Heat insulating structural system suitable for existing building masonry and construction method thereof

A technology of existing buildings and construction methods, applied in the direction of building structure, building components, and building materials, can solve problems such as poor fire performance, poor heat preservation, poor heat insulation performance, and complicated construction process, and achieve a good society Benefits and economic benefits, ensuring safety and durability, and reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

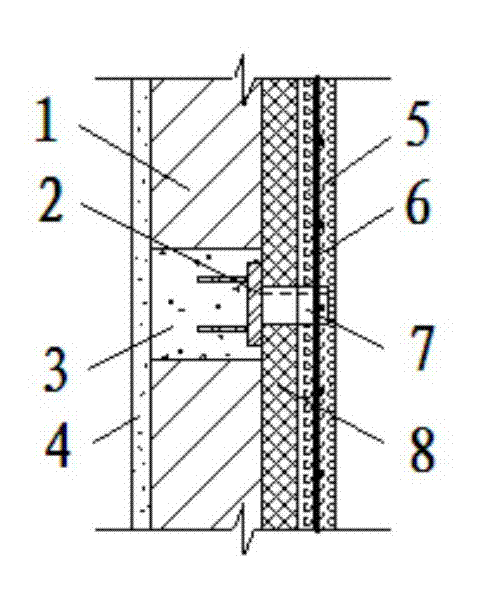

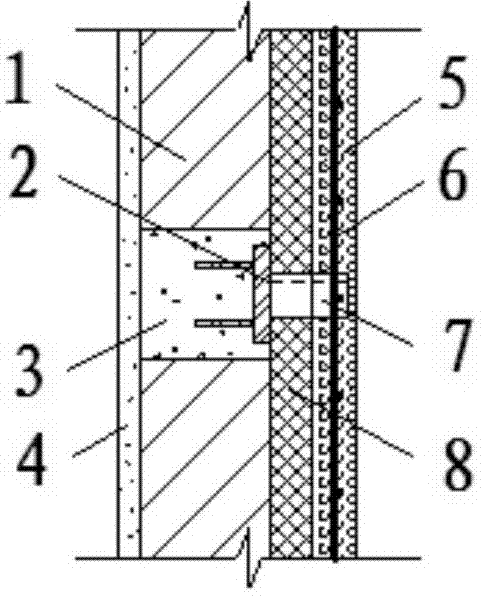

[0029] Example 1 A thermal insulation structural system suitable for existing building masonry, see figure 1 , from the inside to the outside, including the inner decorative layer 4, the existing foundation wall layer 1, the thermal insulation layer (XPS insulation board) 8, the concrete protective layer (thickness 50mm) 5, its strength is not lower than C25, the thermal insulation layer 8 is fixed between the existing foundation wall layer 1 and the concrete protective layer 5, and is provided with concrete anchors 3 at certain distances along the vertical and horizontal directions of the existing foundation wall layer 1, and the concrete anchors 3 are embedded with The embedded part 2 is provided with a reinforcing steel bar 6 in the concrete protective layer 5 , and the reinforcing steel bar 6 is anchored to the embedded part 2 through a tension member 7 penetrating the thermal insulation layer 8 .

[0030] The thickness of the XPS insulation board is set according to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com