Special dry-mixed mortar for plastering construction via 2D guniting method

A dry-mixed mortar and shotcrete technology, applied in the field of mortar, can solve the problems of low tensile bond strength, low early strength, and high bond strength, and achieve the effects of reducing porosity, reducing shrinkage deformation, and solving dust accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

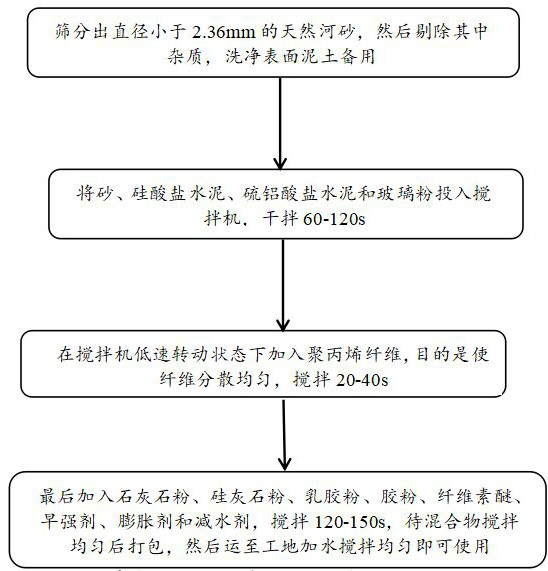

[0049] The preparation method of the special dry-mixed mortar for 2D shotcrete plastering construction of the present invention comprises the following steps: putting sand, Portland cement, low-alkalinity sulfoaluminate cement and glass powder into a mixer, and dry-mixing for 60-120s; Then add polypropylene fibers in the state of low-speed rotation of the mixer, the purpose is to disperse the fibers evenly, and stir for 20-40s; finally add limestone powder, wollastonite powder, latex powder, rubber powder, cellulose ether, early strength agent, expansion agent and Water reducing agent, stir for 120-150s. After the mixture is evenly stirred, it is packaged and transported to the construction site. Add water and mix well at the construction site before use. In the whole preparation process, the amount of materials is accurately weighed according to the mixing ratio.

[0050] In the following examples, the strength grade of Portland cement and sulfoaluminate cement is not less tha...

Embodiment 1

[0052] A special dry-mixed mortar for 2D shotcrete plastering construction is prepared from the following raw materials by weight:

[0053] 441 parts of ordinary Portland cement, 45 parts of sulfoaluminate cement, 1150 parts of river sand, 213 parts of water, 1 part of cellulose ether, 46 parts of early strength agent, 36 parts of swelling agent and 8 parts of water reducing agent.

[0054] The preparation method of the present embodiment comprises the following steps:

[0055] (1) In the test preparation stage, first weigh the above-mentioned various materials required;

[0056] (2) Put the weighed river sand, ordinary Portland cement and sulfoaluminate cement into the mixer, and dry mix for 60-120s;

[0057](3) Finally, add the weighed water, cellulose ether, early strength agent, swelling agent and water reducing agent, stir for 120-150s, and the mixture can be used after stirring evenly.

Embodiment 2

[0059] A special dry-mixed mortar for 2D shotcrete plastering construction is prepared from the following raw materials by weight:

[0060] 401 parts of ordinary Portland cement, 32 parts of sulfoaluminate cement, 1000 parts of river sand, 213 parts of water, 27 parts of polypropylene fiber, 50 parts of limestone powder, 30 parts of glass powder, 24 parts of wollastonite powder, 8 parts of latex powder 12 parts of rubber powder, 1 part of cellulose ether, 46 parts of early strength agent, 36 parts of swelling agent, and 8 parts of water reducing agent.

[0061] The preparation method of the present embodiment comprises the following steps:

[0062] (1) In the test preparation stage, first weigh the above-mentioned various materials required;

[0063] (2) Put the weighed river sand, Portland cement, sulfoaluminate cement and glass powder into the mixer, and dry mix for 60-120s;

[0064] (3) Add the weighed polypropylene fiber under the low-speed rotation of the mixer, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com