Method for preparing raw material of desulfurizing agent by using waste chlorination molten salt generated in production of TiCl4

A desulfurizer and molten salt technology, applied in the field of processing waste molten salt and Cl-containing wastewater, can solve the problem of low utilization rate of desulfurizer and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

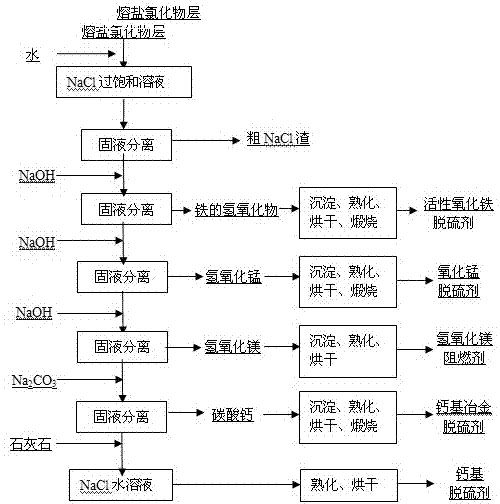

[0019] Such as the process flow of processing waste molten salt figure 1 As shown, in the waste molten salt chloride layer, water accounting for 90.0%-280.0% of the chloride mass is gradually added to form a chloride supersaturated solution, and the thick NaCl solid and chloride saturated solution are separated after filtration; the chloride saturated solution is first Fe in solution 2+ and Fe 3+ Equivalent (get slightly greater than Fe 2+ and Fe 3+ equivalent) of NaOH, to obtain a precipitate and chloride solution, the precipitate is mainly Fe (OH) 2 and Fe(OH) 3 , the wet ferric hydroxide and ferrous hydroxide separated by filtration are then cleaned, precipitated and matured, dried and other processes, and finally α-Fe with desulfurization activity is obtained 2 o 3 ·H 2 O, γ-Fe 2 o 3 ·H 2 O and γ-Fe 2 o 3 Active iron oxide in three forms, then add binder and pore-forming agent according to the proportion, adjust the pH value to make it alkaline, and then form, ...

Embodiment 2

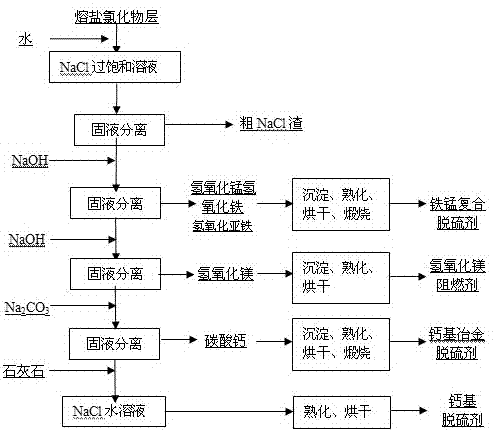

[0025] Such as the process flow of processing waste molten salt figure 2 As shown, water accounting for 90.0%-280.0% of the chloride mass is gradually added to the waste molten salt chloride layer to form a chloride supersaturated solution at a temperature of 40-95°C, and the crude NaCl solid and hot chloride saturated solution are separated after filtration. solution; the chloride saturated solution, first added to the solution with Mn 2+ , Fe 2+ and Fe 3+ Equivalent (get slightly greater than Mn 2+ , Fe 2+ and Fe 3+ equivalent) of NaOH, to obtain a precipitate and chloride solution, the precipitate is mainly Mn (OH) 3 , Fe(OH) 2 and Fe(OH) 3 , the wet manganese hydroxide, ferric hydroxide and ferrous hydroxide separated by filtration are then cleaned, precipitated and matured, dried and other processes, and finally the manganese oxide and α-Fe with desulfurization activity are obtained. 2 o 3 ·H 2 O, γ-Fe 2 o 3 ·H 2 O and γ-Fe 2 o 3 Active iron oxide and mang...

Embodiment 3

[0030] Such as the process flow of processing waste molten salt image 3 As shown, water accounting for 90.0%-280.0% of the chloride mass is gradually added to the waste molten salt chloride layer to form a chloride supersaturated solution at a temperature of 40-95°C, and the crude NaCl solid and hot chloride saturated solution are separated after filtration. solution; the chloride saturated solution, first added to the Fe in the solution 2+ and Fe 3+ Equivalent (get slightly greater than Fe 2+ and Fe 3+ equivalent) of milk of lime to obtain precipitate and chloride solution, the precipitate is mainly Fe(OH) 2 and Fe(OH) 3 , the wet ferric hydroxide and ferrous hydroxide separated by filtration are then cleaned, precipitated and matured, dried and other processes, and finally α-Fe with desulfurization activity is obtained 2 o 3 ·H 2 O, γ-Fe 2 o 3 ·H 2 O and γ-Fe 2 o 3 Active iron oxide in three forms, then add binder and pore-forming agent according to the proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com