Novel vitrified brick gum

A technology of vitrified tiles and back glue, which is applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems of uneven quality, vitrified tiles falling off, hollowing, etc., achieve good corrosion resistance and improve construction The effect of high resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

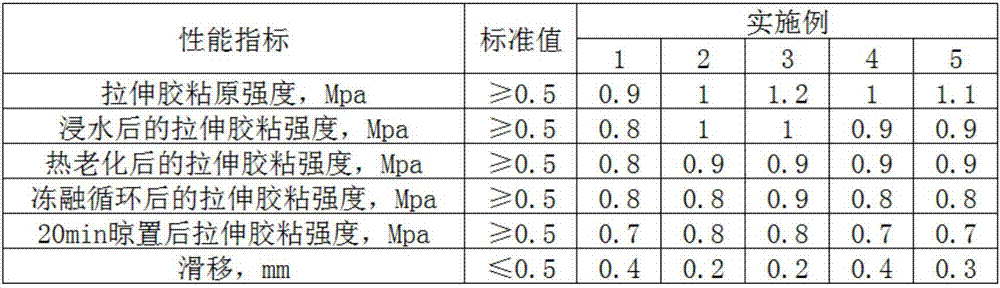

Examples

Embodiment 1

[0018] A new type of vitrified tile adhesive, including slurry and powder, the weight percentage of the slurry and powder is 1:3.5, wherein,

[0019] The slurry includes: 10 parts of TX-5169 elastic emulsion, 5 parts of DY100 styrene-acrylic emulsion, 10 parts of water-based epoxy resin, 7 parts of fumed silica, 10 parts of KH560 silane coupling agent, 1.8 parts of palladium calcium carbonate catalyst, preservative 0.5 parts, 0.5 parts of cellulose;

[0020] The powder includes: 1 part of rutile titanium dioxide, 5 parts of 400-mesh ground calcium carbonate, and 10 parts of quartz sand.

Embodiment 2

[0022] A new type of vitrified tile adhesive, including slurry and powder, the weight percentage of the slurry and powder is 1:4, wherein,

[0023] The slurry includes: 30 parts of TX-5169 elastic emulsion, 25 parts of DY100 styrene-acrylic emulsion, 20 parts of water-based epoxy resin, 15 parts of fumed silica, 15 parts of KH560 silane coupling agent, 3 parts of palladium calcium carbonate catalyst, preservative 3 parts, 1.5 parts of cellulose;

[0024] The powder includes: 8 parts of rutile titanium dioxide, 8 parts of 400-mesh ground calcium carbonate, and 20 parts of quartz sand.

Embodiment 3

[0026] A new type of vitrified tile adhesive, including slurry and powder, the weight percentage of the slurry and powder is 1:4, wherein,

[0027] The slurry includes: 20 parts of TX-5169 elastic emulsion, 15 parts of DY100 styrene-acrylic emulsion, 12 parts of water-based epoxy resin, 8 parts of fumed silica, 9 parts of KH560 silane coupling agent, 2 parts of palladium calcium carbonate catalyst, preservative 2 parts, 1 part cellulose;

[0028] The powder includes: 5 parts of rutile titanium dioxide, 10 parts of 400-mesh ground calcium carbonate, and 15 parts of quartz sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com