of the to-be-constructed bottom plate, and a bottom plate mold plate is erected; ground plate mold plates are erected above the bottom plate rebars, and the ground plate mold plates are located on the two sides of the to-be-constructed ground plate; a capping mold plate is laid above the bottom plate rebars, the capping mold plate is located on the outer side of a ground plate pouring space and seals the bottom plate pouring space, and the capping mold plate is fixedly connected with the corresponding ground plate mold plate; concrete is poured into the bottom plate pouring space, and the structure bottom plate is formed; and after the pouring of the concrete of the bottom plate is completed, steel fiber reinforced concrete is poured into the ground plate pouring space from the portion above the concrete of the bottom plate, and the ground plate is formed. According to the construction method, the structure bottom plate and the ground plate are formed ata time, and the problems that the material transportation is difficult, the working plane is narrow, and construction is not facilitated due to insufficient light in the post-construction process ofthe building ground plate are avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Cracking-resistant cement mortar

The invention relates to a cracking-resistant cement mortar for building plastering, which belongs to building materials, which is prepared from perlite, cement and 801 glue with a volume ratio of (7.5-9):(2.8-3.3):1. The cement mortar solves the cracking, bubbling and poor bonding property problems of the prior plastering material; and has the advantages of high coagulation and setting speed, and good fire resistant, acid and alkali-resistant, thermal insulation and sound absorption properties.

Owner:SHANDONG WANXIN CONSTR

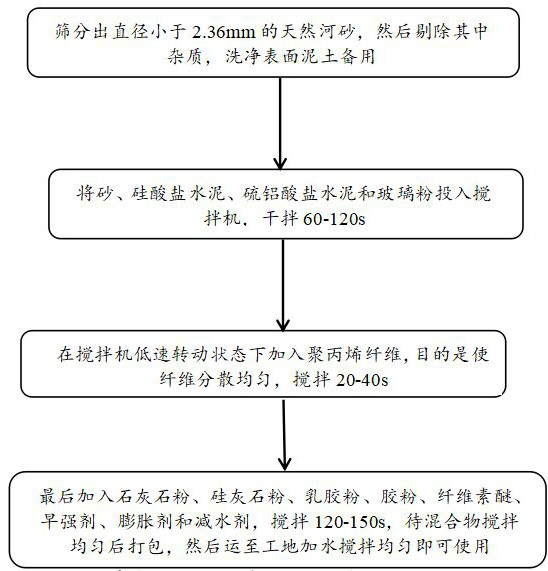

Special dry-mixed mortar for plastering construction via 2D guniting method

The invention discloses special dry-mixed mortar for plastering construction via a 2D guniting method. The dry-mixed mortar is prepared from ordinary Portland cement, sulphoaluminate cement, river sand, water, polypropylene fibers, limestone powder, glass powder, coating-grade wollastonite powder, latex powder, rubber powder, cellulose ether, an early strength agent, an expanding agent and a waterreducing agent. The mortar has the advantages of solving the problems of segregation, bleeding, low early strength, no water resistance, low tensile bonding strength, easy generation of initial micro-cracks, rough surface, easy dust accumulation and the like of conventional mortar, and being good in workability, high in bonding strength, capable of effectively preventing the mortar of a plaster layer from falling off, hollowing and cracking, excellent in cost performance and capable of eliminating obstacles in popularization of a mechanical guniting technology; and therefore, a series of problems caused by manual operation are solved.

Owner:GUANGZHOU UNIVERSITY +1

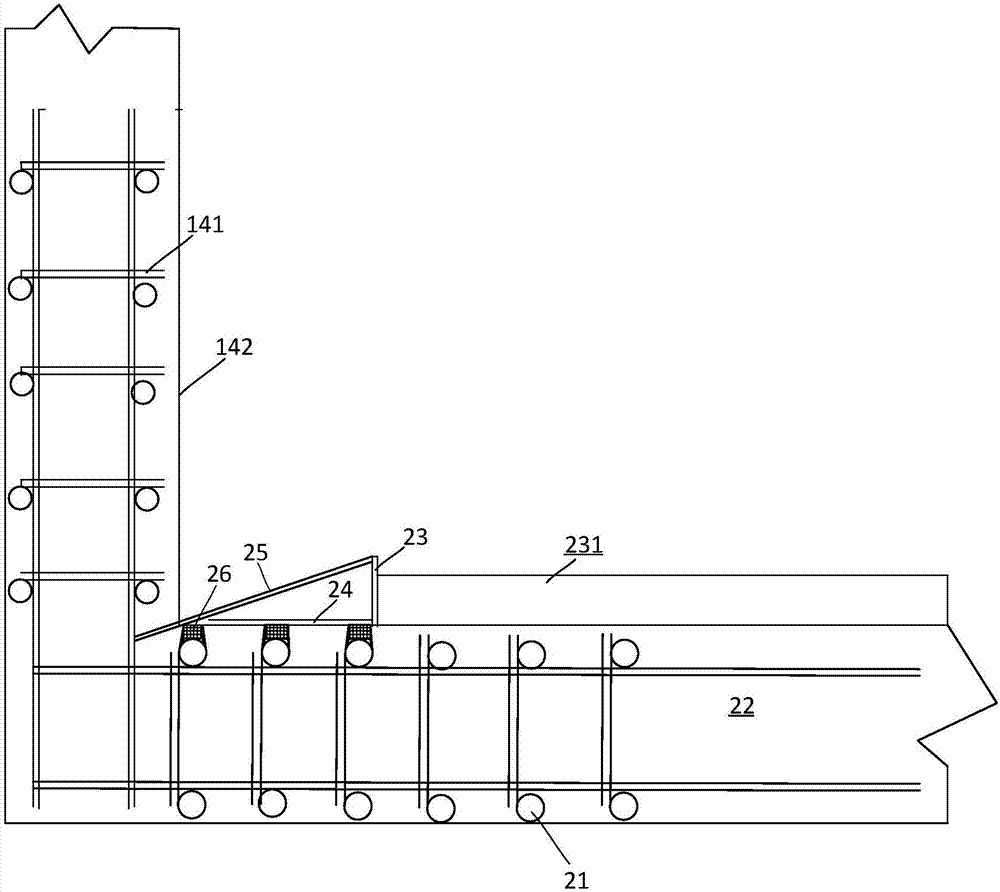

Thermal bridge dispersion type built-in thermal insulation concrete structure system

InactiveCN101787747BReduce the impactUniform heat transferHeat proofingBuilding material handlingThermal bridgeStructure of the Earth

The invention relates to a thermal bridge dispersed built-in thermal insulation concrete structure system. It includes load-bearing concrete structure layer, thermal insulation material layer and concrete protection layer from the inside to the outside. There are reserved holes at regular intervals along the vertical and horizontal directions of the thermal insulation material layer. There are transverse steel bars, load-bearing concrete structure layer and concrete protection layer in the holes. The steel bars in it are connected to form a tension bridge with the poured concrete, and an inner insulation material layer slightly larger than the reserved hole is fixed on the inner side of the load-bearing concrete structure layer corresponding to the reserved hole. The invention can disperse the thermal bridge effect, balance the heat transfer of the building envelope, significantly reduce the thermal bridge effect, and have good thermal insulation performance; the built-in thermal insulation layer is safe to use and can last the same life as the structure, greatly exceeding the external thermal insulation system 25-year service life; it can eliminate hidden dangers such as easy cracks, hollowing, leakage, and shedding caused by the use of external wall paste and external insulation layers. It combines many advantages such as thermal insulation, earthquake resistance, environmental protection, short construction period, and low cost.

Owner:河南省第一建设集团第七建筑工程有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com