Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Solve the problem of polluting the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

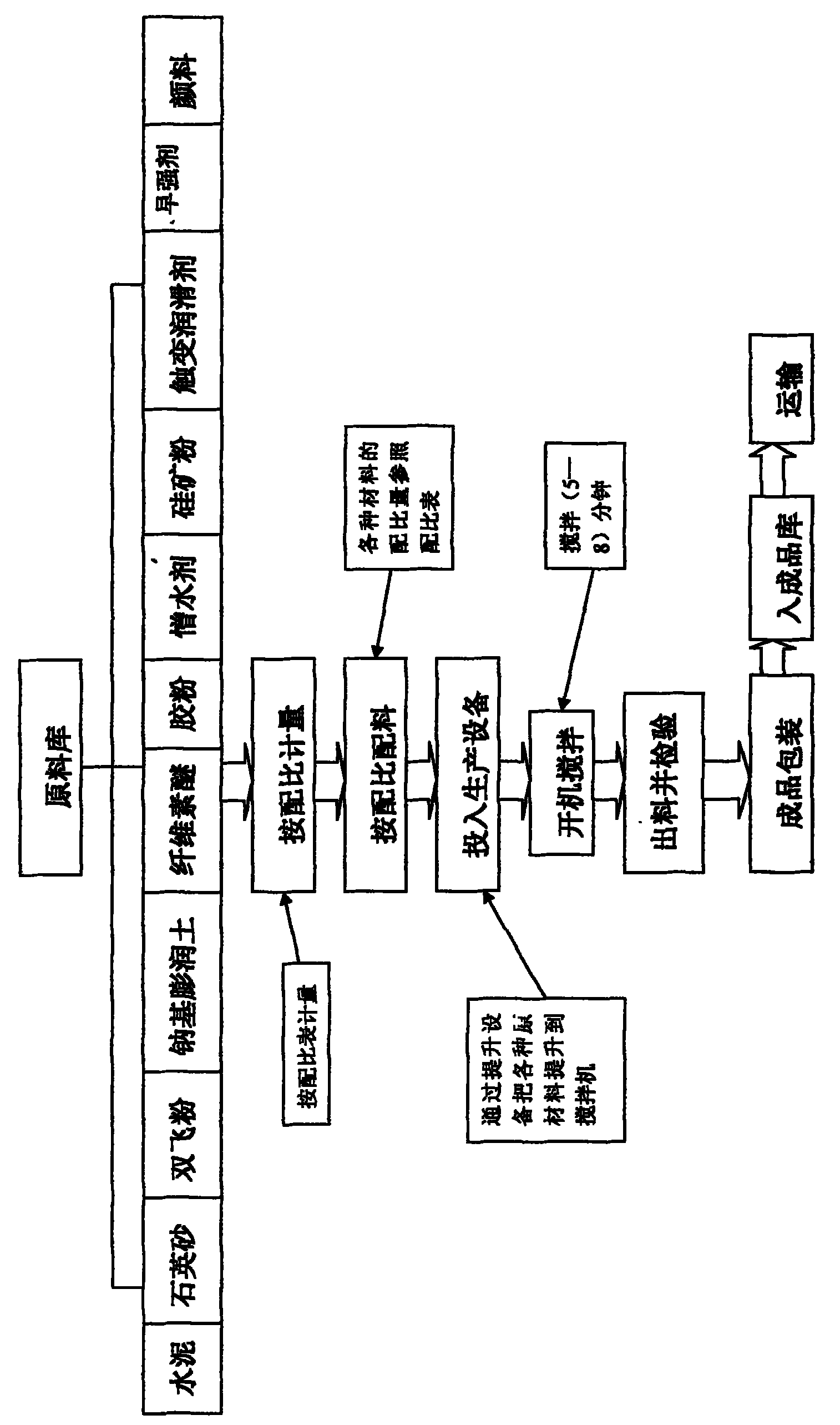

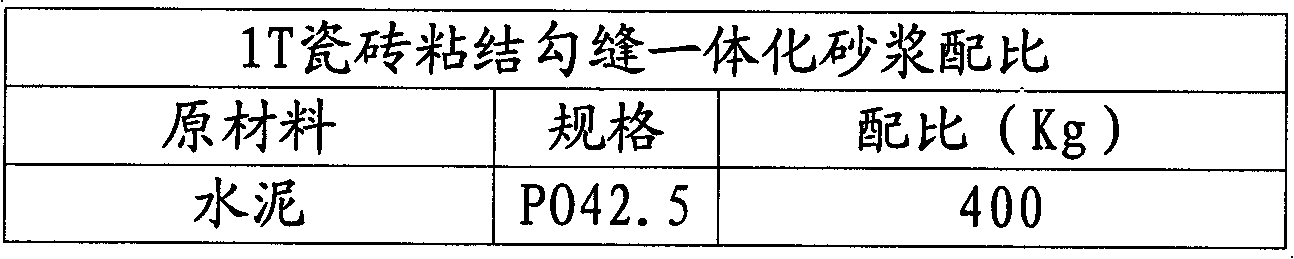

Tile bonding and pointing integrated mortar and its production technology

ActiveCN102424549ASolve the problem of aesthetic influenceReduce construction processCelluloseSodium Bentonite

The invention discloses tile bonding and pointing integrated mortar, which is prepared by subjecting 400 parts by weight of cement, 300 parts by weight of quartz sand, 100 parts by weight of Shuangfei Powder, 25 parts by weight of sodium bentonite, 5 parts by weight of cellulose ether, 15 parts by weight of dispersible latex powder, 2 parts by weight of a water repellent, 40 parts by weight of silicon powder, 3 parts by weight of a thixotropic lubricant, 10 parts by weight of an early strength, and a pigment metered according to a client demand to uniform stirring in a stirrer. The construction process of the tile bonding and pointing integrated mortar comprises: stirring water and cement in a water cement ratio of 0.25 in a stirring bucket into paste with a portable electric mixer, applying the pasty tile glue to the back side of a tile and filling it to the full with a spatula, conducting tiling, tearing off paper after 20min, carrying out pointing with a special circle tool in linewith the size of a tile joint, doing cleaning with a sponge, and cleaning the tile with clear water after 120min. With the mortar of the invention, tile bonding and pointing can be completed in one time. With various colors, the mortar of the invention maintains the color consistency between the underlayer and joints, thus having no influence on appearance. Also, the technology of full applying for pointing can be omitted, and cleaning becomes convenient. Thus, all procedures can be finished at one go.

Owner:贵州皓科新型材料有限公司

Efficient planting technology for inter-planting white gourd and corn in wheat

ActiveCN102283003AStabilize grain acreageImprove the comprehensive grain production capacityPlant protectionSeed coating/dressingWeedFertilizer

The invention discloses an efficient planting technology for inter-planting white gourd and corn in wheat, and relates to a crop culture technology. The technology is characterized by comprising the following steps of: determining a reasonable sowing width, wherein the sowing width for sowing the wheat is generally 4 to 4.5 meters; reserving a reserved row, wherein the width of the reserved row is generally 1 meter and is not less than 0.8 meter; selecting fine matched seeds; applying sufficient base fertilizer; appropriately sowing seeds, wherein the appropriate sowing time of wheat Xinong 979 is about October 25th; raising white gourd seedlings in the first or middle ten days of March, planting the white gourd seedlings in about 20 days before the wheat is harvested, and directly sowing the corn in the middle of the wheat sowing belt in time after the wheat is harvested; performing reasonable thick planting; timely performing topdressing; scientifically irrigating water in time, particularly overwintering water and jointing water; irrigating seedling survival water after the white gourd seedlings are transplanted, irrigating germination accelerating water after the wheat is harvested, and irrigating water manure after melons are seated; and trimming, guiding vines and pressing the vines, wherein the main vine and 2 pieces of strong child vines at the base part of the main vine of the white gourd are reserved, other child vines of the white gourd are early removed, and diseases, pests and weeds are comprehensively prevented and controlled. By the technology, the planting area of grains is stabilized, the comprehensive production capacity of the grains is improved, multi-mature intercropping is developed, the multi-cropping index is improved, and the income of peasants is improved.

Owner:GUZHEN YUPENG VEGETABLE DEV CO LTD

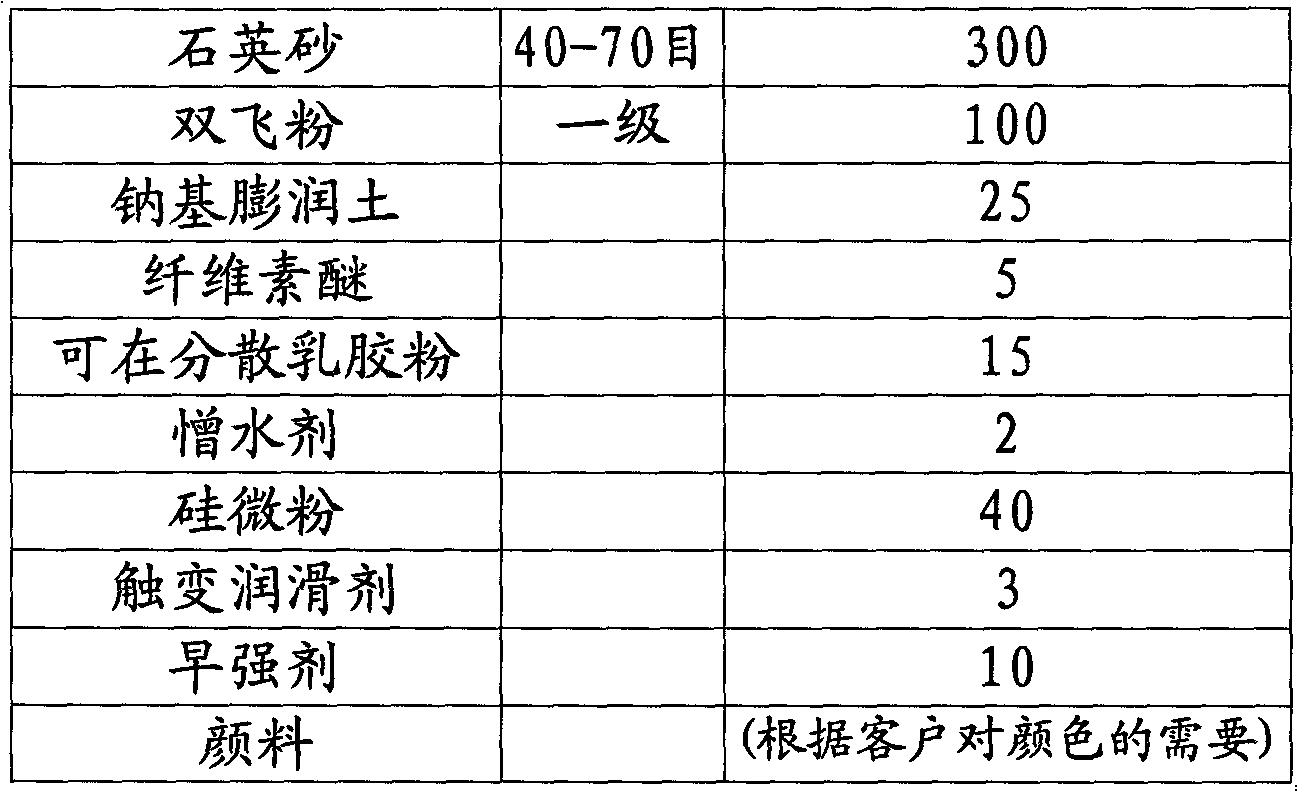

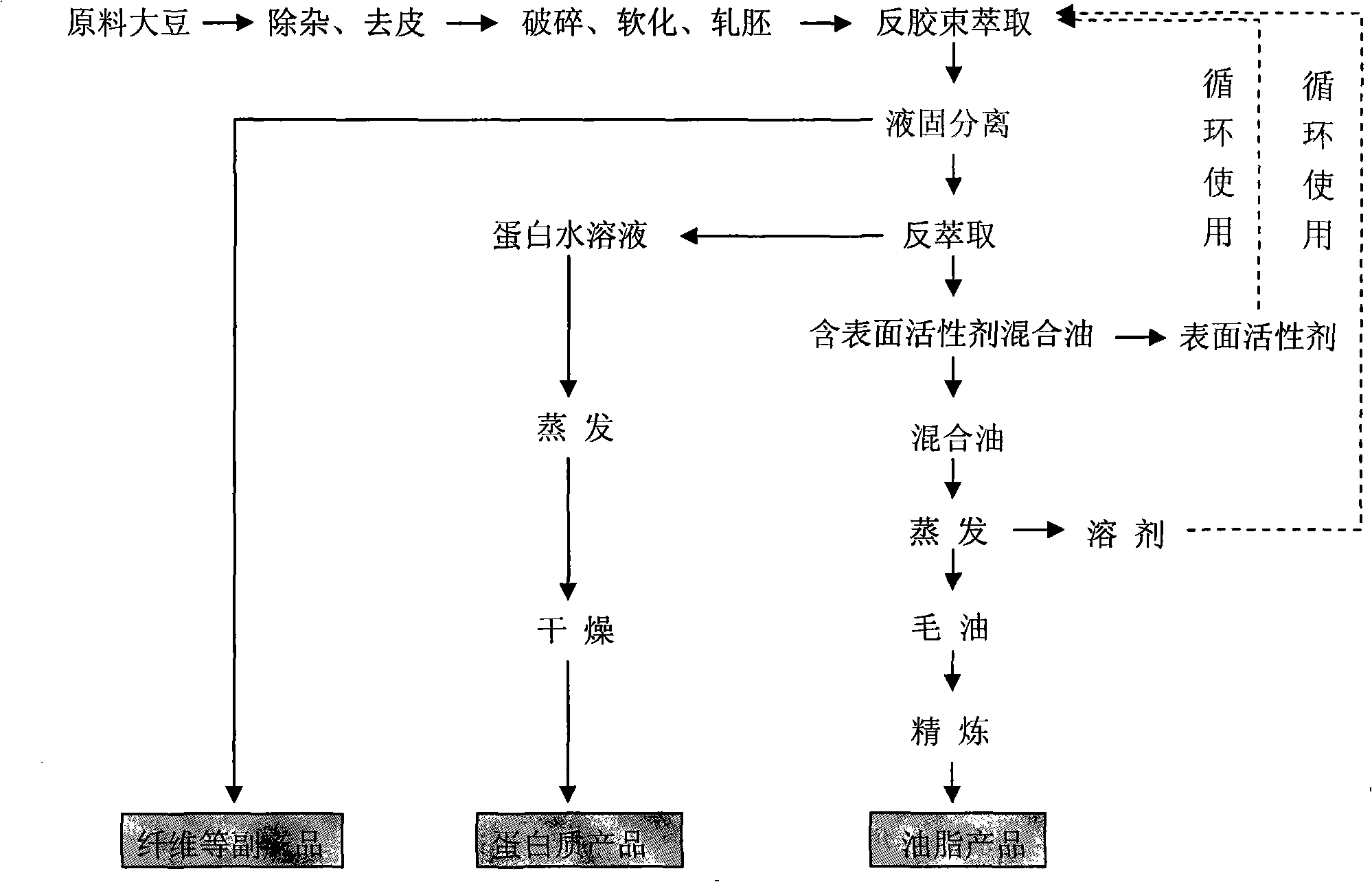

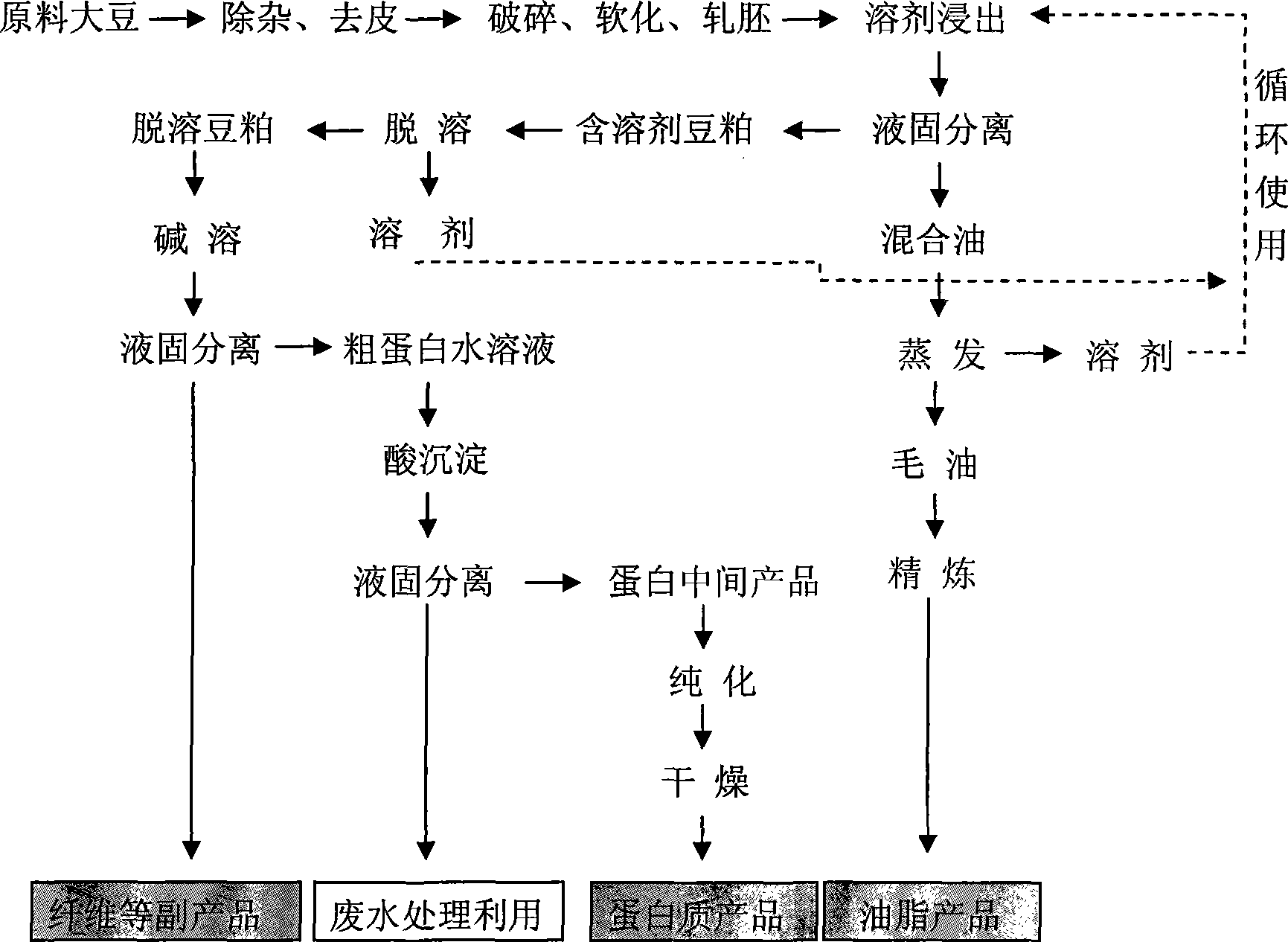

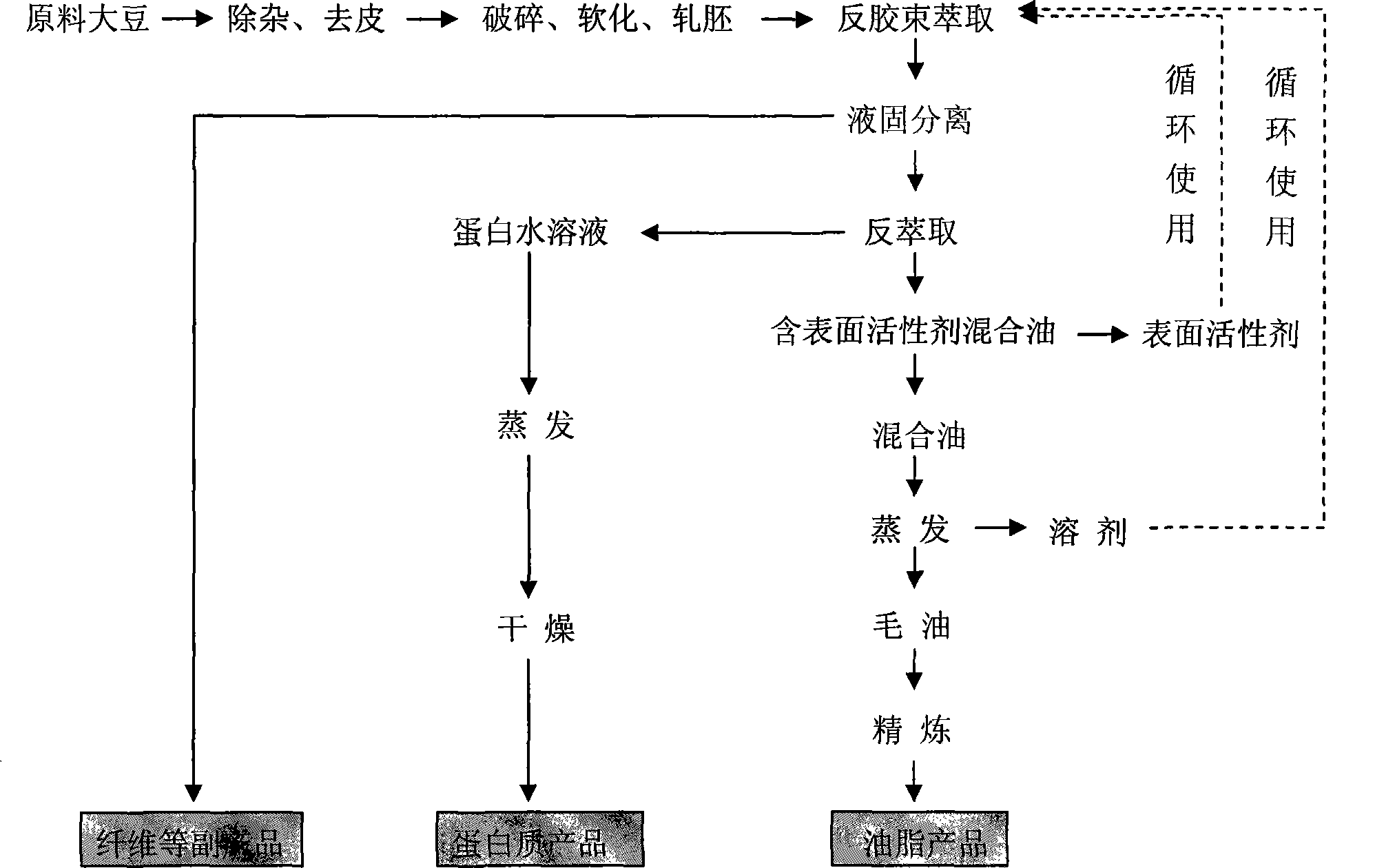

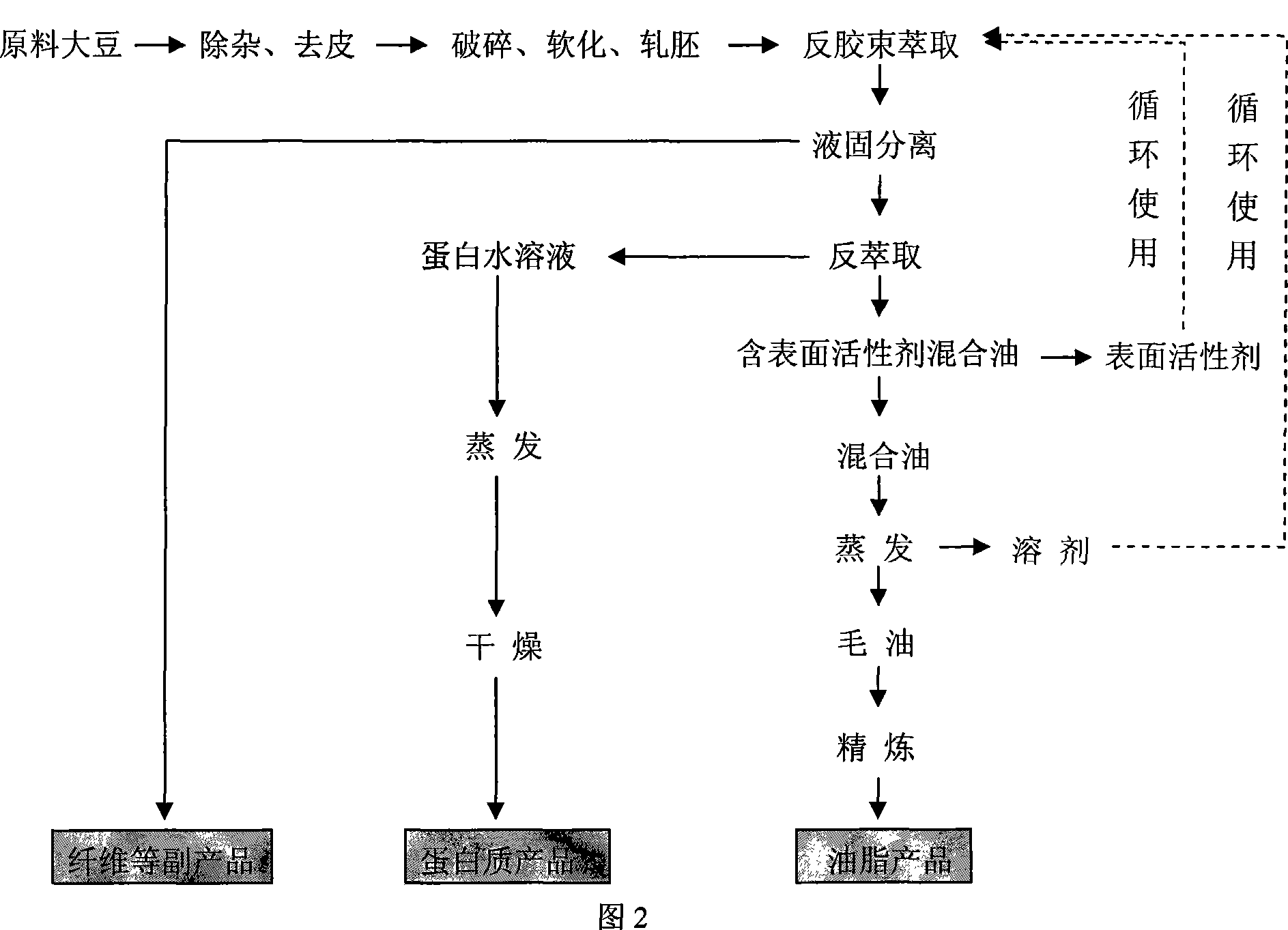

Method for simultaneously separating soy protein and oil fat with inverse micelle abstraction technique

ActiveCN101343309AThe production process is simpleReduce production costs and fixed asset investmentPeptide preparation methodsFermentationSolventChemistry

Disclosed is a method for separating soybean protein and fat by the reversed micellar extraction, which comprises the following procedures: (1) reversed micellar solution is prepared; (2)a pretreated raw material of soybean is added into the reversed micellar solution to extract protein and fat; (3) electrolyte solution is added so that the protein is transferred into the aqueous phase from the reversed micellar solution to be separated, thereby realizing back extraction of the protein, and protein aqueous solution and mixed oil are obtained; (4) the obtained protein product and the fat product are processed. The method has the following main advantages: the fat and the protein are separated at the same time in the reversed micellar extraction system, so the production process is greatly simplified, and the production cost and the investment on the fixed assets are reduced; the method has the advantages of solvent extraction; in the process of extraction, the protein is surrounded by the water environment in the reversed micellar, and the environment is close to the environment in the cells with mild condition, so the protein is not denatured and can keep the biological activity of the protein, and the purity of the product is high; and no acid and alkali wastewater is discharged without pollution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Apparatus for rapidly recovering energy source storage of electric automobile and operational method thereof

InactiveCN1557659ASo as not to damageAvoid damageElectric propulsion mountingElectric/fluid circuitElectricityElectric-vehicle battery

The present invention is one novel accumulator fast replacing device and operation method for electric automatic. Standard power source unit or combined power source unit and corresponding device are adopted for fast replacement of accumulator. At the same time, the method including user's buying only the use right of the accumulator, card consumption, electricity buying before running, recharging, establishing of charging station network, circulation of accumulator, supply of standard power source unit or combined power source unit by the accumulator producer and comprehensive recovering of waste accumulator is adopted. The present invention is suitable for various kinds of electric automobile.

Owner:于耀庆

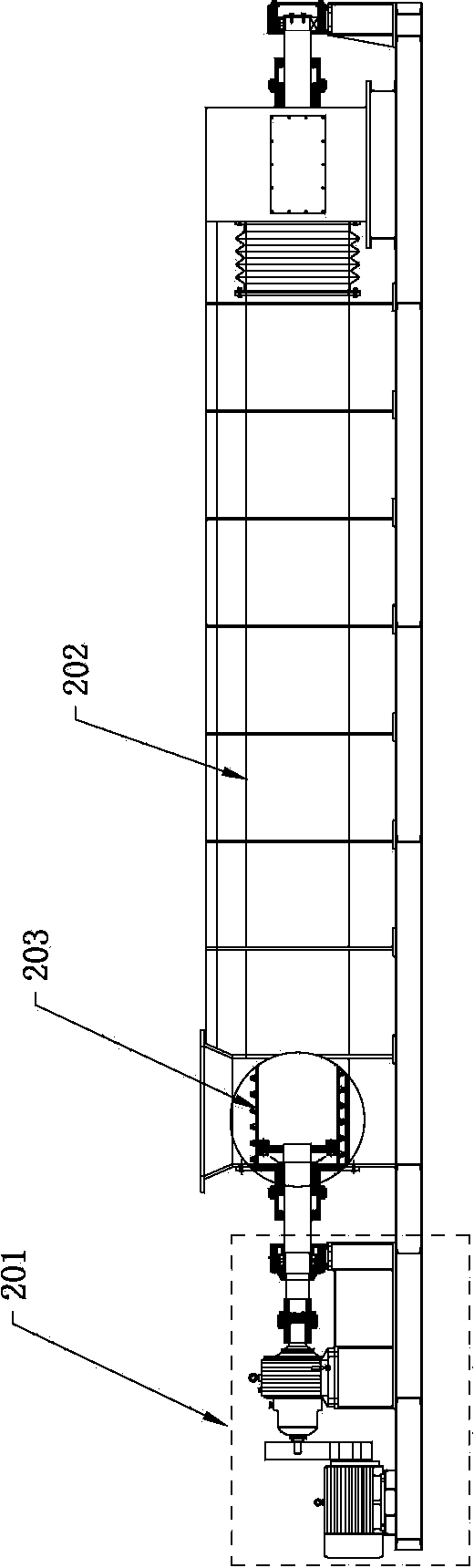

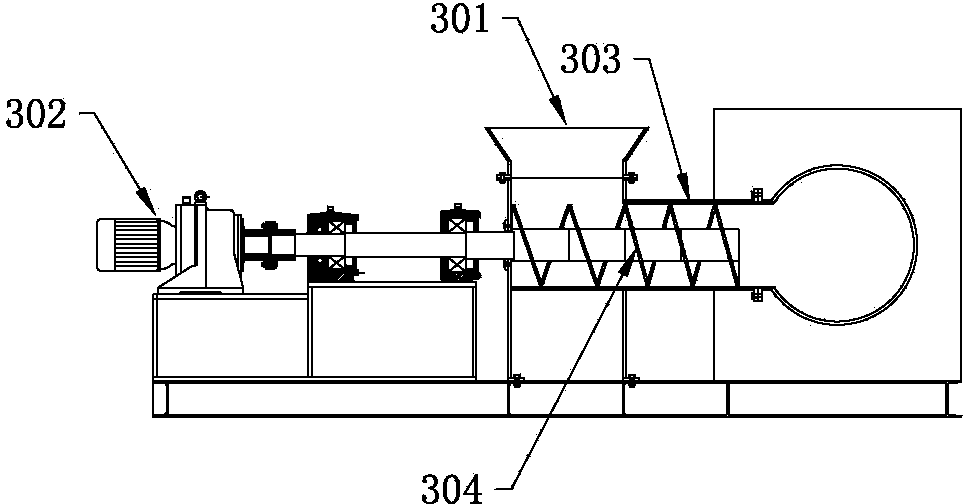

Garbage thermal cracking treatment technology

ActiveCN103464448AAchieve decompositionTo achieve the purpose of sterilizationSolid waste disposalThermodynamicsCombustible gas

The invention discloses a garbage thermal cracking treatment technology which comprises the following steps: (1) coarse crushing; (2) magnetic separation; (3) sieving; (4) fine crushing; (5) drying; (6) thermal pretreatment; (7) high temperature cracking. The garbage thermal cracking treatment technology disclosed by the invention is reasonable in design of working procedures and simple in structure, and can be used for effectively treating city household garbage and solving the problem of environmental pollution caused by the city household garbage; products, such as coke coal, tar and combustible gas, obtained from city household garbage treatment, can be collected and recycled; the garbage thermal cracking treatment technology creates new economic benefits, fully meets the requirements on reutilization, harmless treatment and reduction of garbage, and realizes zero release of garbage treatment and maximum benefit of reutilization of garbage treatment products.

Owner:GAOZHOU ZHONGLIANG MACHINERY MFG

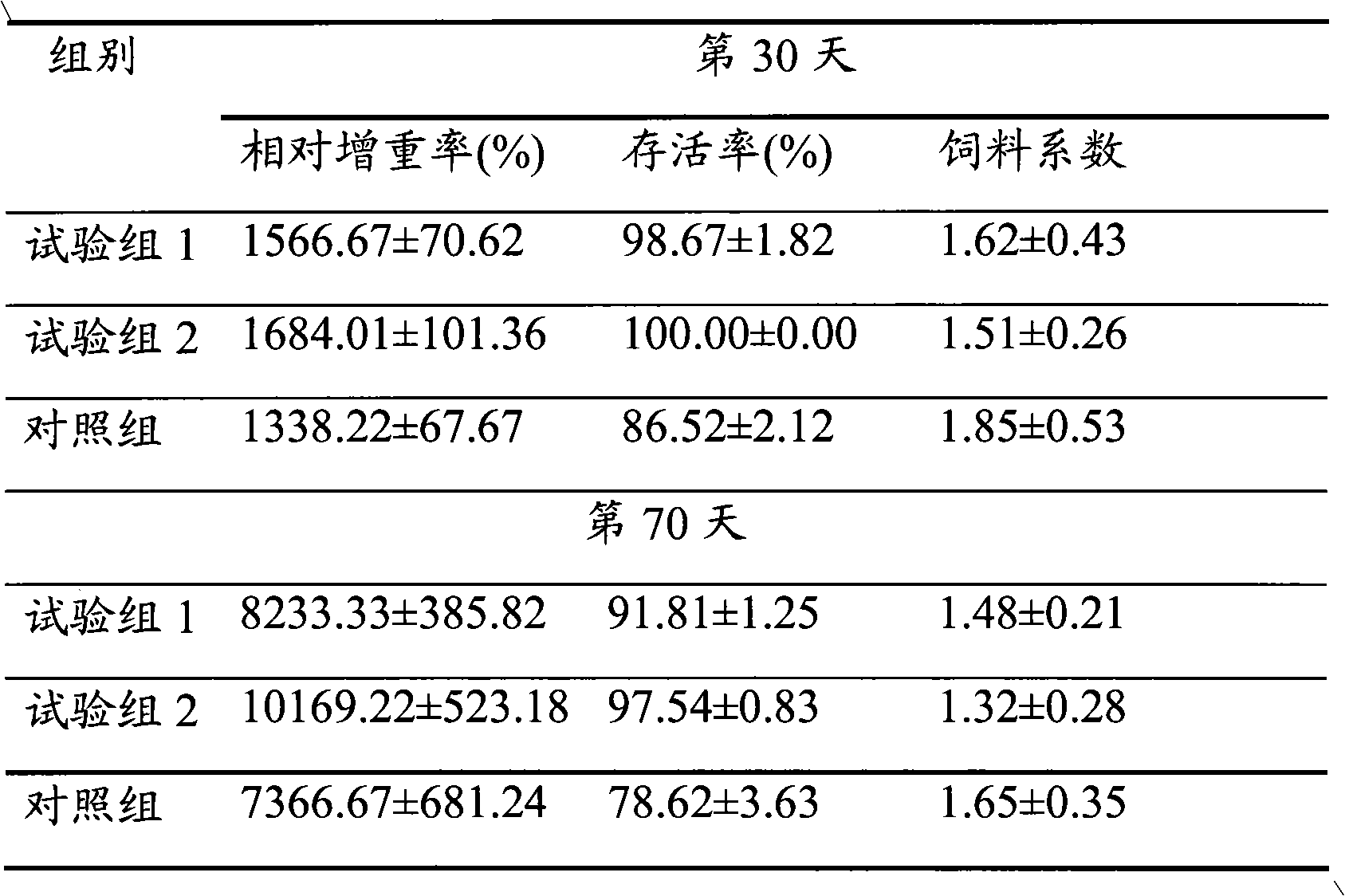

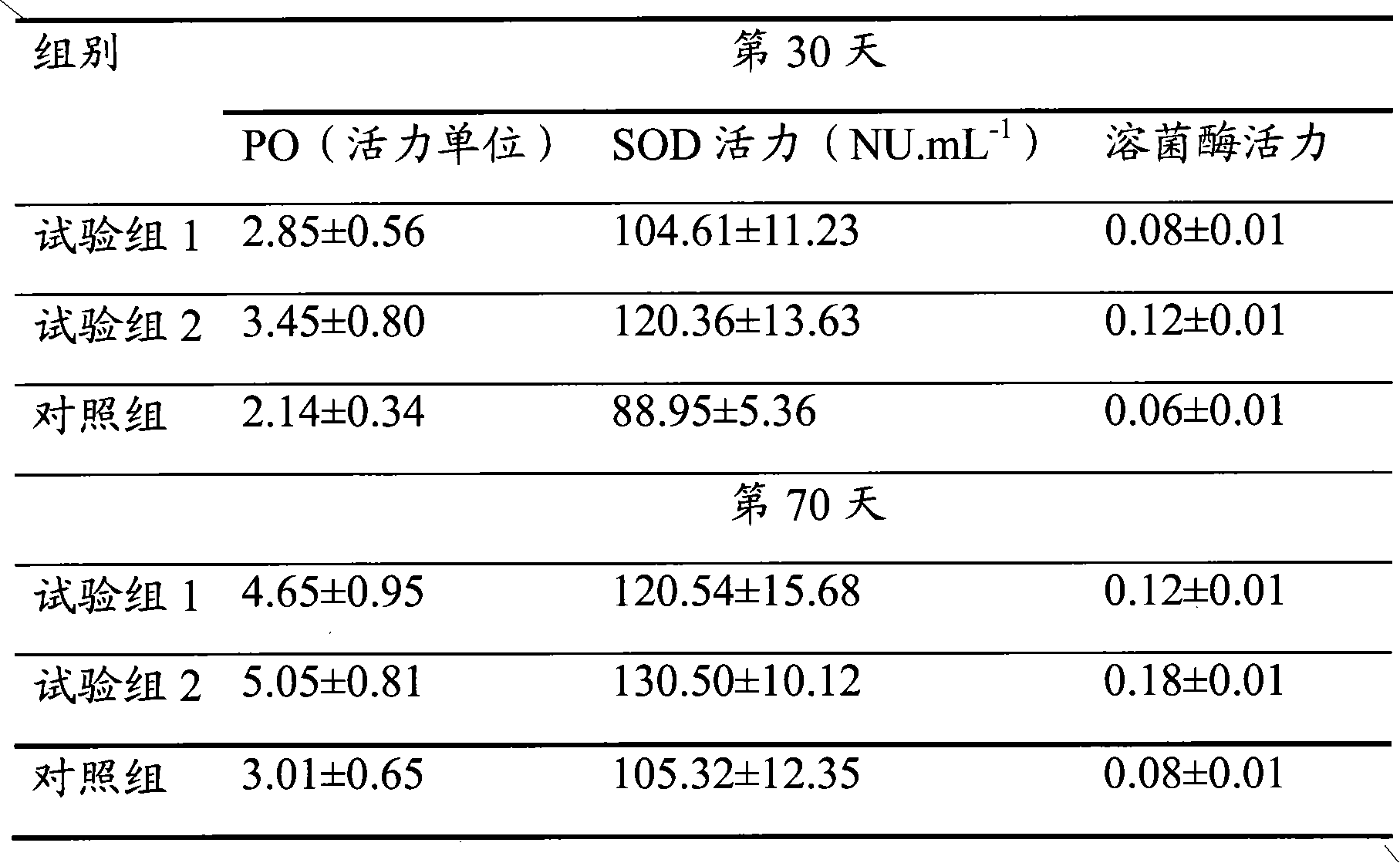

Immune feed additive and preparation method thereof

ActiveCN101999527AImprove the status quoSolve the problem of polluting the environmentAnimal feeding stuffAccessory food factorsEnvironmental resistanceFood additive

The invention discloses an immune feed additive, which is prepared from maggots, wherein the maggots are fed with fermented leftovers from aquatic product processing by enzymolysis. The invention also provides a method for preparing the immune feed additive, which comprises the following steps: 1, fermenting the leftovers from aquatic product processing; 2, feeding maggots with the fermented leftovers from aquatic product processing; 3, performing the enzymolysis of the maggots to obtain the immune feed additive. The feed additive provided by the invention contains rich nutrients and functional elements and can promote growth and obviously improve immunity and pathogenic bacterium resistance in animals; therefore, the feed additive is a high-efficiency immune feed additive. The preparation method of the feed additive adopts a biological technique, avoids producing any waste in a production process, and is green, environmentally-friendly, simple in process, high in maneuverability and capable of allowing for large-scale production.

Owner:湛江市明珠科技实业有限公司

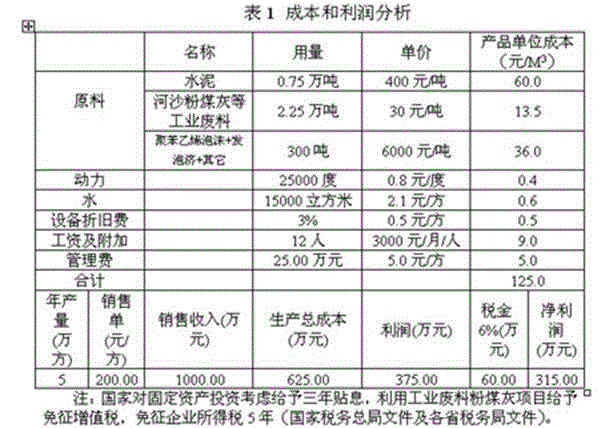

Polystyrene foam aggregate concrete insulation building block

ActiveCN103539398ASolve the problem of polluting the environmentGet secondary useCeramicwareRiver sandCoal

The invention belongs to the field of concrete insulation building block materials, and specifically provides a polystyrene foam aggregate concrete insulation building block. The building block consists of polystyrene foam aggregate, slurry and a foaming agent, wherein the mass ratio of the polystyrene foam aggregate to the slurry to the foaming agent is (0.004-0.01): 1.0: (0.008-0.015); in the slurry, the mass ratio of water to cement to river sand or coal ash to early strength agent is equal to (0.5-0.55): 1.0: (3.0-4.0): (0.01-0.02). The polystyrene foam aggregate concrete insulation building block gives consideration to the relationship of the building block strength, a production technology and the production cost, the compressive strength of the building block is more than two times than those of like products, but the cost of the building block is 20% less than that of the like products.

Owner:HUNAN INSTITUTE OF ENGINEERING

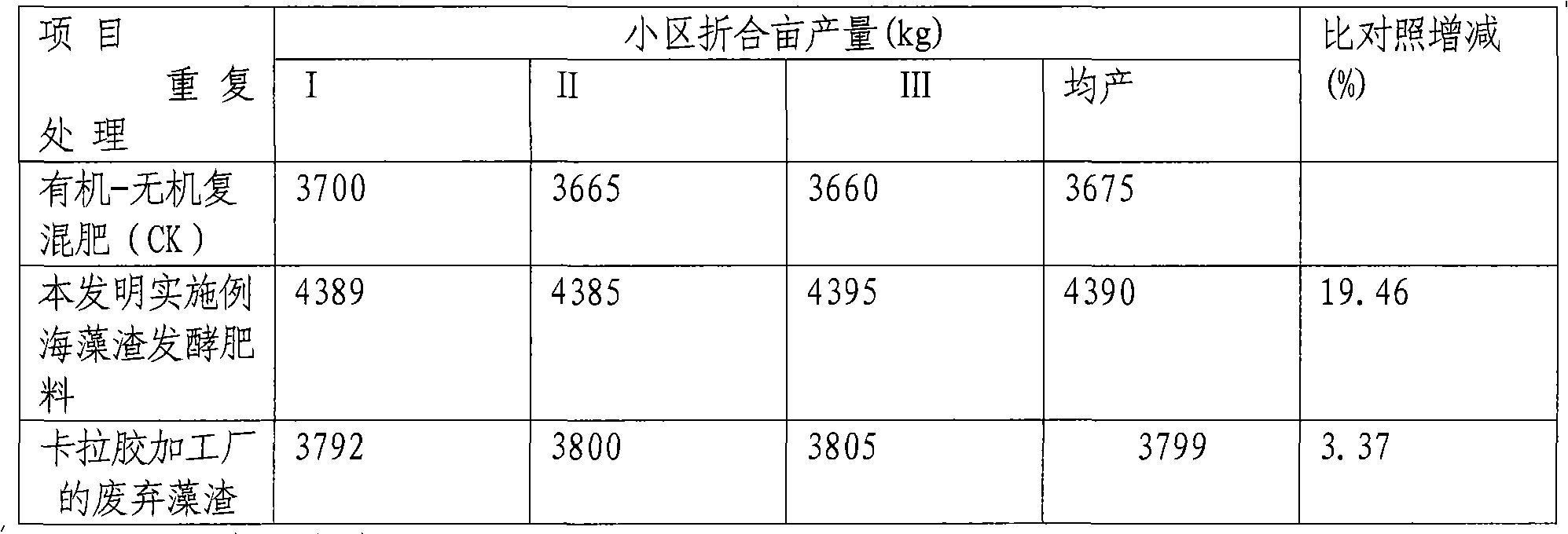

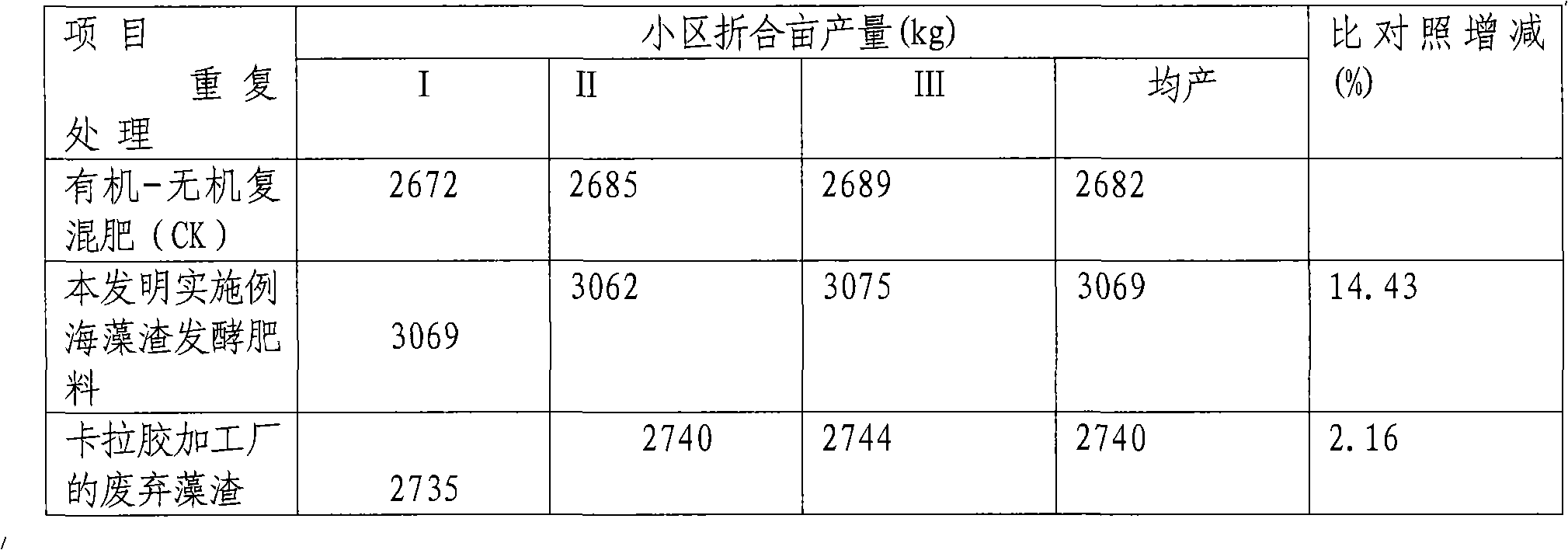

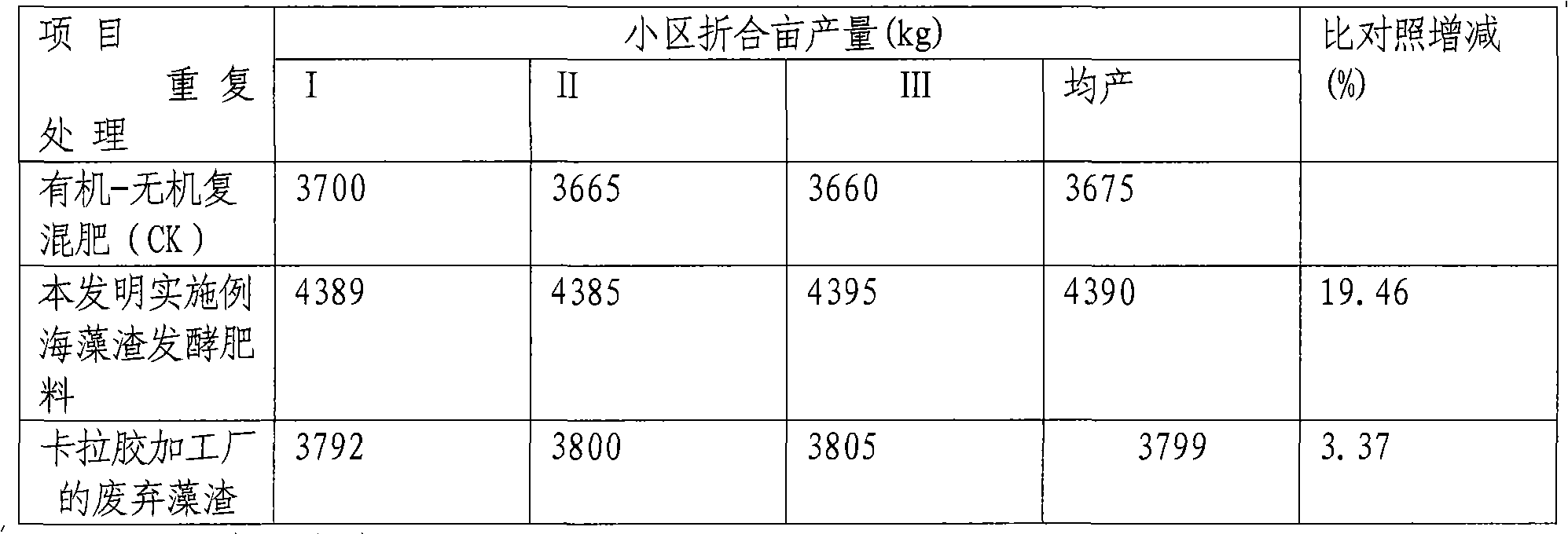

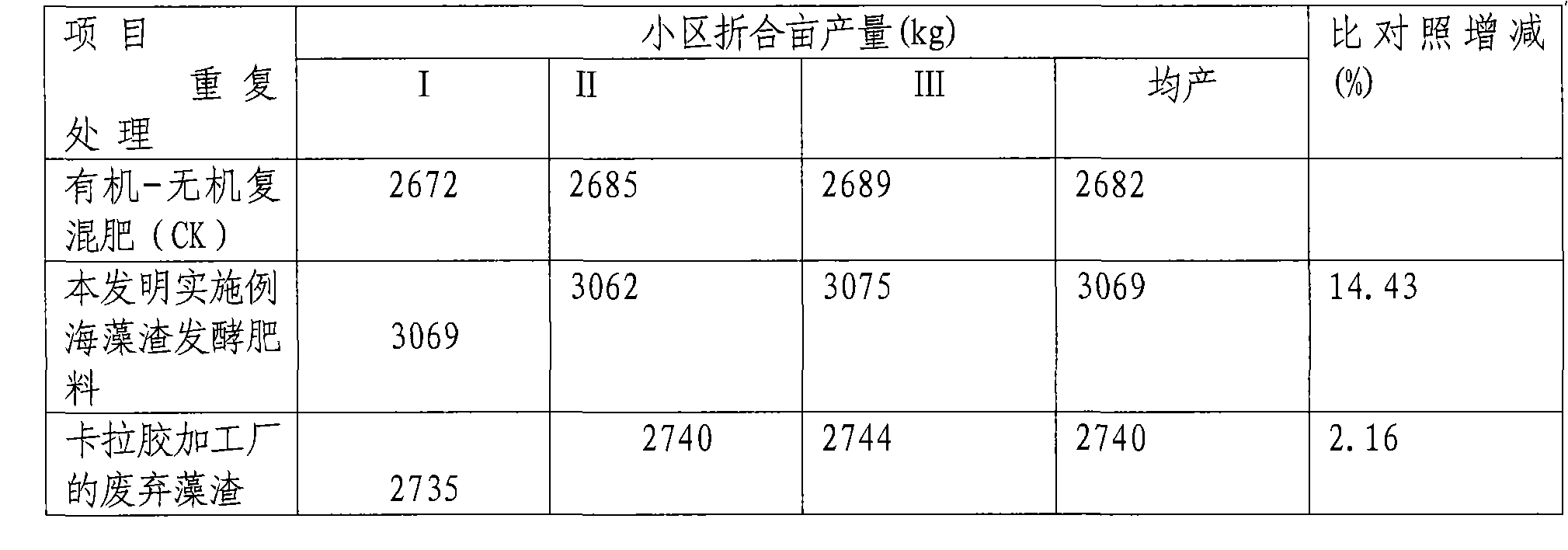

Carrageenan algae residue organic fertilizer and preparation method thereof

InactiveCN102372506ALower the pH valueReduce lossesBio-organic fraction processingClimate change adaptationCarrageenanPhosphate

The invention relates to the field of biological fertilizers and in particular discloses a carrageenan algae residue organic fertilizer and a preparation method thereof. The carrageenan algae residue organic fertilizer consists of the following components in percentage by weight: 0.05 to 0.5 percent of monoammonium phosphate, 0 to 30 percent of auxiliary materials, 0.025 to 0.5 percent of microbial fermentation agent and the balance of carrageenan algae residue. The preparation method comprises the following steps of: adding the monoammonium phosphate into the carrageenan algae residue according to the proportion, regulating the pH value of materials to be 7.0 to 8.0, adding bran and the microbial fermentation agent into the materials, fully mixing and stirring, fermenting a compost, turning the pile in time and supplementing the moisture when the fermentation temperature is 65 to 68 DEG C, turning the pile once on 3rd, 5th and 7th days after inoculation respectively, and maintaining the fermentation temperature of the compost to 45 to 65 DEG C, wherein the aerobic fermentation time is 12 to 20 days; and after the composting is finished, ensuring that the water content of the fermented materials is 20 to 25 percent at the temperature of between 50 and 70 DEG C to obtain the carrageenan algae residue organic fertilizer. By the method, the waste is turned into wealth, the high-efficiency and low-cost organic fertilizer is obtained, the environmental pollution is also treated, and the ecological balance is better kept.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

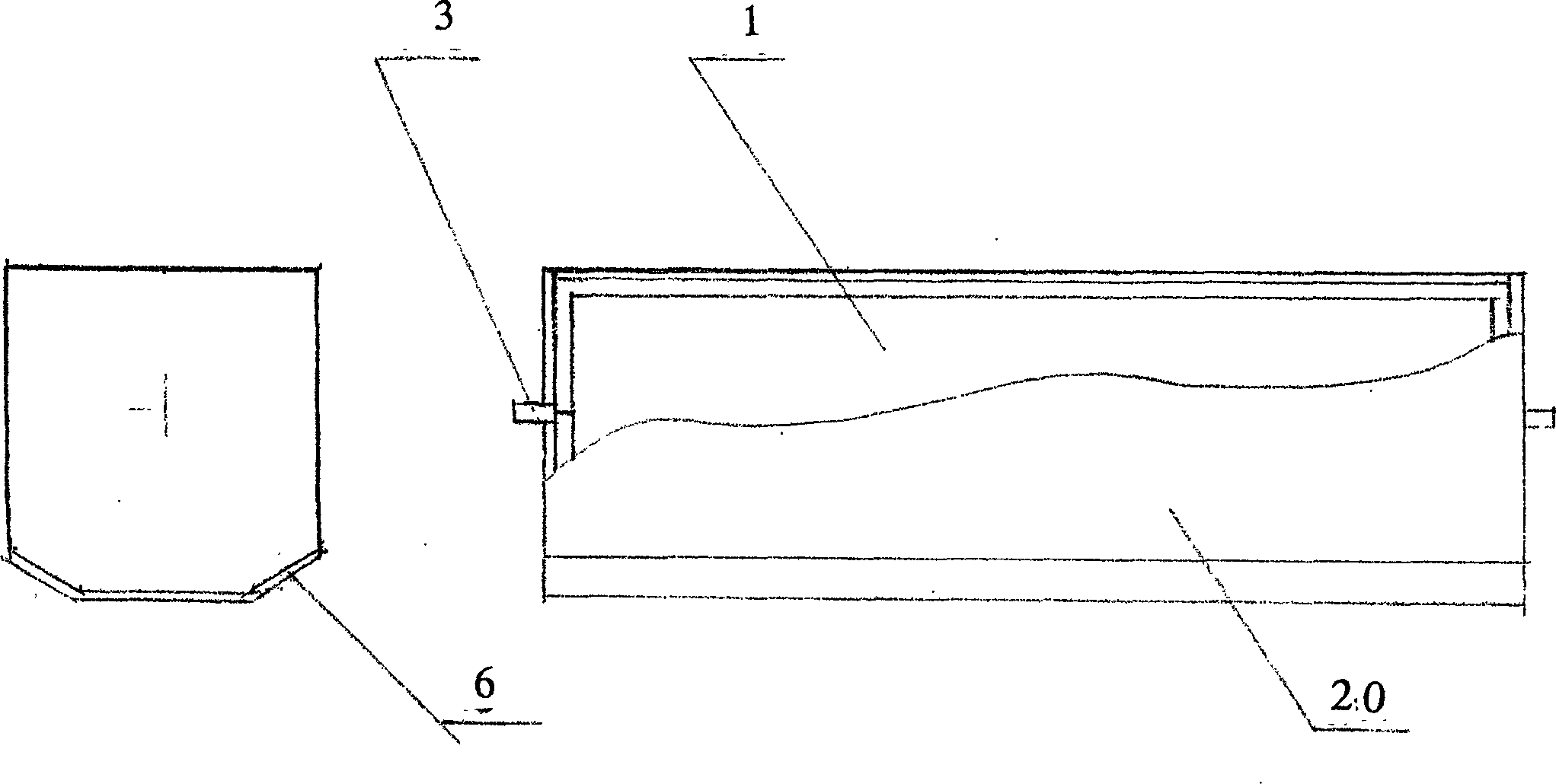

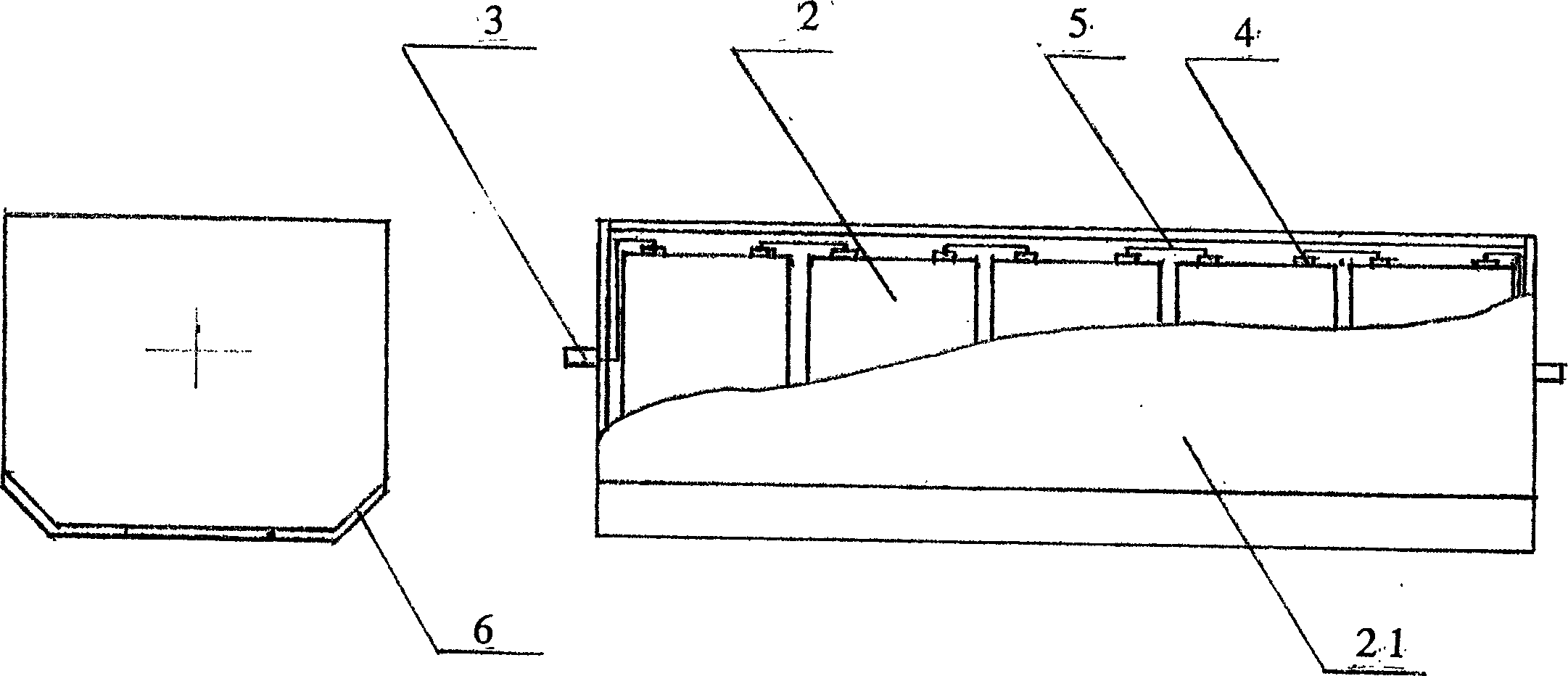

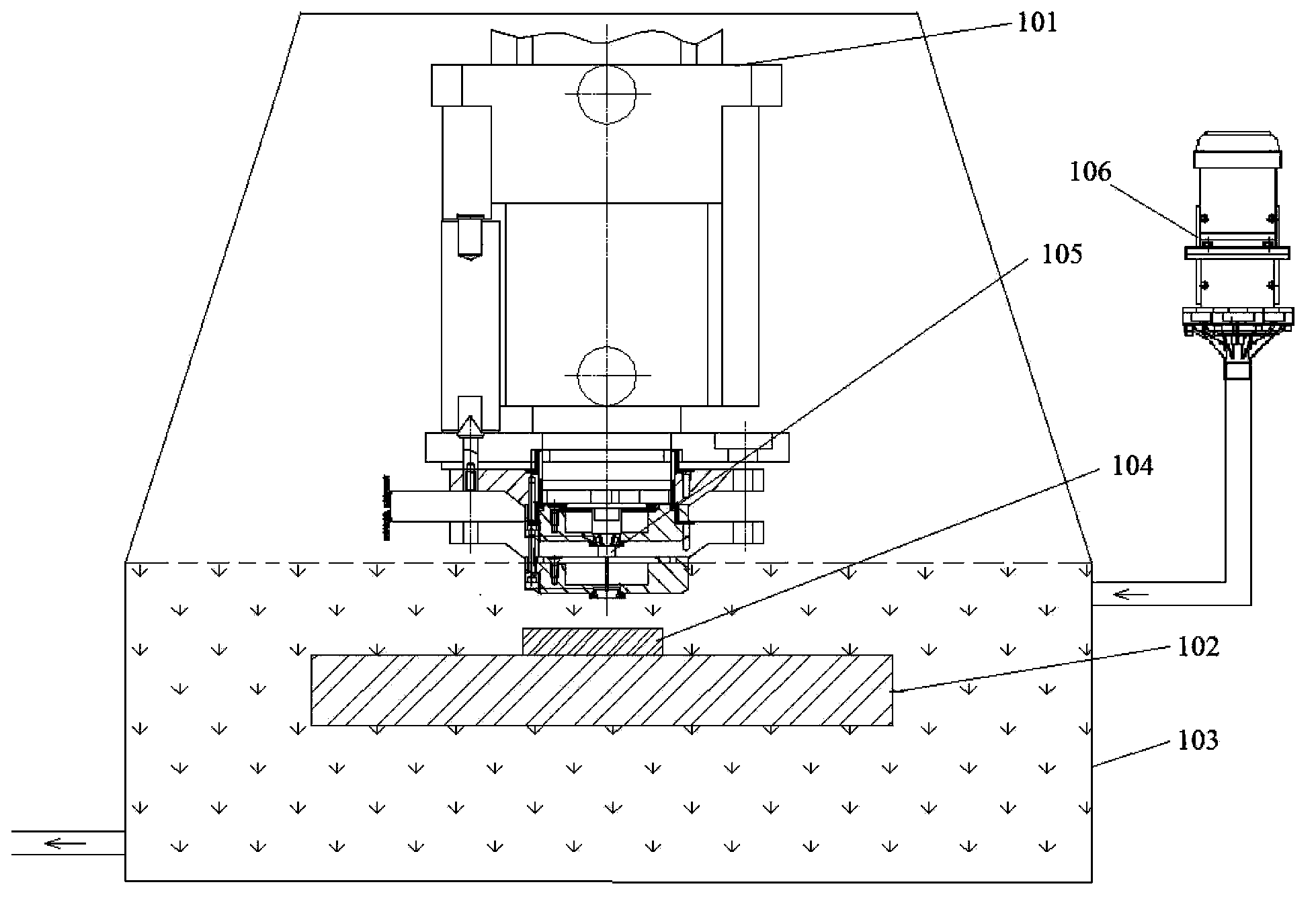

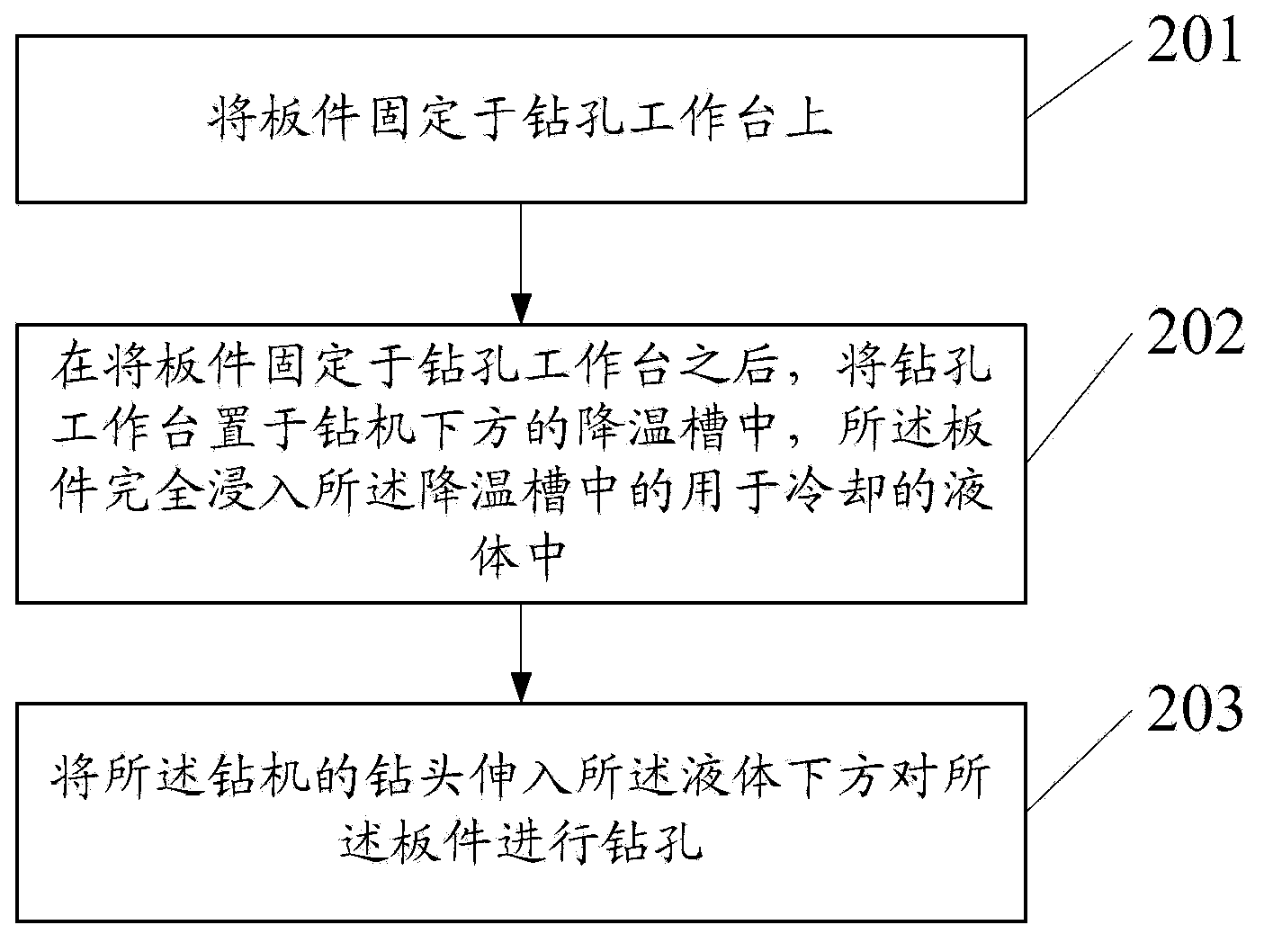

Numerical control drilling machine and numerical control drilling method

ActiveCN103909547AAvoid stickingSolve the problem of polluting the environmentMetal working apparatusNumerical controlEngineering

The invention discloses a numerical control drilling machine and a numerical control drilling method. The numerical control drilling machine comprises a drilling machine body and a drilling workbench for holding a plate, a cooling tank is mounted under the drilling machine body and is filled with cooling liquid, and the drilling workbench is mounted in the liquid in the cooling tank. According to the numerical control drilling machine, the plate is drilled in the cooling liquid, a drill bit and the plate are cooled by the liquid so that the plate adhesion caused by overhigh temperature is avoided. Because the plate is drilled in the cooling liquid, the dust generated by drilling is held in the liquid, and the environment pollution problem caused by the dust is solved. The drill bit and other components of the drilling machine are in contact with the cooling liquid, so that the temperature is lowered in working, and the service life is prolonged.

Owner:SHENNAN CIRCUITS

Method for extracting cellulose, lignose and compound fertilizer from cotton-seed hull

InactiveCN101476252AIncrease profitSolve the disadvantages that only a single product can be extractedLignin derivativesPaper material treatmentFiberCellulose

The invention provides a method for extracting cellulose, lignin and composite fertilizer from cottonseed shell, which comprises the following steps: adding lignin dissolving agent and water into a container according to the proportion of 1-5:1000; adding 10-20 liquid amount of cottonseed shells; heating to 70-90 degrees centigrade and keeping for 6-10 hours; separating out crude fibers, rinsing, refining and drying to obtain the finished fiber product; sending the rinsed solution into the socking container for reuse; acidifying the solution in the first boiling pool, and press filtering to precipitate solid that is lignin; adjusting the pH value of the solution after lignin extraction to neutral, concentrating, drying, granulating to obtain composite fertilizer. Besides the cellulose, the invention can co-produce lignin and composite fertilizer, changes improves the abuses of single product, water resource waste and serious environment pollution existing in the current technologies in our country.

Owner:JIAHE BIOTECH

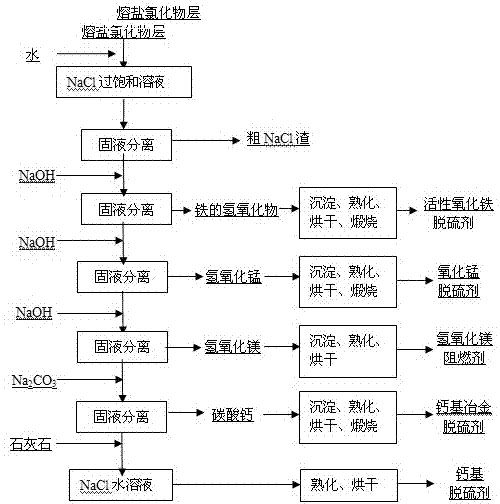

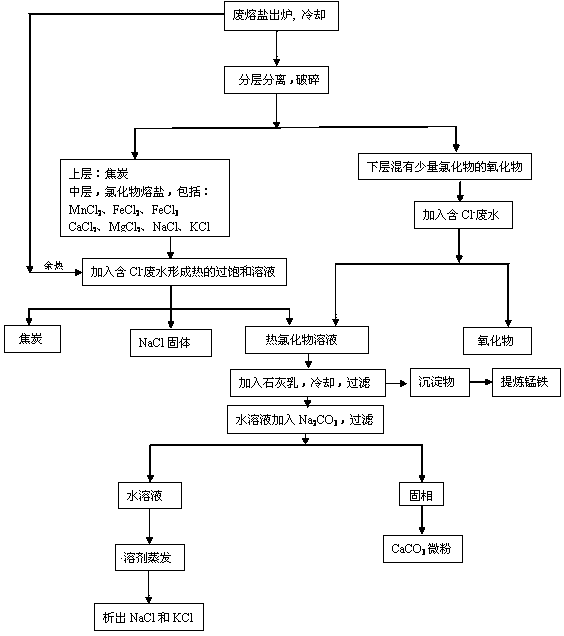

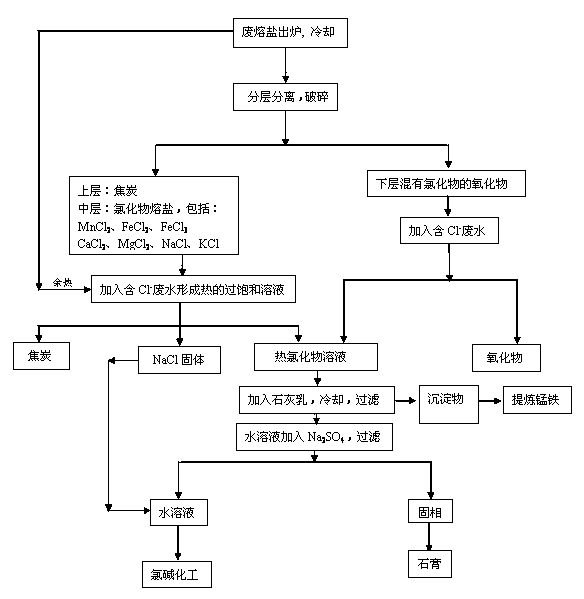

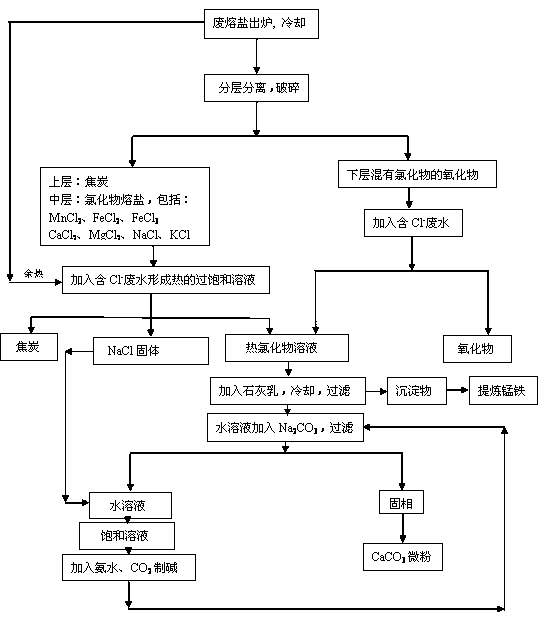

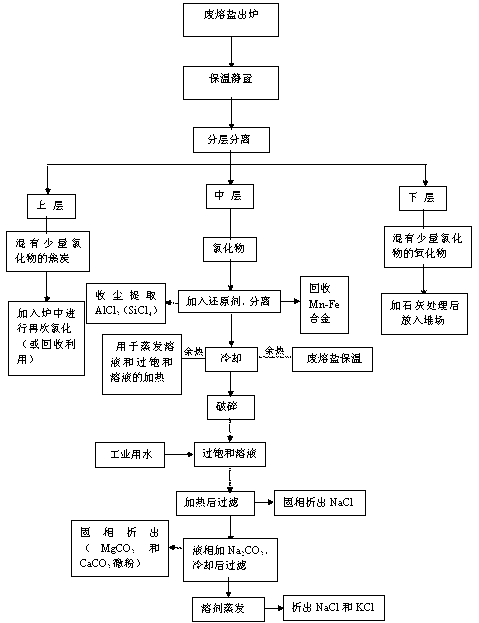

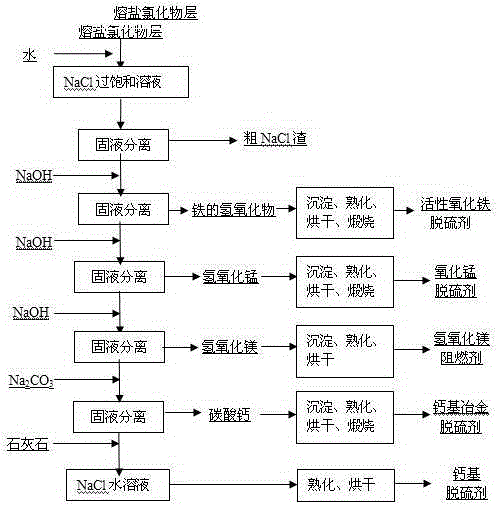

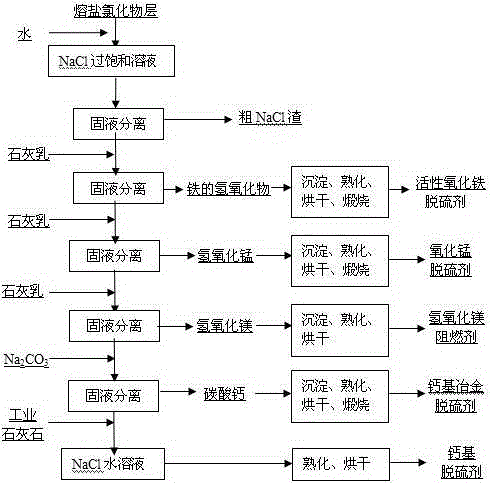

Method for preparing raw material of desulfurizing agent by using waste chlorination molten salt generated in production of TiCl4

InactiveCN103566719AAchieve regenerationRealize comprehensive utilizationSolid waste disposalDispersed particle separationElectrolysisManganese

The invention discloses a method for preparing a raw material of a desulfurizing agent by using waste chlorination molten salt generated in production of TiCl4, and relates to a method for treating waste molten salt and wastewater containing Cl<->. The method comprises the following steps: performing water solution treatment on a crushed waste molten salt chloride layer, filtering out dregs, subsequently performing treatment of iron removal, manganese removal, magnesium removal and calcium removal on the obtained water solution of the chloride step by step, so as to respectively obtain solutions of ferric hydroxide, ferrous hydroxide, manganese hydroxide, magnesium hydroxide, CaCO3 and NaCl, treating ferric hydroxide, ferrous hydroxide, manganese hydroxide, magnesium hydroxide and CaCO3, subsequently preparing a series of desulfurizing agents, and taking the NaCl aqueous solution as a modifying agent of a calcium-based desulfurizing agent. Due to the adoption of the method, the problem of environment pollution of waste molten salt and wastewater containing Cl<-> in preparation of TiCl4 by using a molten salt electrolysis method, which plagues people for a long time, is solved, the waste molten salt can be prepared into iron-based, magnesium-based, ferro-manganese-based and calcium-based desulfurizing agents for treating a great deal of industrial wastewater containing NaCl, and recycling utilization of the waste molten salt and the industrial wastewater containing NaCl is achieved.

Owner:重庆阁林环保科技有限公司

Process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste

ActiveCN108435754ALess investmentLow costSolid waste disposalExcrement fertilisersLiquid wasteSludge

The invention discloses a process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste. The process comprises the steps of step one, waste leachate treatment and foul smell deodorization; step two, waste screening, sorting and coarse crushing; step three, non-organic matter magnetic separation, winnowing and fine crushing; step four, agricultural and forestry waste crushing and screening; step five, stirring of waste combustible materials, agricultural and forestry waste, sludge and water, compression molding, airing and biomass fuel obtaining; andstep six, waste organic matter adding of livestock and poultry manure, and organic fertilizer obtaining. According to the process, the biomass fuel can be directly used in a boiler, and the problem that the livestock and poultry manure pollutes the environment in a livestock farm is solved through the organic fertilizer; for the construction of waste treatment plants, the investment is small, thecost is low, and implementation is easy; the agricultural and forestry waste is collected with paying performed, so that the income of farmers is increased, and the pollution is reduced; the profit rate is high, and operating can last without government subsidy; the waste gas, the waste liquid and the waste residue are subjected to the environmental protection treatment so that new pollution can be avoided.

Owner:于继林

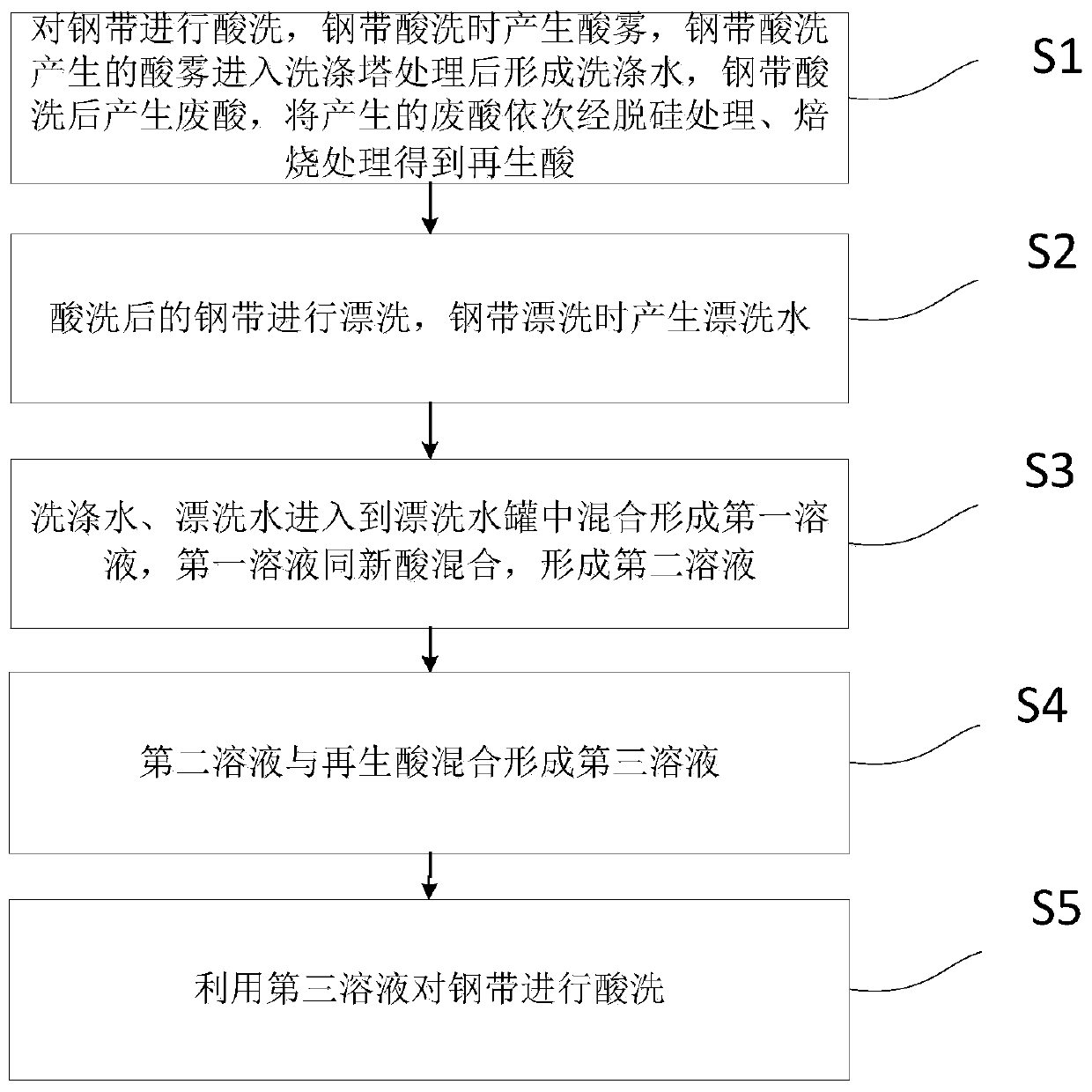

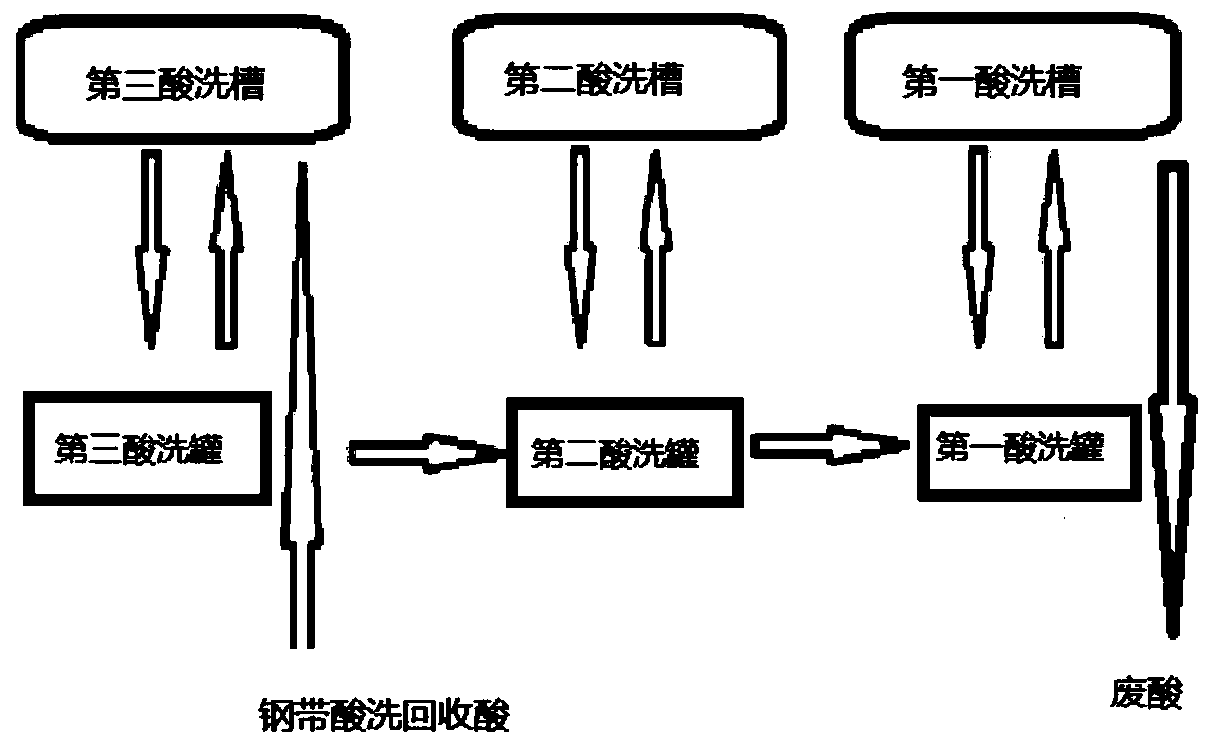

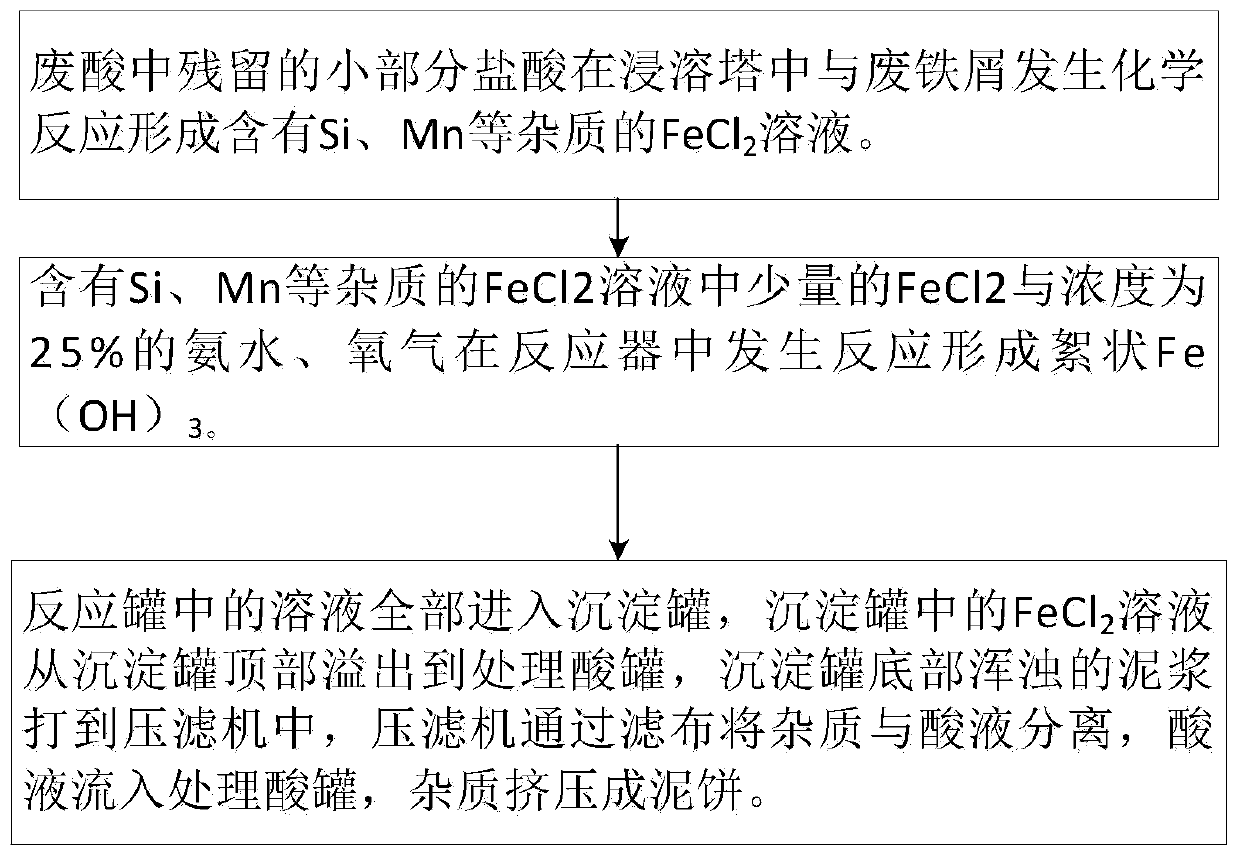

Acid washing method for steel strip

InactiveCN110344067AAchieve recyclingSolve the problem of polluting the environmentRinse waterAcid washing

The invention belongs to the technical field of steel rolling, and particularly relates to an acid washing method for a steel strip. The acid washing method for the steel strip comprises the followingsteps: carrying out acid washing on the steel strip, generating acid mist during the acid washing for the steel strip, enabling the acid mist generated during the acid washing for the steel strip toenter into a washing tower and treating to form washing water, generating waste acid after the acid washing for the steel strip, and sequentially carrying out desilicication treatment and roasting treatment on the generated waste acid to obtain regenerated acid; carrying out strip rinsing on the steel strip subjected to the acid washing, and generating rinsing water during the rinsing for the steel strip; enabling the washing water and the rinsing water to enter into a rinsing water tank and mixing to form a first solution, mixing the first solution with new acid in a set ratio to form a second solution, wherein the set ratio is (6 to 8): (9 to 11); and mixing the second solution with the regenerated acid to form a third solution, and carrying out acid washing on the steel strip by virtueof the third solution. According to the acid washing method for the steel strip, recycling and reutilization for the waste acid, the acid mist and the rinsing water are realized, so that environment protection is much benefited.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

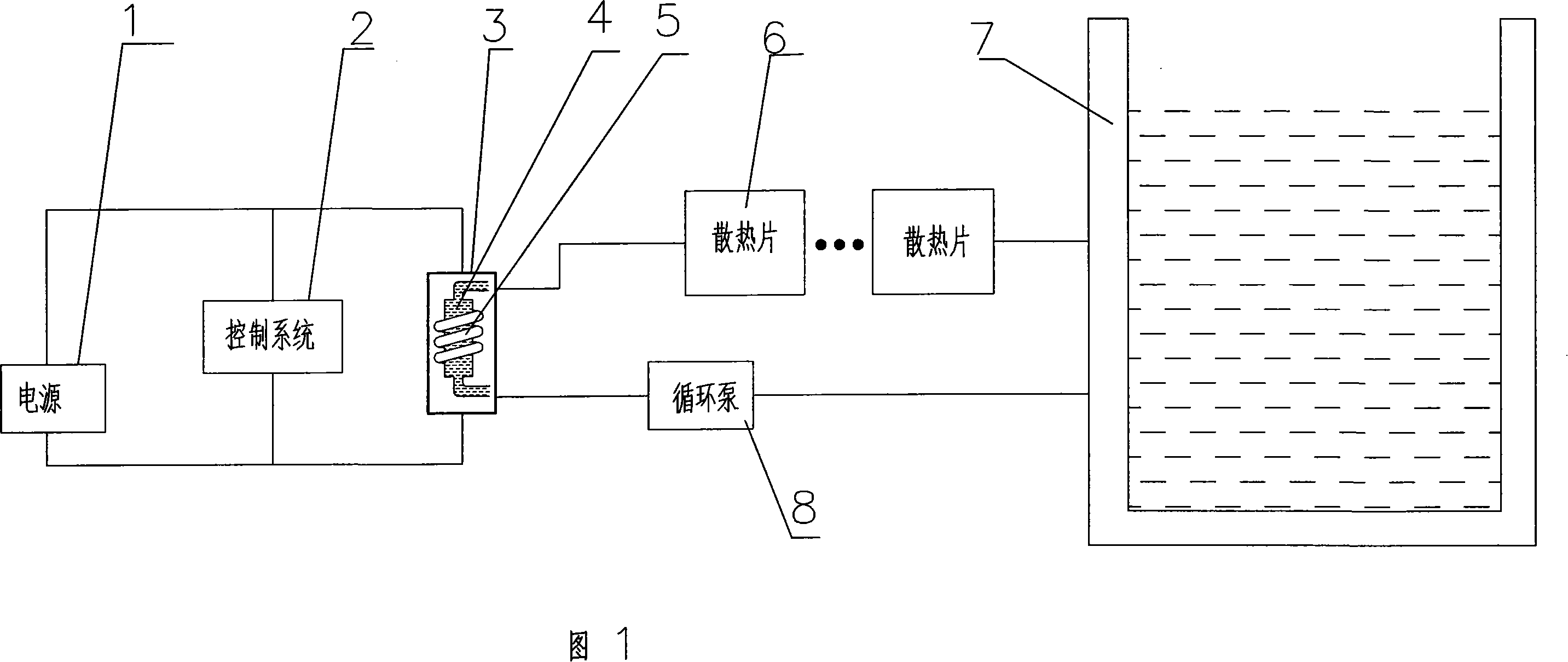

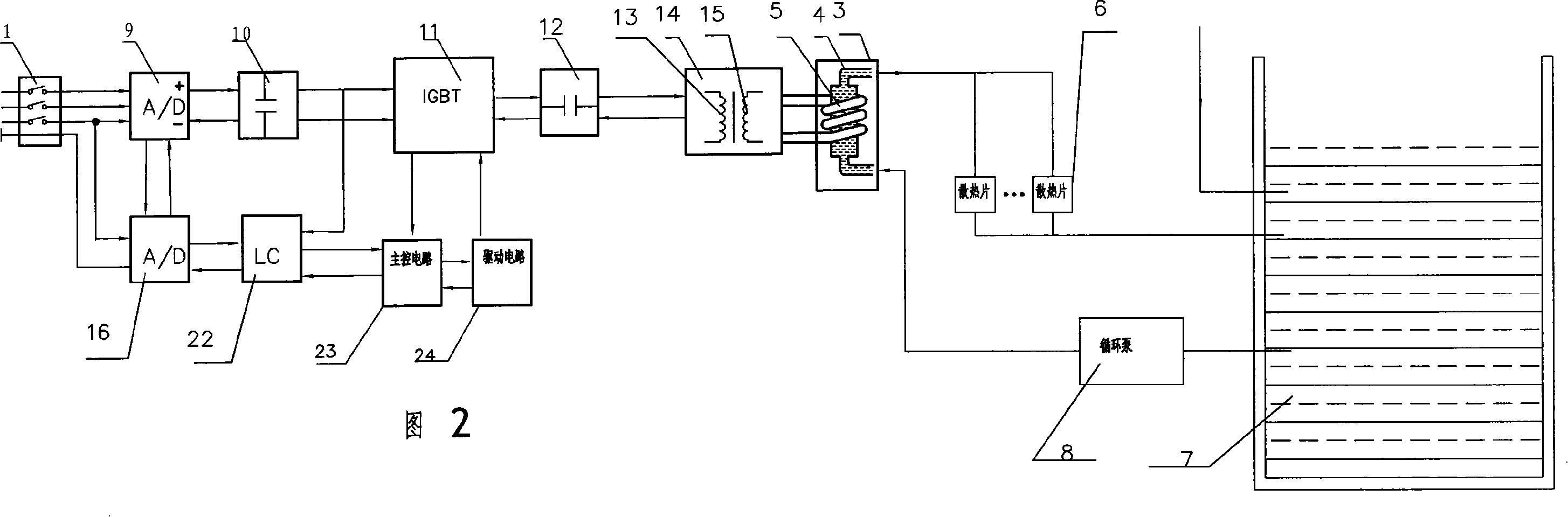

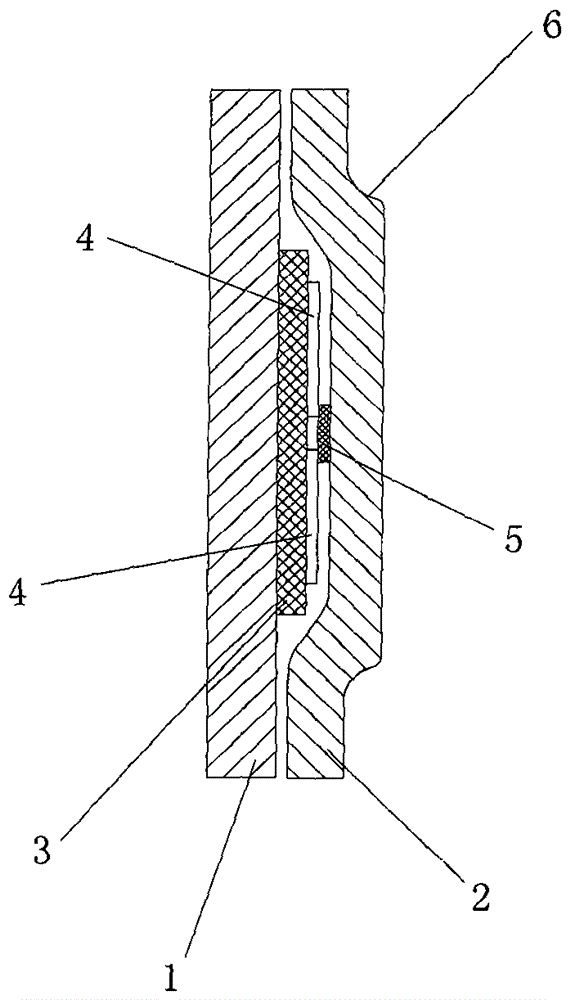

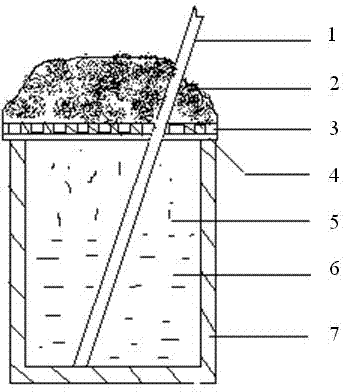

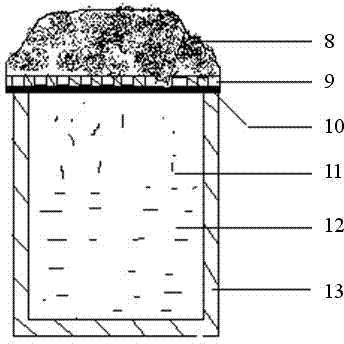

Intermediate frequency electronic heating and warming device

InactiveCN101149165ASolve the problem of polluting the environmentHeating up fastLighting and heating apparatusSpace heating and ventilation detailsHeat sinkVoltage

This invention is a heating device, especially an intermediate frequency electron heating device. It saves energy, non-polluted and intelligent controllable. It also has high thermal efficiency. It includes power source, water tank and circulating valve. Oscillating circuit, which generates intermediate frequency alternating voltage and alternating current, connects to the intermediate frequency electron heating device that generates alternating magnetic field and electromagnetic oscillation. The said oscillating circuit is controlled by controlling system. The intermediate frequency electron heating device is a magnetic metal container, with the heating coil at external part and liquid at internal part. Tandem radiating fins form the pipeline system. The water tank and circulating valve are connected to from circulating system. The intermediate frequency electron heating device, pipeline system and circulating system are connected in series to form the heating circulating loop. This invention can fulfill central heating.

Owner:齐向臣

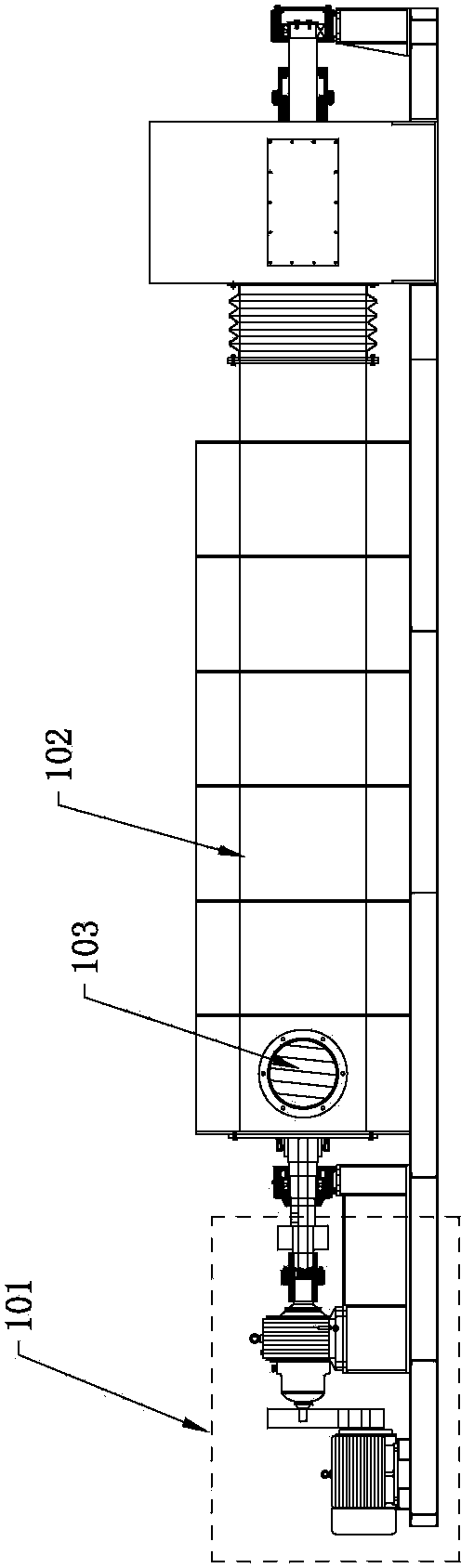

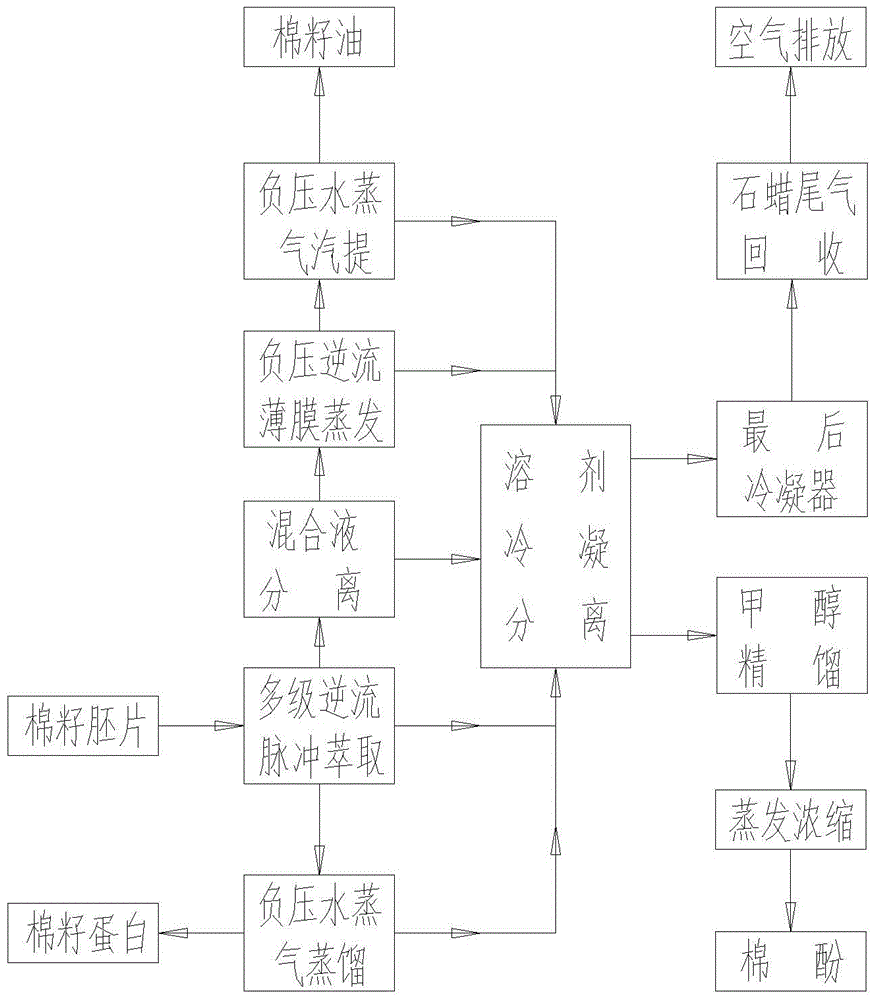

Production method for synchronously extracting cottonseed oil and degossypolized cottonseed protein from cottonseed germ flakes

ActiveCN104673484AResidue reductionReduce extraction timeDispersed particle separationFatty-oils/fats refiningCottonseed oilEnergy consumption

The invention discloses a production method for synchronously extracting cottonseed oil and degossypolized cottonseed protein from cottonseed germ flakes. The method comprises the following steps: performing multi-stage countercurrent pulsed extraction, namely, feeding the cottonseed germ flakes into an extracting device, and performing N-stage spraying soaking extraction through an extracting agent containing cottonseed oil and gossypol to obtain a mixed solution and wet cottonseed meal, wherein the mass fraction of the cottonseed oil in the extracting agent at the M stage is more than that of the cottonseed oil in the extracting agent at the M-1 stage, and M is not less than 2 and not greater than N; extracting degossypolized cottonseed protein, namely, distilling the wet cottonseed meal through steam to obtain degossypolized cottonseed protein; extracting cottonseed oil, namely, performing solution division, evaporating and steam stripping for the mixed solution to obtain the cottonseed oil. With the adoption of the method, the time of extracting of degossypolized cottonseed protein can be greatly reduced, so that the problems of large energy consumption and high oil content in degossypolized protein in degossypolized cottonseed protein industrial production can be solved; the production method is free of environmental pollution, and low in production cost.

Owner:安徽嘉旗粮油工程技术有限公司

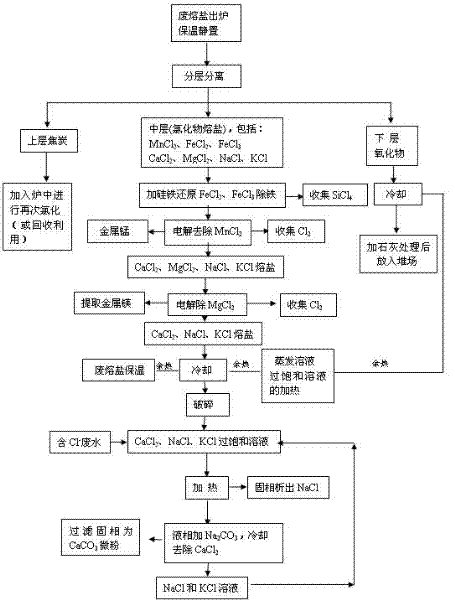

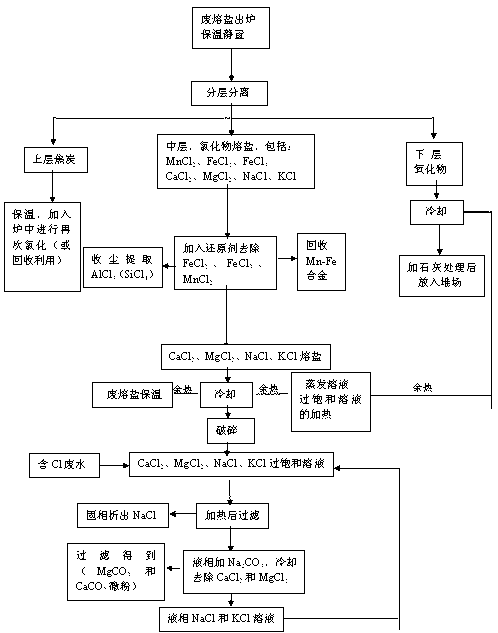

Method for treating waste fused salt produced in production of TiCl4

InactiveCN102560538ASolve the problem of polluting the environmentAchieve regenerationCalcium/strontium/barium carbonatesChlorine/hydrogen-chlorideMagnesiumOxide

The invention discloses a method for treating waste fused salt produced in production of TiCl4, and relates to a method for treating waste fused salt. The method comprises the following steps of: performing heat preservation on the waste fused salt discharged out of a furnace so that the waste fused salt is divided into an upper coke layer, a middle fused salt layer and a lower oxide layer; performing layer-by-layer separation, and removing iron, manganese and magnesium from the fused salt of the middle layer, wherein one part of fused salt is used as electrolyte for smelting magnesium by an electrolytic process; performing heat preservation, cooling, water dissolution and Na2CO3 or Na2SO4 treatment on the other part of fused salt, then reclaiming or circularly using all the waste fused salt, and reclaiming Mn-Fe alloy, metallic manganese, metallic magnesium, chlorine and CaCO3 micro powder; and utilizing the waste heat of the waste fused salt, and treating wastewater containing Cl<->. The waste fused salt can be completely recycled, meanwhile, the Mn-Fe alloy, the metallic manganese, the metallic magnesium, the chlorine and the CaCO3 micro powder can be reclaimed, the waste heat of the waste fused salt can be utilized, and the wastewater containing the Cl<-> can be treated.

Owner:重庆阁林环保科技有限公司

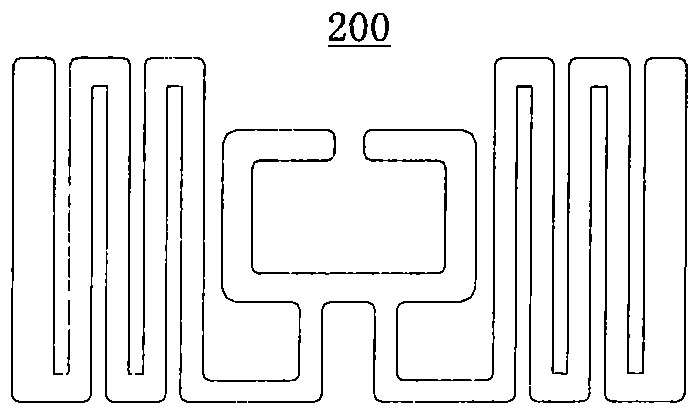

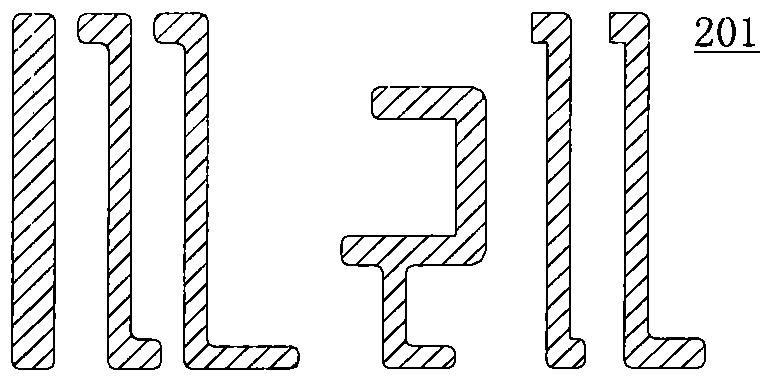

A kind of manufacturing method of punching aluminum foil rfid radio frequency antenna

ActiveCN104577321BReduce manufacturing costNo chemical etching requiredRadiating elements structural formsLoop antennasPunchingAcupuncture

A method for manufacturing an RFID radio frequency antenna by punching an aluminum foil. A complex RFID radio frequency antenna pattern is decomposed into two or three groups of simple segment patterns, then two or three groups of punching dies are manufactured according to the two or three groups of segment patterns, aluminum foil segments punched respectively are connected to one another in a lapped mode, the lap joint parts of the aluminum foil segments are welded using ultrasonic waves or treated using an acupuncture process, and the two or three groups of punched aluminum foil segments are combined to form a complete radio frequency antenna. According to the method, an aluminum foil radio frequency antenna can be manufactured by punching on paper, films and rubber having different thicknesses, radio frequency products of different materials can be manufactured conveniently, the production process is simple, generation of waste water is avoided, and pollution to the environment is avoided; moreover, aluminum foil waste is easy to recover, efficiency is high, the manufacturing cost is low, and the aluminum foil radio frequency antenna is suitable for large-scale production.

Owner:SHENZHEN JG TECH IND

Treatment method for chlorinated waste generated during production of TiC14

InactiveCN102765748ASolve the problem of polluting the environmentSolve the problem of long-term stacking pollution of the environmentTitanium halidesSlagSludge

A treatment method for chlorinated waste generated during production of TiC14 relates to a method for treating chlorinated waste. During discharging of the chlorinated waste, alkaline matters are coated on the surface of the chlorinated waste, dry alkaline matters are in contact with the chlorinated waste directly, and water-bearing alkaline matters are covered with the dry alkaline matters and then are in contact with the chlorinated waste; or the alkaline matters are covered with a steel plate or an iron plate with breather holes and then are in contact with the chlorinated waste; the space between metalware containing the chlorinated waste and the steel plate or the iron plate with the breather holes is sealed with wet clay; clay between the metalware containing the chlorinated waste and the steel plate or the iron plate with the breather holes is sealed; and the chlorinated waste is covered with the alkaline matters containing sodium series and lime series after being poured out of a container containing chlorinated waste salt. Through the treatment method, the long-standing problem that the environment is polluted during the discharging of waste salt and waste slag when TiC14 is prepared by the chloride process is solved, industrial waste such as calcium carbide sludge, magnesium slag and caustic sludge can be utilized, and the cost for preparing the chlorinated waste is lowered greatly.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for oil field sewage treatment

InactiveCN107176670ASolve the problem of polluting the environmentLow costWater/sewage treatment by irradiationTreatment involving filtrationIonChemistry

The invention provides a method for treating oilfield sewage, comprising: using a reducing agent greater than 1 ppm as an oxidizing agent, wherein the reducing agent contains ferrous ions, disulfides, organic compounds or contains at least one of the above and contains hydrogen peroxide , potassium permanganate, chlorine gas, sodium hypochlorite, calcium hypochlorite, sodium percarbonate, sodium perborate, ozone and ultraviolet rays are used to oxidize waste water. The method of the invention is simple and convenient to operate, low in cost, convenient for industrialized production, can achieve the purpose of reusing / reusing oilfield wastewater, and realizes comprehensive utilization of oilfield wastewater.

Owner:江阴宇博科技有限公司

Method for preparing precipitated barium sulphate from petrochemical barium residues and reclaiming polyisobutylene

InactiveCN101704542AAvoid wasting resourcesSolve the problem of polluting the environmentSolid waste disposalCalcium/strontium/barium sulfatesChemical reactionBarium dichloride

The invention discloses a method for preparing precipitated barium sulphate from petrochemical barium residues and reclaiming polyisobutylene. The main technical scheme is that the method comprises the following steps: performing physical purification and chemical purification on the petrochemical barium residues to obtain a pure barium chloride solution; performing chemical reaction between the barium chloride and sulfuric acid in certain proportion to obtain a mixed solution of the precipitated barium sulphate and hydrochloric acid; and filtering the mixed solution to obtain a hydrochloric acid solution for reuse, and washing, dehydrating, drying and crushing a filter cake to obtain the precipitated barium sulphate. In order to thoroughly solve the problem, the invention develops a set of methods specially used for treating petrochemical waste residues. The method not only can take out valuable substances from the waste residues, but also generates no secondary pollution. The method aims to change wastes into valuable and benefit the mankind.

Owner:王嘉兴

Method for coproduction of cellulose, active carbon and compound fertilizer from plant stalk

InactiveCN101476253BIncrease profitSolve the disadvantages that only a single product can be extractedLignin derivativesPaper material treatmentCelluloseFiber

Owner:JIAHE BIOTECH

Method for planting pasture on rare earth tailings and comprehensive treatment method of rare earth tailings

ActiveCN111642335AIncrease the depth of fertilizationImproved substratePlant cultivationCultivating equipmentsEdaphicBiology

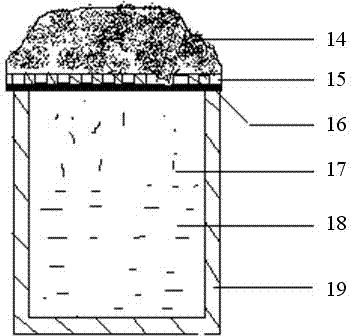

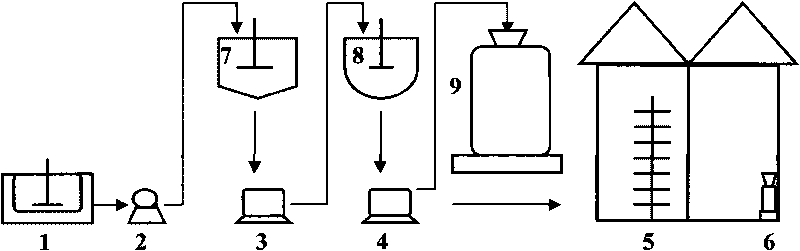

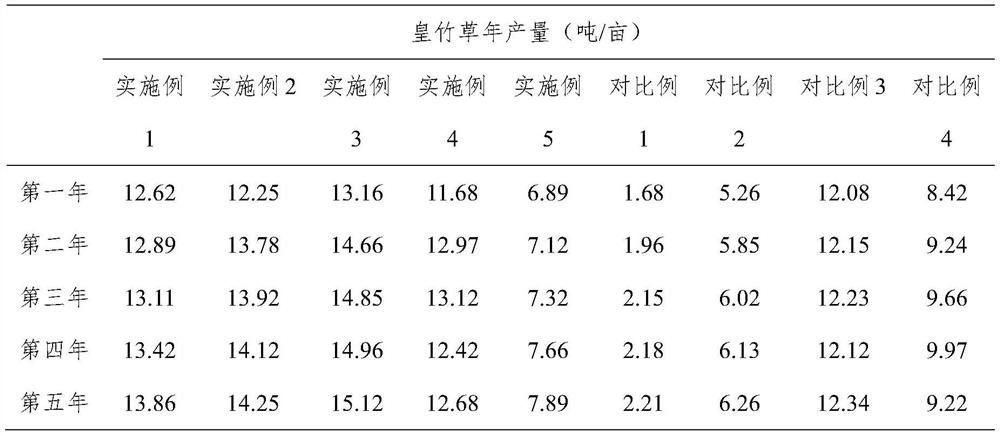

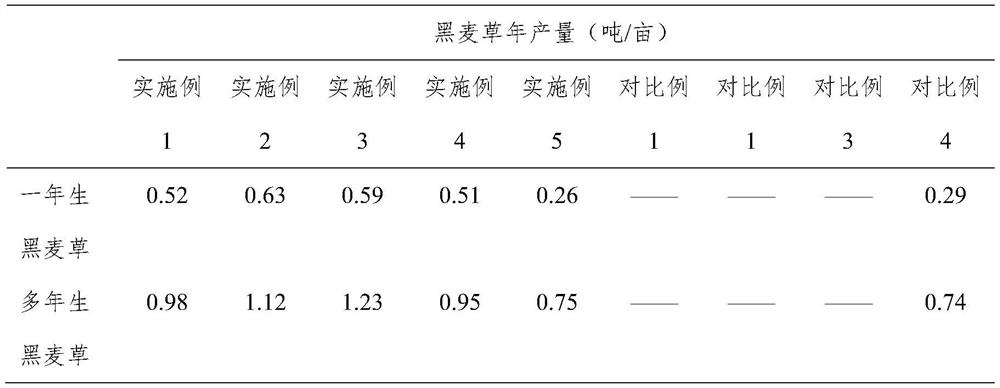

The invention discloses a method for planting pasture on rare earth tailings and a comprehensive treatment method of the rare earth tailings. The method for planting pasture on rare earth tailings includes: using earthworm manure as a base fertilizer in the rare earth tailings area, planting Pennisetum hydridum and ryegrass, and the Pennisetum hydridum and the ryegrass can be alternately planted in multiple rows at intervals. The comprehensive treatment method of the rare earth tailings includes: establishing a cattle farm in the rare earth tailings area, and using Pennisetum hydridum and ryegrass to prepare feed to feed the cattle; cultivating earthworms with cattle dung to obtain earthworm manure, fermenting cow urine to obtain biogas slurry, and then planting and irrigating Pennisetum hydridum and ryegrass through earthworm manure and biogas slurry. According to the method, the rare earth tailings area can be fully utilized to breed cattle, and a problem of environment pollution caused by cattle farm dung can be solved; organic matter content of the soil of the rare earth tailings can be increased by fully utilizing cattle dung, acidity of the rare earth tailings can be neutralized by utilizing the characteristics of earthworm dung alkalinity, rich in various beneficial microorganisms, active ingredients, enzymes and various nutrient substances, survival rate and growth speed of plants can be improved, and a source problem of organic fertilizers in the treatment of the rare earth tailings can be solved.

Owner:赣州市畜牧研究所

Method for producing high-purity magnesium oxide through utilizing low-grade magnesium oxide and magnesite

InactiveCN103274611AHigh puritySolve the problem of polluting the environmentMagnesiaSocial benefitsMagnesium salt

The invention relates to a method for producing pure magnesium oxide, and concretely relates to a method for producing high-purity magnesium oxide through utilizing low-grade magnesium oxide and magnesite. The method comprises the following steps: adding a magnesium salt to low-grade magnesia having a magnesium oxide mass percentage content of 94.0-97.5% or magnesite having a magnesium oxide mass percentage content of 40.0-46.0%, uniformly mixing, and carrying out heating calcining to prepare high-purity magnesium oxide having a purity of above 98.0%. High-purity magnesium oxide is produced through the addition of the magnesium salt to the low-grade magnesium oxide and the heating treatment in the invention. The method solves a magnesium chloride-polluted environment problem generated in the sponge titanium production process, reduces the production cost, and brings considerable economic and social benefits.

Owner:重庆阁林环保科技有限公司

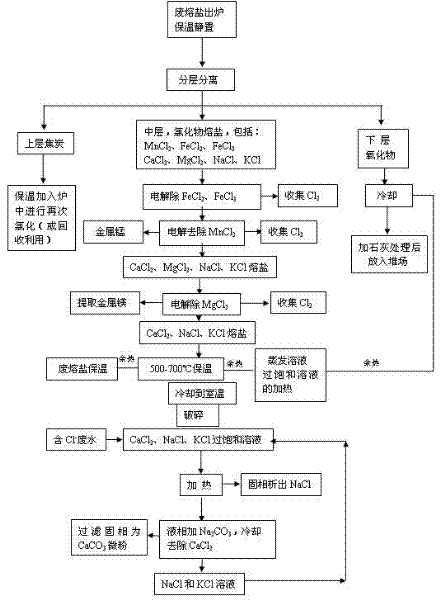

Method for combined treatment on chlorinated waste molten salts and Cl-containing waste water

InactiveCN102718233BSolve the problem of polluting the environmentAchieve recyclingEnergy inputWater/sewage treatmentIndustrial waste waterElectrolysis

Owner:重庆环投生态环境监测网络与工程治理有限公司

Process for preparing biomass fuel from domestic garbage and agricultural and forestry waste in rural areas

ActiveCN108435754BLess investmentLow costSolid waste disposalExcrement fertilisersSludgePoultry manure

The invention discloses a process for preparing biomass fuel from domestic garbage and agricultural and forestry waste in rural areas. Steps: The first step is landfill leachate treatment, odor deodorization; the second step is garbage screening, sorting, coarse crushing; the third step is non-organic magnetic separation, winnowing, and fine crushing; the fourth step is agricultural and forestry waste crushing, Screening; the fifth step, mixing combustible garbage, agricultural and forestry waste, sludge, and water, pressing and molding, and drying to make biomass fuel; the sixth step, adding the organic matter of garbage to livestock and poultry manure to make organic fertilizer. Biomass fuel can be directly used in boilers, and organic fertilizer solves the problem of environmental pollution caused by livestock and poultry manure in farms. The construction of a waste treatment plant requires less investment, low cost, and is easy to implement. Collect agricultural and forestry waste for a fee, increase farmers' income and reduce pollution. High profit margins, sustainable operation without government subsidies. Waste gas, waste liquid, and waste residue have all been treated in an environmentally friendly manner, and no new pollution will be generated.

Owner:于继林

Polystyrene foam aggregate concrete insulation building block

ActiveCN103539398BSolve the problem of polluting the environmentGet secondary useCeramicwareCompressive resistanceFoaming agent

The present invention belongs to the field of concrete insulation masonry materials. It specifically provides a polystyrene foam osteogenesis concrete insulation block, which consists of polystyrene foam aggregate, slurry and foaming agent.For: polystyrene foam aggregate: slurry: foaming agent = (0.004 ~ 0.01): 1.0: (0.008 ~ 0.015);: Early strong agent = (0.5 ~ 0.55): 1.0: (3.0 ~ 4.0): (0.01 ~ 0.02).The invention of polystyrene foam osteogeneous concrete insulation blocks can take into account the relationship between the intensity of the masonry, production process, and production cost. The pressure resistance is more than 2 times that of similar products, but the cost is 20%lower than similar products.

Owner:HUNAN INSTITUTE OF ENGINEERING

Method for simultaneously separating soy protein and oil fat with inverse micelle abstraction technique

ActiveCN101343309BSimple production processReduce manufacturing costPeptide preparation methodsFatty-oils/fats productionSolventDrug biological activity

Disclosed is a method for separating soybean protein and fat by the reversed micellar extraction, which comprises the following procedures: (1) reversed micellar solution is prepared; (2)a pretreated raw material of soybean is added into the reversed micellar solution to extract protein and fat; (3) electrolyte solution is added so that the protein is transferred into the aqueous phase from the reversed micellar solution to be separated, thereby realizing back extraction of the protein, and protein aqueous solution and mixed oil are obtained; (4) the obtained protein product and the fat product are processed. The method has the following main advantages: the fat and the protein are separated at the same time in the reversed micellar extraction system, so the production process is greatly simplified, and the production cost and the investment on the fixed assets are reduced; the method has the advantages of solvent extraction; in the process of extraction, the protein is surrounded by the water environment in the reversed micellar, and the environment is close to the environment in the cells with mild condition, so the protein is not denatured and can keep the biological activity of the protein, and the purity of the product is high; and no acid and alkali wastewater is discharged without pollution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

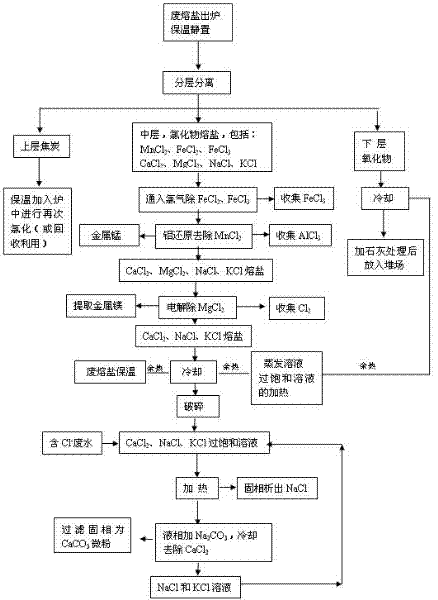

Method for treating scrapped molten salt generated in molten salt chlorination production method of TiCl4

InactiveCN102443710BSolve the problem of polluting the environmentAchieve recyclingEnergy inputProcess efficiency improvementReduction treatmentManganese

The invention discloses a method for treating scrapped molten salt generated in the molten salt chlorination production method of TiCl4. The method comprises the following steps: directly keeping the temperature of the discharged scrapped molten salt at 500-900 DEG C, standing to ensure that the molten salt is divided into three layers, namely an upper layer (floating layer), a middle layer (molten salt layer) and a lower layer (precipitate layer), and then layering, wherein the upper layer is coke mixed with a little molten salt, and can be sent back to a molten salt chlorination furnace after separation for reuse, or can be used to recycle waste coke; and after deironing and demanganizing reduction treatment, the middle layer molten salt is cooled to the room temperature and treated with water and Na2CO3, thus the molten salt can be completely recycled and be used to produce Mn-Fe alloys (or Mn), MgCO3 and CaCO3 micropowder, AlCl3, SiCl4 and Cl2, the waste heat of the scrapped molten salt can be utilized, and the wastewater containing Cl<-> can be treated. Therefore, economic benefit and social benefit can be obtained.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

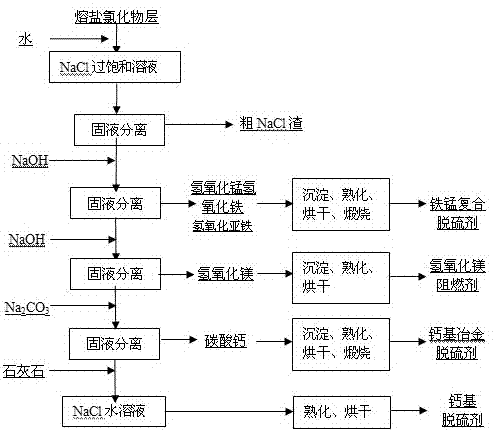

Method for preparing raw material of desulfurizer by using chlorinated waste molten salt produced in the production of tcl4

InactiveCN103566719BAchieve regenerationRealize comprehensive utilizationSolid waste disposalDispersed particle separationFerric hydroxideElectrolysis

The invention discloses a method for preparing a raw material of a desulfurizing agent by using waste chlorination molten salt generated in production of TiCl4, and relates to a method for treating waste molten salt and wastewater containing Cl<->. The method comprises the following steps: performing water solution treatment on a crushed waste molten salt chloride layer, filtering out dregs, subsequently performing treatment of iron removal, manganese removal, magnesium removal and calcium removal on the obtained water solution of the chloride step by step, so as to respectively obtain solutions of ferric hydroxide, ferrous hydroxide, manganese hydroxide, magnesium hydroxide, CaCO3 and NaCl, treating ferric hydroxide, ferrous hydroxide, manganese hydroxide, magnesium hydroxide and CaCO3, subsequently preparing a series of desulfurizing agents, and taking the NaCl aqueous solution as a modifying agent of a calcium-based desulfurizing agent. Due to the adoption of the method, the problem of environment pollution of waste molten salt and wastewater containing Cl<-> in preparation of TiCl4 by using a molten salt electrolysis method, which plagues people for a long time, is solved, the waste molten salt can be prepared into iron-based, magnesium-based, ferro-manganese-based and calcium-based desulfurizing agents for treating a great deal of industrial wastewater containing NaCl, and recycling utilization of the waste molten salt and the industrial wastewater containing NaCl is achieved.

Owner:重庆阁林环保科技有限公司

Carrageenan algae residue organic fertilizer and preparation method thereof

InactiveCN102372506BLower the pH valueReduce lossesBio-organic fraction processingClimate change adaptationCarrageenanPhosphate

The invention relates to the field of biological fertilizers and in particular discloses a carrageenan algae residue organic fertilizer and a preparation method thereof. The carrageenan algae residue organic fertilizer consists of the following components in percentage by weight: 0.05 to 0.5 percent of monoammonium phosphate, 0 to 30 percent of auxiliary materials, 0.025 to 0.5 percent of microbial fermentation agent and the balance of carrageenan algae residue. The preparation method comprises the following steps of: adding the monoammonium phosphate into the carrageenan algae residue according to the proportion, regulating the pH value of materials to be 7.0 to 8.0, adding bran and the microbial fermentation agent into the materials, fully mixing and stirring, fermenting a compost, turning the pile in time and supplementing the moisture when the fermentation temperature is 65 to 68 DEG C, turning the pile once on 3rd, 5th and 7th days after inoculation respectively, and maintaining the fermentation temperature of the compost to 45 to 65 DEG C, wherein the aerobic fermentation time is 12 to 20 days; and after the composting is finished, ensuring that the water content of the fermented materials is 20 to 25 percent at the temperature of between 50 and 70 DEG C to obtain the carrageenan algae residue organic fertilizer. By the method, the waste is turned into wealth, the high-efficiency and low-cost organic fertilizer is obtained, the environmental pollution is also treated, and the ecological balance is better kept.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com