Gypsum plastering mortar suitable for mechanical spray coating construction and construction process of gypsum plastering mortar

A technology of plastering mortar and gypsum, which is applied in the direction of construction and building construction, etc., to achieve the effects of easy pumping, increased strength and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

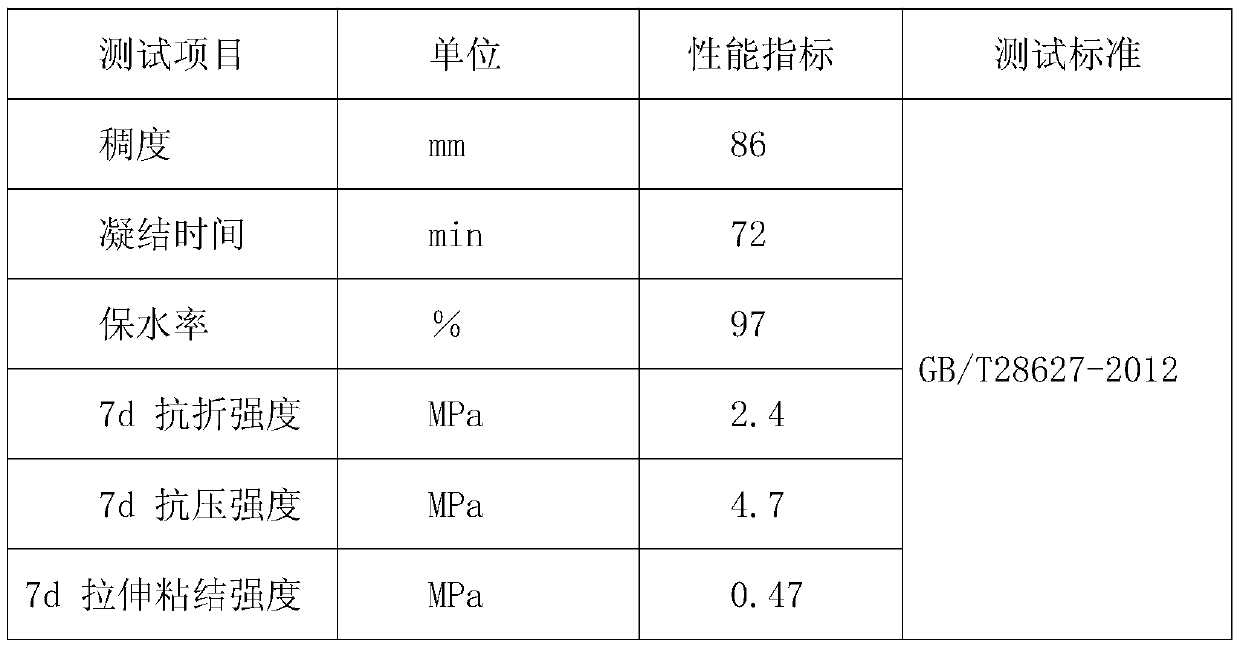

Embodiment 1

[0031] Embodiment 1, the gypsum plastering mortar suitable for machine spraying spraying construction comprises the raw materials of following weight ratio:

[0032] Gypsum composite gel 43.9%, said gypsum composite gel comprises the following components by weight: desulfurized gypsum 25.2%, waste phosphogypsum 18.5%, gypsum retarder 0.2%, alkaline activator 0.05%, said alkaline The activator is quicklime;

[0033] 20% fine aggregate, using river sand, the maximum particle size is not greater than 0.3mm;

[0034] 3% modified attapulgite, the modified attapulgite is calcined at 400°C for 2h in a muffle furnace, and then calcined at 820°C for 2h to obtain calcined modified attapulgite;

[0035] 8% fly ash, adding fly ash is beneficial to improve the gradation of gypsum plastering mortar and increase the fluidity of slurry;

[0036] Vitrified microbeads 3.5%;

[0037] Redispersible latex powder 1%;

[0038] 0.5% of anti-cracking water-retaining agent, containing 0.1% of hydro...

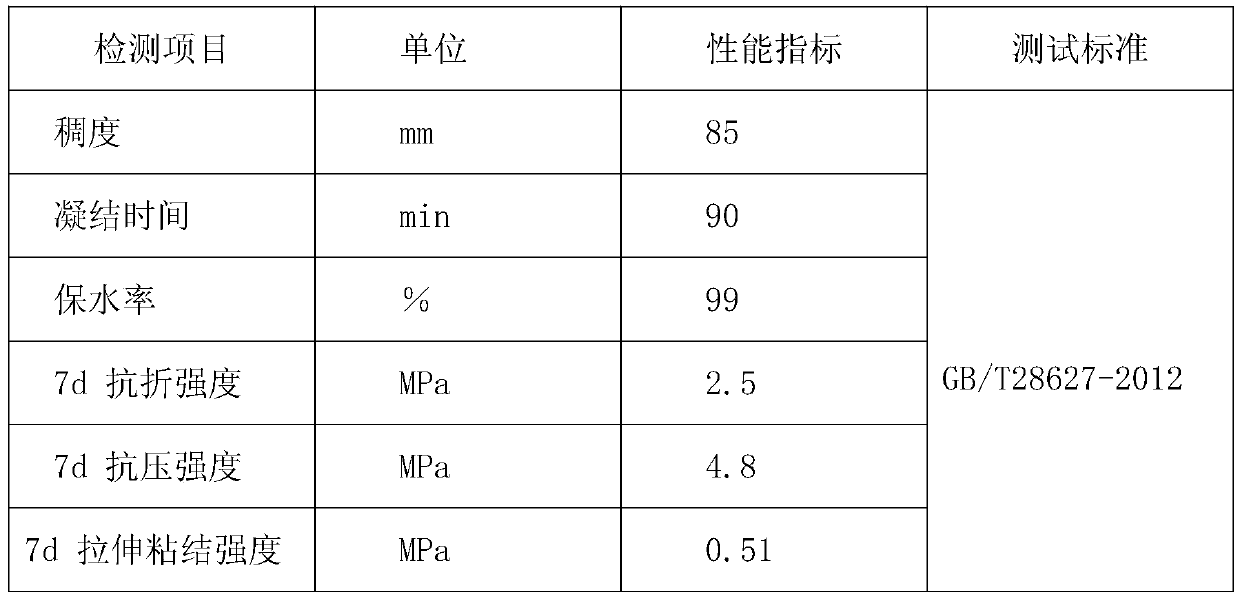

Embodiment 2

[0050] Embodiment two, the gypsum plastering mortar suitable for machine spraying spraying construction comprises the raw materials of following weight ratio:

[0051] Gypsum composite gel 37.9%, said gypsum composite gel comprises the following components by weight: desulfurized gypsum 21.6%, waste phosphogypsum 16.1%, gypsum retarder 0.2%, alkaline activator 0.05%, said alkaline The activator is quicklime;

[0052] 24% fine aggregate, using river sand, the maximum particle size is not greater than 0.3mm;

[0053] 3% modified attapulgite, the modified attapulgite is calcined at 400°C for 2h in a muffle furnace, and then calcined at 820°C for 2h to obtain calcined modified attapulgite;

[0054] Fly ash 6%, adding fly ash is beneficial to improve the gradation of gypsum plastering mortar and increase the fluidity of slurry;

[0055] Vitrified microbeads 2.5%;

[0056] Redispersible latex powder 1%;

[0057] 0.5% of anti-cracking water-retaining agent, containing 0.1% of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com