High-weather-resistant fir plate preparation method

A weather resistance, fir technology, applied in the direction of wood treatment, impregnated wood, wood impregnation, etc., can solve the problem of fir boards prone to discoloration, achieve significant economic value and social benefits, excellent wear resistance, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

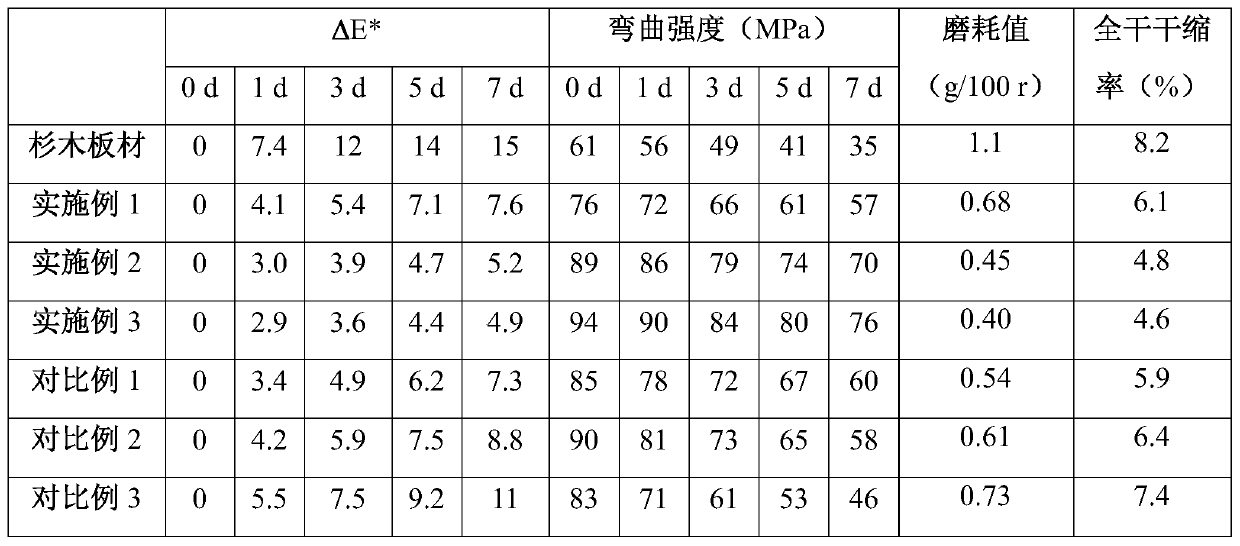

Examples

Embodiment 1

[0022] (1) Add 2g of γ-(2,3-glycidyloxypropoxy)propyltrimethoxysilane modified nano-titanium dioxide to 100mLN, N-dimethylformamide, after ultrasonication for 30min, nitrogen gas is introduced, and the temperature is raised to 40°C, under magnetic stirring, add 0.05g ethylenediamine and 0.5g 2,4-dihydroxybenzophenone in sequence, and continue the magnetic stirring reaction for 8h; N, N-dimethylformamide was fully washed, and vacuum-dried at 40° C. for 24 hours to obtain 2,4-dihydroxybenzophenone-grafted nano-titanium dioxide;

[0023] (2) Add 20g of 2,4-dihydroxybenzophenone grafted nano-titanium dioxide, 10g of antioxidant 1010, 2g of sodium polyacrylate and 1g of polydimethylsiloxane into 1000mL of water, and mechanically stir for 60min at room temperature , ultrasonication for 60 minutes, and finally mechanical stirring for 30 minutes to obtain a mixed dispersion of 2,4-dihydroxybenzophenone grafted nano-titanium dioxide and an antioxidant;

[0024] (3) Put the fir plate s...

Embodiment 2

[0027] (1) Add 5g of γ-(2,3-glycidyloxypropoxy)propyltrimethoxysilane modified nano-titanium dioxide to 250mLN, N-dimethylformamide, after ultrasonication for 45min, feed nitrogen, and heat up to 60°C, under magnetic stirring, sequentially add 0.15g m-phenylenediamine and 0.8g 2,4-dihydroxybenzophenone, continue the magnetic stirring reaction for 6h; 250mL of N,N-dimethylformamide was fully washed, and vacuum-dried at 40°C for 24 hours to obtain 2,4-dihydroxybenzophenone-grafted nano-titanium dioxide;

[0028] (2) 40g2, 4-dihydroxybenzophenone graft nano-titanium dioxide, 15g antioxidant 2246, 5g didecyldimethylammonium chloride and 5g polyoxypropylene oxide ethylene glyceryl ether are added to 1500mL water, in At room temperature, first mechanically stir for 90 minutes, then sonicate for 90 minutes, and finally mechanically stir for 45 minutes to obtain a mixed dispersion of 2,4-dihydroxybenzophenone-grafted nano-titanium dioxide and an antioxidant;

[0029] (3) Place the fi...

Embodiment 3

[0032](1) Add 8g of γ-(2,3-glycidyloxypropoxy)propyltrimethoxysilane modified nano-titanium dioxide to 400mLN, N-dimethylformamide, after ultrasonication for 60min, feed nitrogen, and heat up to 80°C, under magnetic stirring, add 0.4g of 2-methylimidazole and 1g of 2,4-dihydroxybenzophenone in sequence, and continue the magnetic stirring reaction for 4h; N, N-dimethylformamide was fully washed, and vacuum-dried at 40° C. for 24 hours to obtain 2,4-dihydroxybenzophenone-grafted nano-titanium dioxide;

[0033] (2) Add 60g of 2,4-dihydroxybenzophenone grafted nano-titanium dioxide, 20g of antioxidant 264, 8g of sodium polyacrylate and 10g of defoamer DF7010 into 2000mL of water, mechanically stir for 120min at room temperature, and then Ultrasound for 120 minutes, and finally mechanically stirred for 60 minutes to prepare a mixed dispersion of 2,4-dihydroxybenzophenone grafted nano-titanium dioxide and antioxidant;

[0034] (3) Place the fir plate sample in an automatic vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com