Adhesive for tiles and preparation method of adhesive

A technology of tile adhesive and redispersed latex powder, which is applied in the field of building materials, can solve the problems of high hardness, easy cracking of brick surface, high alkalinity, etc., and achieve the effect of high bonding strength, good corrosion resistance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Yet another embodiment of the present invention provides a kind of preparation method of above-mentioned tile glue, comprises the following steps:

[0041] Step 1: Preparation of powdery materials: take the Yellow River sediment, dry fine sand and silt and transport them to the feeder and pulverizer in turn, put them in the dryer for drying, and then sieve to obtain powdery materials of 200-300 mesh;

[0042] Step 2: Preparation of rosin saponification: Take rosin, sodium hydroxide and water and put them into a reaction kettle and heat at 160-190°C for 20-40 minutes to obtain a brown transparent paste. Put the paste into a vacuum of 93.3-98.6KPa. Dry the body in a vacuum oven at a temperature of 60-80°C for 5-7 hours, and then pulverize to obtain saponified rosin;

[0043] Step 3: Preparation of tile adhesive: Take the cement and the powdered material obtained in Step 1 and add them to the mixer, stir in a dry state for 1 to 2 minutes, then add water-soluble silicate, red...

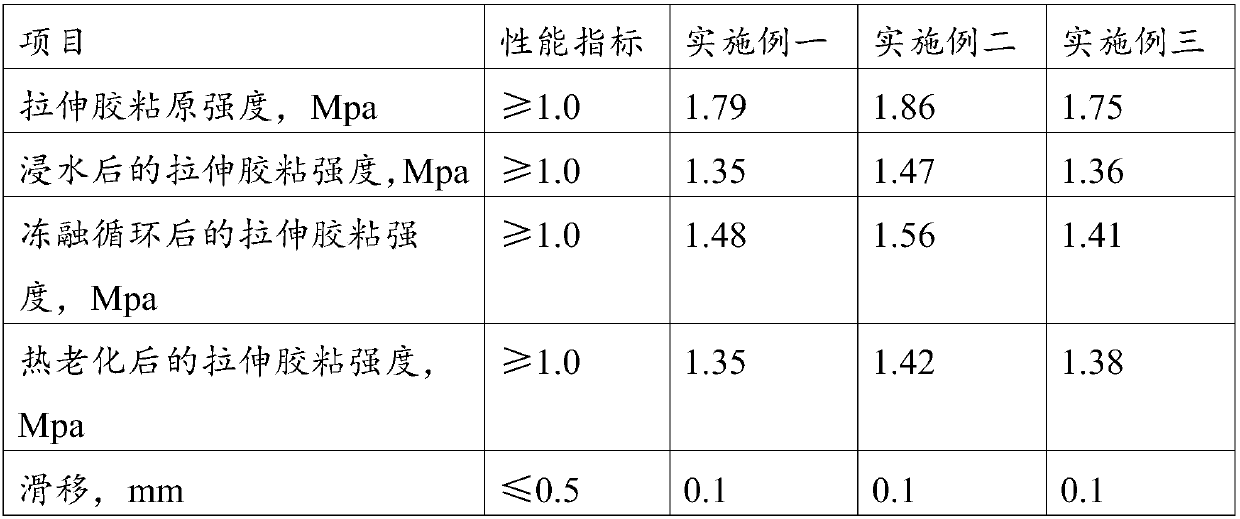

Embodiment 1

[0046] Embodiment 1: a kind of tile adhesive, comprising the following raw material components in parts by weight: comprising the raw material components in the following parts by weight: 25 parts of Yellow River silt, 35 parts of dry fine sand, 10 parts of silt, 20 parts cement, 2 parts of rosin saponification, 5 parts of water-soluble silicate, 1 part of redispersible latex powder, 2 parts of micro-expansion agent, 0.5 part of water reducer, 0.2 part of superplasticizer, 5 parts of thickener and 0.1 part of anti-crack fiber.

[0047] Said rosin saponified product comprises parts by weight of 70 parts of rosin, 10 parts of sodium hydroxide and 120 parts of water; said micro-swelling agent is calcium magnesium oxide and calcium sulfoaluminate; said redispersible latex powder is Styrene-acrylic acid copolymer latex powder; the water reducer is melamine; the superplasticizer includes vinyl acetate-ethylene copolymer dry powder and polyethylene dry powder; the thickener includes ...

Embodiment 2

[0052] Embodiment 2: a kind of tile adhesive, comprising the following raw material components in parts by weight: comprising the following raw material components in parts by weight: 35 parts of Yellow River silt, 30 parts of dry fine sand, 20 parts of silt, 12 parts cement, 6 parts of rosin saponification, 3 parts of water-soluble silicate, 2 parts of redispersible latex powder, 1.5 parts of micro-expansion agent, 2 parts of water reducing agent, 1.5 parts of superplasticizer, 3 parts thickener and 1.4 parts anti-crack fiber.

[0053] Said rosin saponified product comprises parts by weight of 60 parts of rosin, 16 parts of sodium hydroxide and 89 parts of water; said micro-swelling agent is calcium magnesium oxide and calcium sulfoaluminate; said redispersible latex powder is Ethylene-vinyl acetate copolymer latex powder; the water reducer is polycarboxylic acid; the superplasticizer is polyacrylate dry powder; the thickener includes a mixture of polyacrylamide, polyvinyl al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com