A-level flame-retardant modified polystyrene board heat-insulating system

A thermal insulation system, polystyrene board technology, applied in thermal insulation, building components, fire prevention and other directions, can solve the problems of high toxicity of combustion materials, poor fire resistance, slag loss, etc., and achieve low thermal conductivity, good waterproof performance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

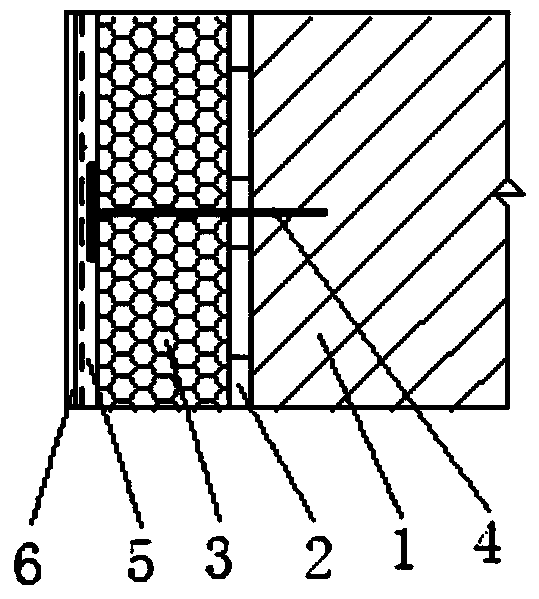

[0032] Such as figure 1 As shown, this embodiment includes a base layer 1, an adhesive layer 2, an insulation layer 3, a connector 4, a plaster layer 5, and a finish layer 6 from inside to outside in sequence, and the insulation layer 3, the adhesive layer 2, and the base layer 1 pass through The connector 4 is fixed; the insulation layer 3 is made of A-grade flame-retardant modified polystyrene board, and the A-grade flame-retardant modified polystyrene board, by weight, includes 20 parts of flame-retardant polystyrene resin, hair 0.4 parts of foaming agent, 40 parts of talcum powder, 6 parts of aluminum hydroxide, 2 parts of surfactant, and 3 parts of curing agent.

[0033] The base layer 1 of this embodiment is a concrete wall or a masonry wall.

[0034] The bonding layer 2 is made of bonding mortar, and the bonding mortar includes 350 parts of 42.5 ordinary Portland cement, 500 parts of 30-150 mesh quartz sand, and 50 parts of heavy calcium powder by weight, which can be ...

Embodiment 2

[0064] The Class A flame-retardant modified polystyrene board of this embodiment, by weight, includes 25 parts of flame-retardant polystyrene resin, 0.5 parts of foaming agent, 50 parts of talcum powder, 10 parts of aluminum hydroxide, and 4 parts of surfactant parts, curing agent 5 parts.

[0065] The bonding layer 2 is made of bonding mortar, and the bonding mortar includes 400 parts of 42.5 ordinary Portland cement, 550 parts of 30-150 mesh quartz sand, and 100 parts of heavy calcium powder by weight, which can be redispersed 20 parts of latex powder, 2.5 parts of cellulose ether, and 5 parts of lignin.

[0066] The plastering layer 5 is made of plastering mortar, and mesh cloth is laid inside the plastering mortar. The plastering mortar includes 300 parts by weight of 42.5 ordinary Portland cement, 650 parts of 40-140 mesh quartz sand, and 100 parts of calcium powder, 30 parts of redispersible latex powder, 3 parts of cellulose ether, 4 parts of water-repellent agent, 2 p...

Embodiment 3

[0069] The Class A flame-retardant modified polystyrene board of this embodiment, by weight, includes 22 parts of flame-retardant polystyrene resin, 0.5 parts of foaming agent, 45 parts of talcum powder, 8 parts of aluminum hydroxide, and 3 parts of surfactant parts, 4 parts of curing agent.

[0070] The bonding layer 2 is made of bonding mortar, and the bonding mortar includes 380 parts of 42.5 ordinary Portland cement, 520 parts of 30-150 mesh quartz sand, and 80 parts of heavy calcium powder by weight, which can be redispersed 18 parts of latex powder, 2 parts of cellulose ether, 4 parts of lignin.

[0071] The plastering layer 5 is made of plastering mortar, and mesh cloth is laid inside the plastering mortar. The plastering mortar includes 290 parts by weight of 42.5 ordinary Portland cement, 630 parts of 40-140 mesh quartz sand, and 80 parts of calcium powder, 25 parts of redispersible latex powder, 3 parts of cellulose ether, 3 parts of water repellent, 1 part of polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com