Water-based fluorocarbon coating for communication iron tower and preparation method thereof

A water-based fluorocarbon and water-based fluorocarbon resin technology, which is applied in antifouling/underwater coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of limiting the application range of fluorocarbon coatings and the high price of fluorocarbon resins, and achieve improvement The effect of salt spray resistance, solving the effect of returning to rust when encountering water, and improving rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

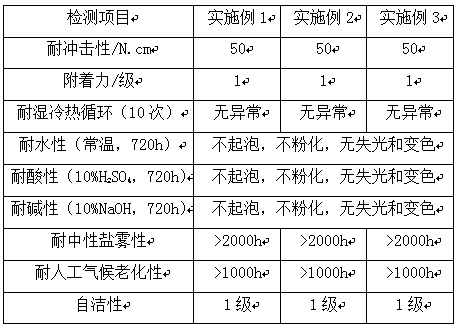

Examples

Embodiment 1

[0025] A water-based fluorocarbon coating for a communication tower, made of the following raw materials in parts by weight:

[0026] 25 parts of water-based fluorocarbon resin, 8 parts of hydrophilic graphene dispersion, 15 parts of hydroxyl acrylic resin, 0.5 parts of alcohol ester twelve, 5 parts of alkyd resin, 5 parts of water-based polyurethane, 0.5 parts of environmentally friendly water-based anti-flash rust agent , 5 parts of superfine wollastonite powder, 5 parts of modified nano-calcium carbonate, and 5 parts of deionized water.

[0027] The hydrophilic graphene dispersion is obtained by adding monochloroacetic acid to graphene oxide for acyl chloride treatment, adding hexadecyltrimethylammonium bromide for amidation treatment, and finally emulsifying.

[0028] The water-based polyurethane is obtained by reacting polyol compounds and polyisocyanates to form prepolymers, and then extending chains with diols or diamines.

[0029] The environment-friendly water-based ...

Embodiment 2

[0037] A water-based fluorocarbon coating for a communication tower, made of the following raw materials in parts by weight:

[0038] 30 parts of water-based fluorocarbon resin, 12 parts of hydrophilic graphene dispersion, 20 parts of hydroxyl acrylic resin, 0.8 parts of alcohol ester twelve, 6 parts of alkyd resin, 7 parts of water-based polyurethane, 1 part of environmentally friendly water-based anti-flash rust agent , 8 parts of superfine wollastonite powder, 8 parts of modified nano-calcium carbonate, and 10 parts of deionized water.

[0039] The hydrophilic graphene dispersion is obtained by adding monochloroacetic acid to graphene oxide for acyl chloride treatment, adding hexadecyltrimethylammonium bromide for amidation treatment, and finally emulsifying.

[0040] The water-based polyurethane is obtained by reacting polyol compounds and polyisocyanates to form prepolymers, and then extending chains with diols or diamines.

[0041] The environment-friendly water-based ant...

Embodiment 3

[0049] A water-based fluorocarbon coating for a communication tower, made of the following raw materials in parts by weight:

[0050] 35 parts of water-based fluorocarbon resin, 16 parts of hydrophilic graphene dispersion, 25 parts of hydroxyl acrylic resin, 1 part of alcohol ester twelve, 8 parts of alkyd resin, 8 parts of water-based polyurethane, 1.5 parts of environmentally friendly water-based anti-flash rust agent , 10 parts of superfine wollastonite powder, 10 parts of modified nano-calcium carbonate, and 15 parts of deionized water.

[0051] The hydrophilic graphene dispersion is obtained by adding monochloroacetic acid to graphene oxide for acyl chloride treatment, adding hexadecyltrimethylammonium bromide for amidation treatment, and finally emulsifying.

[0052] The water-based polyurethane is obtained by reacting polyol compounds and polyisocyanates to form prepolymers, and then extending chains with diols or diamines.

[0053] The environment-friendly water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com