Treatment method for chlorinated waste generated during production of TiC14

A treatment method and waste technology, applied in the direction of titanium halide, etc., can solve problems such as chloride smoke and dust pollution of the environment, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

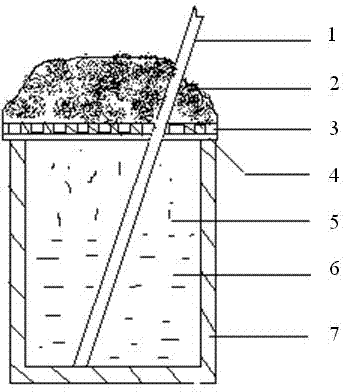

[0018] Embodiment one: if figure 1 The schematic diagram of treating chlorinated waste molten salt is shown in the furnace. In the process of chlorinated waste molten salt 6 coming out of the furnace, a porous iron plate 3 is added on the iron bowl 7 holding the waste molten salt through the metal conduit 1, and a porous iron plate 3 is placed between the iron bowl 7 holding the waste molten salt and the porous iron plate 3. Use wet bentonite 4 to seal between them, and cover the carbide slag 2 on the porous iron plate 3, so that the carbide slag absorbs the gas 5 produced by the waste molten salt in the air during the discharge process of the waste molten salt, preventing the chlorination of the waste molten salt. Salt produces chloride fumes during the process of being baked and pollutes the environment.

Embodiment 2

[0019] Embodiment two: as figure 1 The schematic diagram of treating chlorinated waste molten salt is shown in the furnace. In the process of chlorinating the waste molten salt 6 out of the furnace, a porous steel plate 3 is added on the iron bowl 7 containing the waste molten salt through the metal conduit 1, and a porous steel plate 3 is used between the iron bowl 7 containing the waste molten salt and the porous steel plate 3. Wet attapulgite 4 is sealed, and covers quicklime 2 on the porous iron plate 3, so that quicklime absorbs the gas 5 produced by the waste molten salt meeting air in the discharge process of the waste molten salt, so as to prevent the chlorination of the waste molten salt in the air. Chloride fumes are produced during the furnace process to pollute the environment.

Embodiment 3

[0020] Embodiment three: as figure 1 The schematic diagram of treating chlorinated waste molten salt is shown in the furnace. In the process of chlorinating the waste molten salt 6 out of the furnace, a porous steel plate 3 is added on the iron bowl 7 containing the waste molten salt through the metal conduit 1, and a porous steel plate 3 is used between the iron bowl 7 containing the waste molten salt and the porous steel plate 3. Wet calcium-based bentonite 4 is sealed, and covered with slaked lime 2 on the porous iron plate 3, so that slaked lime has just absorbed the gas 5 produced by the waste molten salt meeting air in the discharge process of the waste molten salt, so as to prevent the chlorination of the waste molten salt in the air. Chloride fumes are produced during the furnace process to pollute the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com