Production method for synchronously extracting cottonseed oil and degossypolized cottonseed protein from cottonseed germ flakes

A technology for dephenolizing cottonseed protein and cottonseed germ slices, which is applied in the field of agricultural resource extraction, can solve the problems of high gossypol residue, high production cost, and long extraction time, and achieve less solvent residue, good product quality, and short extraction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

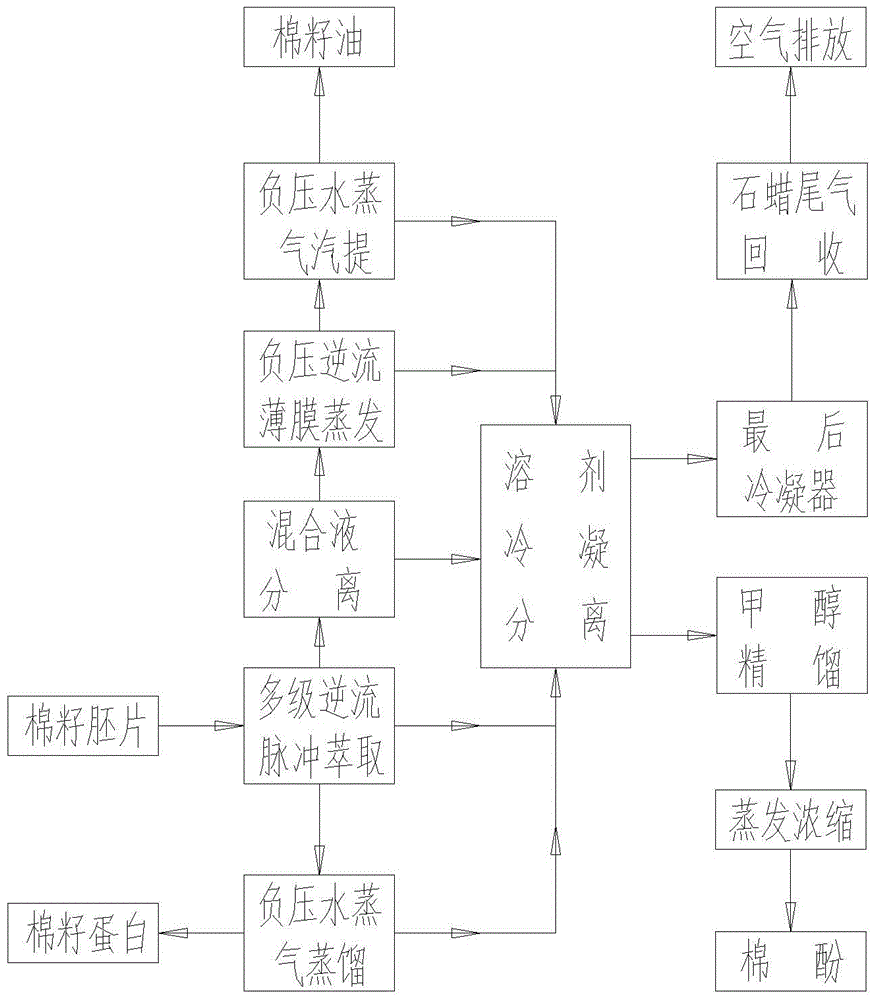

[0051] like figure 1 and figure 2 as shown, figure 1 It is a process flow diagram of a production method for synchronously extracting cottonseed oil and dephenolized cottonseed protein from cottonseed germ sheets proposed by the present invention, figure 2 It is a simplified process flow diagram of a production method for synchronously extracting cottonseed oil and dephenolized cottonseed protein from cottonseed germ slices proposed by the present invention.

[0052] refer to figure 1 and figure 2 A production method for synchronously extracting cottonseed oil and dephenolized cottonseed protein from cottonseed germ slices proposed by the present invention, comprising the following steps

[0053] S1. Multi-stage countercurrent pulse extraction: send the cottonseed germ slices into the extractor, and at 57°C, first spray and soak the extractant with a mass fraction of cottonseed oil of 22wt%%. Fractions of 18wt%, 15wt%, 10wt%, 5wt%, 2wt%, 0.6wt%, 0wt% of the extractant ...

Embodiment 2

[0062] A production method for synchronously extracting cottonseed oil and dephenolized cottonseed protein from cottonseed germ slices proposed by the present invention comprises the following steps

[0063] S1. Multi-stage countercurrent pulse extraction: send the cottonseed germ slices into the extractor, and at 55°C, first spray and soak the extraction agent containing 24wt% cottonseed oil, and then separately 19wt%, 16wt%, 11wt%, 6wt%, 3wt%, 0.8wt%, 0wt% of the extractant were sequentially carried out eight-stage spray soaking extraction, extraction 90min, to obtain a mixed solution and cottonseed wet meal; wherein, the extractant and The mass ratio of cottonseed germ flakes is 1.2:1, and the extractant is composed of methanol and n-hexane with a mass ratio of 0.6:1;

[0064] S2. Extraction of dephenolized cottonseed protein: Send the wet cottonseed meal obtained in S1 into a steam distillation desolventization tower. The steam distillation desolventization tower is equipp...

Embodiment 3

[0072] A production method for synchronously extracting cottonseed oil and dephenolized gossypol protein from cottonseed embryo slices provided by the present invention comprises the following steps

[0073] S1. Multi-stage countercurrent pulse extraction: The cottonseed embryos are sent into the extractor, and at 60°C, firstly, the extractant containing cottonseed oil with a mass fraction of 20 wt% is sprayed and soaked for extraction, and then the cottonseed oil containing mass fraction of 17wt%, 14wt%, 9wt%, 4wt%, 1.5wt%, 0.3wt%, 0wt% of the extractant were sequentially subjected to eight-stage spray soaking extraction, and extracted for 120min to obtain a mixed solution and cottonseed wet meal; wherein, the extractant was The mass ratio to cottonseed embryo chips is 1.5:1, and the extractant is composed of methanol and n-hexane in a mass ratio of 0.4:1;

[0074] S2, extracting dephenolized gossyptin: the cottonseed wet meal obtained in S1 is sent to a steam distillation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com