Road system capable of being quickly assembled and constructed

A road system and fast technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as labor-consuming and time-consuming road maintenance, long construction period, and large footprint of approach bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

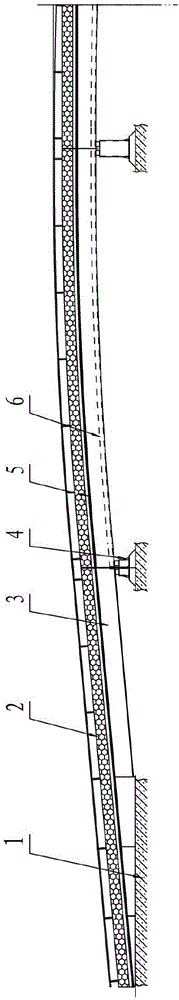

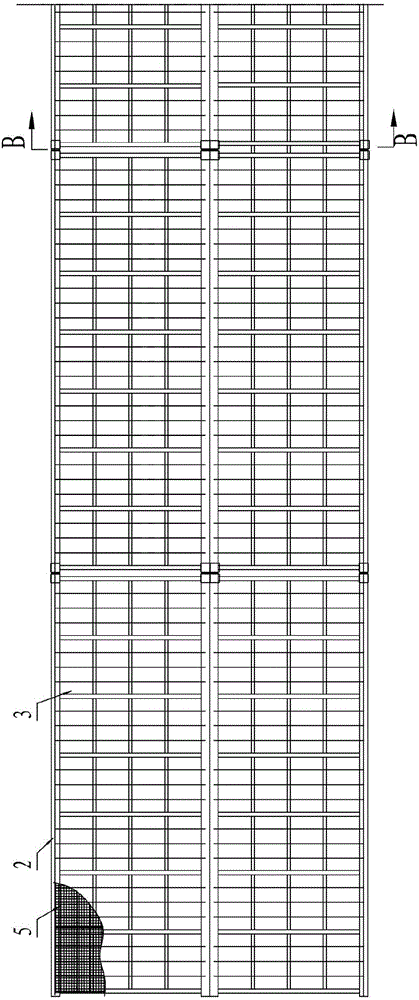

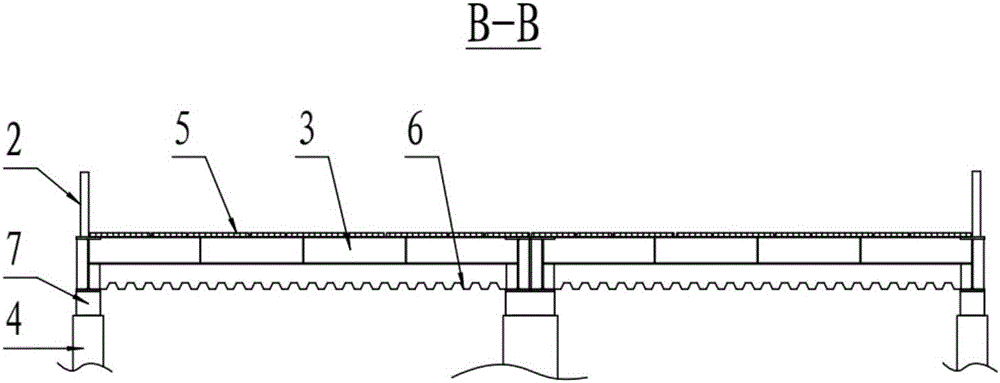

[0025] see figure 1 , figure 2 , the road system of the present invention includes a truss structure layer 3 , a grid pavement layer 5 and a column 4 . The truss structure layer is the skeleton structure of the road system, and the truss structure layer is supported by the foundation 1 and the column 4 according to the erection height of the road surface. The grid pavement layer is laid on the truss structure layer, the grid pavement layer is the surface structure of the road system, and the grid pavement layer is directly in contact with the walking wheels or pedestrians. The grid pavement layer and the truss structure layer are connected by bolts. Anti-collision barriers 2 are arranged on both sides of the grid pavement layer. The truss structure layer is formed by docking truss modules 3-1; the grid pavement layer is formed by laying grid modules 5-1. Both the truss module and the grid module can be pre-produced in the factory, and can be quickly assembled after being ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com