Tile bonding and pointing integrated mortar and its production technology

A ceramic tile and mortar technology, which is applied in the field of ceramic tile bonding and pointing integrated mortar and its production technology, can solve the problems of difficult cleaning and the influence of color difference on the aesthetics of building exterior finishes, so as to improve the strength of mortar, maintain color consistency, and save energy. The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments, features and effects of the integrated mortar for tile bonding and pointing according to the present invention and its production process will be described in detail below with reference to the embodiments and the accompanying drawings.

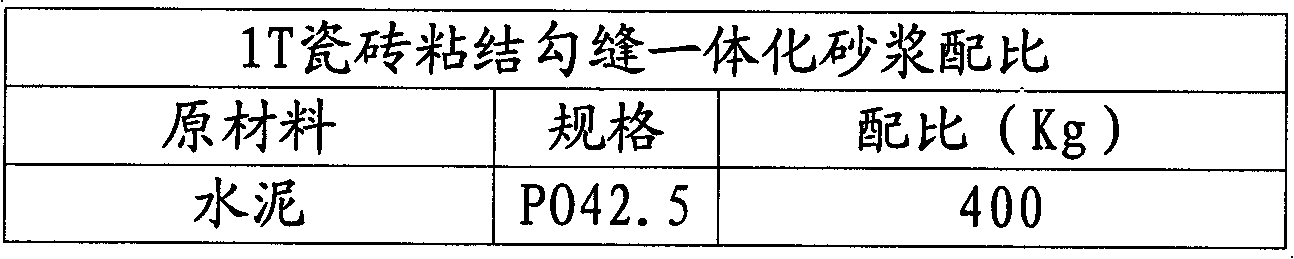

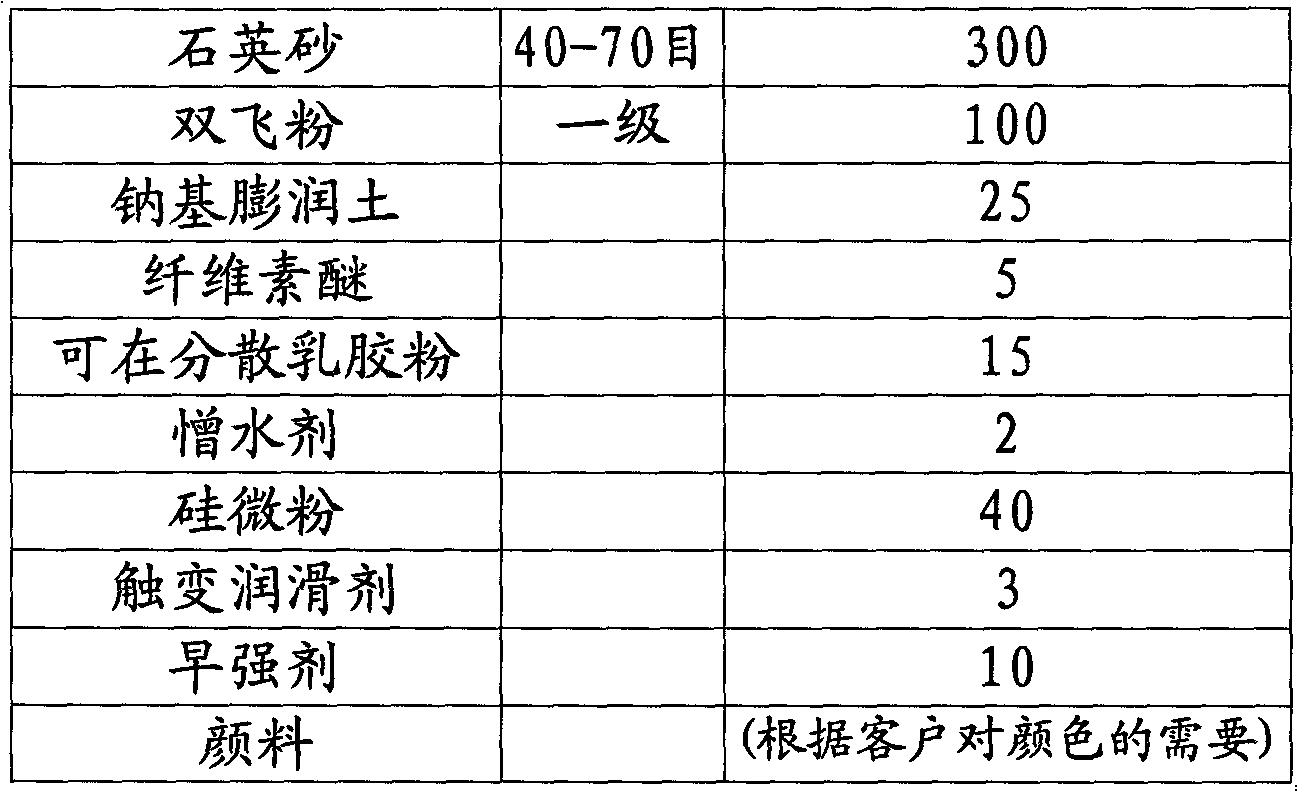

[0050] The integrated mortar for tile bonding and jointing proposed by the present invention is composed of components by weight: 400 parts of cement, 300 parts of quartz sand, 100 parts of double fly powder, 25 parts of sodium bentonite, 5 parts of cellulose ether, and dispersible latex. 15 parts of powder, 2 parts of water repellent, 40 parts of silicon micropowder, 3 parts of thixotropic lubricant, 10 parts of early strength agent, and pigments are accurately measured according to customer needs.

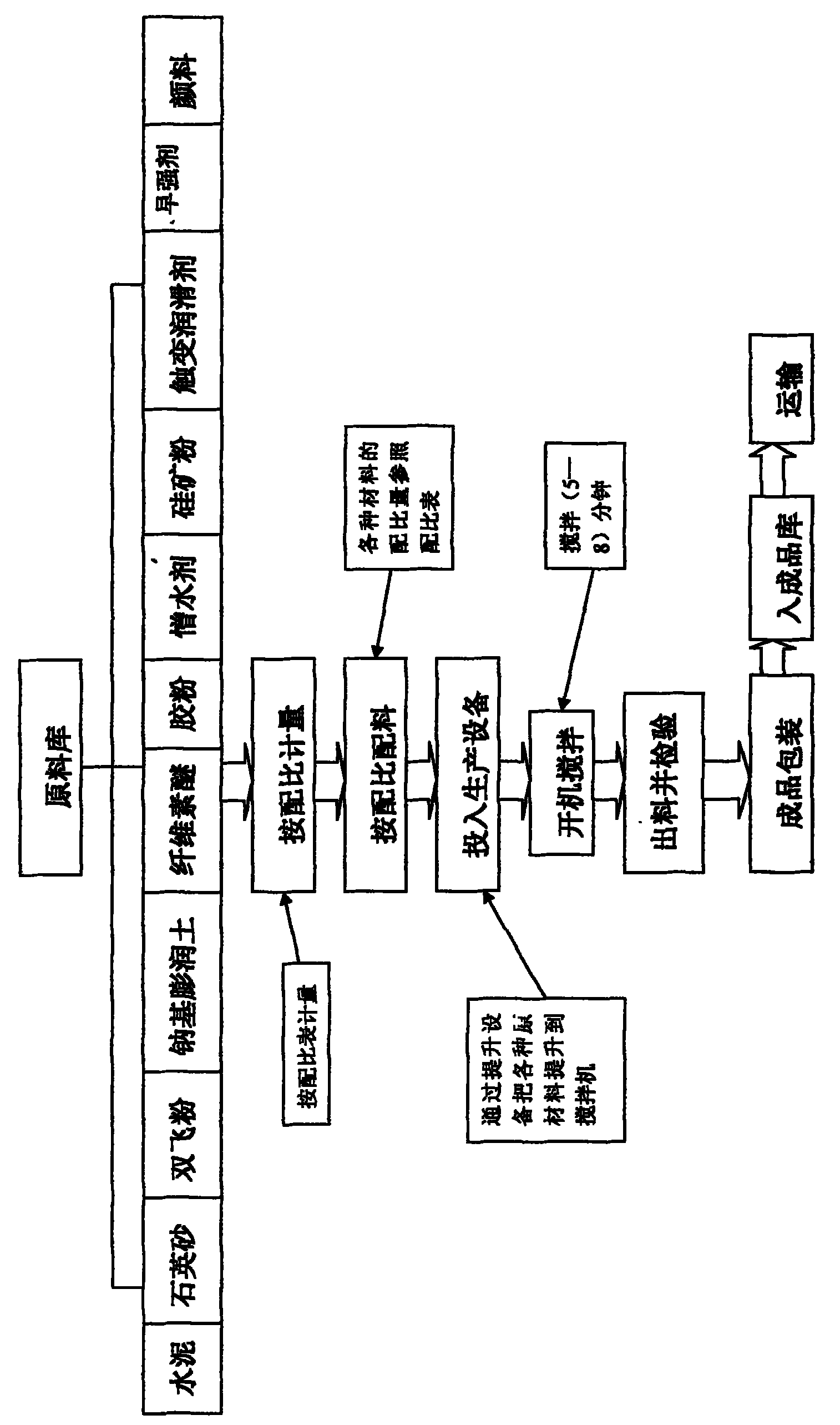

[0051] The production process of the integrated mortar for tile bonding and jointing of the present invention: each component of cement, quartz sand, shuangfei powder, sodium bentonite, cellulose ether, dispersibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com