Method for preparing precipitated barium sulphate from petrochemical barium residues and reclaiming polyisobutylene

A technology for precipitating barium sulfate and polyisobutylene, applied in calcium/strontium/barium sulfate, plastic recycling, recycling technology, etc., can solve the problems of resource waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

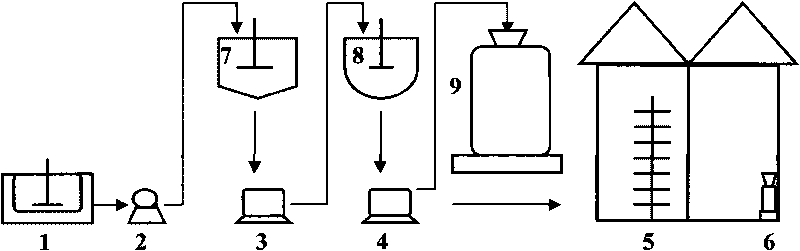

[0013] Embodiment one: at first 300kg of petrochemical barium slag containing about 30% polyisobutylene was added with industrial water according to 1:0.5 in a closed leaching tank (1) and stirred with normal temperature water for five to ten minutes, then centrifugally filtered (2) The barium slag filter cake and leached organic water are obtained by separation. Obtained the barium slag (barium hydroxide meter) filter cake of 210kg and industrial hydrochloric acid with the mass ratio 1: 0.17 of pure substance and react in purifier (7) under agitation, reaction obtains relatively pure barium chloride 101.72kg solution . And the polyisobutylene organic aqueous solution of leaching needs further processing.

[0014] The barium chloride 101.71kg solution obtained above is treated with a small amount of barium sulfate to remove the chloride inside, and then reduced to barium chloride again, and the barium chloride solution at this time has become very pure. Continue to react wit...

Embodiment 2

[0016] Embodiment Two: First, 300kg of petrochemical barium slag containing about 30% polyisobutylene is stirred with normal temperature industrial water according to 1:1.5 in a closed leaching tank (1) for five to ten minutes, and then separated by centrifugal suction filtration (2) Obtain barium residue filter cake and leached aqueous solution. Obtained the barium slag (barium hydroxide meter) filter cake of 210kg reacts in purifier (7) with the mass ratio 1: 0.37 of pure substance again with industrial hydrochloric acid, reacts to obtain relatively pure barium chloride (221.39 kg) solution. And the polyisobutylene organic aqueous solution of leaching needs further processing.

[0017] The barium chloride 221.39kg solution obtained above is treated with a small amount of barium sulfate to remove the chloride inside, and then reduced to barium chloride again, and the barium chloride solution at this time has become very pure. Continue to react in the reactor (8) with the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com