Repair method of existing building wall thermal insulation system

A technology for existing buildings and thermal insulation systems, applied in building maintenance, thermal insulation, construction, etc., can solve problems such as poor wind pressure resistance and thin thickness of metal exterior wall veneer, achieve strong applicability, and solve wall hollowing , The effect of simple construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

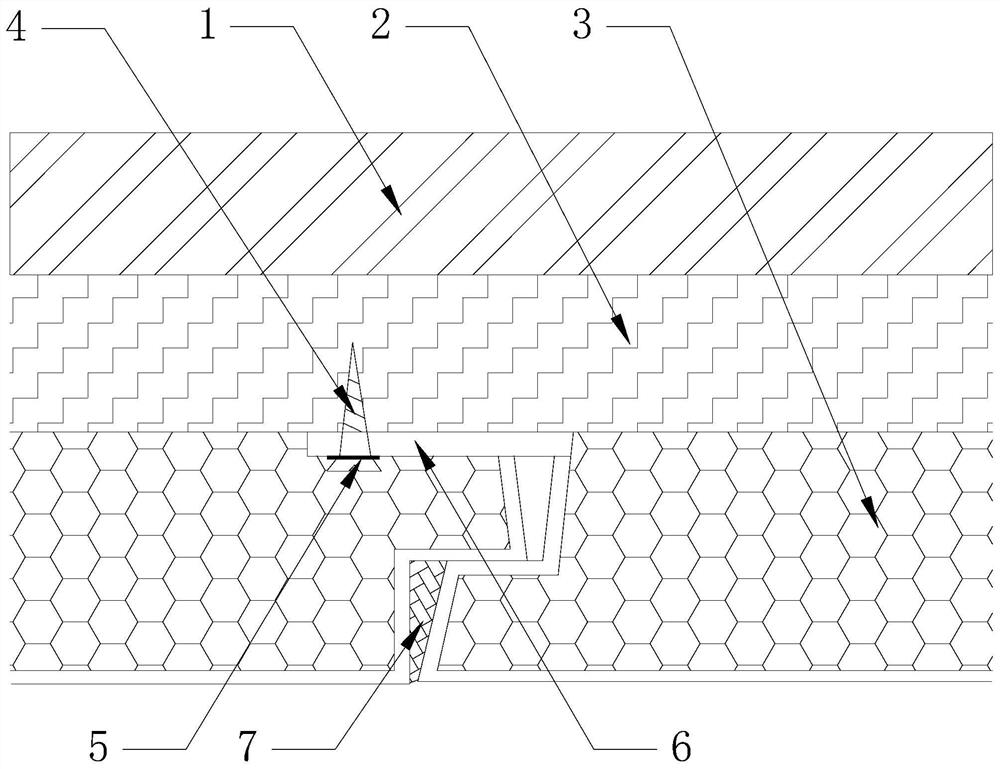

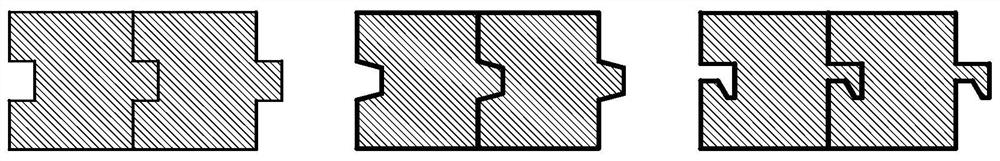

[0028] Such as figure 1 A method for repairing an existing building wall insulation system is shown. The existing building wall insulation system includes a keel 2 and a metal exterior wall decorative panel 3 arranged outside the base wall 1. The repair method includes the following steps:

[0029] A. Keel 2 design: Use the finite element method to model the keel 2, calculate the building wind load, and design the material and density of the keel 2 according to the different heights and shape characteristics of the existing buildings;

[0030] B. Base treatment: Detect the flatness of the existing building walls, fix the drums and openings of the insulation layer on the base wall 1 with adhesives, so that the flatness of the base is less than 4mm;

[0031] C. Keel 2 laying: According to the design requirements, lay keel 2 on the outer surface of the existing building wall, and the keel 2 is anchored on the main structure of the building with anchor bolts;

[0032] D. Laying o...

Embodiment 2

[0037] A method for repairing an existing building wall thermal insulation system. The existing building wall thermal insulation system includes a keel 2 and a metal exterior wall decorative panel 3 arranged outside a base wall 1. The repair method includes the following steps:

[0038] A. Keel 2 design: Use the finite element method to model the keel 2, calculate the building wind load, and design the material and density of the keel 2 according to the different heights and shape characteristics of the existing buildings;

[0039] B. Base treatment: Check the flatness of the existing building wall, anchor the drum and opening of the insulation layer on the base wall 1 with anchor bolts, so that the flatness of the base is less than 4mm;

[0040] C. Keel 2 laying: According to the design requirements, lay keel 2 on the outer surface of the existing building wall, and the keel 2 is anchored on the main structure of the building with anchor bolts;

[0041] D. Laying of metal ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com