Water-retaining agent and manufacture method thereof

A production method and water-retaining agent technology, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of post-processing granulator drying difficulties, water-retaining agent fine powder, plant growth threats, etc., to achieve the benefit of manufacturing Granular and dry, short reaction time, hard appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

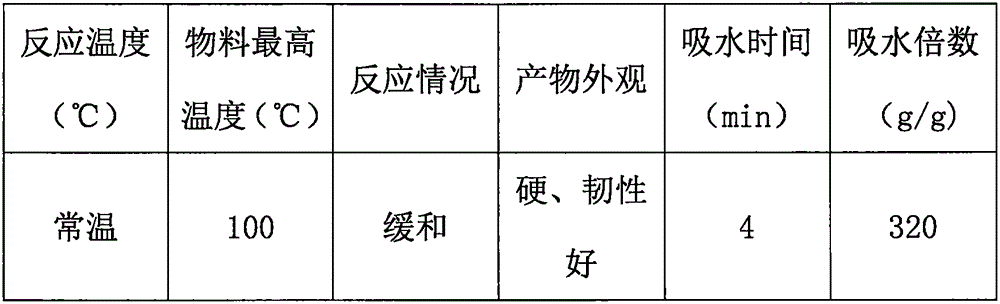

Embodiment example

[0021] The steps to implement the case are as follows:

[0022] (a) Acid-base neutralization: acrylic acid is formulated into a 50% aqueous solution, neutralized with 15% potassium hydroxide aqueous solution, wherein the mass ratio of acrylic acid to potassium hydroxide is 4:1, and acrylic acid is neutralized with potassium hydroxide aqueous solution Finished, and then add ammonium carbonate solid to neutralize the aqueous acrylic acid solution again, finally, the neutralization degree of acrylic acid is controlled to 70%, and neutralization mixture A (acrylic acid, potassium acrylate, ammonium acrylate mixture) is obtained;

[0023] (b) Polymerization reaction: Add acrylamide and crosslinking agent N, N'-methylenebisacrylamide to the neutralization mixture A, the dosages are respectively 30% and 0.18% of the total mass of the reaction monomer acrylic acid and acrylamide, After stirring and dissolving, put it into a strip-shaped polymerization reaction tray, and then add induc...

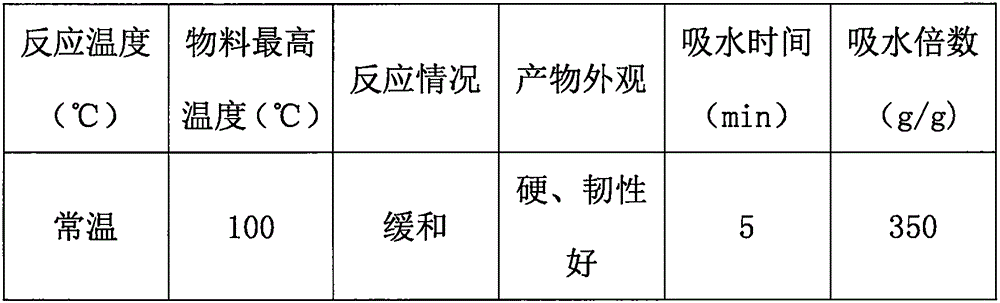

Embodiment 2

[0029] The steps to implement the case are as follows:

[0030] (a) Acid-base neutralization: acrylic acid is formulated into a 52% aqueous solution, neutralized with 10% potassium hydroxide aqueous solution, wherein the mass ratio of acrylic acid to potassium hydroxide is 4.5:1, and acrylic acid is neutralized with potassium hydroxide aqueous solution Finished, and then add ammonium carbonate solid to neutralize the aqueous acrylic acid solution again, finally, the neutralization degree of acrylic acid is controlled to 75%, to obtain neutralization mixture A (acrylic acid, potassium acrylate, ammonium acrylate mixture);

[0031](b) Polymerization reaction: Add acrylamide and crosslinking agent N, N'-methylenebisacrylamide to the neutralization mixture A, the dosages are respectively 34% and 0.2% of the total mass of the reaction monomer acrylic acid and acrylamide, After stirring and dissolving, put it into a strip-shaped polymerization reaction plate, and then add the induce...

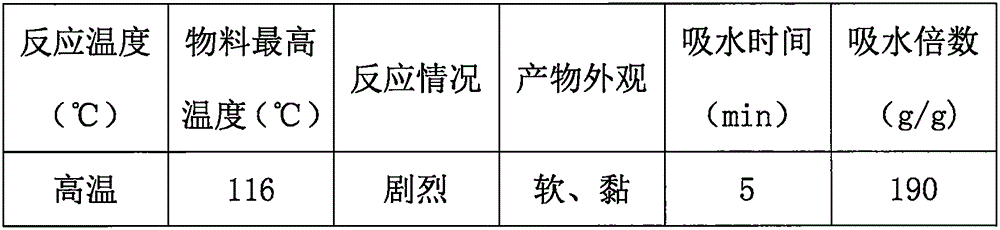

Embodiment 3

[0038] The steps to implement the case are as follows:

[0039] (a) Acid-base neutralization: prepare acrylic acid into a 50% aqueous solution, neutralize with 15% potassium hydroxide aqueous solution, and finally control the neutralization degree of acrylic acid to 75%, and obtain neutralization mixture A (acrylic acid, potassium acrylate mixture) ;

[0040] (b) Polymerization reaction: Add acrylamide and crosslinking agent N, N'-methylenebisacrylamide to the neutralization mixture A, the dosages are respectively 30% and 0.18% of the total mass of the reaction monomer acrylic acid and acrylamide, After stirring and dissolving, put it into a strip-shaped polymerization reaction plate, and then add inducing agents potassium persulfate and potassium sulfite in sequence, the doses are respectively 0.1% and 0.1% of the total mass of the reactants, stir well and carry out polymerization synthesis at room temperature to obtain strips -like intermediate B;

[0041] (c) Granulation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com