Soft transparent polyurethane surface film and preparation method thereof

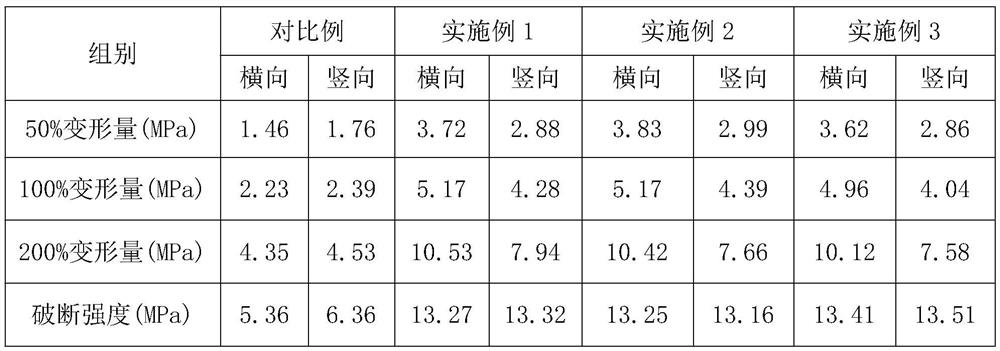

A polyurethane and skin technology, used in textiles and papermaking, can solve the problems of inability to meet high-strength requirements, high production costs, and large fluctuations in product performance, achieving excellent light aging resistance, improved flexibility, and enhanced transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

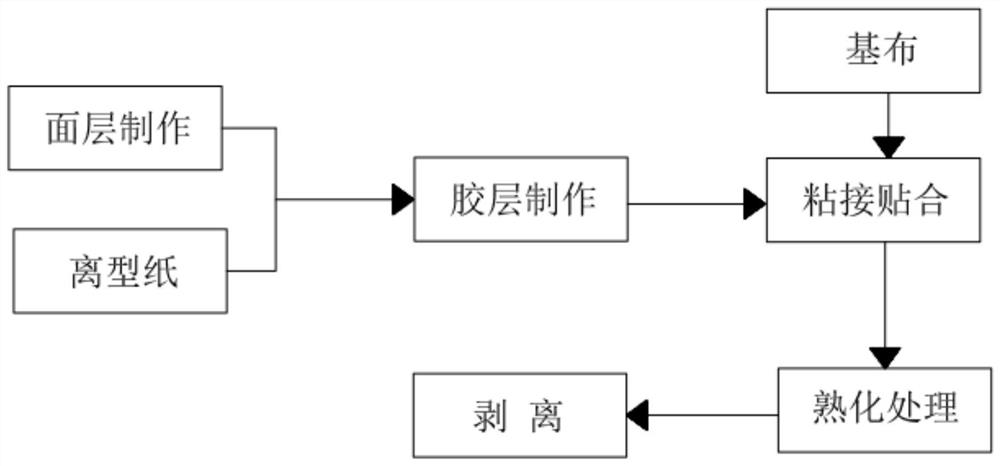

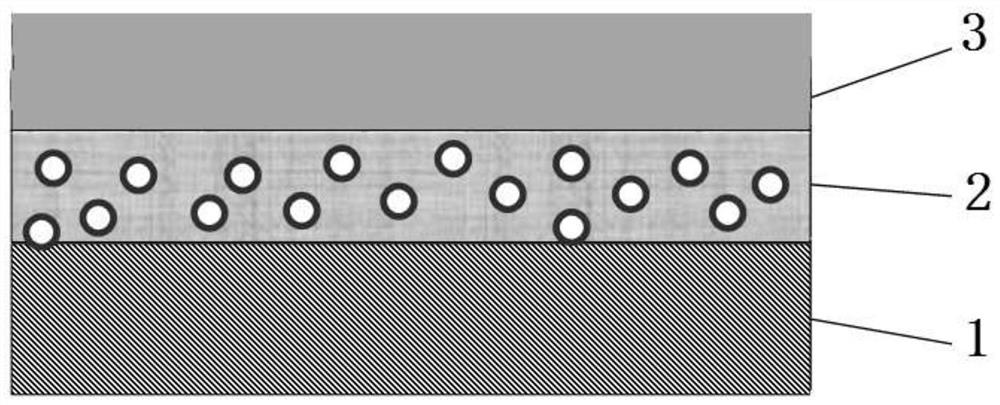

[0036] The invention provides a soft and transparent polyurethane skin film and a preparation method thereof. The transparent polyurethane skin film comprises a base fabric 1, an adhesive layer 2 and a surface layer 3, and an adhesive layer 2 is formed between the base fabric 1 and the surface layer 3 The base fabric 1 and the surface layer 3 are bonded together through the adhesive layer 2, and the mass ratio of the surface layer 3, the adhesive layer 2, and the base fabric 1 is 2:3:3-5.

[0037] The surface layer 3 includes polyurethane, a bridging agent, a thickener, a leveling agent, and a defoamer, and the parts by mass of each material component of the surface layer 3 are: 100 parts of polyurethane, 5 to 10 parts of a bridging agent, 0.5-1 part of leveling agent, 0.3-1 part of defoamer, 20-50 parts of thickener; the bridging agent is a multifunctional carbodiimide polymer, the leveling agent is silicone, and the thickener is Acrylic polymer, defoamer is silicone polymer....

Embodiment 1

[0049] A soft and transparent polyurethane skin film provided in this embodiment and a preparation method thereof,

[0050] Prepare the release paper and base cloth first; the production environment temperature is 0°C-40°C, and the humidity is 20%-80%;

[0051] S1 surface layer production, according to the material components of the surface layer 3, the number of selected parts is 100 parts of polyurethane, 5 parts of carbodiimide polymer for bridging agent, 0.5 part of leveling agent silicone, and defoamer silicone 0.3 parts of polymer, 50 parts of thickener acrylic polymer; the stirring speed of the prepared surface liquid is 720rpm-880rpm, the stirring time is 60min-65min, and the viscosity of the surface liquid is 3000cps; The treatment time is 60min~65min; the negative pressure value of the vacuum degassing treatment is -90kPa; the defoaming treatment is stirred at the same time; the speed of the surface layer coating process is 8m / min, and the usage amount is 70g / m 2 ;T...

Embodiment 2

[0058] Another soft and transparent polyurethane skin film provided in this embodiment and its preparation method differ from Example 1 in that:

[0059] S1 surface layer production, according to the material components of the surface layer 3, the selected parts are 100 parts of polyurethane, 8 parts of carbodiimide polymer as bridging agent, 0.8 parts of leveling agent silicone, and defoaming agent silicone 0.7 parts of polymers, 15 parts of pigments, inorganic pigments, iron oxide and carbon black, 40 parts of thickener acrylic polymers; the stirring speed of the prepared surface layer liquid is 720rpm-880rpm, and the stirring time is 60min-65min. The viscosity is 4000cps; the treatment time of the surface layer liquid defoaming treatment is 60min~65min; the negative pressure value of the negative pressure vacuum defoaming treatment is -90kPa; the defoaming treatment is stirred at the same time; the speed of the surface layer liquid coating process is 6m / min, the dosage is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com