Thermal bridge dispersion type built-in thermal insulation concrete structure system

A technology of thermal insulation concrete and concrete structure, which is applied in the direction of thermal insulation, building components, building structure, etc. It can solve problems affecting the normal use and durability of buildings, the impact of indoor living environment, and mildew on the inner walls of houses, so as to ensure the internal Quality and appearance effect, reduce the influence of thermal bridge effect, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

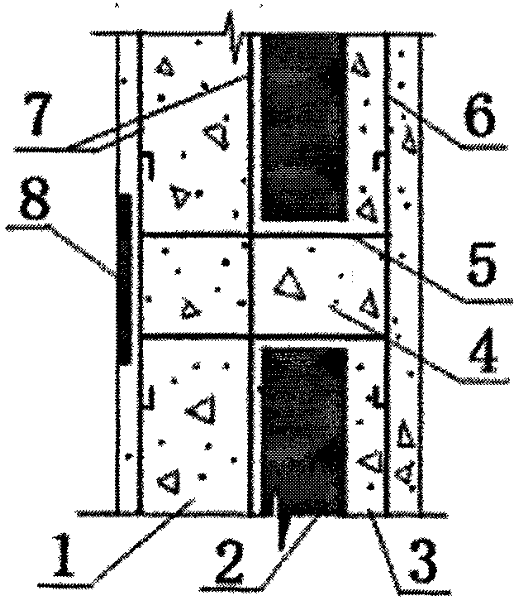

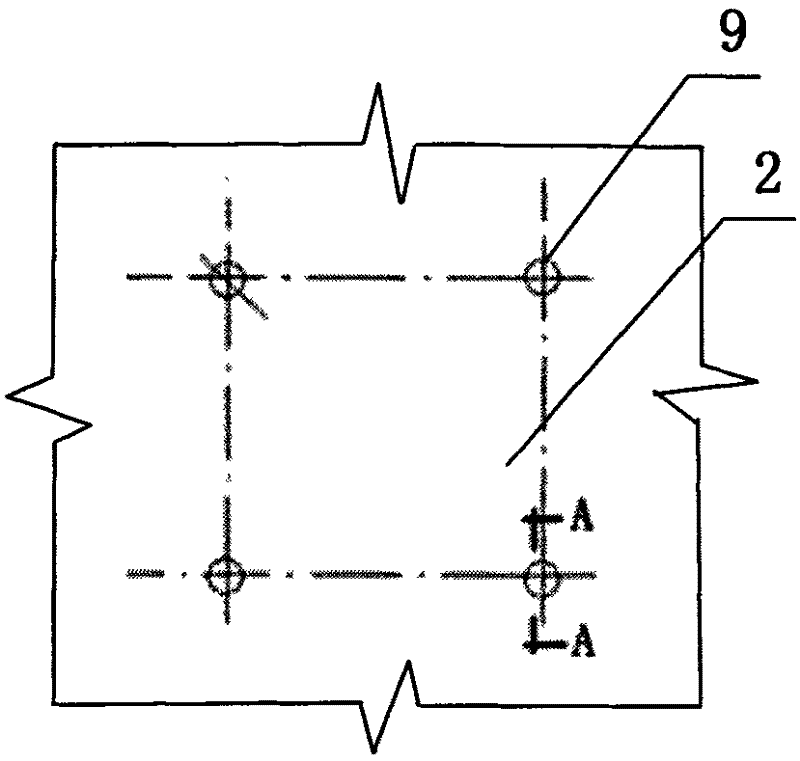

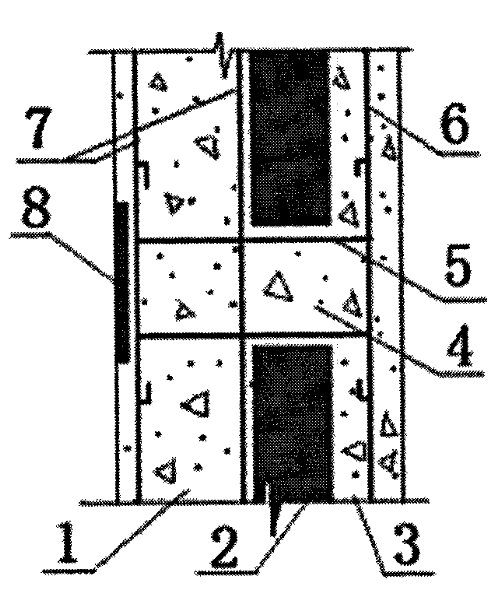

[0035] Embodiment 1 A thermal bridge dispersed built-in thermal insulation concrete structure system, see figure 1 , figure 2 , including load-bearing concrete structure layer 1, thermal insulation material layer (XPS insulation board) 2, concrete protection layer 3, concrete protection layer 3 (thickness 50mm) from inside to outside, its strength is not lower than C25, and the load-bearing concrete structure layer 1 It is connected with the concrete protective layer 3 through a certain number of tension bridges 4 that pass through the reserved holes 9 of the XPS insulation board 2 in a dispersed manner. 1500mm, the cross-section of the reserved hole 9 is circular (Φ80mm), the sum of the area of the cross-section of all the reserved holes 9 accounts for 0.3-0.6% of the corresponding wall area, and the inner side of the load-bearing concrete layer 1 is set to block the reserved hole Inner insulation material layer (square XPS insulation board, side length 120mm, thickness 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com