Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Cashew Oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oil extracted from the nut fruit of Anacardium occidentale. Cashew oil is primarily used as a cooking oil.

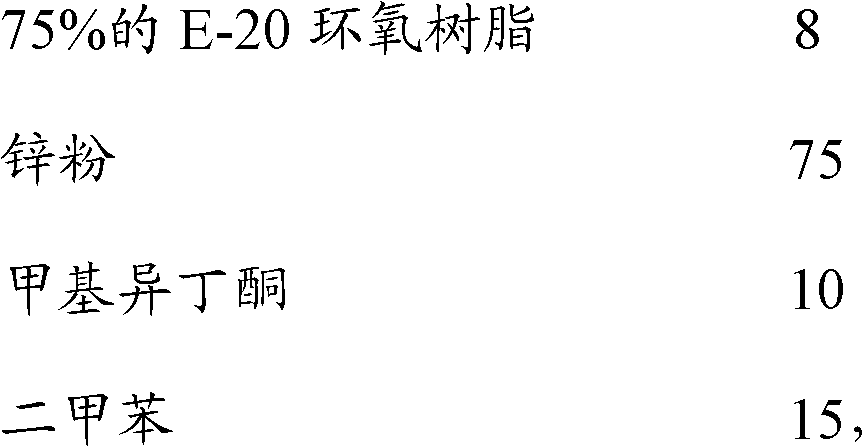

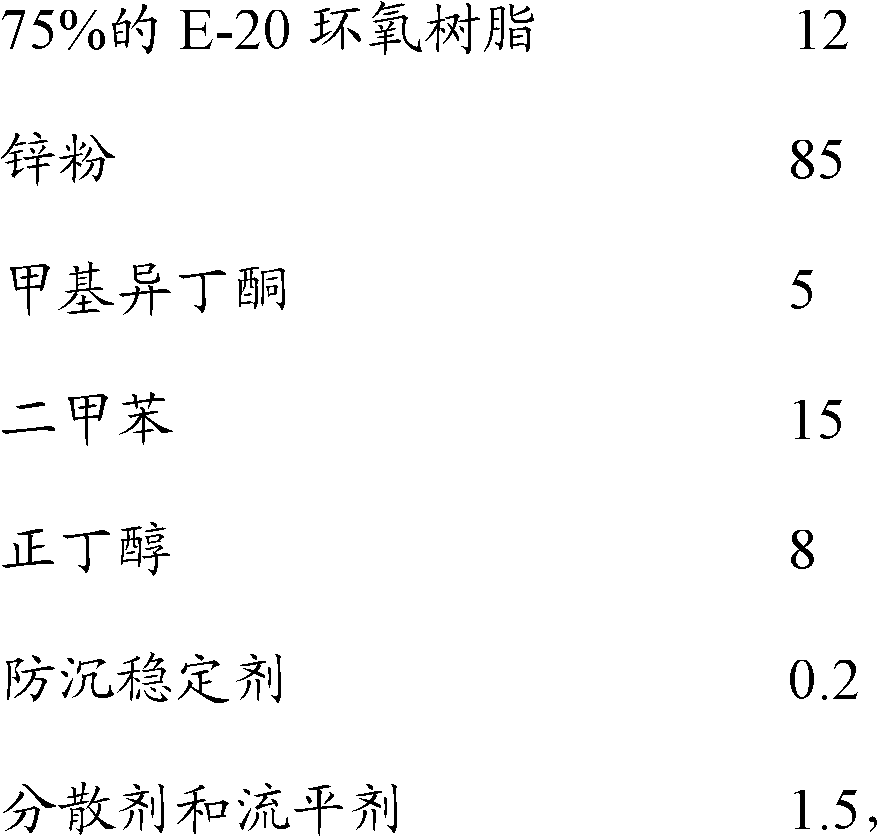

Epoxy zinc-rich paint

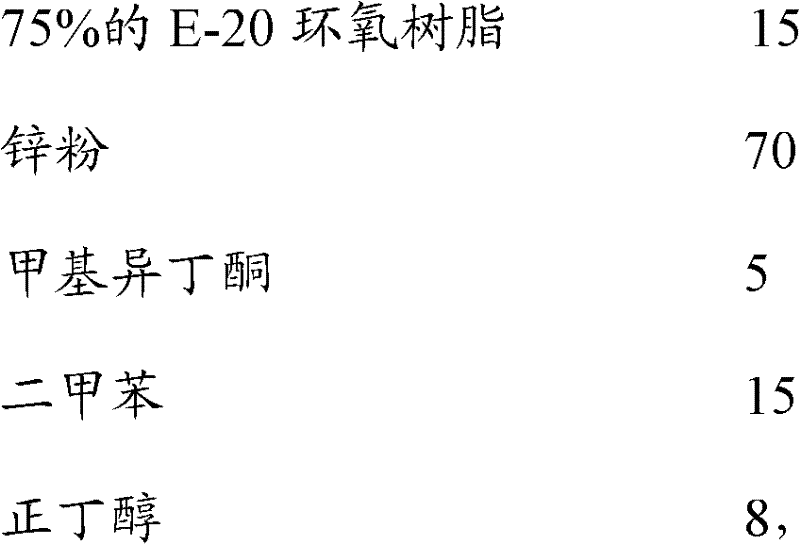

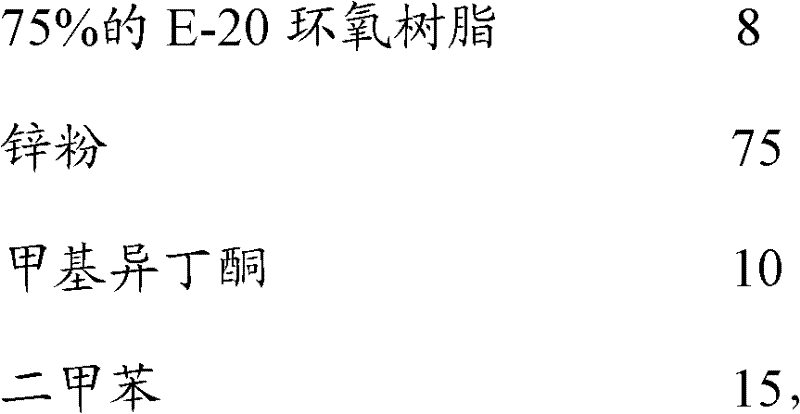

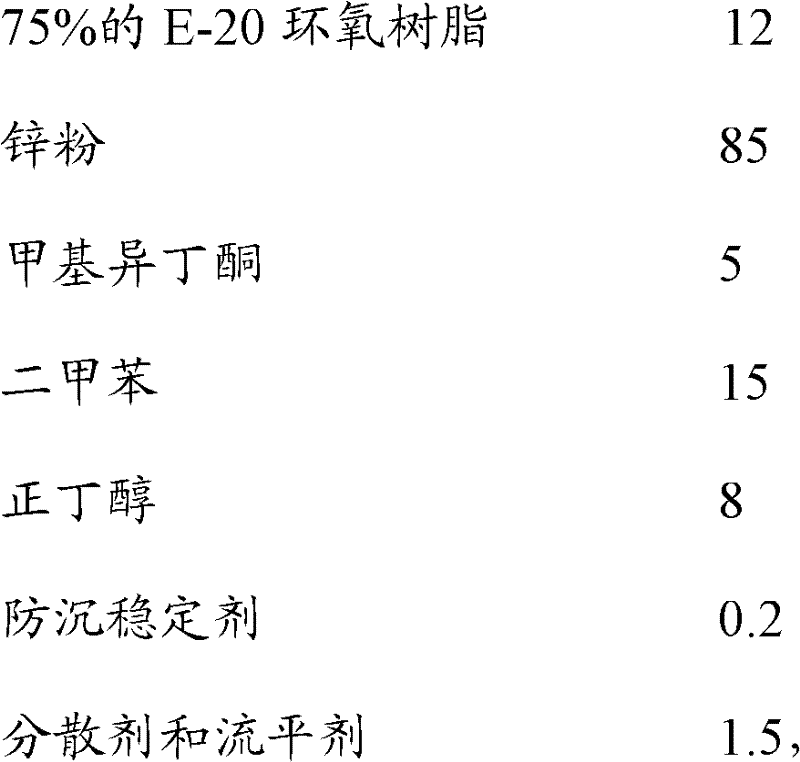

InactiveCN102417784AGood flexibilityStrong impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention relates to epoxy zinc-rich paint. The epoxy zinc-rich paint is characterized in that epoxy resin as a base material, cashew oil polyamide as a curing agent, ultrafine zinc powder as a main antirust pigment, and certain amounts of auxiliary agents and solvents are mixed according to a certain ratio and are prepared into the epoxy zinc-rich paint. The epoxy zinc-rich paint provided by the invention is suitable for being used by a dip-coating method. A coated epoxy zinc-rich paint film has excellent corrosion resistance, chemical resistance and solvent resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Double-component epoxide resin type anti-rust lacquer and preparation thereof

InactiveCN101372600AHarm reductionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

The invention provides double-component epoxy resin anticorrosive paint and a preparation method thereof. Component A comprises the compositions by weight percentage of 15-25 percent of epoxy resin, 10-20 percent of modified petroleum resin, 30-40 percent of pigment, 2-5 percent of fillers, 5-6 percent of promoter and 10-20 percent of solvent. Component B comprises the compositions by weight percentage of 50-60 percent of polyamide curing agent, 10-20 percent of modified cashew oil curing agent and 30-40 percent of solvent. The viscosity of the component A is 3.0-8.0Pa.s. The weight ratio of component A to component B is 2-6 to 1. The paint contains no coal tar pitch. Damages to human bodies and the environment are greatly reduced. One-time thick membrane spraying construction can be implemented. And the paint has good chemicals resistance and corrosion resistance, can be used as paint for ballast water tank and accords with requirements of IMO convention. The process method has the advantages of convenience, simplicity, energy saving performance and low cost. Good membrane forming performance and good storing stability can be shown at room temperature.

Owner:上海华谊精细化工有限公司上海开林造漆厂

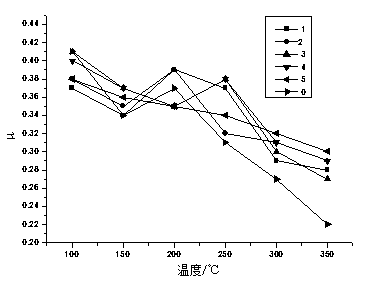

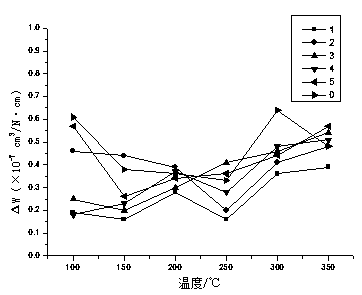

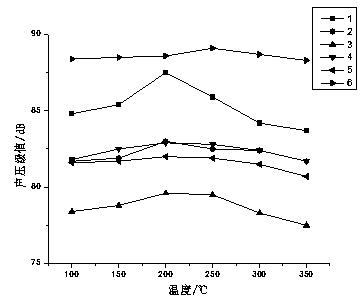

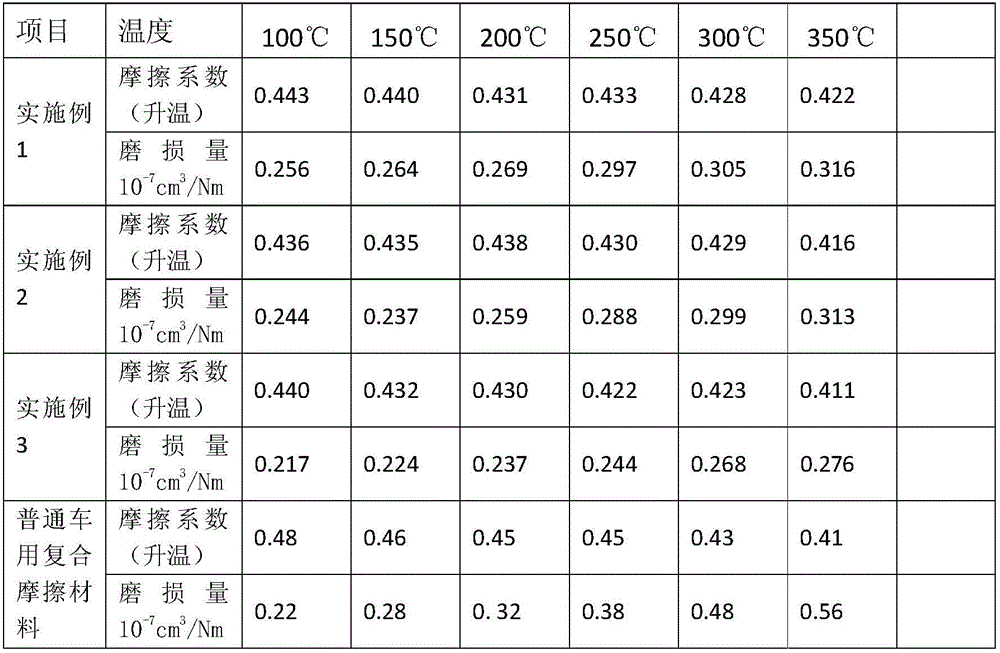

Low-noise heat-fade-resistant resin-base friction material

InactiveCN104109342AStable coefficient of frictionReduce noiseOther chemical processesLow noisePolymer science

The invention discloses a l-noise heat-fade-resistant resin-base friction material which is prepared from the following components in percentage by mass: 10-15% of nano aluminum oxide modified phenol aldehyde resin, 3-6% of aramid fiber pulp, 12-18% of mineral fiber, 5-7% of graphite, 3-5% of antimony trisulfide, 5-7% of coke, 0.5-1.5% of aluminum oxide, 3-5% of ferric oxide, 5-7% of cashew oil friction powder, 3-9% of expanded vermiculite, 2-6% of kieselguhr, 3-9% of nitrile-butadiene rubber and the balance of barium sulfate. The material has the advantages of appropriate and stable friction factor, favorable heat fade resistance, low abrasion ratio, low braking noise, high plastic deformation resistance, high shock resistance and the like, and conforms to the operating requirements.

Owner:YANCHENG INST OF TECH

Method of preparing pnenolic aldehyde foam from modified foamable phenolic resin

The invention relates to a method for preparing phenolic foam with the modified phenolic resin. In the invention, it mixes 100 weight share of cashew oil modified phenolic resin, 1~4 weight share of surfactant, 2~8 weight share of foaming agent, and then it adds 8~15 weight share of curing agent into the mixture and stirs it for 2~15 minutes, and then it cures the mixture at 65 ~ 80deg.C environment for 30 ~ 125 minutes to achieve the phenolic foam.

Owner:安徽复材科技有限公司

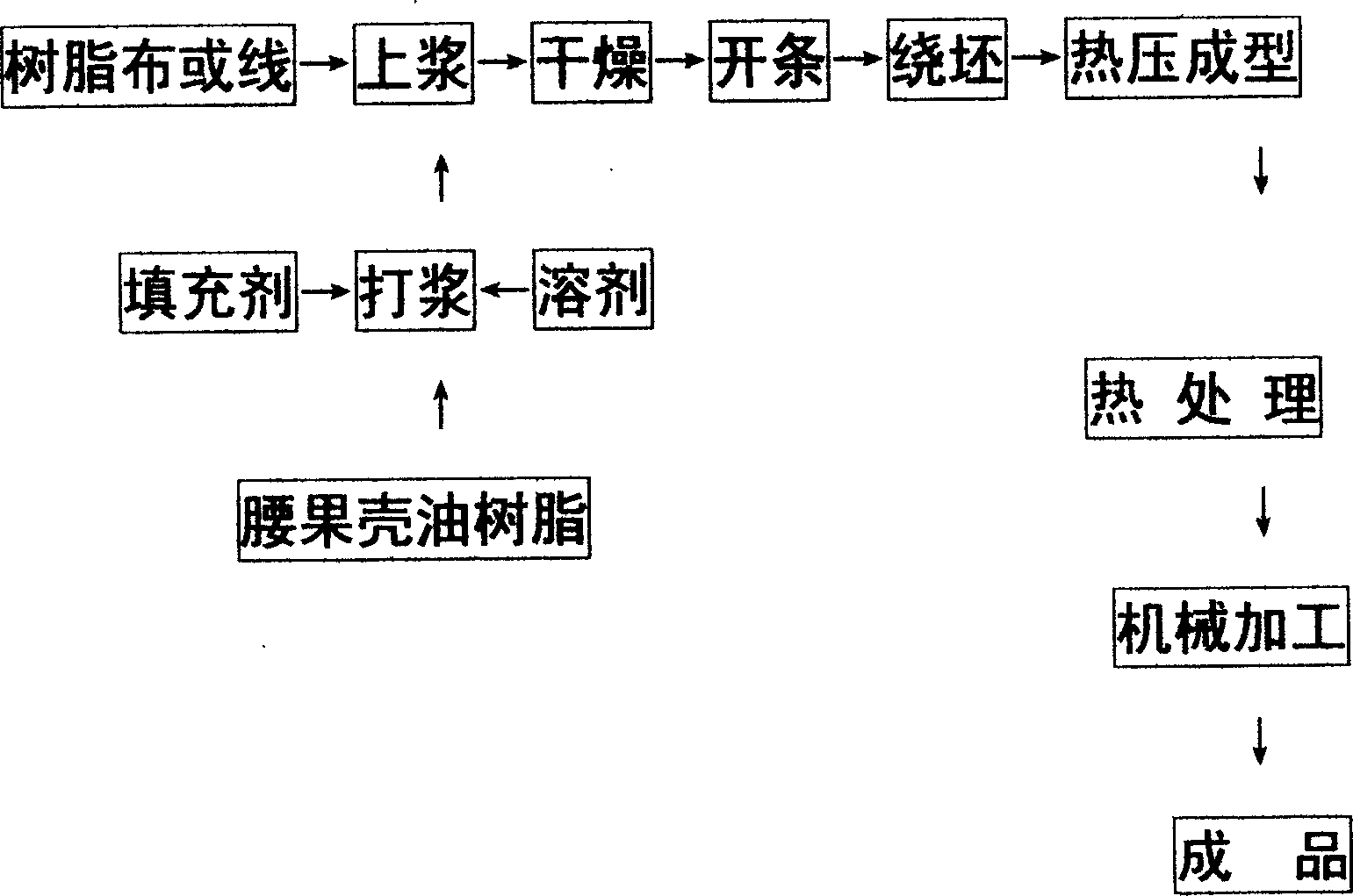

Formula of rubber-free type winding form clutch plate and technique thereof

The invention discloses a formula and its technique of non-rubber wound formed clutch piece as the structure of composite material of cashew oil resin slurry and winding fiber textile, which is characterized by the following: reducing the consumption of petroleum because not synthesizing rubber and solvent petroleum; saving the manufacturing cost of the product greatly; releasing the pressure of petroleum inlet to certain extent; adopting pure cashew oil as raw material without phenol; improving the elasticity, flexibility and mechanic strength; making each property reach the technical demand of GB5764-1998 'automobile clutch piece' national standard regulation and industrial mechanic amianthine friction disk GB11834-2000.

Owner:李刚

Automotive iron-based powder metallurgy composite frictional material and manufacturing method thereof

The invention discloses an automotive iron-based powder metallurgy composite frictional material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that an iron-based powder metallurgy friction material is obtained; secondly, the iron-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the iron-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is preserved at the temperature of 150-180 DEG C, cooled to the room temperature and then discharged from the furnace. The automotive iron-based powder metallurgy composite frictional material remains the stable friction coefficient and good abrasive resistance of the conventional powder metallurgy friction material, service life of the friction material is prolonged and its high-temperature stability is also improved.

Owner:SOUTH CHINA UNIV OF TECH

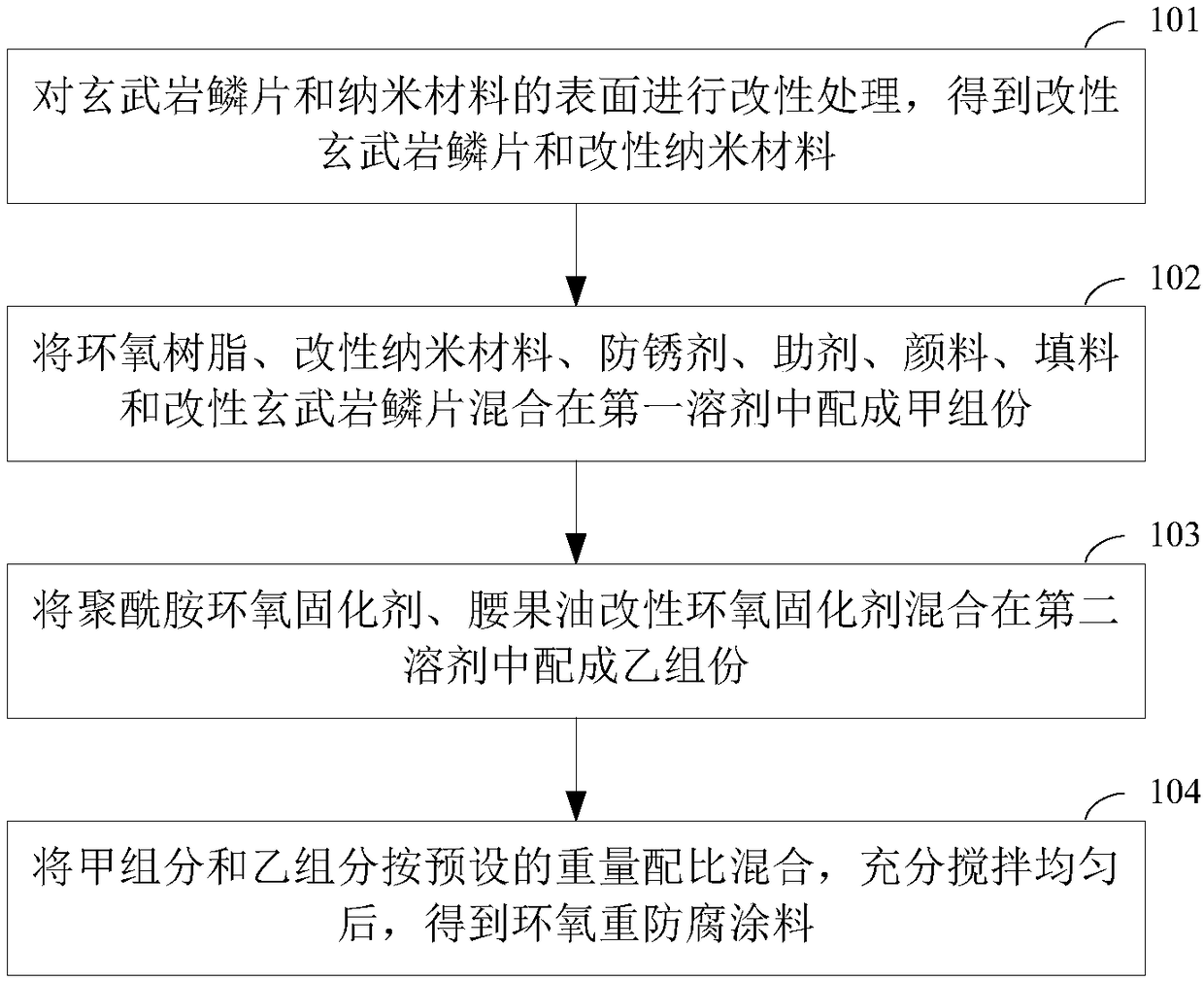

Preparation method of epoxy heavy duty anticorrosion coating

InactiveCN108129949AImprove penetration resistanceImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides a preparation method of an epoxy heavy duty anticorrosion coating. The preparation method comprises following steps: basalt scale and a nanometer material are subjected to surface modification treatment so as to obtain modified basalt scale and a modified nanometer material; epoxy resin, the modified nanometer material, an antirust agent, an auxiliary agent, a pigment, a filling material, and modified basalt scale are mixed in a first solvent so as to obtain a component A; a polyamide epoxy hardener, and a cashew oil modified epoxy hardener are mixed in a second solventso as to obtain a component B; the component A and the component B are mixed at a preset weight ratio, full stirring is carried out so as to obtain the epoxy heavy duty anticorrosion coating. The preparation method is capable of improving the compactibility, the corrosion resistance, and the durability of the epoxy heavy duty anticorrosion coating.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Hexa-potassium tianate crystal whisker reinforced, non-zillerite, non- metal friction material for industry

InactiveCN101153083AImprove mechanical propertiesGood physical propertiesManufacturing technologyPotassium

The present invention provides a friction material containing no asbestos or metal for industrial use, and in particular relates to a manufacturing technology for industrial friction materials such as port machinery, crane machinery, and wind-power generator groups and so on. The potassium titanate is used as the main raw material; the glass fiber and cellulose fiber are used as the assistant materials; the cashew oil modified resin and nitrile modified resin are used together as bonding agent; the magnesium oxide, graphite and friction powder are used as friction-reducing agent; the alumina oxide and brown corundum are used as friction-increasing agent; the barium sulfate and barite are used as additive; the raw material are mixed according to a formula proportion and then blended; the friction component of best performances can be made after molding and heat treatment; the friction component is in particular suitable for port machinery, crane machinery, and wind-power generator groups and so on.

Owner:SHANXI JIANGHUAI HEAVY IND

Foaming phenolic resin and phenolic foam with foaming phenolic resin

The invention discloses a foaming phenolic resin and a phenolic foam with the foaming phenolic resin, wherein the constituents of the foaming phenolic resin are as follows (in parts by weight and based on 100 parts of phenol ): 100 parts of phenol, 65-105 parts of solid formaldehyde, 5-25 parts of cashew oil, 0.5-5 parts of a catalyst, 7-25 parts of carbamide, 6-30 parts of an inorganic powder, and 1-6 parts of other modifiers. The phenolic foam with the foaming phenolic resin comprises the foaming phenolic resin, foaming agent, stabilizing agent and acid curing agent as mentioned in the claim 1. The phenolic foam is made from phenolic resin, so that the hydrophobicity of the phenolic resin is increased while the rigidity is improved.

Owner:JIANGSU QIANXIANG NEW MATERIAL TECH CO LTD

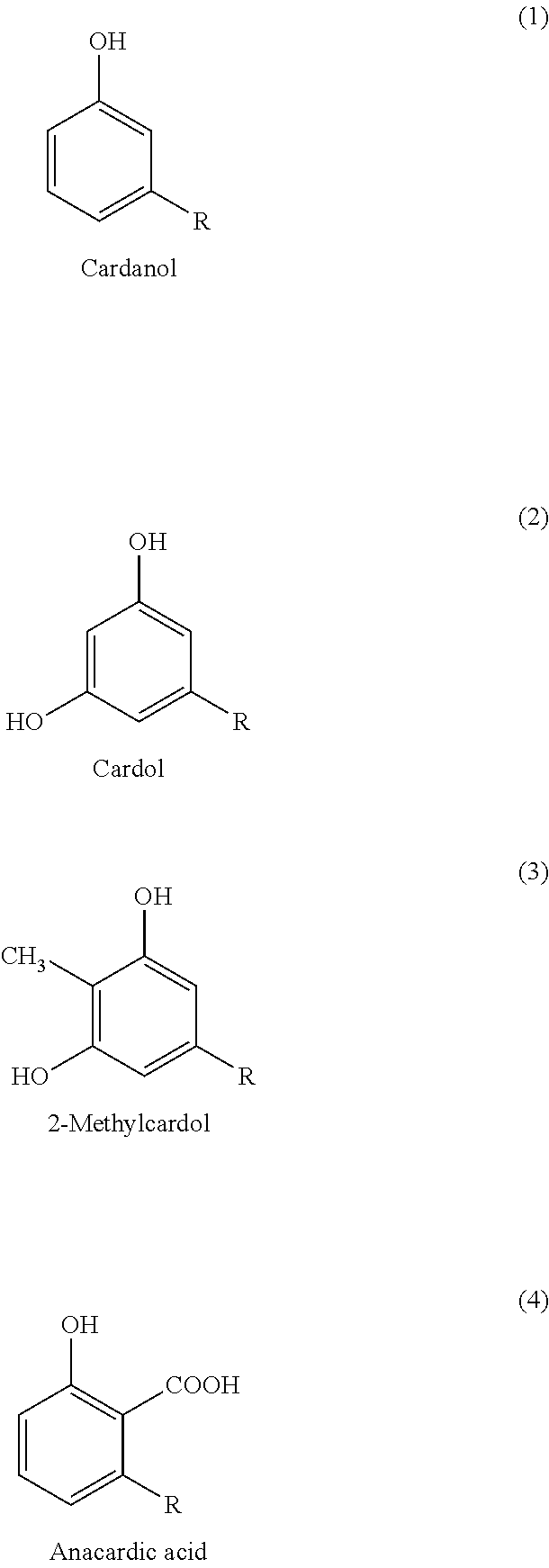

Solid-state cardanol and preparation thereof

InactiveCN101412661AHigh yieldDifficult to enterOrganic chemistryOrganic compound preparationPtru catalystSide chain

The invention provides solid cardanol. The component of the solid cardanol is cardanol of which the side chain is saturated. The preparation method for the solid cardanol comprises the following steps: putting the cardanol or cashew nut oil into an autoclave, adding catalyst into the autoclave, firstly introducing a protective gas to exhaust air in the autoclave, then introducing hydrogen, and stirring for reaction for 3 to 6 hours at a temperature of between 100 and 200 DEG C and atmospheric pressure of between 1 and 5 MPa; and after the reaction is finished, collecting the product, then decompressing and distilling the product, and cooling the distillate to obtain the solid cardanol. The solid cardanol has the following advantages that the side chain of the solid cardanol is saturated, so the side chain does not generate self-gathering during fine purification at high temperature or high temperature treatment process for synthesizing other products; the solid cardanol is not easily oxidized nor lost by self-gathering during storage and transportation; and the solid cardanol does not generate self-gathering during fine purification of decompression and distillation, so the yield of the solid cardanol is improved.

Owner:ZHENGZHOU UNIV

Special anti-corrosion rust-proof paint with rust removal and preparation method thereof

InactiveCN101519565AGood resistance to nitroStrong resistance to salt waterAnti-corrosive paintsEpoxy resin coatingsOxygenSolvent

The invention discloses a special anti-corrosion rust-proof paint with rust removal. The paint comprises the components by weight: 21 to 29 percent of epoxy complex acid-propylene modified resin, 13 to 19 percent of epoxy saturated resin, 38.5 to 44.5 percent of mixed rust-proof pigment, 0.3 percent of addition agent, 16 percent of mixed solvent, 0.5 percent of leveling oil resistance agent and 0.7 percent of anti-settling agent. The paint is prepared from the epoxy modified resin with complex acid, a cashew nut oil curing agent, red iron oxide, zinc oxide, a solvent, the addition agent, and the like. The paint prepared in proportion is sprayed or brushed on a rusty iron piece. The paint with excellent penetrability permeates into the bottom of an oxide layer. A generated paint film has the advantages of high density, good hardness and strong wearing resistance and impact force resistance. Therefore, the special anti-corrosion rust-proof paint with rust removal completely eliminates the secondary contact of new iron with the moisture and oxygen of the outside world, and eliminates the possibility of secondary rust fundamentally.

Owner:YIXING JUREN PAINT

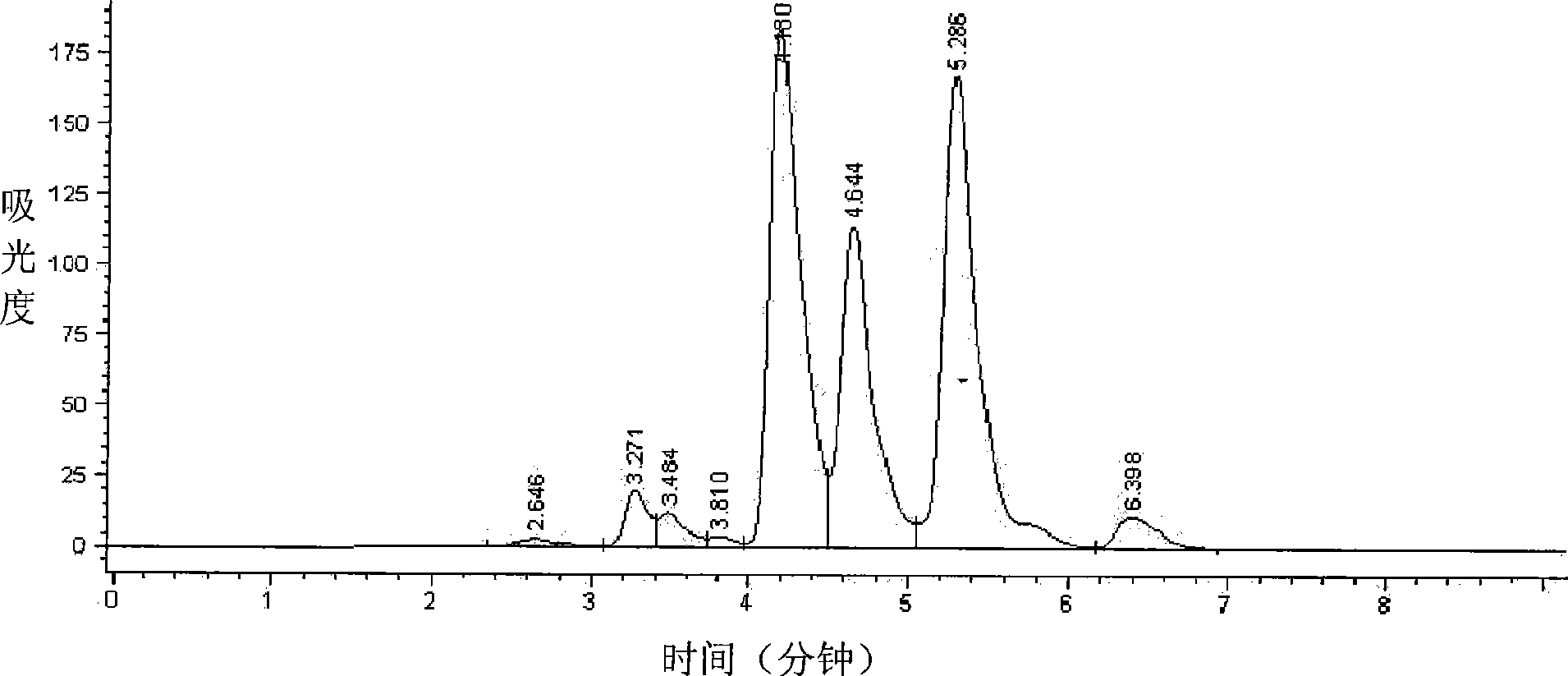

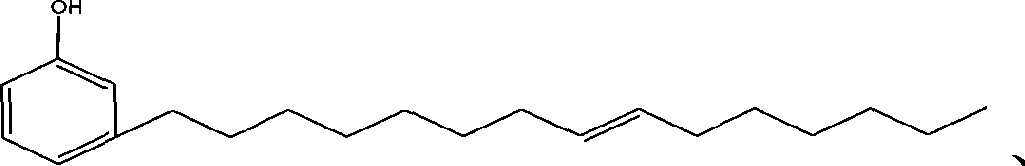

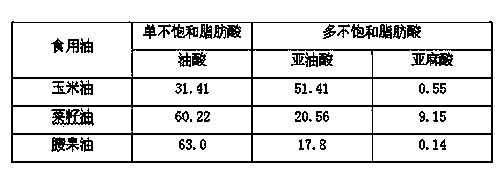

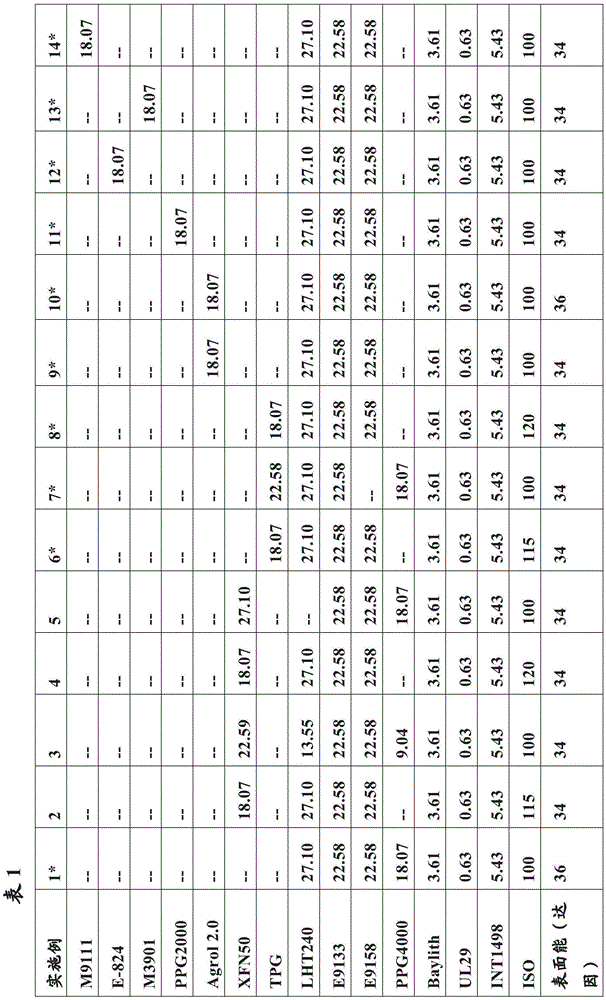

Edible oil and blending method thereof

ActiveCN103404609ASolve single hungerTackle fatty acidsEdible oils/fats production/working-upAdditive ingredientRapeseed

The invention belongs to the field of edible oil and particularly relates to edible oil and a blending method thereof. The edible oil provided by the invention comprises following raw materials by weight percentage: 30%-80% of corn oil, 5%-17% of cashew oil and 15%-53% of rapeseed oil. According to the edible soil provided by the invention, the problem that the proportion of monounsaturated fatty acid to polyunsaturated fatty acid in existing edible oil is not proper is solved; the blending method is simple; the nutritional ingredients of the daily edible oil is comprehensive.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

Composite rubber reinforcing system, styrene butadiene rubber using reinforcing system and preparation method of styrene butadiene rubber

The invention relates to the technical field of rubber, particularly to a composite rubber reinforcing system, styrene butadiene rubber using the reinforcing system and a preparation method of the styrene butadiene rubber. The styrene butadiene rubber comprises raw materials in parts by weight as follows: 100 parts of styrene butadiene rubber, 40 parts of carbon black, 2-10 parts of chitin, 10 parts of cashew nut oil, 3 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of an accelerant, 1-3 parts of an anti-aging agent and 1-3 parts of sulfur. According to the composite reinforcing system, the chitin and the carbon black are combined together through chemical bonds and hydrogen bonds by the aid of reactions of surface groups of the chitin and the carbon black, a special reinforcing structure with a chitin network used as a base and the carbon black, attached to the chitin network, used as reinforcing points is formed, the rubber performance is improved, meanwhile, the carbon black is not required to be modified before usage, the environmental protection property of a product is improved, and the usage cost is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

Polyurethane pultrusion formulations for the production of articles with improved coating adhesion and articles produced therefrom

Polyurethane composites to which paint will adhere without the need for an aggressive pretreatment are produced by a pultrusion process using a polyurethane-forming system that includes a polyisocyanate component containing at least one polyisocyanate and an isocyanate-reactive component containing at least one cashew oil-based polyether polyol.

Owner:COVESTRO LLC

Polyurethane pultrusion formulations for the production of articles with improved coating adhesion and articles produced therefrom

Polyurethane composites to which paint will adhere without the need for an aggressive pretreatment are produced by a pultrusion process using a polyurethane-forming system that includes a polyisocyanate component containing at least one polyisocyanate and an isocyanate-reactive component containing at least one cashew oil-based polyether polyol.

Owner:COVESTRO LLC

Preparation method of special carbon-based slow release fertilizer for wheat

ActiveCN104355887AGood sustained release effectAchieve the effect of increasing productionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium bicarbonateMicrosphere

The invention relates to a preparation method of a special carbon-based slow release fertilizer for wheat, and belongs to the technical field of fertilizers. The preparation method comprises the following steps: uniformly mixing polyethylene wax with organic acid, starch, sodium bicarbonate and an alcohols solvent; then placing a mixture into a tube furnace, increasing temperature for carbonization at an inert gas atmosphere, cooling, washing solid residues by using a sodium hydroxide solution, drying, and then grinding to obtain a carbon microsphere; uniformly mixing the carbon microsphere with urea, ammonium phosphate, ammonium sulfate and water, increasing the temperature, cooling, filtering out a solid, and drying to obtain a fertilizer base body; mixing cashew nut oil and hexamethylene tetramine in a reaction kettle, uniformly stirring, then heating, keeping the temperature and cooling, then adding polyhydric alcohol and polyisocyanate, uniformly stirring and mixing, and cooling to room temperature to obtain a coating agent; and placing the fertilizer base body into a fluidized bed coating machine, spraying the coating agent on the rolling fertilizer base body, and drying to obtain a coated fertilizer.

Owner:HUAIAN DAHUA BIO TECH

Preparation method of cashew nut oil modified waterborne acrylic acid modified alkyd resin dispersion

The preparation method of the cashew nut oil modified waterborne acrylic acid modified alkyd resin dispersion comprises the following steps: (1) synthesizing cashew nut oil phenolic resin; (2) synthesizing a cashew nut oil modified alkyd resin prepolymer; and (3) synthesizing the acrylic acid modified alkyd resin. The method is simple to operate, the common drier in the field is added to catalyzeair drying, and the method has the characteristics of low drier consumption and high drying speed; the cashew nut oil modified phenolic resin is adopted to enhance the water resistance and salt sprayresistance of the resin, and the water resistance and salt spray resistance are superior to those of common air-drying water-based alkyd resin.

Owner:湘江涂料科技有限公司

Wear brake pad for heavy trucks

The invention discloses a wear brake pad for heavy trucks. By a conventional compressing process, the wear brake pad is made of the following materials, by weight, 10-20% of thermosetting resin, 5-12% of graphite, 5-7% of zirconium silicate, 8-11% of hydroxyapatite, 10-20% of epoxy resin, 3-6% of friction improving agent, 7-14% of coke dust, 6-12% of calcium silicate ceramic powder, 5-12% of cashew-nut oil frictional powder, 3-5% of calcium oxide, 5-7% of molybdenum disulfide and the balance being nitrile rubber. Abrasion of the wear brake is reduced, and the wear brake pad works stably without generation of noises, has good heat conductivity and stable braking performance, and is safe and reliable. According to the special characteristic of wear resistance of the ceramic material, the wear rate of the wear brake pad is reduced effectively on the basis of stabilizing friction coefficient of friction materials, and thus the service life of the friction materials is prolonged.

Owner:QINGDAO GUANGLIANDA PRECISION MACHINERY

Nano-modified epoxy heavy-duty anti-corrosion coating

InactiveCN111004557AClose contactImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolyamide

The invention provides a nano-modified epoxy heavy-duty anti-corrosion coating which comprises a component A and a component B at a mass ratio of (8-10): 1, wherein the component A comprises the following raw materials in parts by mass: 35-50 parts of epoxy resin, 2-10 parts of a modified nano material, 5-20 parts of modified scale aggregate, 6-10 parts of a mixed solvent, 5-15 parts of a silane coupling agent, 2-8 parts of an antirust agent, 1-5 parts of an auxiliary agent, 5-10 parts of a filler and 3-12 parts of a pigment; and the component B comprises the following raw materials in parts by mass: 15-30 parts of a polyamide epoxy curing agent, 10-15 parts of a cashew nut oil modified epoxy curing agent and 35-50 parts of a mixed solvent. By applying the above formula, the compactness ofthe coating can be effectively improved, the corrosion resistance of the coating is enhanced, and the durability of the coating is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Fast curable environment friendly epoxy paint for drilling water tanks and making method thereof

InactiveCN104449245AFast curingEasy constructionAnti-corrosive paintsEpoxy resin coatingsFatty acidAdduct

Belonging to the technical field of paint and making methods, the invention relates to a fast curable environment friendly epoxy paint for drilling water tanks and a making method thereof. The method includes: in a stainless steel charging basket, adding bisphenol A low viscosity type epoxy resin, bisphenol F type epoxy resin, bisphenol A and bisphenol F mixed type epoxy resin and a cashew oil modified monoglycidyl ether epoxy active diluent, mixing the materials, under stirring, adding an anionic compound containing fatty acid and rosin acid, a hydrophobic particle containing organosilicon polymer and a modified urea solution, controlling the temperature at 25+ / -2DEG C, performing high speed stirring, and under stirring, adding zinc chrome, aluminum triphosphate, superfine silica powder and talcum powder, conducting high speed stirring for 0.25h, then carrying out grinding for 0.5-1h by a sand mill so as to obtain an A solution in the paint; and in another stainless steel charging basket, adding a phenolic aldehyde amine curing agent, linear aliphatic amine and an adduct epoxy curing agent, conducting high-speed stirring to mix the materials evenly to obtain a B solution in the paint.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

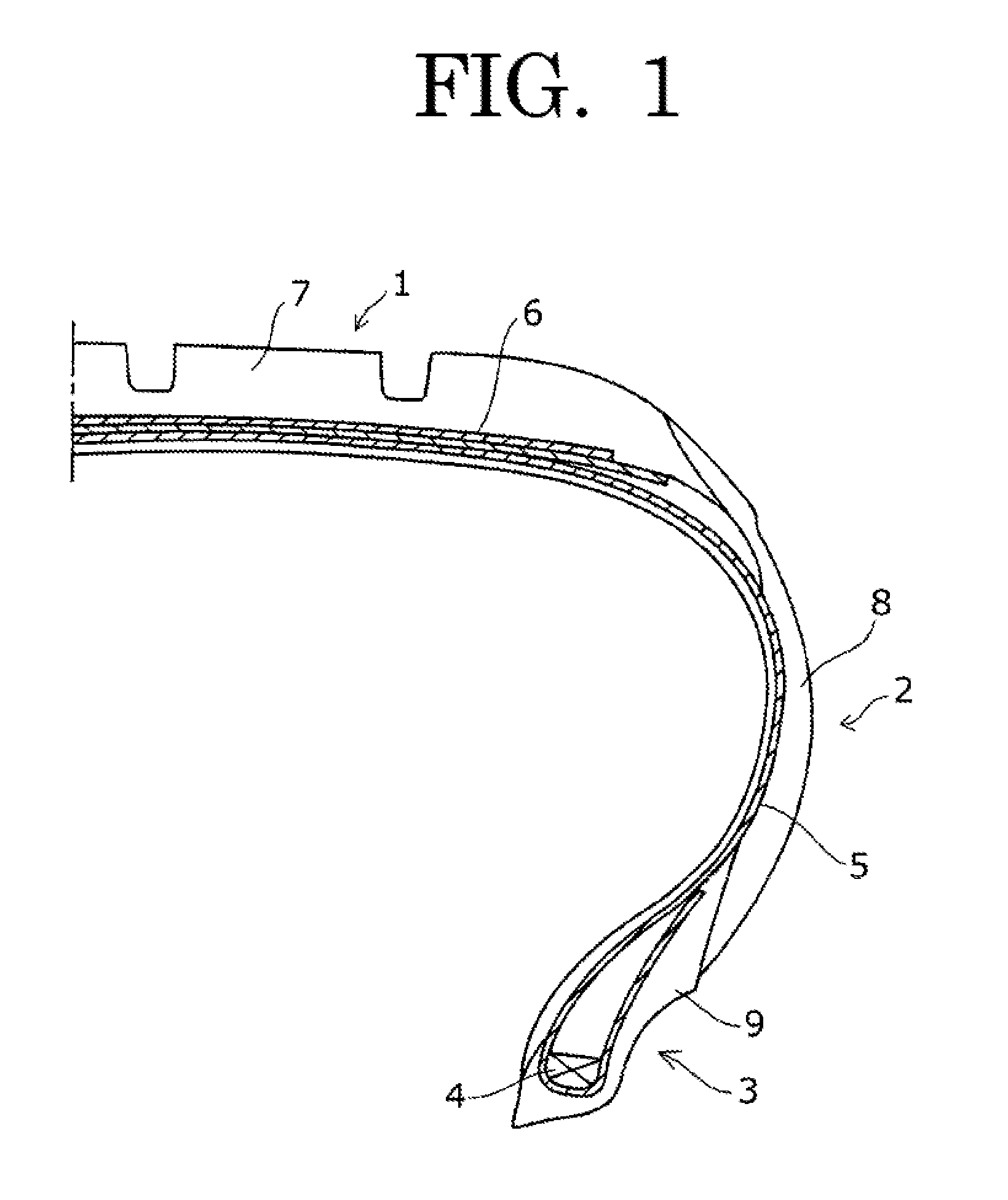

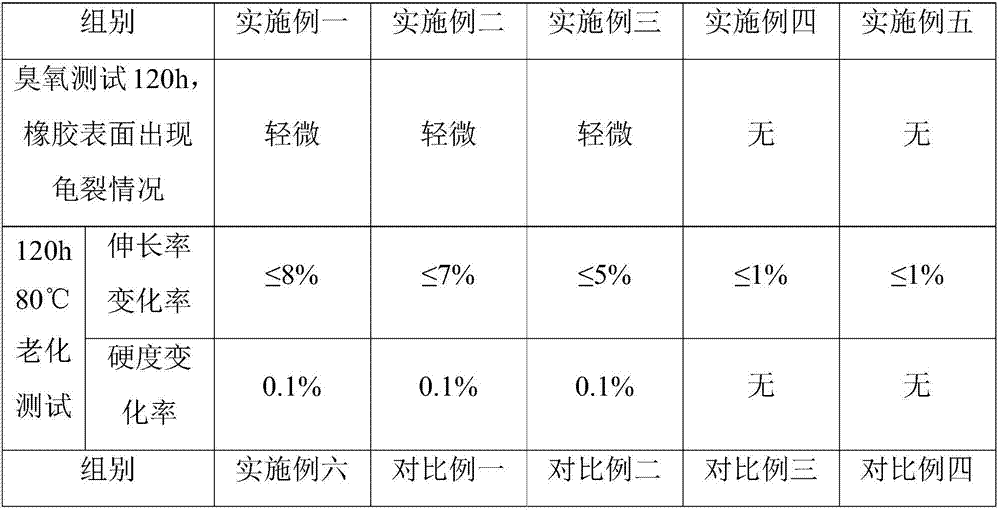

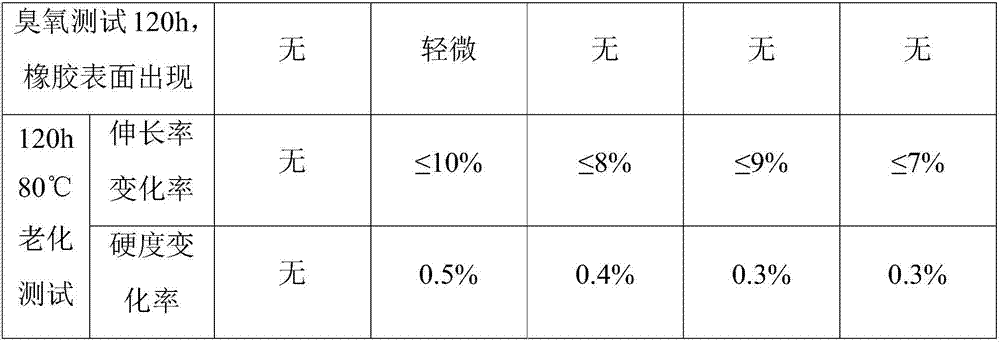

Rubber composition and pneumatic tire

ActiveUS20170022352A1Suppress whiteningGive black and lusterSpecial tyresTyre beadsWaxPolymer science

A rubber composition comprises a diene rubber, a hydrocarbon type wax, cashew oil and a processing aid. The rubber composition can suppress whitening of a rubber surface and additionally can give black and luster to the rubber surface. The processing aid comprises at least one selected from the group consisting of a fatty acid metal salt, a fatty acid amide, a fatty acid ester and a fatty acid ester amide, wherein the proportion of constituent fatty acids having from 18 to 20 carbon atoms is from 20 to 60 mass %. A pneumatic tire has a rubber part (for example, a tread rubber, a side wall rubber or a rim strip) comprising the rubber composition.

Owner:TOYO TIRE & RUBBER CO LTD

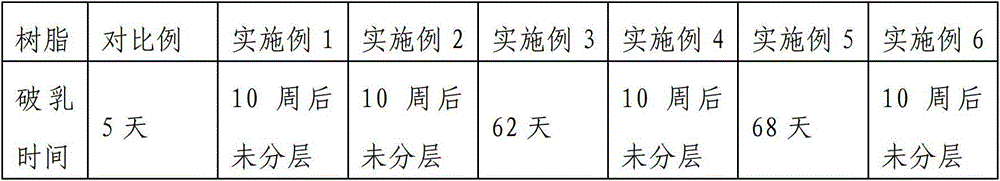

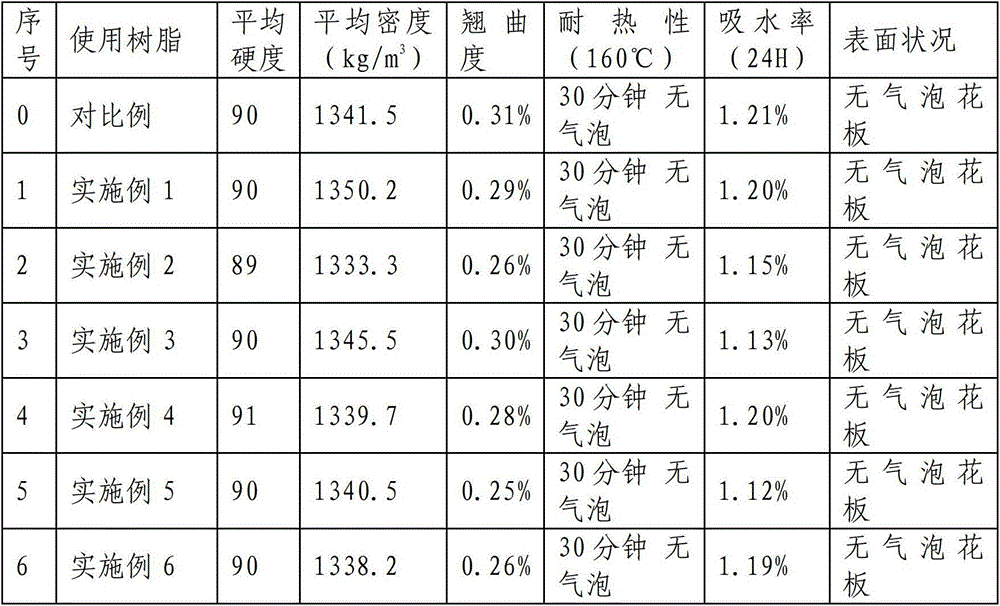

Water soluble resin for impregnated paper backing plate and preparation method thereof

ActiveCN103146328AImprove toughnessExtended shelf lifeMonocarboxylic acid ester polymer adhesivesNon-fibrous pulp additionEmulsionPerformance index

The invention relates to a preparation method of a water soluble resin used for an impregnated paper backing plate. The method comprises the steps of: 1) mixing a hydroxyl-containing aromatic compound with cashew nut oil or tung oil; 2) adding a catalyst into the mixture, raising the temperature to 100DEG C-150DEG C, conducting phenolation for 1-3h, lowering the temperature to 60-90DEG C; and 3) adding aldehyde into the cooled mixture in step 2), then adding an emulsion, and then further letting them to undergo an isothermal reaction until the viscosity of a generated resin solution reaches 50-150cp, and lowering the temperature to less than 40DEG C, thus obtaining the water soluble resin. The water soluble resin for an impregnated paper backing plate provided in the invention has a stable emulsion and a long shelf life, and its performance indexes are all in line with the current standards.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Resin-based powder metallurgy potassium titanate fiber friction material used for vehicle and production method thereof

InactiveCN106084644AGood surface flexibilityReduce hardnessFriction liningActuatorsResin-Based CompositeNitrogen gas

The invention discloses a method for producing a resin-based powder metallurgy potassium titanate fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture into a die, compacting the mixture to several elongated rods, compacting the elongated rods, separating the elongated rods, putting the elongated rods in a sintering furnace, under condition of introducing nitrogen or hydrogen, heating the materials to obtain a Fe-based powder metallurgy friction material; shearing the Fe-based powder metallurgy friction material, crushing the Fe-based powder metallurgy friction material, and sieving; by metering with mass percentage, uniformly mixing 10-20% of cashew oil-modified phenolic resin, 30-50% of the Fe-based powder metallurgy friction material, 10-30% of potassium titanate fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding on the materials, cooling the materials, and discharging. The friction material combines the characteristics of high temperature resistance and low abrasion of the Fe-based powder metallurgy friction material as well as good toughness and low hardness of the potassium titanate resin-based composite friction material, and the obtained material has the characteristics of high temperature resistance, low abrasion, good toughness, and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

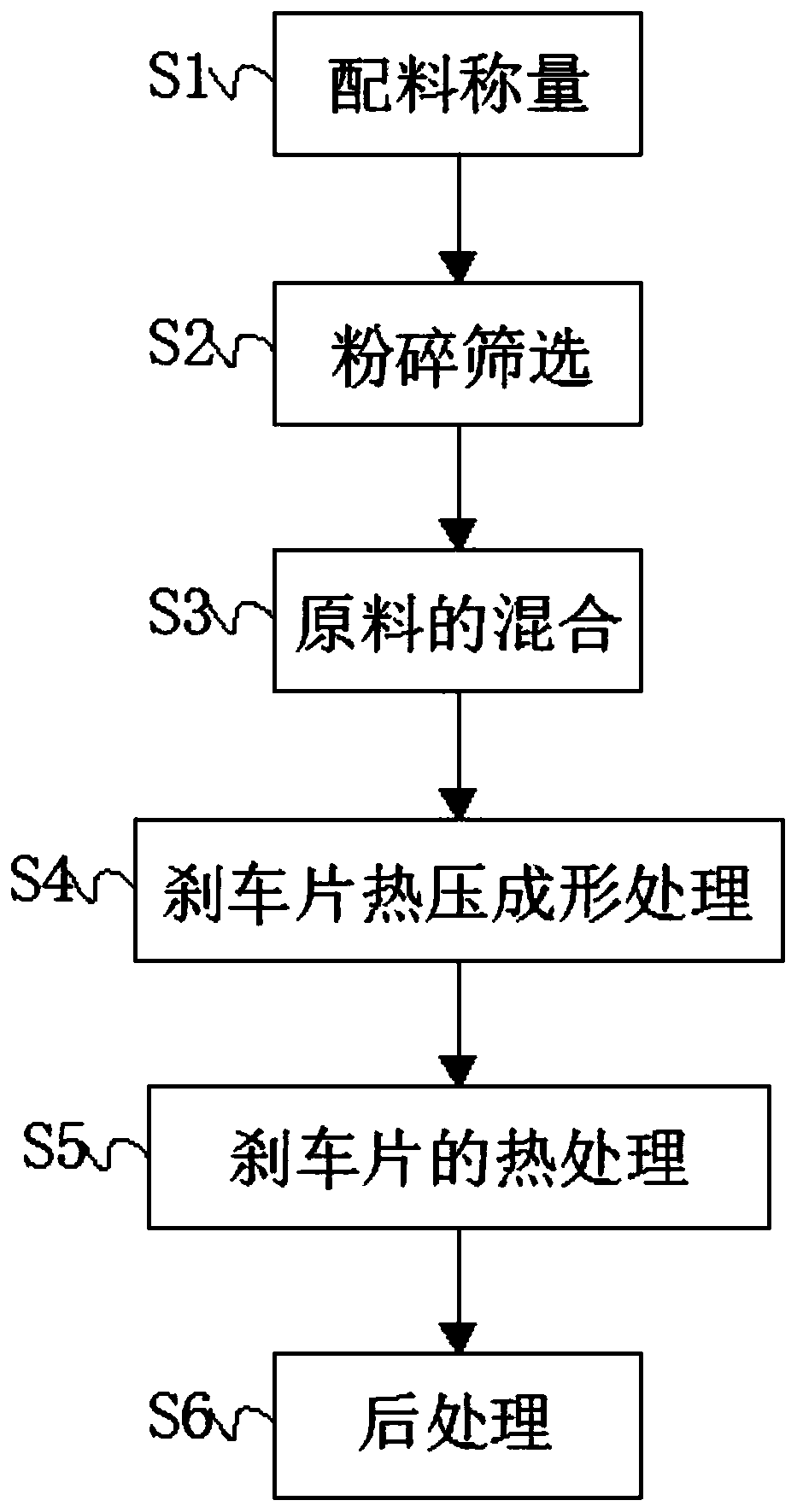

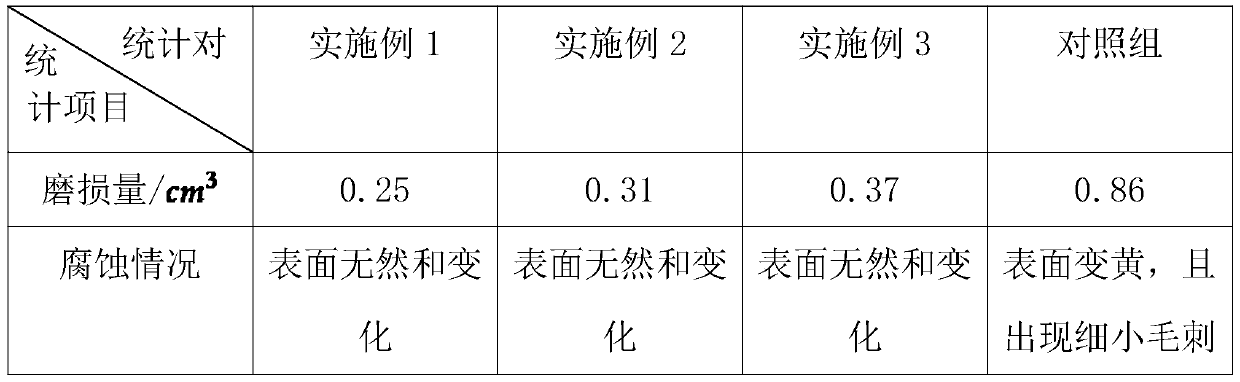

High-performance brake pad and machining method thereof

InactiveCN111019296AImprove wear resistanceAccelerated corrosionFriction liningBuilding insulationsEpoxyPolyamide

The invention discloses a high-performance brake pad and a machining method thereof. The brake pad is prepared from the following raw materials in parts by weight: cashew nut oil tri-epoxy resin, silicon resin, polyamide resin, steel fibers, a friction performance regulator, modified wollastonite, modified sepiolite, copper powder, barium sulfate, calcined petroleum coke, siboner, a wear resistance reinforcing filler, high-manganese alloy fibers, a corrosion resistance reinforcing filler and a lubricant. The invention belongs to the technical field of brake pad production. According to the machining method, materials in the brake pad can be modified, so that the wear resistance and the corrosion resistance of the brake pad are improved; the purpose that the mechanical property of the brakepad is improved by 2-3 times on the original basis by adding the modifying fillers is well achieved, the brake pad can be used for a long time under some working conditions with severe environments,the use requirements of people on the performance of the brake pad are well met, and the application range of the brake pad is well widened.

Owner:湖北省豪宇盛世汽车零部件有限公司

Polyurethane pultrusion formulations for the production of articles with improved coating adhesion and articles produced therefrom

Polyurethane composites to which paint will adhere without the need for an aggressive pretreatment are produced by a pultrusion process using a polyurethane-forming system that includes a polyisocyanate component containing at least one polyisocyanate and an isocyanate-reactive component containing at least one cashew oil-based polyether polyol.

Owner:COVESTRO LLC

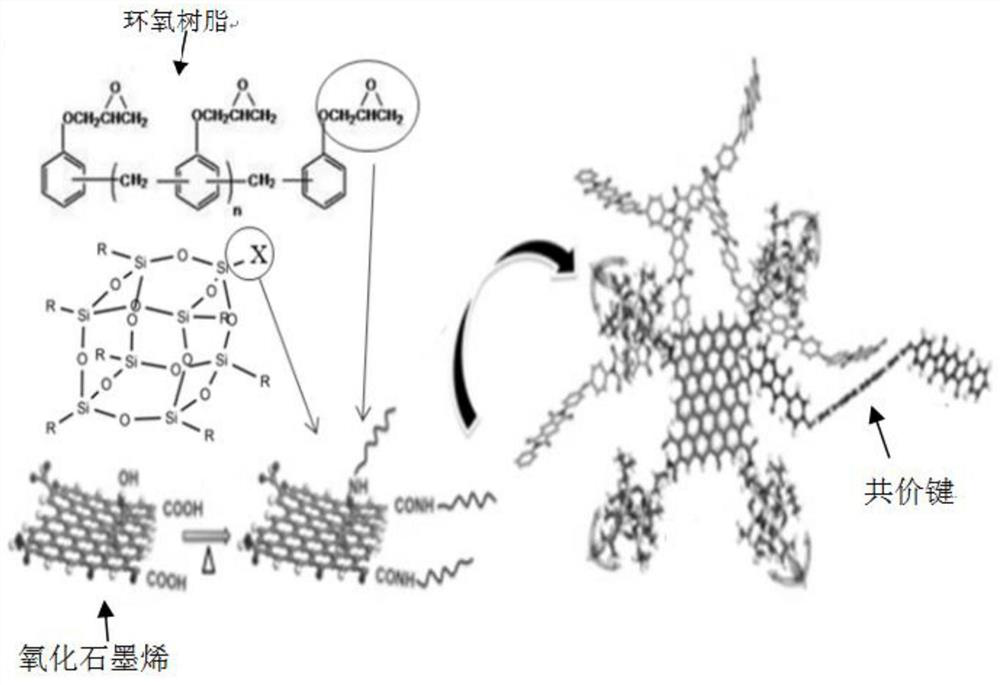

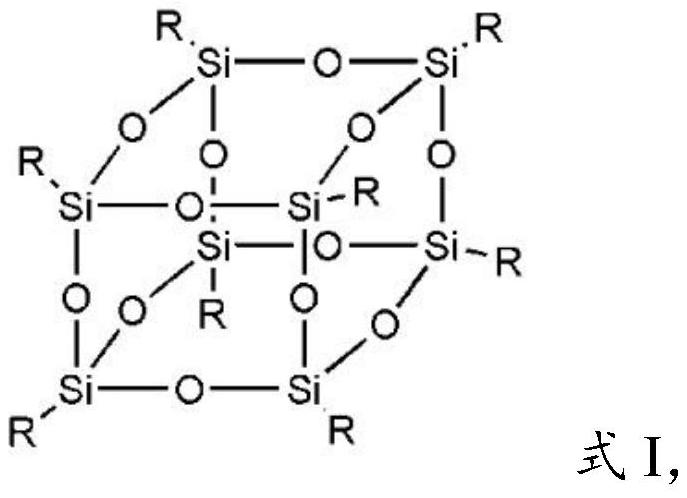

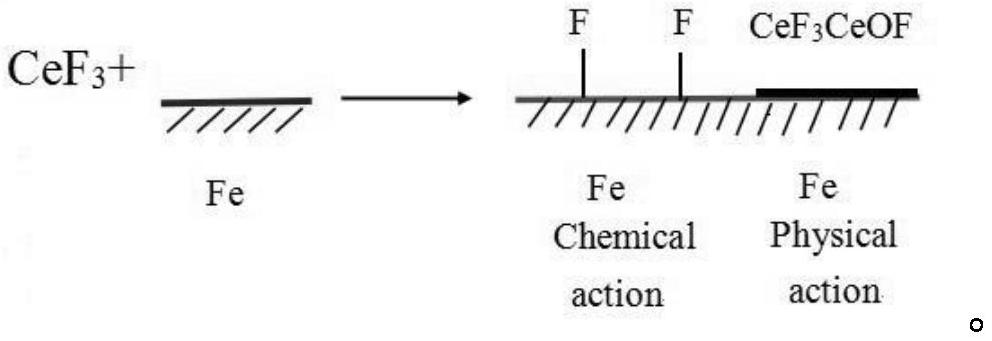

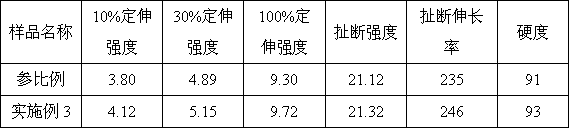

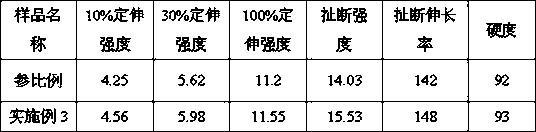

Solid lubricating protective coating as well as preparation method and application thereof

PendingCN113214725AImprove mechanical propertiesGood corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphorous acid

The invention provides a solid lubricating protective coating as well as a preparation method and application thereof, and belongs to the technical field of surface coatings. Epoxy resin and cashew nut oil modified phenolic resin are used as matrix resin, NH2-POSS and GO are used for modifying the matrix resin from the molecular level, molybdenum disulfide is used as a solid lubricant, organobentonite, dibasic lead phosphite, cerium trifluoride and antimony trioxide are used as functional fillers, a mixed solvent is used as a dispersion medium, the corrosion-resistant solid lubricating protective coating with high bearing capacity and long service life is obtained. The coating has good adhesion to a metal substrate, has strong impact resistance and toughness, has the Falex wear-resistant life of not less than 450 minutes under the load of 4450 N, has the bearing capacity of 11200 N, has the protection capacity of protecting a carbon steel test piece against a 100-hour salt spray test, has good aluminum corrosion resistance, medium resistance and thermal stability, and the performance can meet the index requirements specified by the American military specification MIL-L-46010E.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for synthesizing tire rubber reinforcing resin by using bio-oil as raw material

The invention provides a method for synthesizing tire rubber reinforcing resin by utilizing bio-oil as a raw material. The method comprises the following synthesis steps: (1) uniformly mixing formaldehyde, bio-oil and phenol according to a mass ratio of (0.5-0.8):(0.2-0.4):(0.8-1.0), simultaneously adding a catalyst, and controlling the pH value to be between 1 and 3; (2) raising the temperature and controlling the temperature to be 90-100 DEG C for reaction for 1-1.5 hours, and then carrying out reduced pressure distillation to remove water; (3) adding cashew oil, controlling the reaction temperature to be 150-200 DEG C, and carrying out a heat preservation reaction for 1-5 hours, wherein the amount of the cashew oil is 0.3-16% of the amount of phenol; (4) carrying out reduced pressure distillation until the softening point is 70-120 DEG C; and (5) neutralizing acid in the resin with a neutralizing agent to obtain the tire rubber reinforcing resin. The reinforcing resin synthesized byutilizing bio-oil solves the problems of high free phenol and possible gelation in production, improves the reinforcing effect of tire rubber compared with pure phenolic resin, and utilizes biomass pyrolysis byproducts, thereby greatly reducing the production cost.

Owner:山东泰然生物工程有限公司

Extraction method for cashew proteins

InactiveCN103689210AEfficient separationEasy to separateProtein composition from waste materialsProtein composition from vegetable materialsUltra high pressureWarm water

The invention relates to an extraction method for cashew proteins. The method comprises the following steps: (1) crushing and sieving cashew kernels, performing infrared treatment, and separating cashew oil by using a hydraulic cold-pressing method; (2) adding cashew meal in pure water, performing refining through a colloid mill, and performing homogenizing and dynamic ultra-high pressure treatment; (3) performing alkaline extraction in an ultrasonic environment, performing centrifugation, extracting supernatant, regulating the pH to an isoelectric point for precipitation, performing centrifugation, and washing precipitates with warm water; (4) performing homogenizing and spray-drying on the precipitates to obtain the cashew proteins. According to the extraction method, process links are continuous and compact, and products are high in yield and quality.

Owner:NANCHANG UNIV

Epoxy zinc-rich paint

InactiveCN102417784BGood flexibilityStrong impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention relates to epoxy zinc-rich paint. The epoxy zinc-rich paint is characterized in that epoxy resin as a base material, cashew oil polyamide as a curing agent, ultrafine zinc powder as a main antirust pigment, and certain amounts of auxiliary agents and solvents are mixed according to a certain ratio and are prepared into the epoxy zinc-rich paint. The epoxy zinc-rich paint provided by the invention is suitable for being used by a dip-coating method. A coated epoxy zinc-rich paint film has excellent corrosion resistance, chemical resistance and solvent resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Rubber intensifier as well as preparation method and application thereof

The invention relates to a rubber intensifier which contains the following raw material components in parts by weight: 20-30 parts of cashew nut oil and 12-18 parts of hexamethylenetetramine. The method for preparing the cashew nut oil comprises the following steps: uniformly mixing cashew kernel with absolute ethyl alcohol, and then heating; grinding cashew nut shells so as to obtain cashew powder, and drying the cashew powder; uniformly mixing the two products, pressing at a low temperature, filtering the crude oil obtained by low-temperature pressing, and collecting the filtrate, thereby obtaining the cashew nut oil. According to the rubber intensifier as well as the preparation method and application thereof, provided by the invention, the effect of the rubber intensifier for intensifying the rubber can be improved, the heat resistance, aging resistance, wear resistance, scratch resistance and corrosion resistance of the rubber are improved, the rubber aging process is effectively retarded or inhibited, the strength and the rubber flexibility are perfectly combined, and the physical and mechanical properties of the rubber are improved; and moreover, the preparation method is simple, and the production cost is low.

Owner:东光县强龙高分子材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com