Roof water-proof thermal-insulation construction technique

A technology of thermal insulation and construction technology, applied in the direction of building roofs, roof covering layers, etc., can solve the problems of poor air permeability, serious crispness and no affinity of extruded plastic boards, and achieve scientific and reasonable construction technology and outstanding substantive characteristics. , outstanding bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

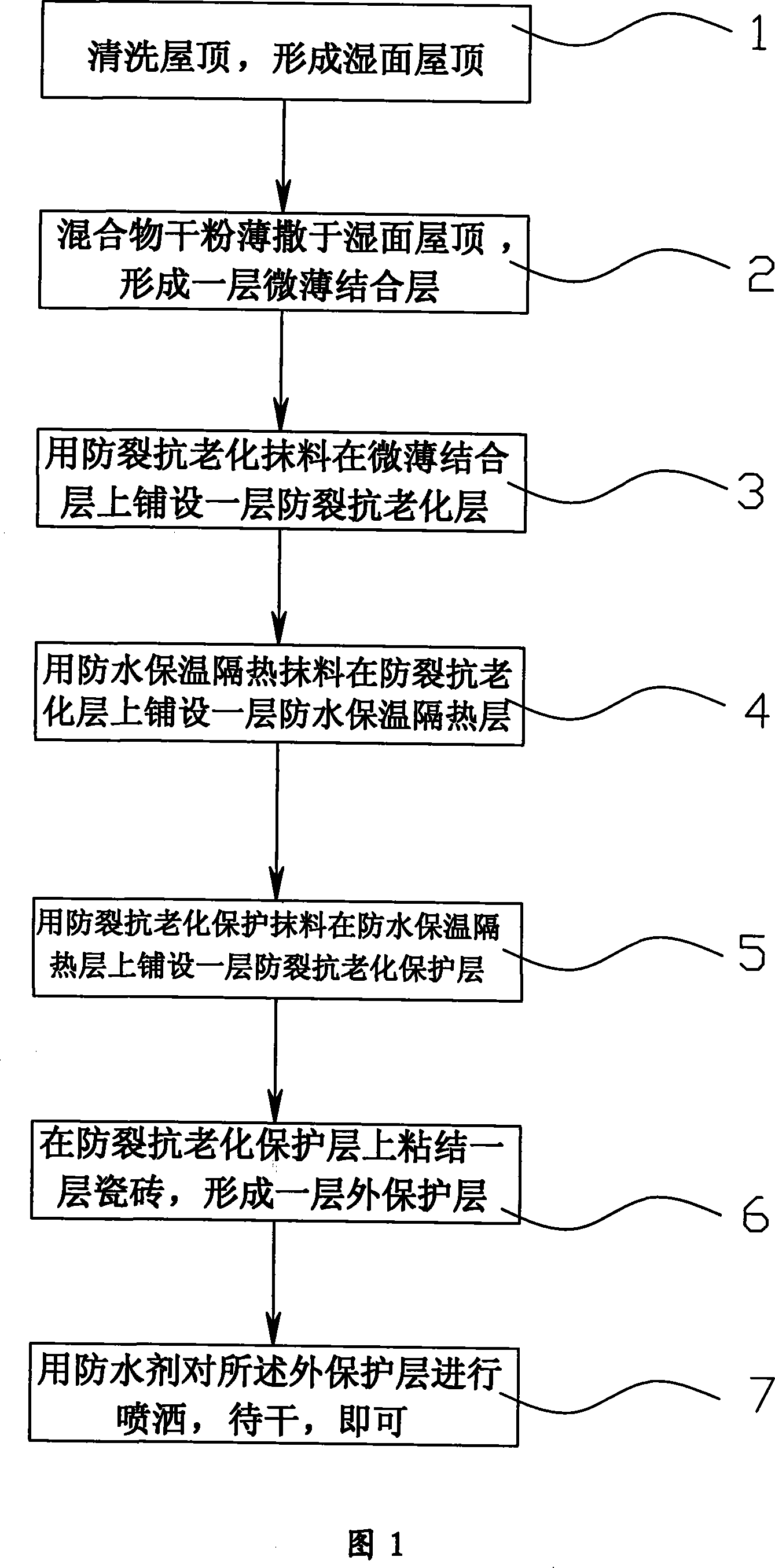

[0032] As shown in Figure 1, a roof waterproof thermal insulation construction process, the construction process includes the following steps:

[0033] Step 1. Remove sundries and floating dust from the roof, and wash it with water to form a wet roof;

[0034] Step 2. Spread the dry powder of the mixture formed by mixing modified calcium carbonate dry powder and cement dry powder on the wet roof, and then sweep back and forth with a broom to make the dry powder of the mixture evenly combine with the wet roof to form a layer A thin bonding layer; the weight ratio of the modified calcium carbonate dry powder to the cement dry powder is 1:10;

[0035] Step 3. Mix the anti-cracking and anti-aging material with the waterproofing agent to construct the anti-cracking and anti-aging micro-smear, and use the anti-cracking and anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com