Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2191results about "Priming paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

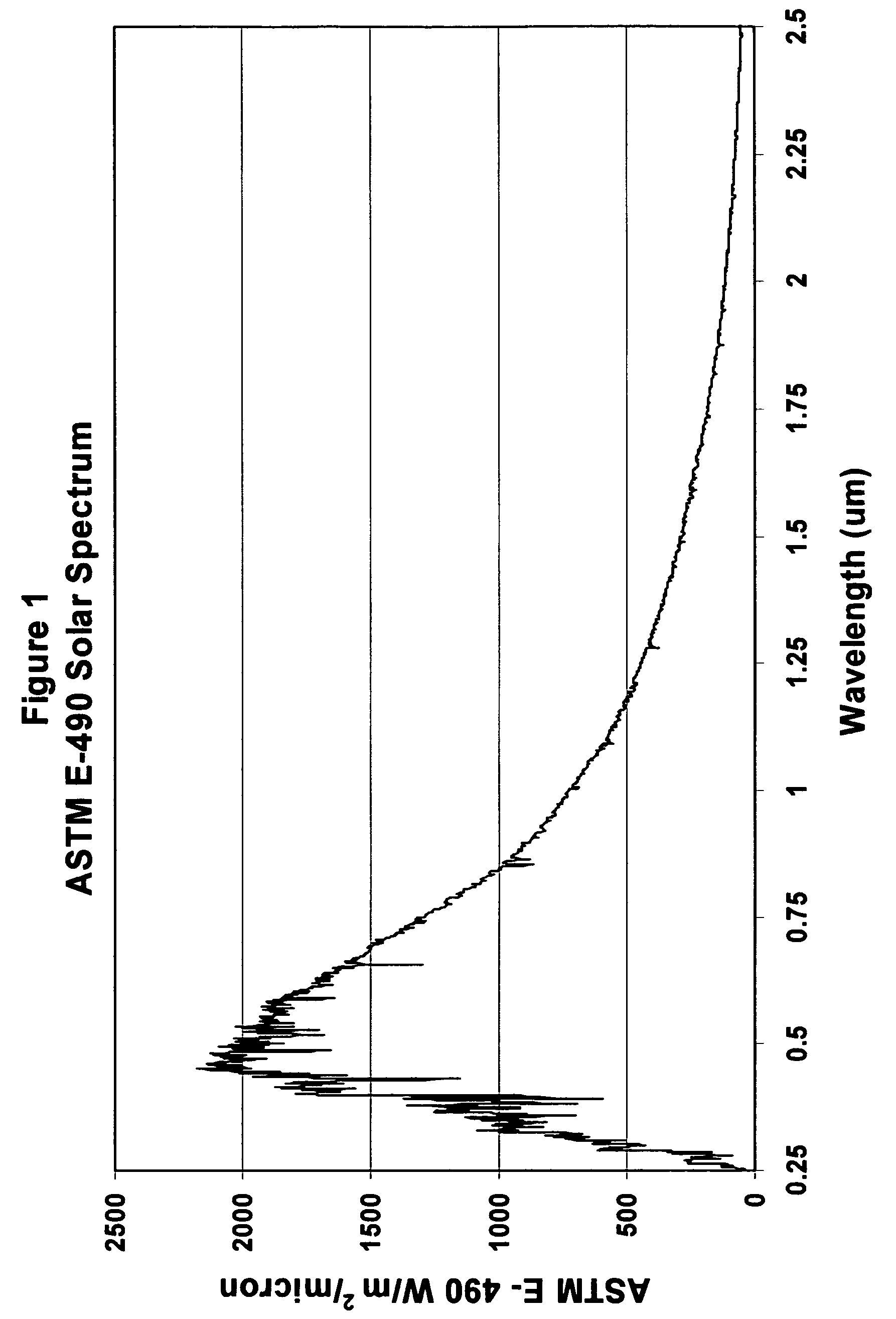

Composition of a thermaly insulating coating system

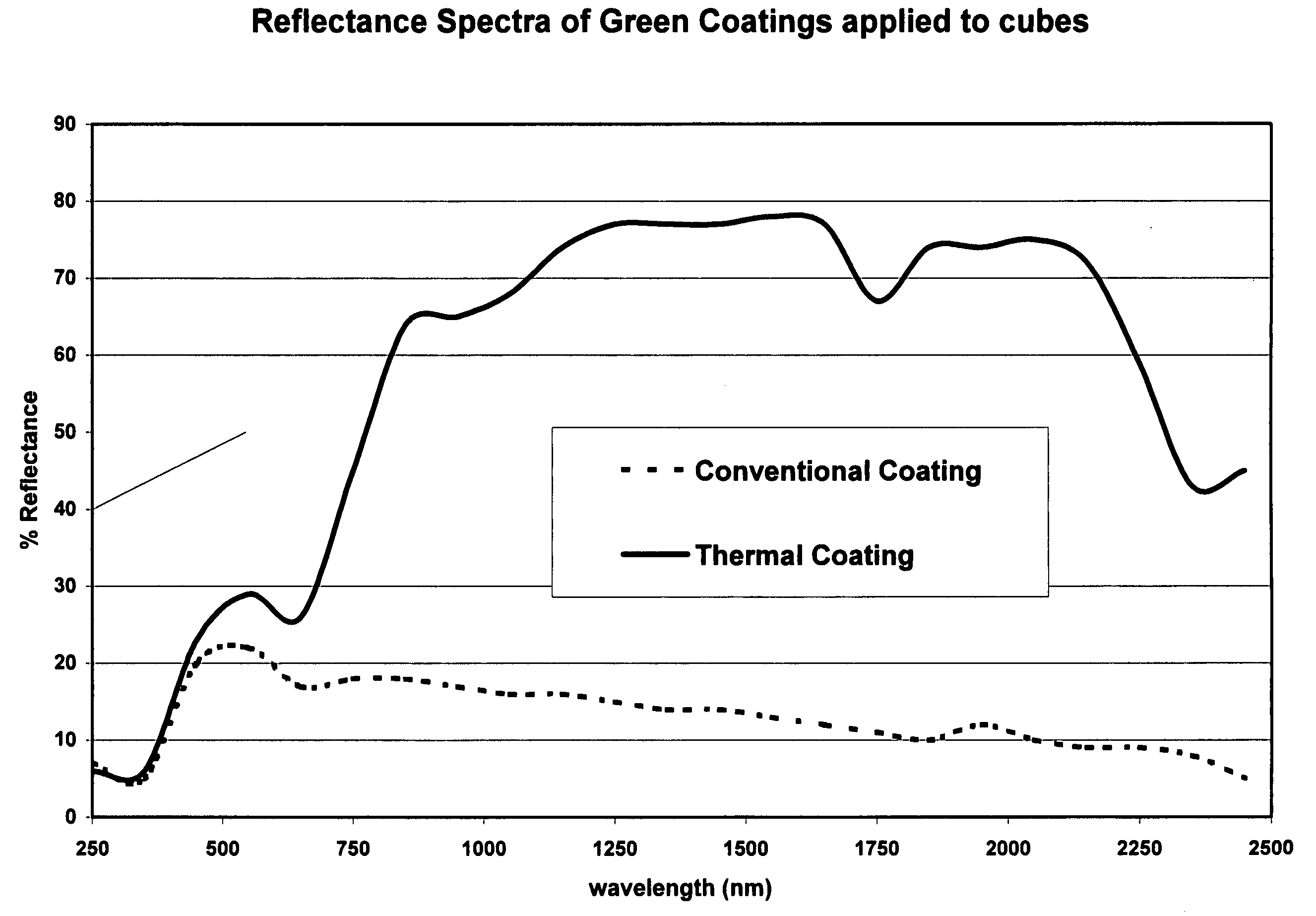

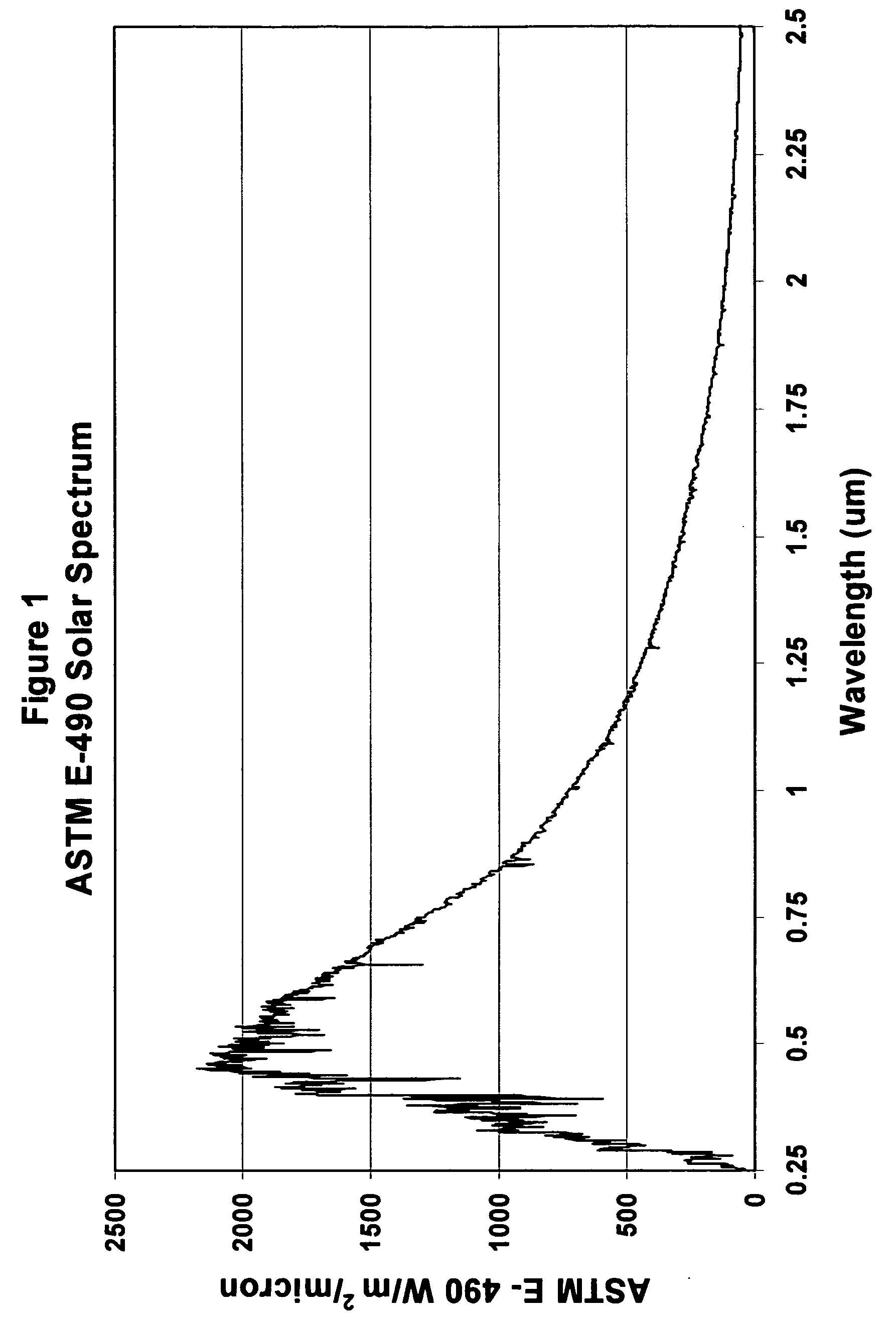

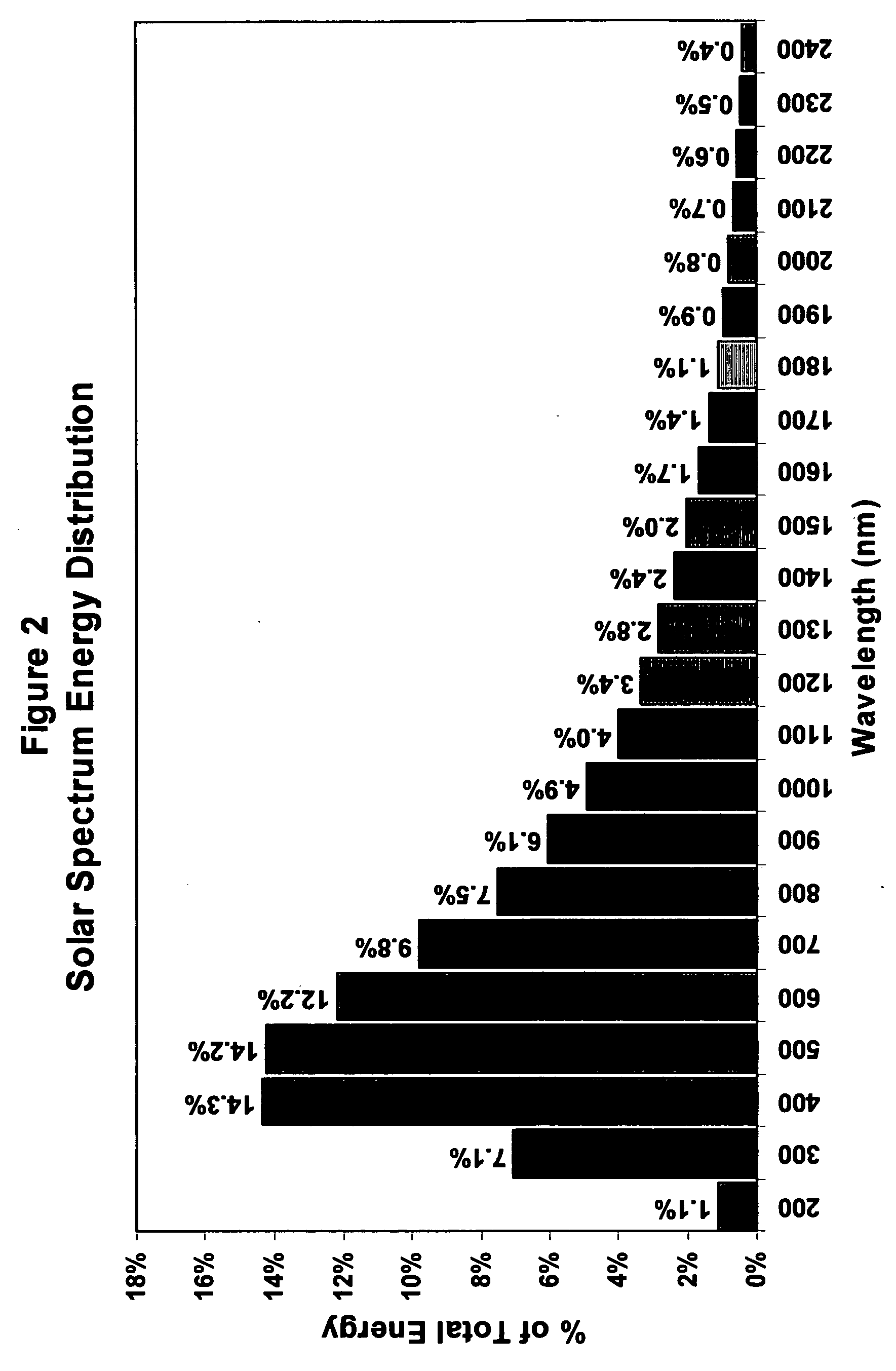

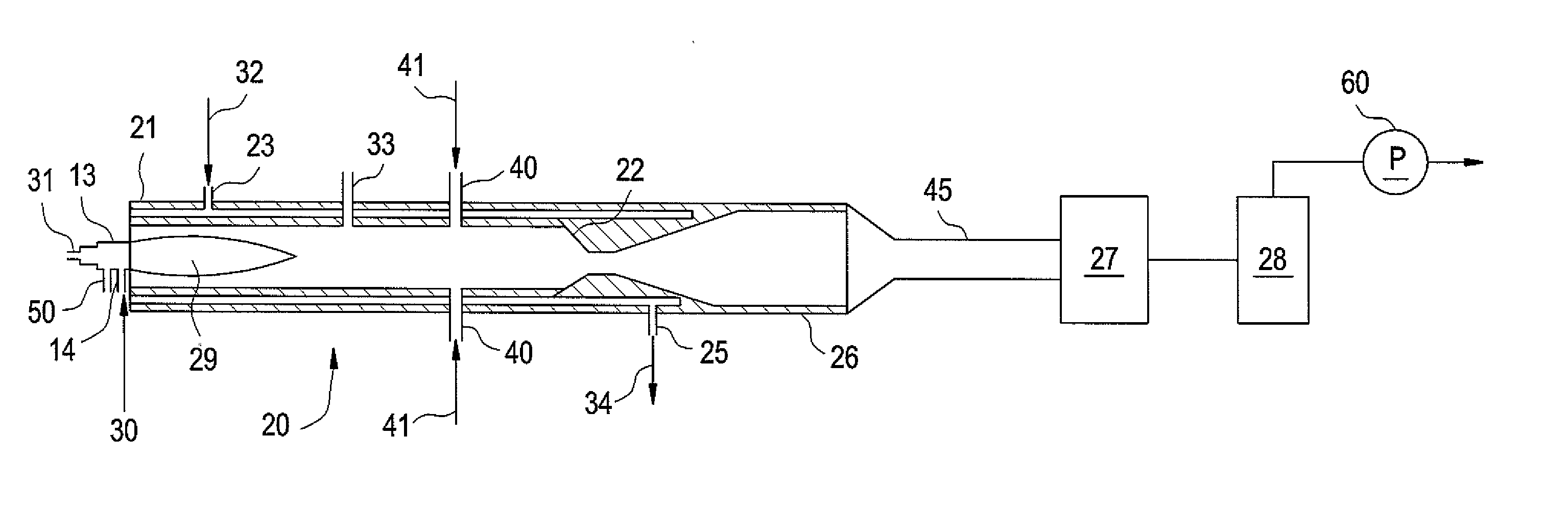

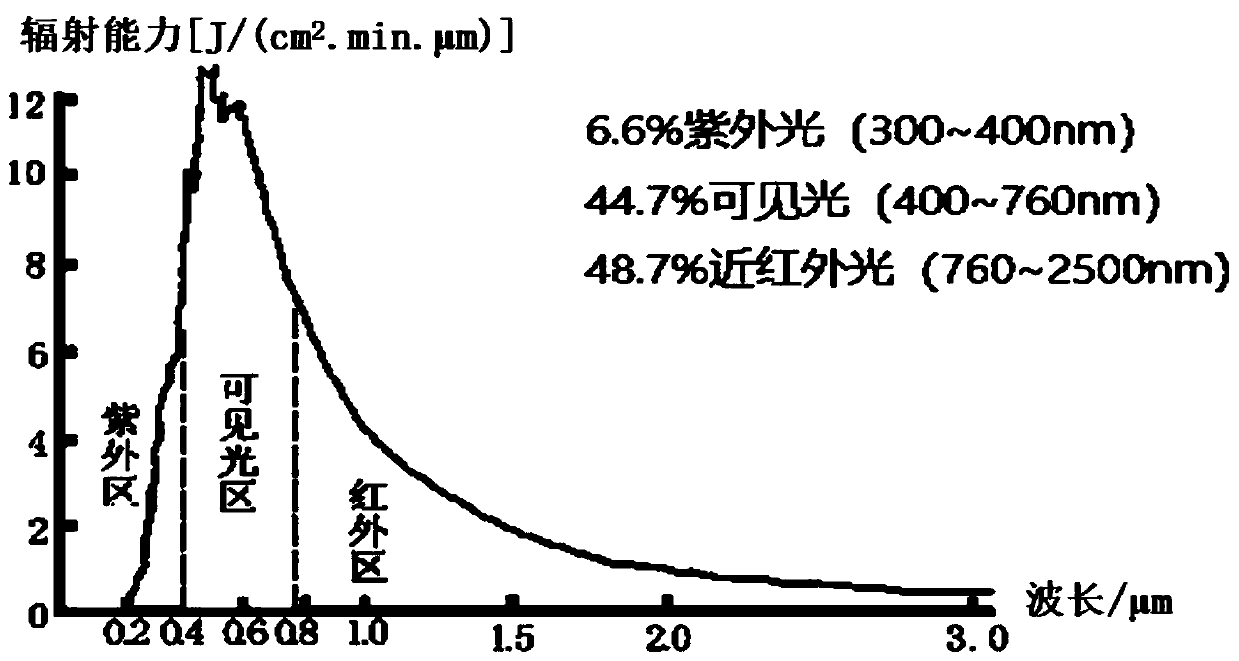

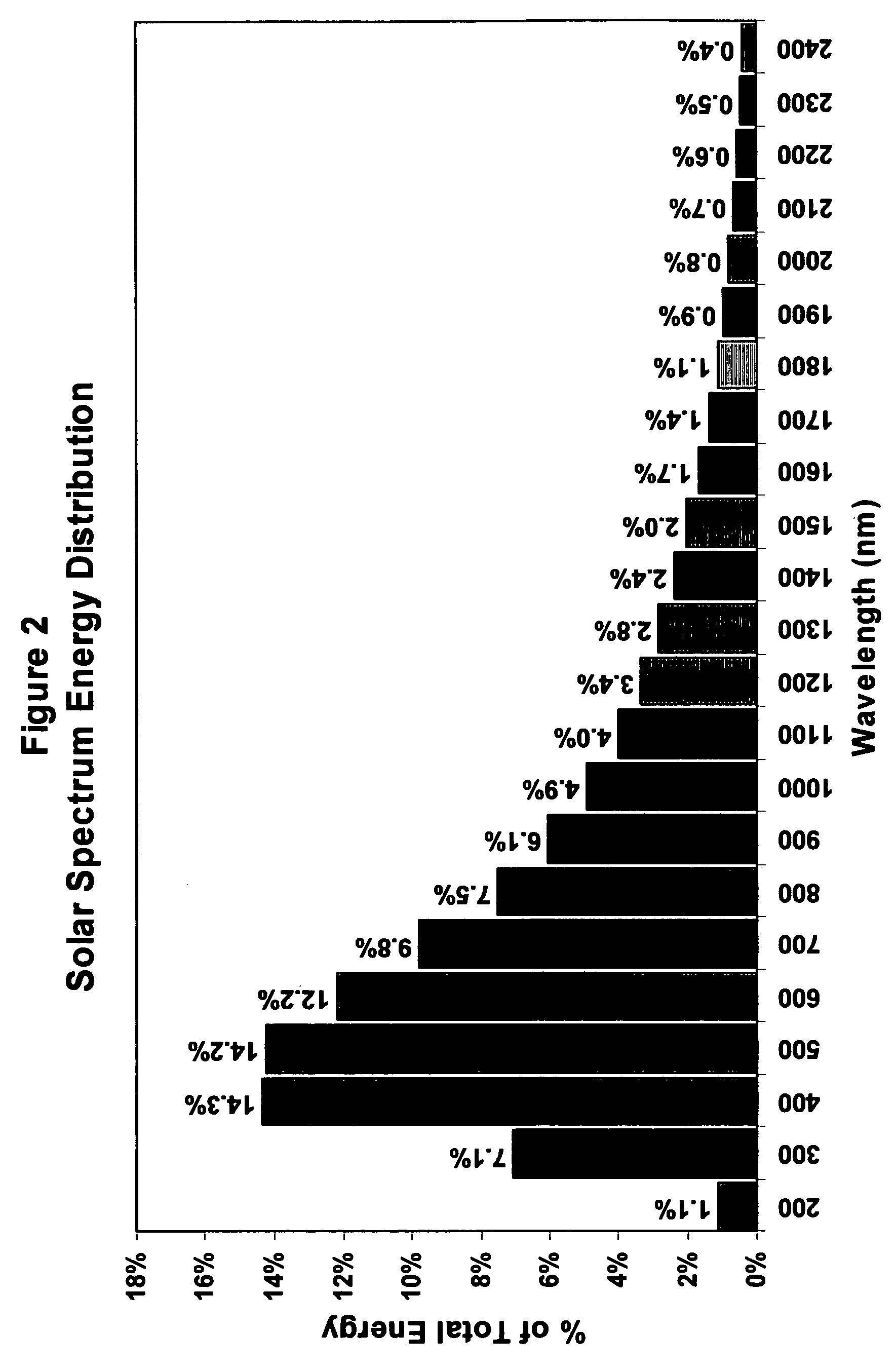

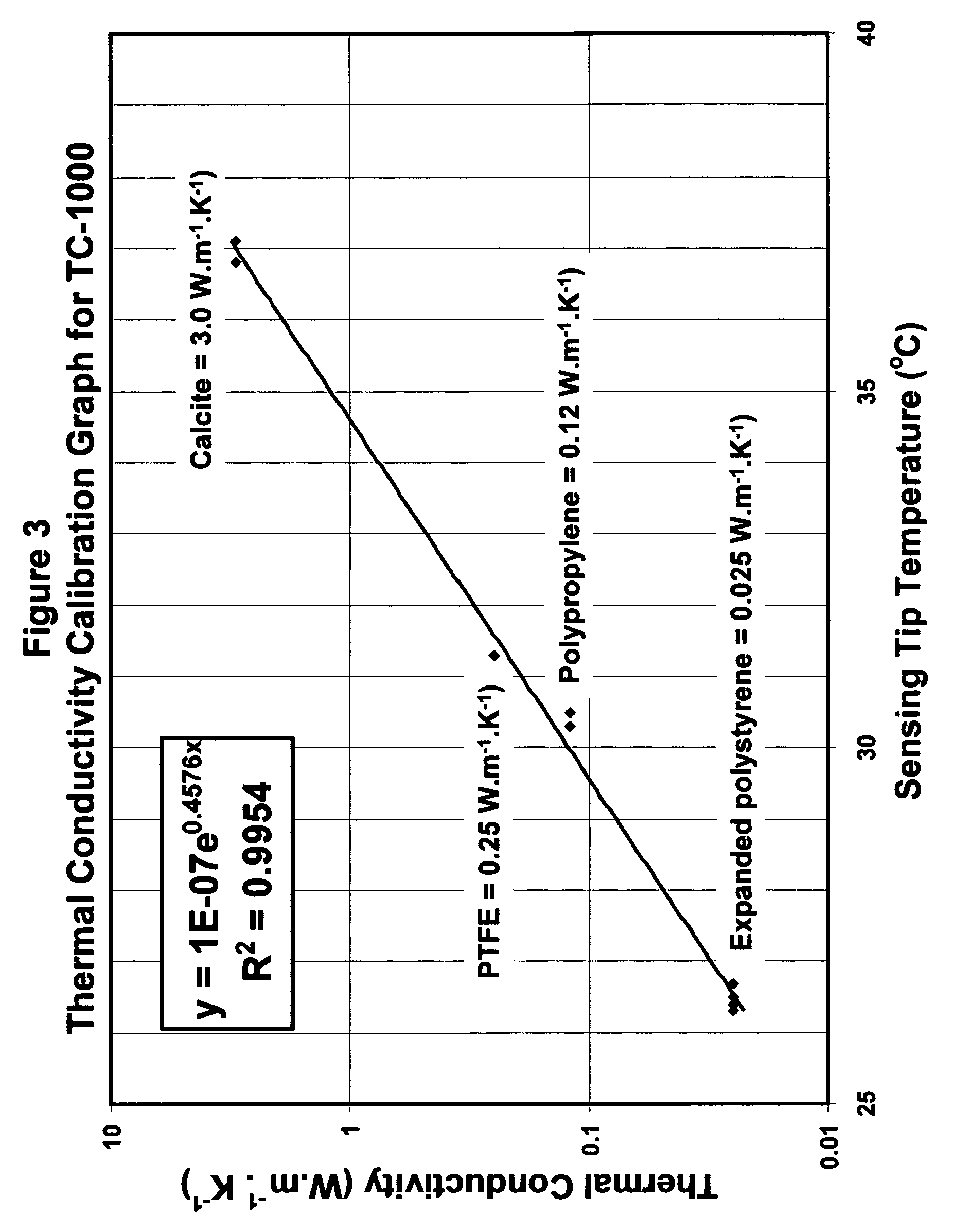

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Treatment Liquid for Plastic Film, Primer Liquid for Printing, Ink Composition, and Method for Ink Jet Recording Using Them

InactiveUS20080152825A1Improve rub resistanceImprove scratch resistanceLiquid surface applicatorsWater-repelling agents additionPlastic filmPolymer chemistry

This invention provides a treatment liquid for an ink jet recording medium having a recording face of a plastic film, wherein the treatment liquid including at least a specific cyclic ester compound or a specific cyclic amide compound, a primer liquid for printing, and an ink composition. According to the present invention, a plastic recorded matter possessing excellent adhesion and waterfastness can be formed on a recording medium having a recording face of a plastic film.

Owner:SEIKO EPSON CORP

Coating compositions exhibiting corrosion resistance properties and related coated substrates

ActiveUS20080090069A1Improve corrosion resistanceLiquid surface applicatorsOther chemical processesSolid particleMaterials science

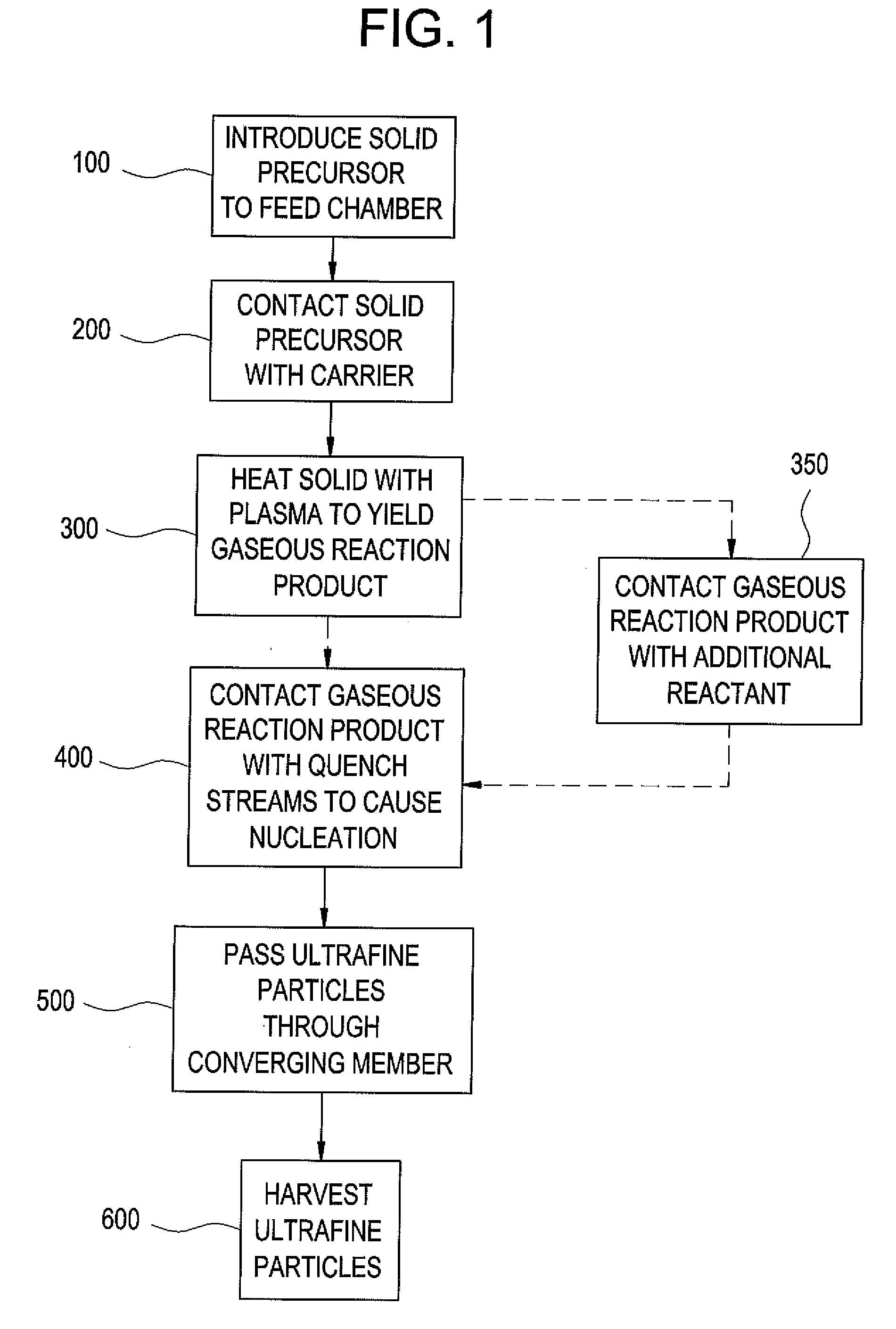

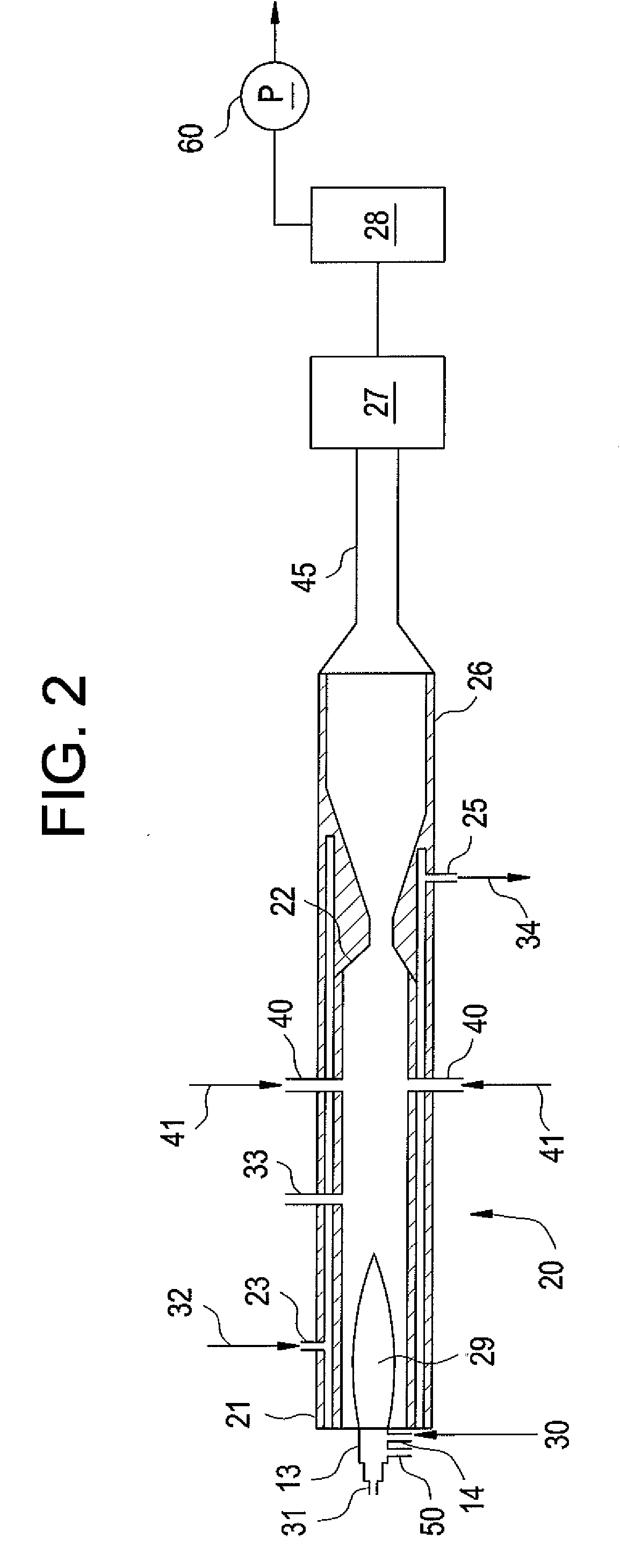

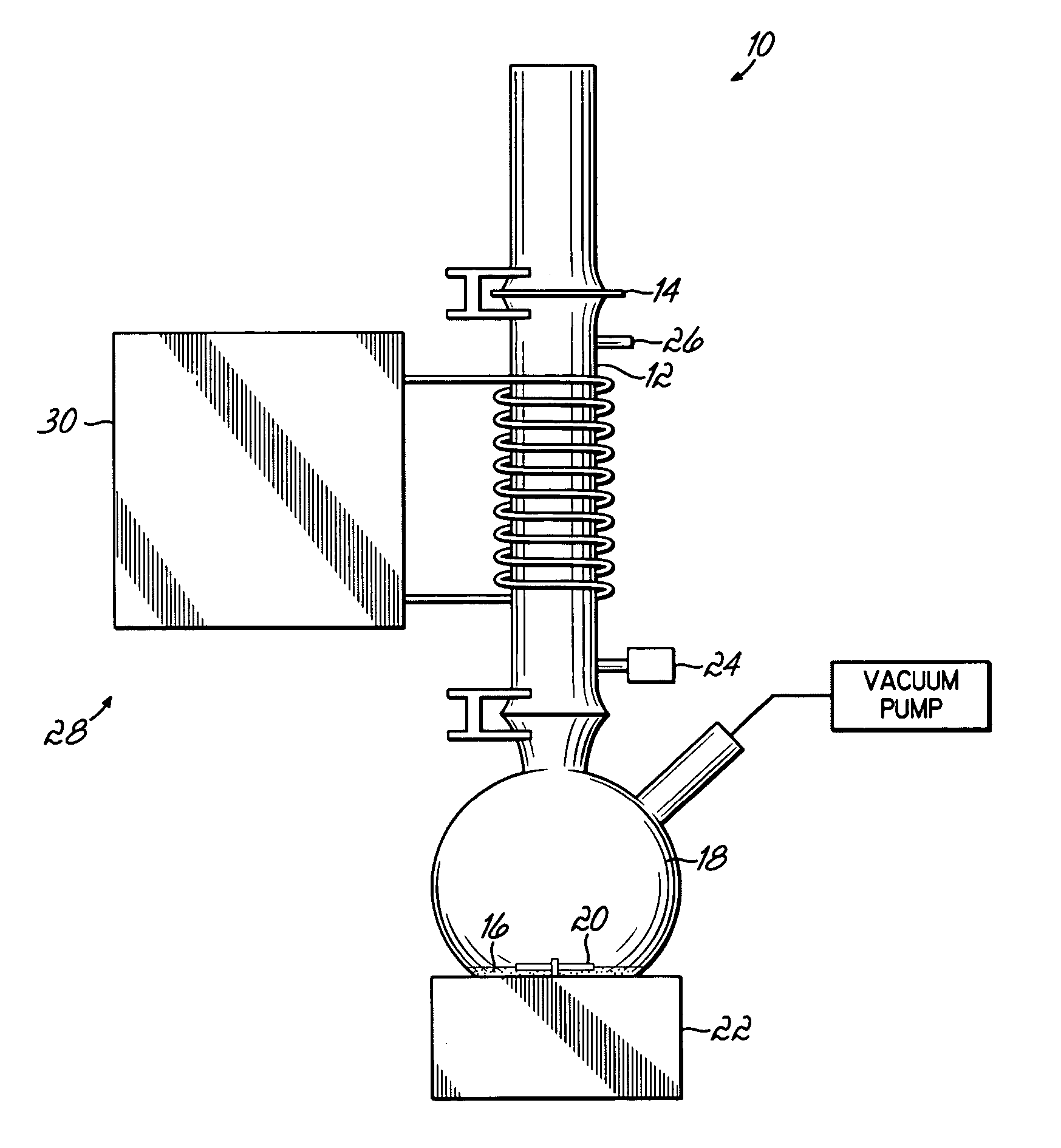

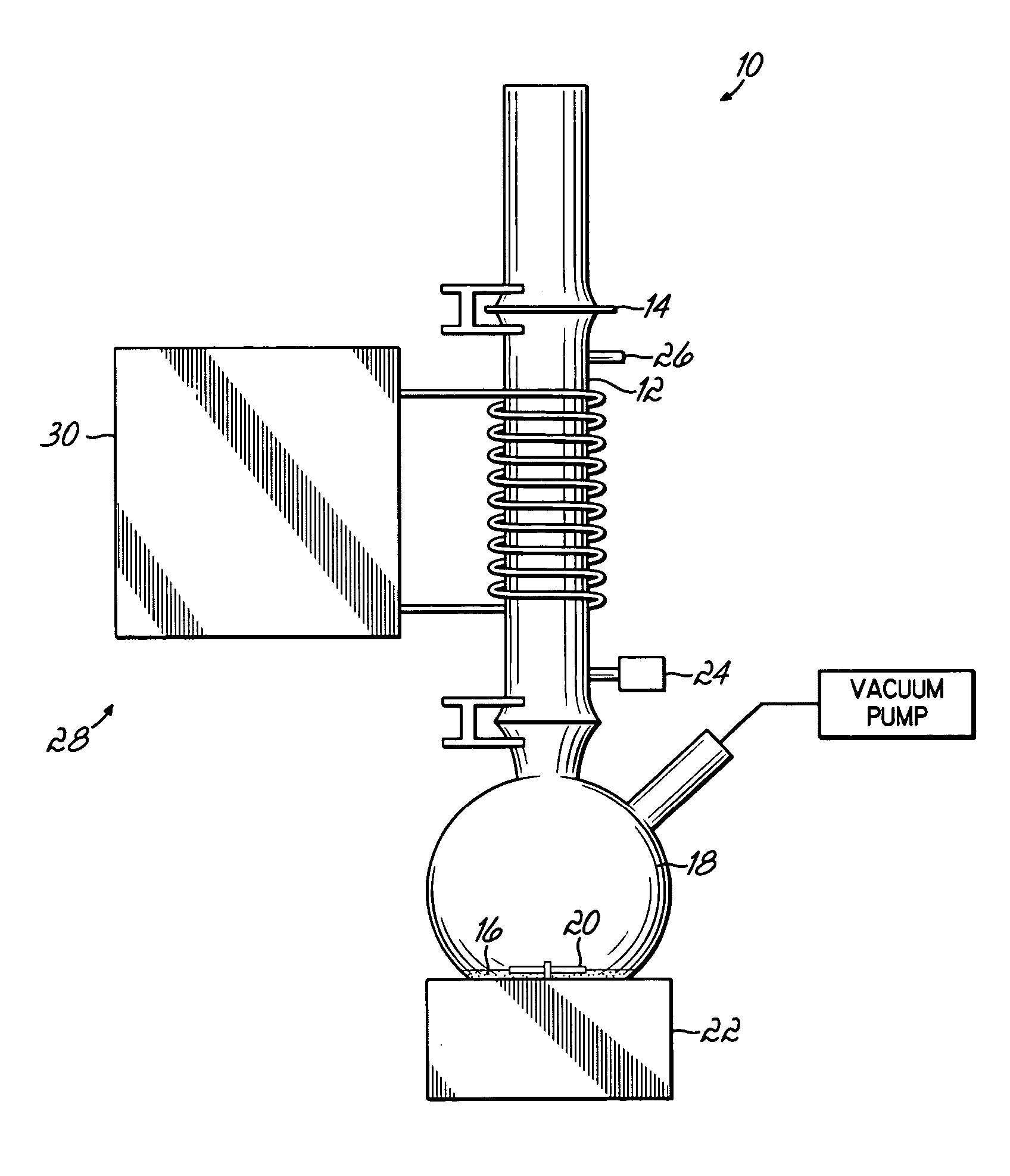

Coating compositions are disclosed that include corrosion resisting particles such that the coating composition can exhibit corrosion resistance properties. Also disclosed are substrates at least partially coated with a coating deposited from such a composition and multi-component composite coatings, wherein at least one coating later is deposited from such a coating composition. Methods and apparatus for making ultrafine solid particles are also disclosed.

Owner:PPG IND OHIO INC

Method for forming multilayer coating film

ActiveUS20130089731A1Inhibition formationEnhance the imagePretreated surfacesRecord information storageMicrometerSolvent

An object of the invention is to provide a method for forming a multilayer coating film with excellent smoothness, distinctness of image, and water resistance, by a 3-coat 1-bake coating method, even when preheating after the application of an aqueous first colored coating composition is omitted. The present invention provides a method for forming a multilayer coating film, including (1) applying an aqueous colored coating composition (A) to a substrate to form a colored coating film; (2) applying an effect pigment-containing aqueous coating composition (B) containing a binder component (b1), an effect pigment (b2), and a hydrophobic solvent (b3) in proportions of 15 to 30 parts by mass of effect pigment (b2) and 25 to 60 parts by mass of hydrophobic solvent (b3) relative to 100 parts by mass of the binder component (b1), to the colored coating film, without preheating the colored coating film, to form an effect coating film having a film thickness of 7 to 13 micrometers when cured; (3) applying a clear coating composition (C) to the effect coating film to form a clear coating film; and (4) heating the three coating films formed in steps (1) to (3) to simultaneously cure these three coating films.

Owner:KANSAI PAINT CO LTD

High friction coating formulations and systems and coated articles thereof exhibiting radar signature reduction and methods of providing the same

InactiveUS20090226673A1Improve featuresImprove securityRadiation/particle handlingPretreated surfacesParticulatesCoating system

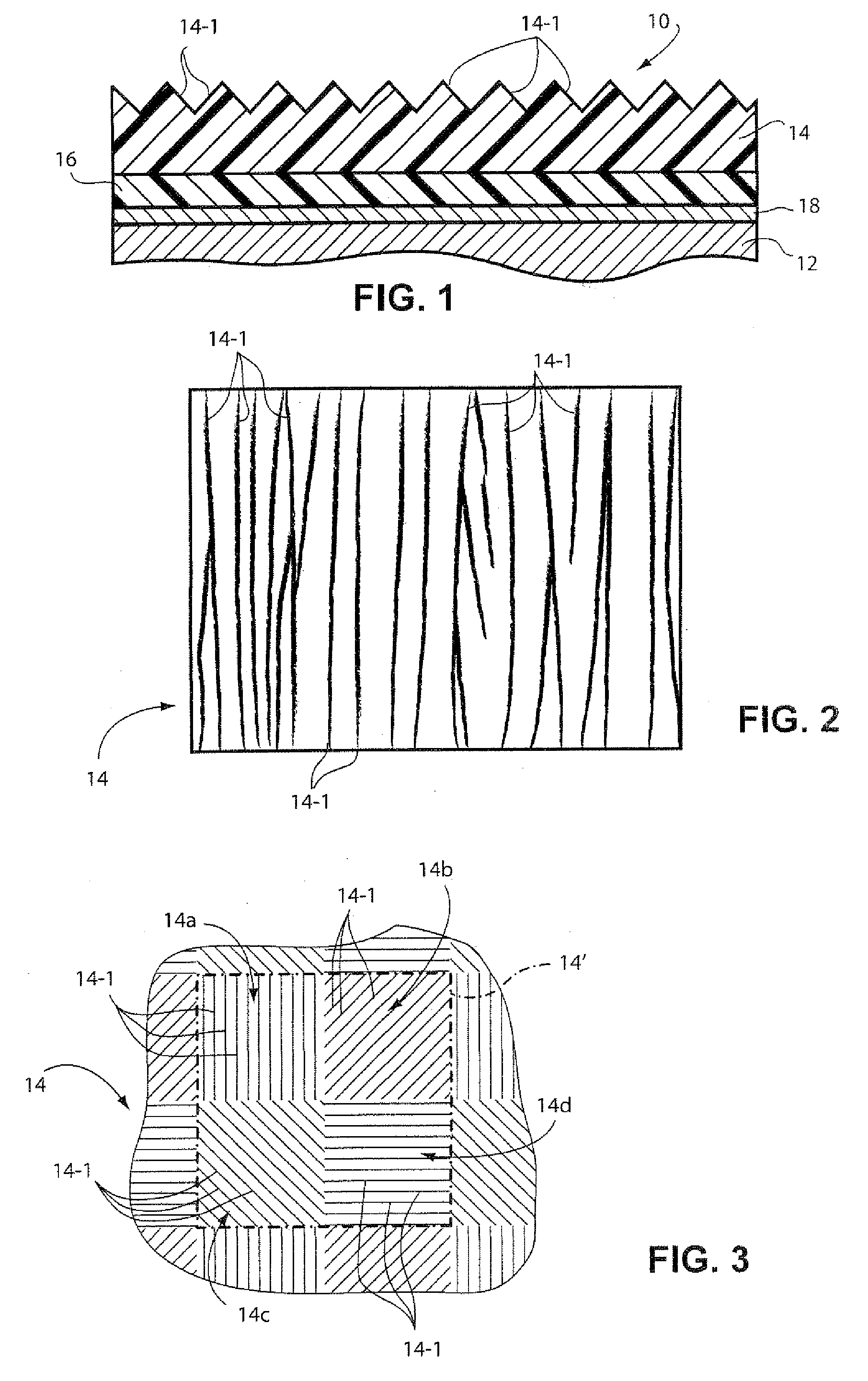

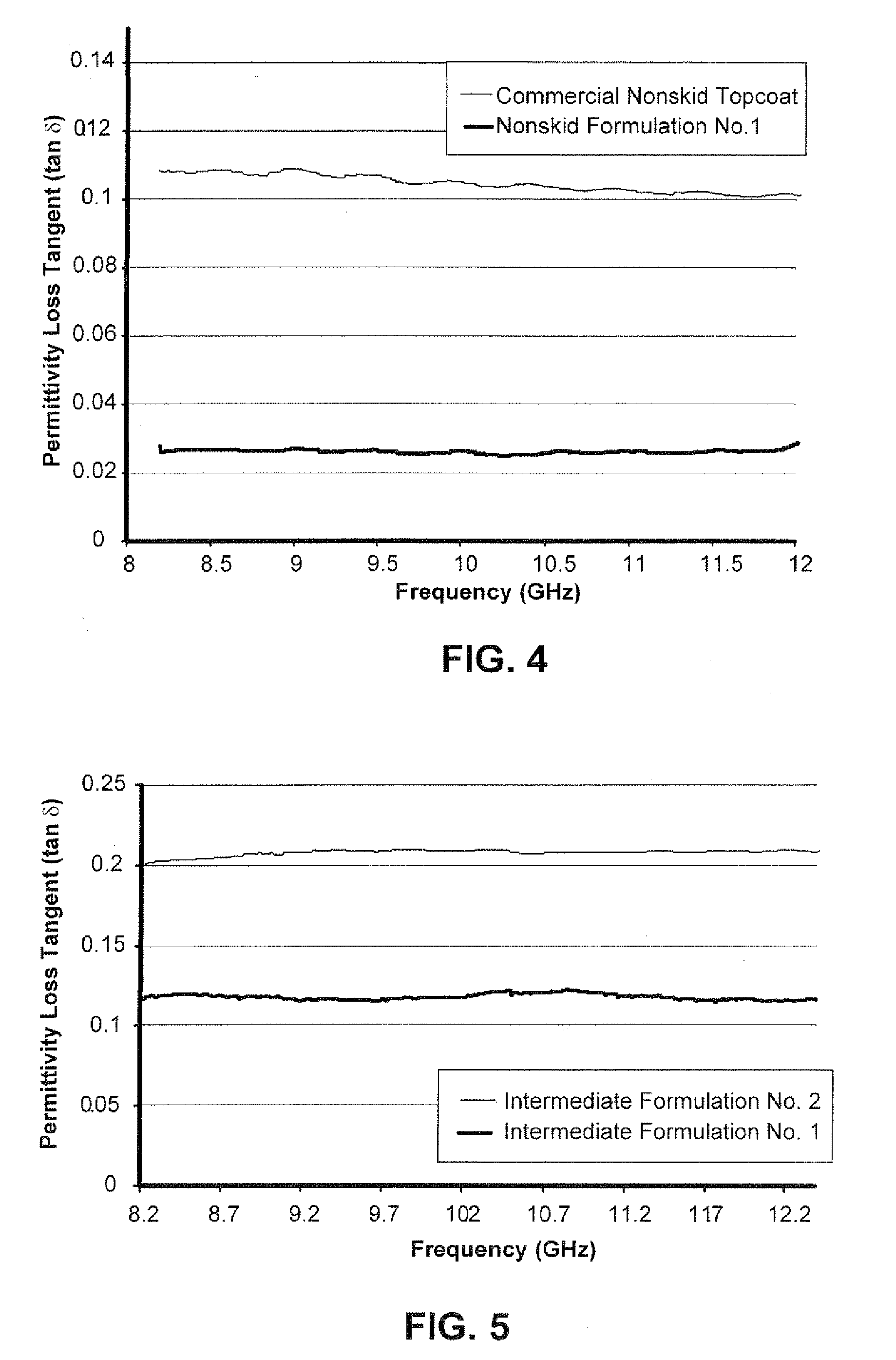

High friction and radar attenuating coating formulations are provided and include a resin matrix, a particulate friction additive dispersed in the resin matrix in an amount sufficient to achieve a minimum coefficient of friction according to MIL-PRF-24667B(SH), and a particulate dielectric filler dispersed in the resin matrix in an amount sufficient to achieve a permitivitty (∈′) of less than about 10 and a loss tangent (tan δ) of less than about 0.05. A substrate surface may be coated with the coating formulation so as to provide a topcoat layer thereon. The topcoat layer may thus be applied directly onto the substrate surface. Alternatively, the coating formulation is present as a topcoat layer component of a coating system on the substrate which further comprises an intermediate layer interposed between the topcoat layer and a surface of the substrate and / or a primer layer coated directly onto the surface of a substrate between the topcoat layer and the substrate. In some embodiments, the coating formulation is applied so as to form a series of substantially parallel ridges having a predetermined directional orientation. In certain preferred embodiments, the coating formulation is applied to a block area on the substrate surface comprised of plural areal regions, wherein the directional orientation of the substantially parallel ridges of one areal region are angularly biased with respect to the directional orientation of the substantially parallel ridges of an adjacent areal region.

Owner:LUNA INNOVATIONS

System for bonding glass into a structure

The invention is a composition comprising a) one or more organotitanates or zirconates having four ligands wherein the ligands are hydrocarbyl, optionally containing one or more functional groups having one or more heteroatoms selected from the group comprising oxygen, nitrogen, phosphorus and sulfur wherein two or more of the ligands may form a cyclic structure with the proviso that one of the ligands has an acidic moiety; one or more strong organic acids or a mixture thereof; b) one or more alkoxysilanes; c) optionally one or more high molecular weight resins; and d) a solvent which dissolves the components of the composition. This composition is referred to as a clear primer hereinafter. Preferably, the composition comprises both an organotitanate or zirconate and a strong acid.

Owner:DOW GLOBAL TECH LLC

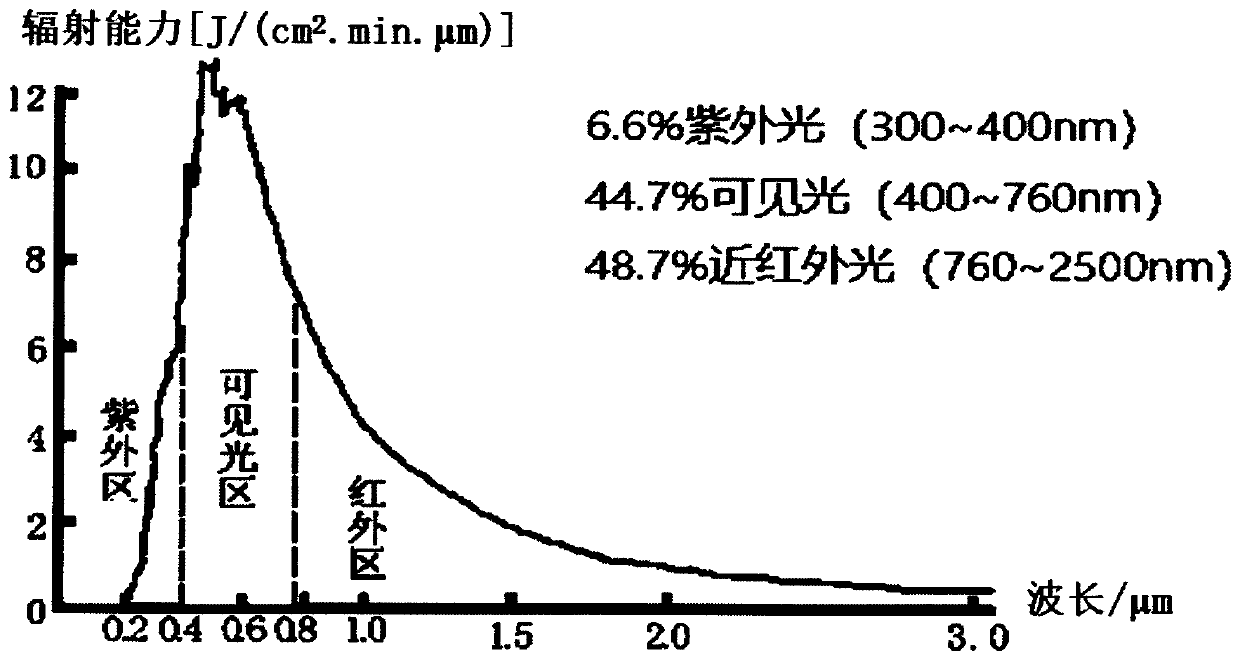

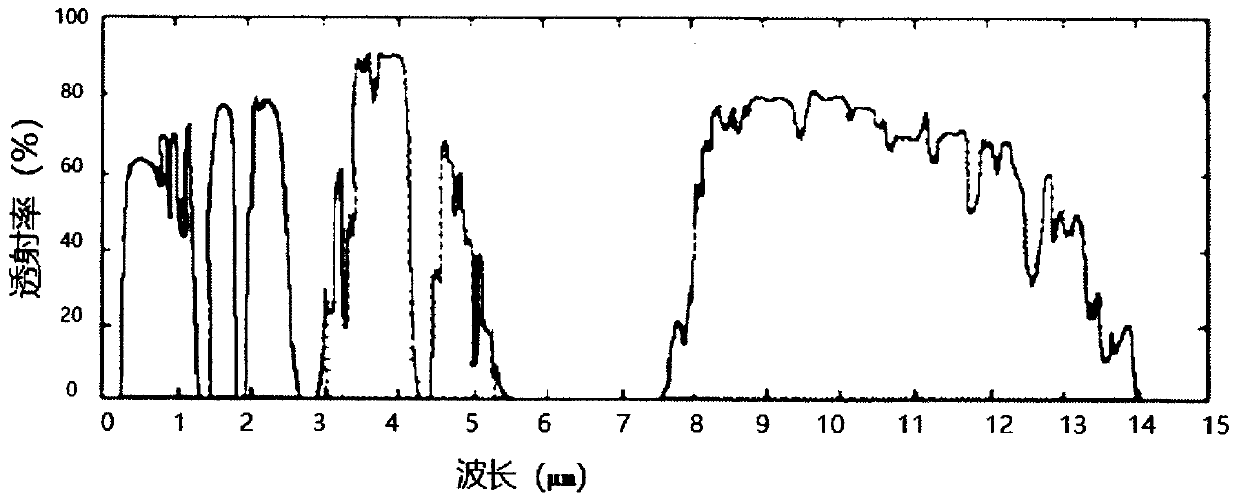

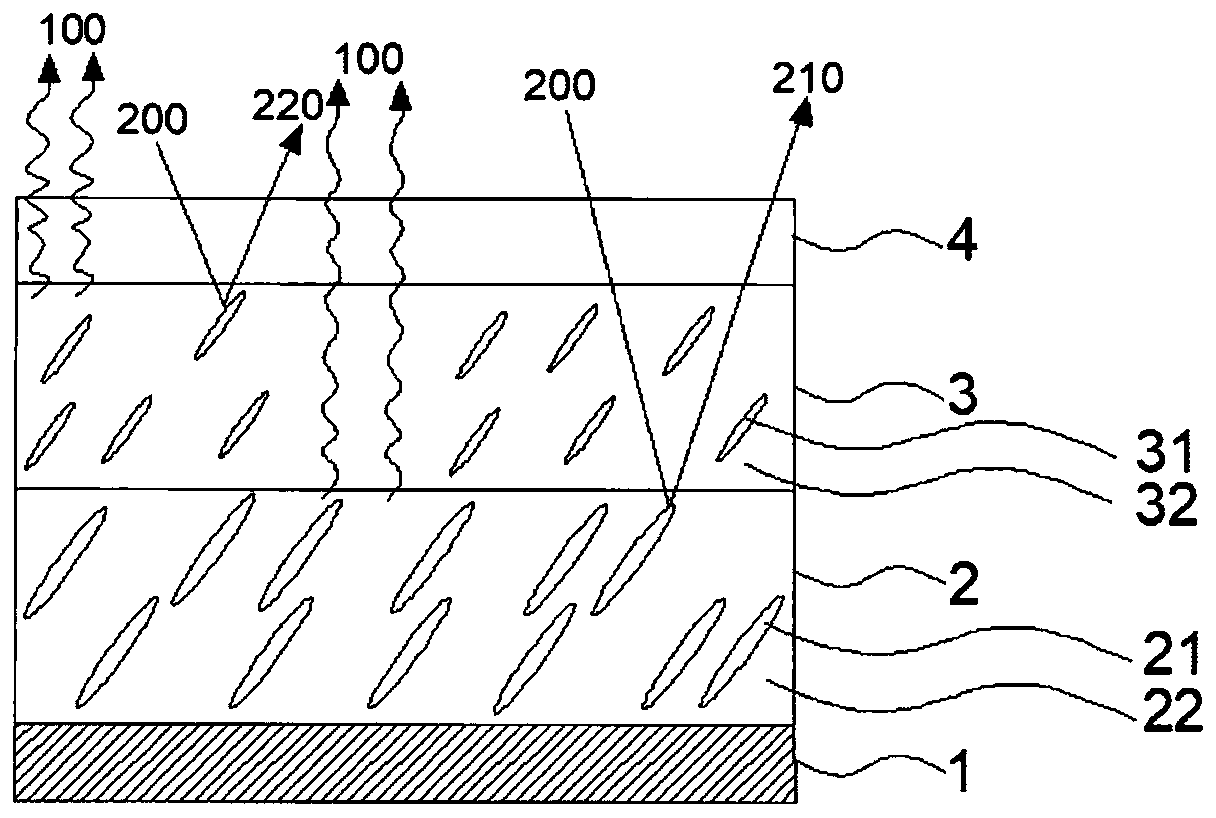

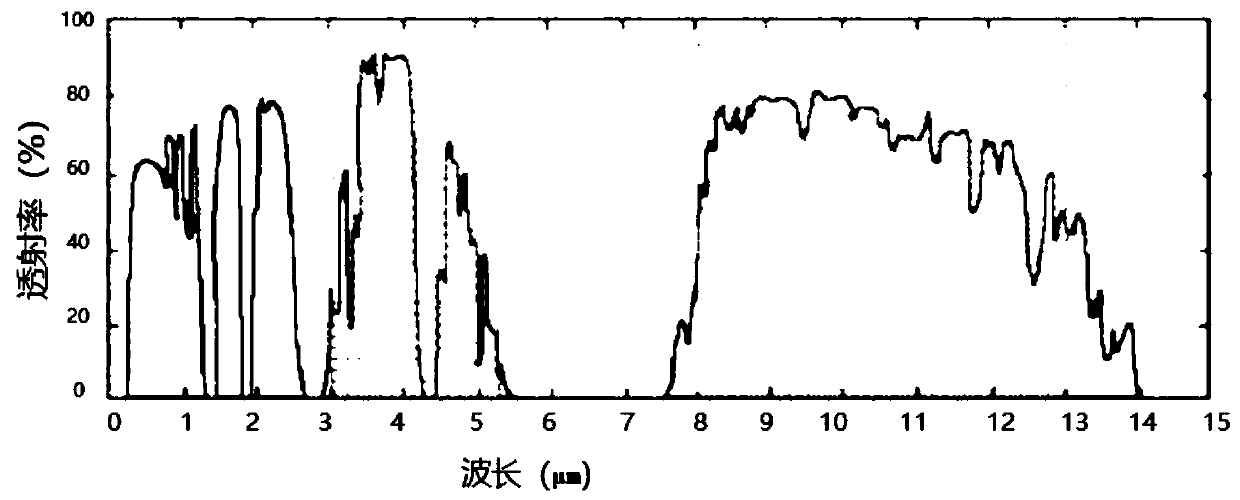

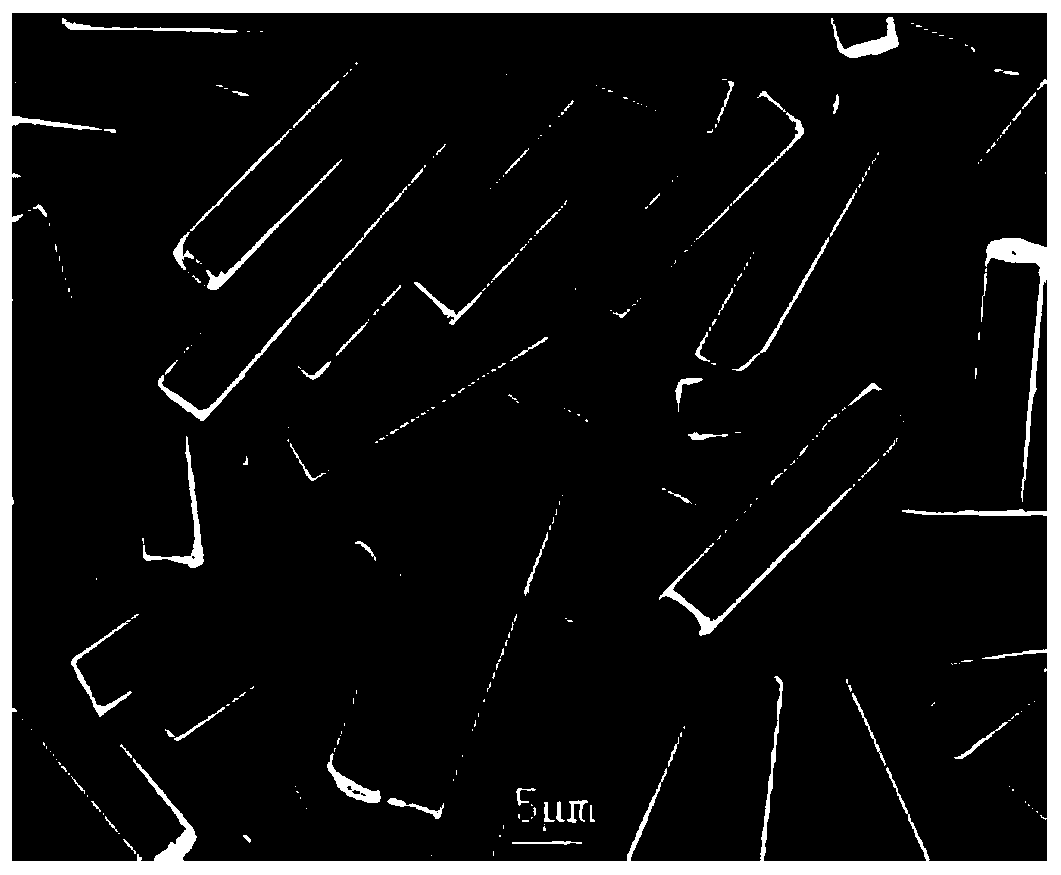

Selective radiation refrigeration coating and composite material and application method thereof

PendingCN110317521AHigh mechanical strengthGood weather resistanceLuminescent paintsBuild-up roofsUltraviolet lightsReflectivity

The invention discloses a selective radiation refrigeration coating and a composite material and application method thereof. The selective radiation refrigeration coating comprises a radiation refrigeration function layer with special structure particle filler. The radiation refrigeration function layer is used for reflecting ultraviolet light and / or visible light and / or near infrared light in sunlight and emitting heat through an atmosphere window in an infrared radiation mode, the radiation refrigeration function layer comprises a rodlike structure particle filler and radiation refrigerationfunction layer resin, and the particle filler is distributed in the radiation refrigeration function layer resin. According to the coating, the reflectivity for solar spectrum energy is larger than or equal to 80%, the reflectivity of the atmosphere window is larger than or equal to 80%, and the radiation refrigeration power being 100 W / m<2> or above can be supplied under the normal temperature.The coating is high in mechanical strength and good in weather resistance and has the quite high practical value.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD +1

Novel radiation curable compositions

A radiation curable composition comprising a curable compound, a photo-initiator and a co-initiator, characterized in that said co-initiator is a oligomer or polymer having a repeating unit, said repeating unit comprising at least two tertiary amines, and said polymer being prepared by the polycondensation of di- or oligofunctional Michael acceptors with mono- or oligofunctional aliphatic primary amines or with di- or oligofunctional aliphatic secondary amines or with a mixture thereof.

Owner:AGFA NV

D1381 supercoatings for optical fiber

InactiveUS20080226909A1Glass optical fibreSynthetic resin layered productsOptical fiber cableRelative humidity

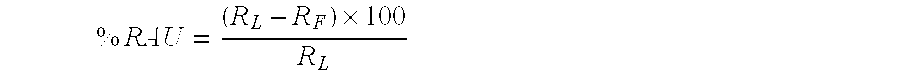

The invention provides an optical fiber coated with a Supercoating, wherein the Supercoating comprises at least two layers, wherein the first layer is a Primary Coating that is in contact with the outer surface of the optical fiber and the second layer is a Secondary Coating in contact with the outer surface of the Primary Coating, wherein the cured Primary Coating on the optical fiber has the following properties after initial cure and after one month aging at 85° C. and 85% relative humidity: A) a % RAU of from about 84% to about 99%;B) an in-situ modulus of between about 0.15 MPa and about 0.60 MPa; andC) a Tube Tg, of from about −25° C. to about −55° C.; wherein the cured Secondary Coating on the optical fiber has the following properties after initial cure and after one month aging at 85° C. and 85% relative humidity: A) a % RAU of from about 80% to about 98%;B) an in-situ modulus of between about 0.60 GPa and about 1.90 GPa; andC) a Tube Tg, of from about 50° C. to about 80° C.

Owner:DSM IP ASSETS BV

Coated chemically strengthened flexible thin glass

InactiveUS20170183255A1Improve antifouling performanceEasy to cleanGlass forming apparatusPriming paintsNiobiumCerium

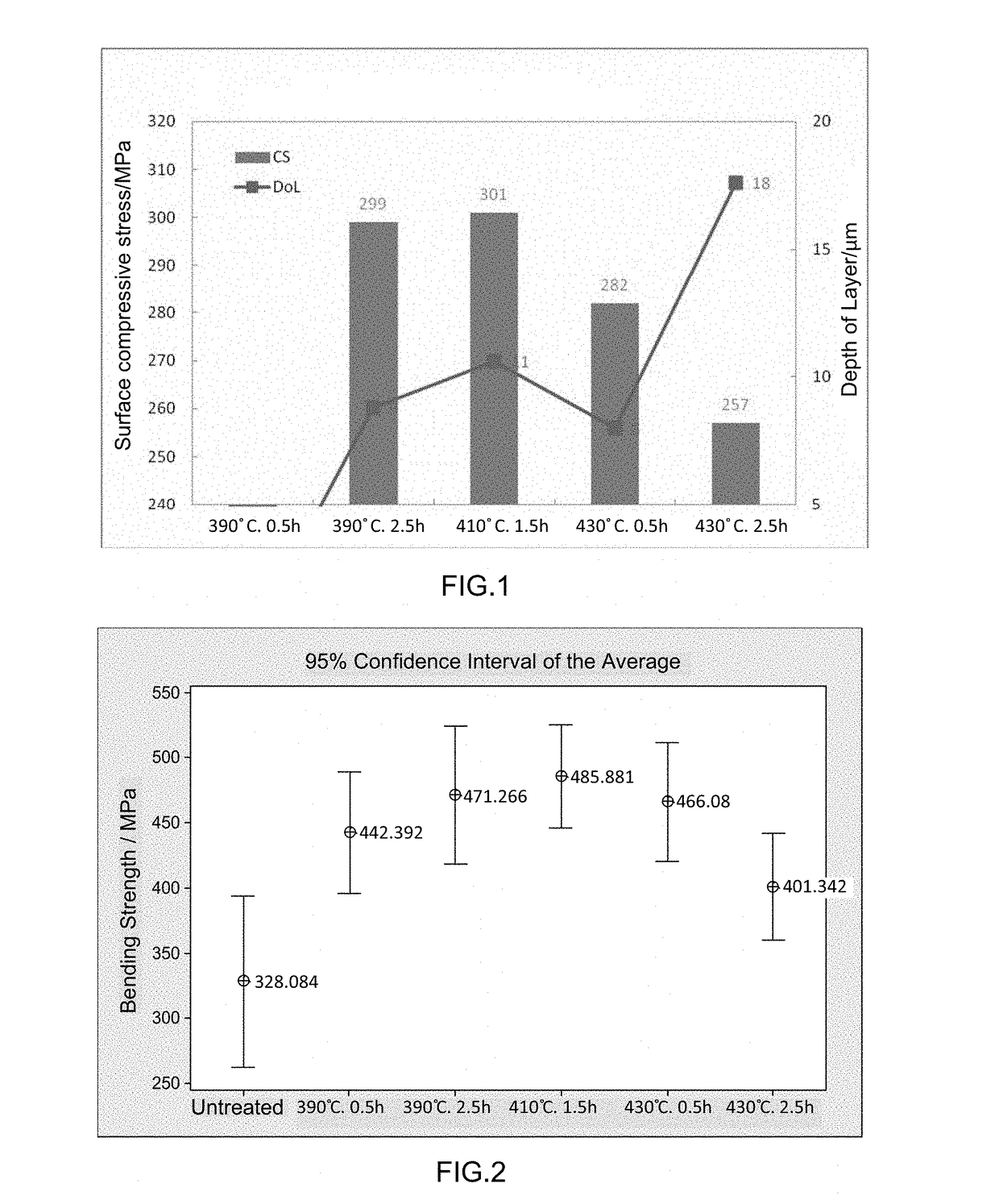

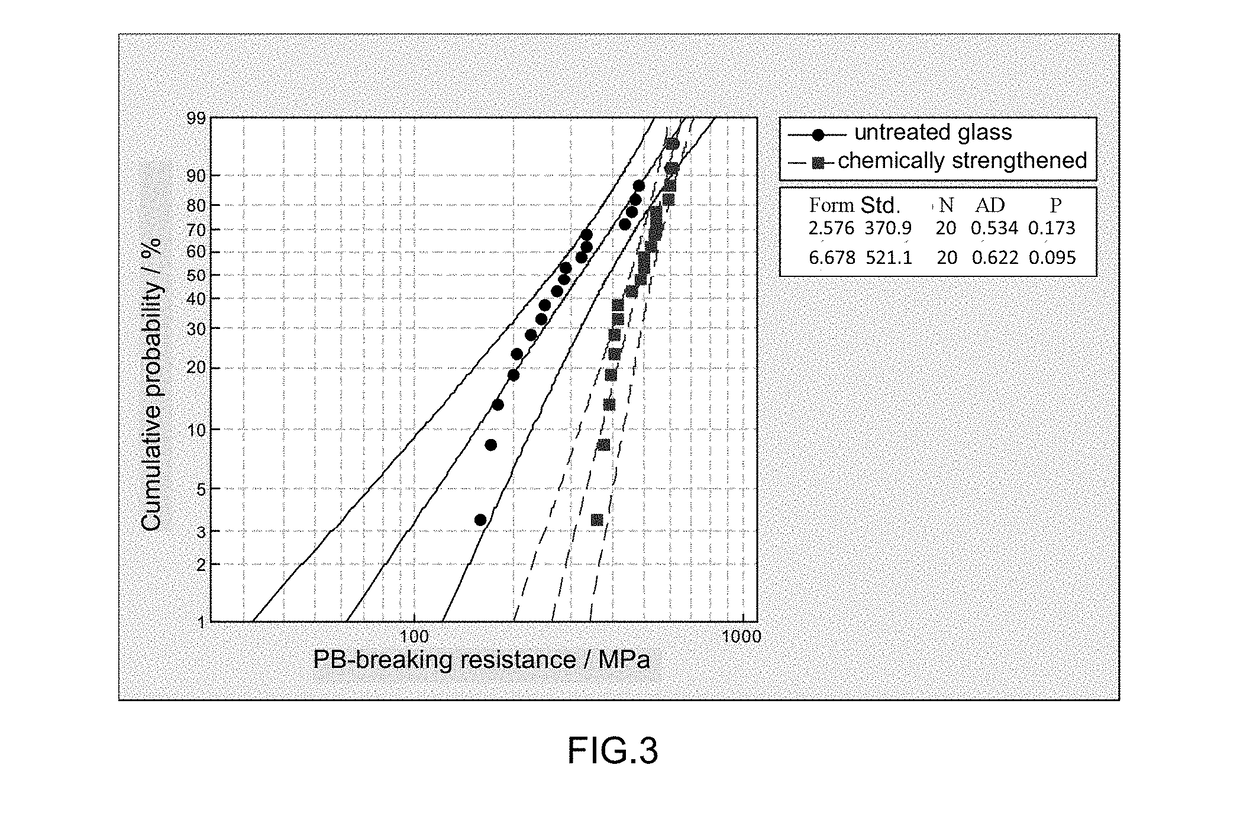

A coated chemically strengthened flexible thin glass includes a coating of an adhesive layer in the form of a silicon mixed oxide layer, which contains or consists of a silicon oxide layer in combination with at least one oxide of aluminum, tin, magnesium, phosphorus, cerium, zirconium, titanium, cesium, barium, strontium, niobium, zinc, or boron, and magnesium fluoride, such as at least aluminum oxide.

Owner:SCHOTT AG

Polycarbonate system having enhanced weatherability and method of making same

InactiveUS20070104956A1Enhanced abrasion resistance and ultraviolet resistance featureGood weather resistanceSynthetic resin layered productsVehicle componentsExtinctionUltraviolet

A polycarbonate system having enhanced weatherability is disclosed. The polycarbonate system comprises a substrate comprising a first surface and a second surface, a primer disposed on the first surface of the substrate, and a top coat disposed on the primer on the first surface for abrasion resistance. At least one of the primer and the top coat comprises an ultraviolet absorber in a solvent for ultraviolet absorption, the ultraviolet absorber having an extinction coefficient of ≧45,000 L-mol−1 cm−1 at λ=325 nm.

Owner:EXATEC LLC

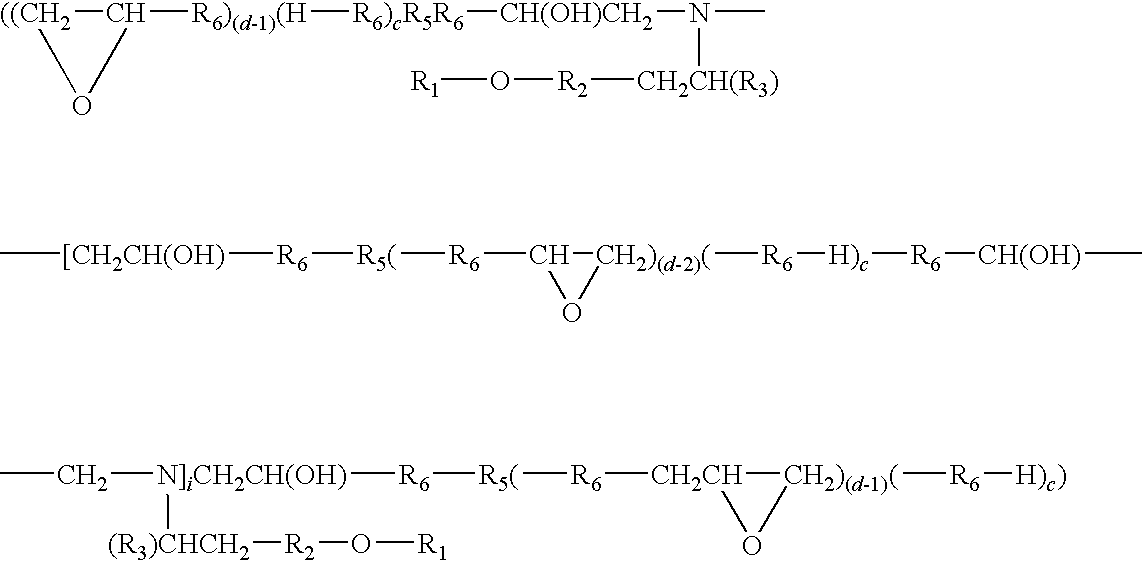

Aqueous two-component or multicomponent aqueous epoxy resin primer composition

InactiveUS20110027591A1Improve adhesionAdhesive processesSynthetic resin layered productsEpoxyAminosilochrome

The invention relates to two-component or multicomponent aqueous epoxy resin primer compositions comprising a first component, a second component, and an optional other component. The first component contains at least water and an epoxy resin while the second component contains at least one polyamine. The composition also comprises carbon black and / or epoxy silane and / or epoxy siloxane and / or an amino silane and / or an amino siloxane and / or mercaptosilane. The aqueous epoxy resin primer compositions improve adhesion of moisture-curing polyurethane adhesives or sealants on various bases.

Owner:SIKA TECH AG

Aqueous primer coating composition and article coated therewith

InactiveUS6344500B1Improve adhesionExcellent in gasohol resistanceEpoxy resin coatingsPolyester coatingsEmulsionPigment dispersion

The present invention provides: an aqueous primer coating composition of which the deterioration of the water resistance is prevented with the high adhesion maintained, and which is excellent in the gasohol resistance and the pigment dispersion stability; and a thing coated with this aqueous primer coating composition. The aqueous primer coating composition according to the present invention, comprises acid anhydride-modified poly(olefin chloride) emulsion resin (A), aqueous alkyd resin (B) and aqueous novolac-type epoxy resin (C), wherein the contents of the (A), (B), and (C) are (A) 20 to 60 weight %, (B) 10 to 60 weight %, and (C) 10 to 60 weight % in terms of solid content weight % to the total resin solid content in the composition. The coated thing, according to the present invention, is coated with the present invention aqueous primer coating composition.

Owner:HONDA MOTOR CO LTD +1

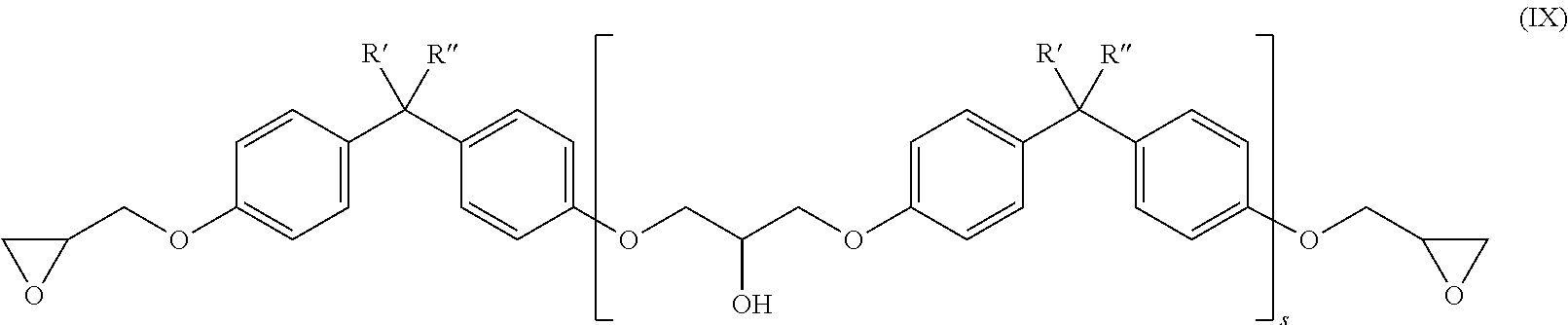

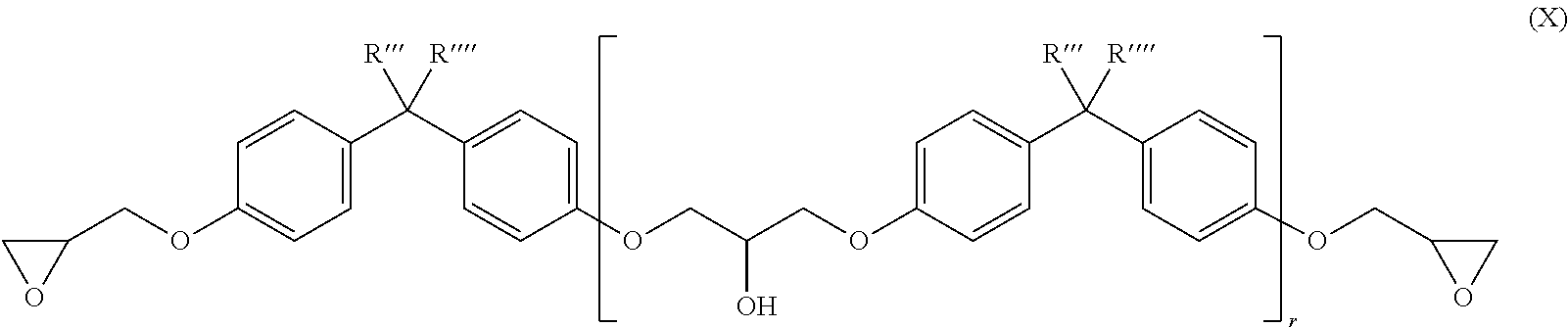

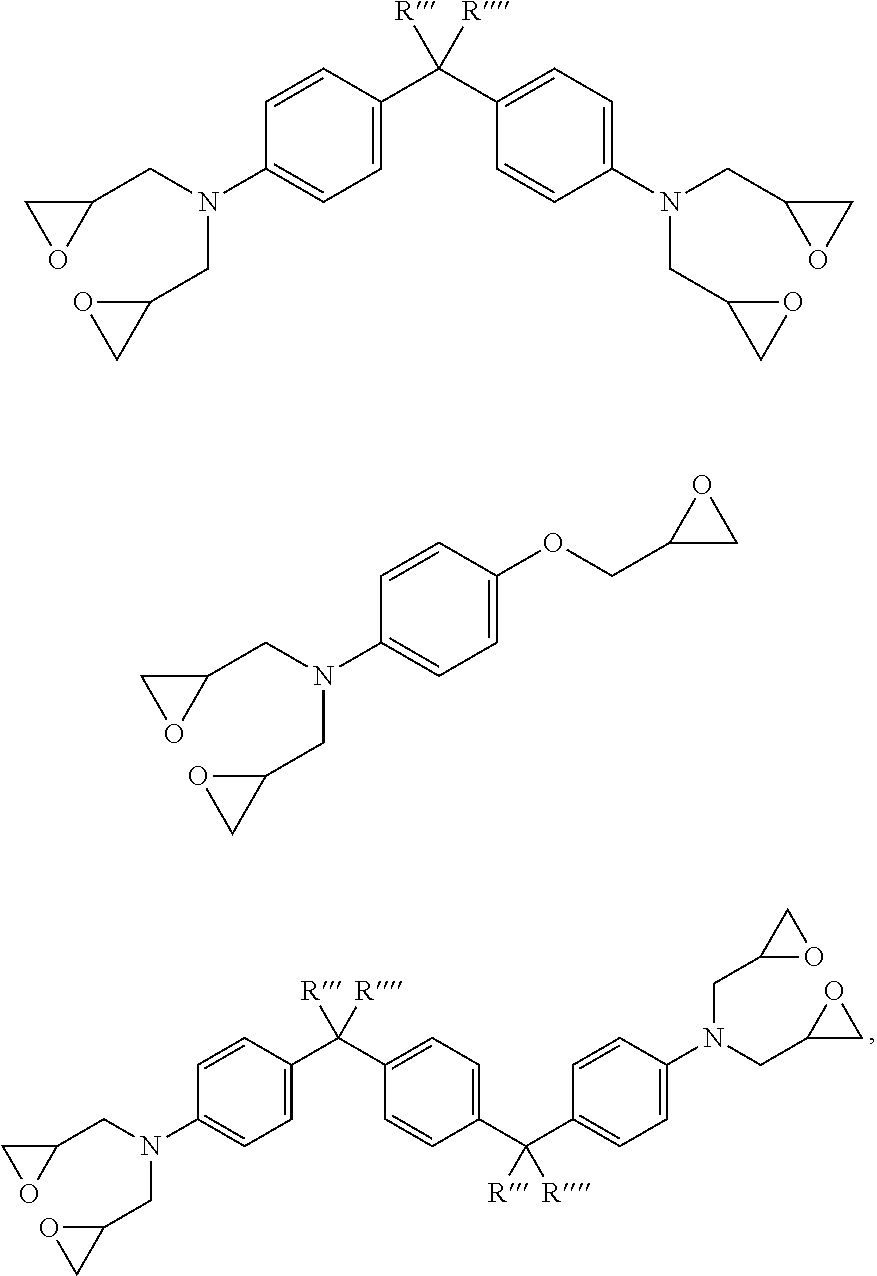

Polymer compositions and coatings for food and beverage packaging

ActiveUS20160122581A1Network stabilityPackaging corrosive chemicalsLinings/internal coatingsCross-linkCyclic ether

The present disclosure relates to coatings and coating compositions that are substantially free of bisphenol A (BPA) and similar compounds, which help reduce or minimize flavor loss associated with foods or beverages stored in contact with the coating compositions. In one aspect, the composition can include the reaction products of an intimate mixture of cyclic ether resins and acrylate resins, which provides a unique cross-linked and interpenetrating network of polmers.

Owner:THE COCA-COLA CO

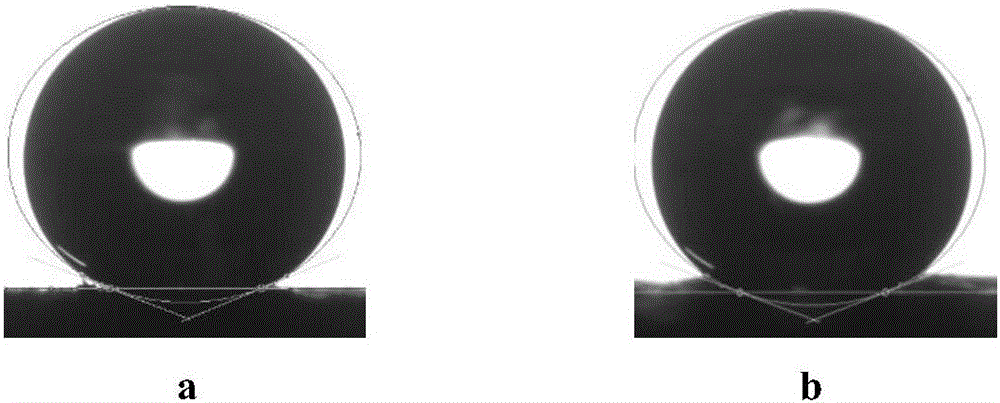

Super-wear-resisting super-hydrophobic coating and preparation method thereof

ActiveCN106398334AHigh strengthHigh hardnessPolyurea/polyurethane coatingsPriming paintsSilica nanoparticlesNon solvent

The invention discloses super-wear-resisting super-hydrophobic coating and a preparation method thereof; the coating is prepared by: stirring well and dispersing non-solvent aliphatic polyether polyol resin, micro-powder granules, 2,4-toluenediisocyanate and fumed silica nanoparticles, applying to the surface of a substrate by brushing or spraying technology, roughing the surface after full curing, spraying, brushing or dipping super-hydrophobic nano coating to the surface of resin primer, and naturally drying. The super-wear-resisting super-hydrophobic coating and the preparation method thereof have the advantages that the equipment and process are simple, operating is easy, and the cost is low; and have industrial scale production prospect. The super-wear-resisting super-hydrophobic coating prepared herein features high bonding force, high hardness and the like, is capable of bearing destruction from external forces such as high pressure friction, and is applicable to the fields, such as building, shipping, naval craft, aircrafts, automobiles, high-speed railway, and wind generators.

Owner:SOUTHEAST UNIV

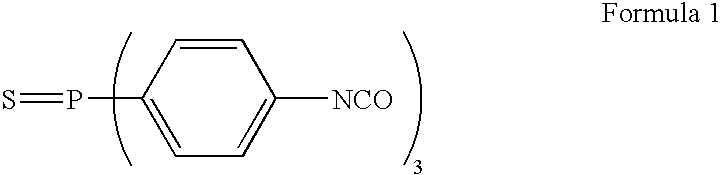

One component glass primer including oxazoladine

Improved long open time one component primer compositions for bonding substrates, methods and the articles made therefrom. The primer compositions include an ingredient including an oxazolidine ring or derivative or analog thereof.

Owner:DOW GLOBAL TECH LLC

Radiation refrigeration functional coating and application thereof

ActiveCN110896639AHigh mechanical strengthGood weather resistanceLuminescent paintsBuild-up roofsUltraviolet lightsNear infrared light

The invention relates to a radiation refrigeration functional coating and an application thereof. The radiation refrigeration functional coating is used for preparoing a radiation refrigeration function layer. The radiation refrigeration function layer is used for reflecting ultraviolet light and / or visible light and / or near infrared light in sunlight and emitting heat through an atmosphere windowin an infrared radiation mode, the radiation refrigeration function layer comprises a particle filler and radiation refrigeration function resin, and the particle filler is distributed in the radiation refrigeration function layer resin.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD +1

Primer compositions for adhesive bonding systems and coatings

ActiveUS20100285309A1Improve the immunityLong lasting resistanceSynthetic resin layered productsPretreated surfacesEpoxySelf emulsifying

The present invention relates to aqueous-based primer composition, comprising at least one thermosetting, self-emulsifying epoxy resin composition; at least one thermosetting, non-self-emulsifying resin composition; water; and at least one curative.

Owner:HENKEL KGAA

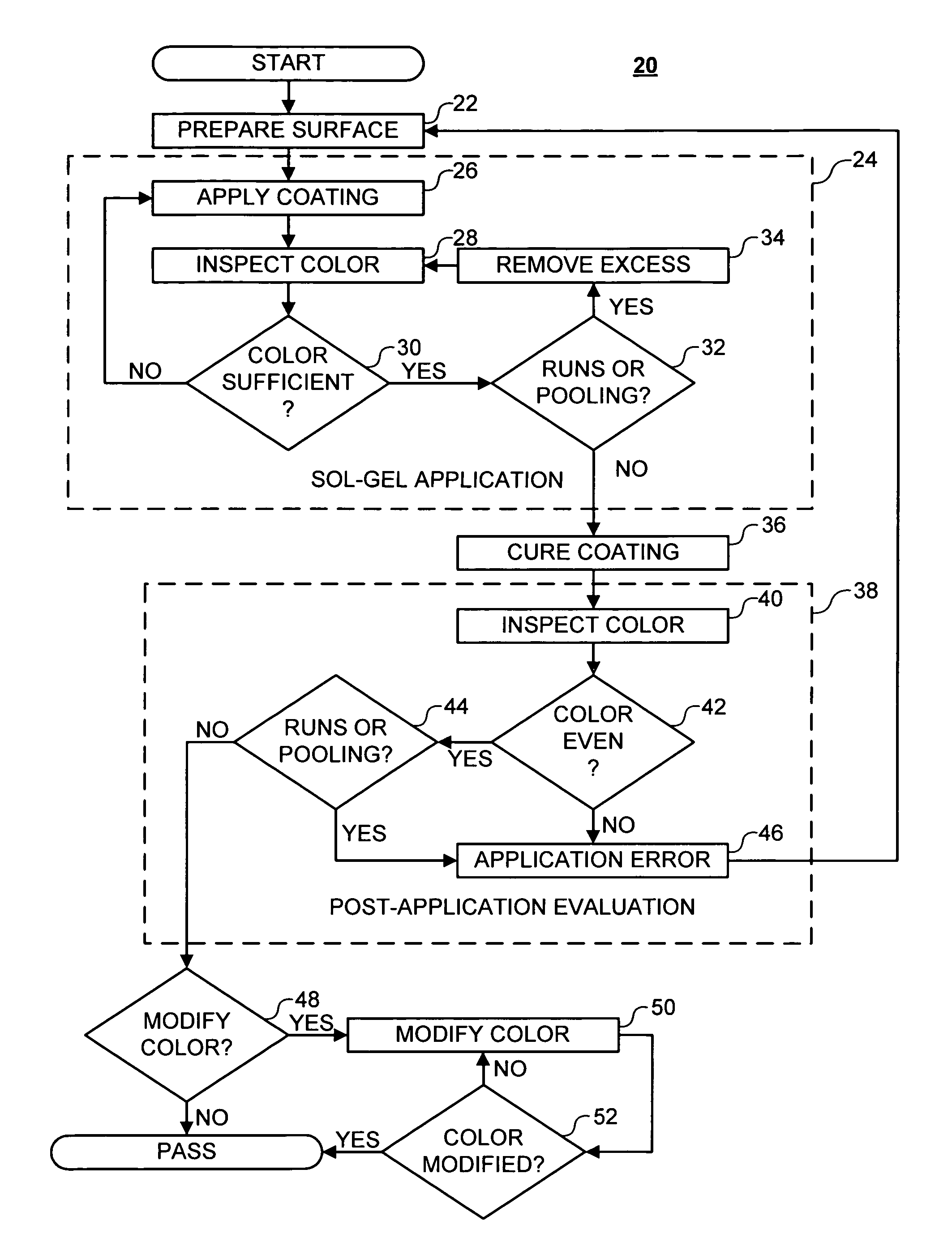

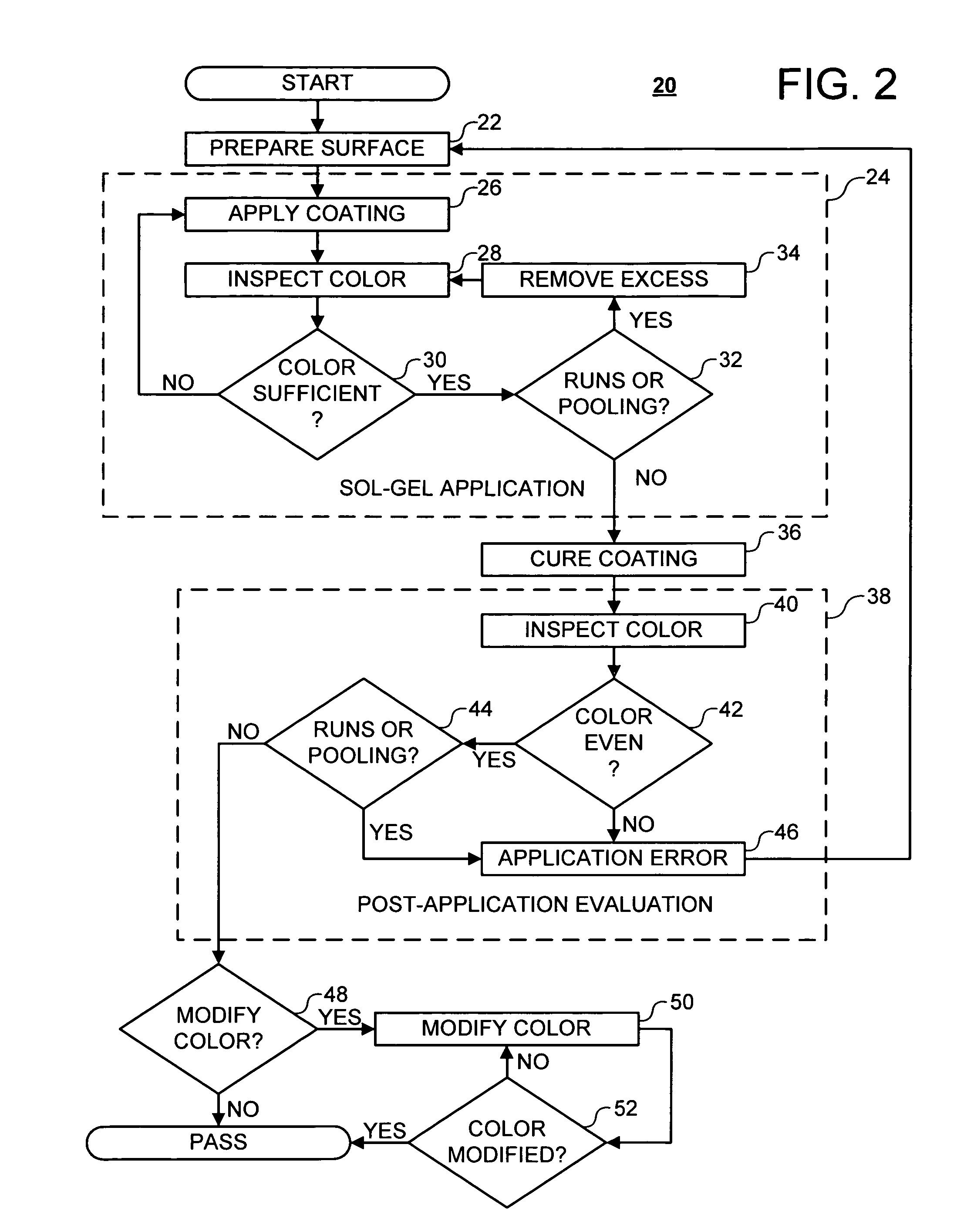

Colored coating and formulation

ActiveUS20070044704A1Easy to determineEqually distributedBleaching apparatusAnti-corrosive paintsEngineeringCoating

Owner:THE BOEING CO

Water-based coating composition and method of forming multilayered coating film

ActiveUS20110300389A1Suppress surface roughnessInhibit swellingSynthetic resin layered productsPretreated surfacesWater basedEmulsion

An object of the present invention is to provide an aqueous coating composition with excellent finished appearance and removability in bell cleaning, and a method for forming a multilayer coating film having excellent smoothness by a 3-coat-1-bake method including successively applying an aqueous first colored coating composition, an aqueous second colored coating composition, and a clear coating composition to a substrate, and heat-curing the resulting three layers of the multilayer coating film all at once. The present invention provides an aqueous coating composition containing an acrylic resin (A), a curing agent (B), and a urethane resin emulsion (C) with a weight average molecular weight of 2,000 to 50,000, the urethane resin emulsion (C) being prepared using constituent components containing a polyisocyanate component and a polyol component as starting materials, wherein the polyisocyanate component contains an alicyclic diisocyanate, and the polyol component contains a polycarbonate diol in an amount of 50 mass %, based on the total amount of the polyol component.

Owner:KANSAI PAINT CO LTD

Slow-release inhibitor for corrosion control of metals

ActiveUS20060091354A1Reduce hydrophilicityImprove hydrophobicityOther chemical processesSynthetic resin layered productsSimple Organic CompoundsDiffusion

The present invention provides for a slow-release inhibitor that is applied to a metal surface, such as by way of a paint or primer coating, for corrosion control of the metal. An exemplary embodiment of the slow-release corrosion inhibitor includes a water-soluble particle, or pigment, and an organic polymeric film that encapsulates the particle. This water-soluble particle may be either organic or inorganic and, preferably, is non-carcinogenic and non-toxic. An additional water-soluble particle having an encapsulating, organic polymeric film further may be provided along with a water-soluble, organic compound to form the corrosion inhibitor. The polymeric film(s) are of a desired hydrophobicity and permeability to permit, upon interaction of the particle(s) with water, controlled diffusion of particle ions therethrough.

Owner:UNIVERSITY OF CINCINNATI

Resin dispersion, coating materials, laminates, and process for production of the same

InactiveUS20090092847A1Good dispersionAvoid bleedingSynthetic resin layered productsSpecial tyresPolymer sciencePolyolefin

To provide an aqueous dispersion of a resin wherein dispersed particles are stable with fine particle sizes and whereby bleeding out is suppressed, which is thus useful as e.g. a surface treating agent, an adhesive or a coating material for a polyolefin substrate.A resin dispersion having, dispersed in water with a 50% particle diameter of at most 0.5 μm, a polymer (C) having a hydrophilic polymer (B) or an acidic group bonded to a propylene / α-olefin copolymer (A) as a copolymer of propylene with an α-olefin other than propylene, wherein the copolymer (A) has a propylene content of at least 50 mol % and less than 100 mol %, and the copolymer (A) has a weight average molecular weight Mw of at least 10,000 and a molecular weight distribution Mw / Mn of at most 3.5; and the resin dispersion has a surfactant content of at most 15 parts by weight per 100 parts by weight of the polymer (C); and a coating material or laminate, made by using such a dispersion.

Owner:MITSUBISHI CHEM CORP

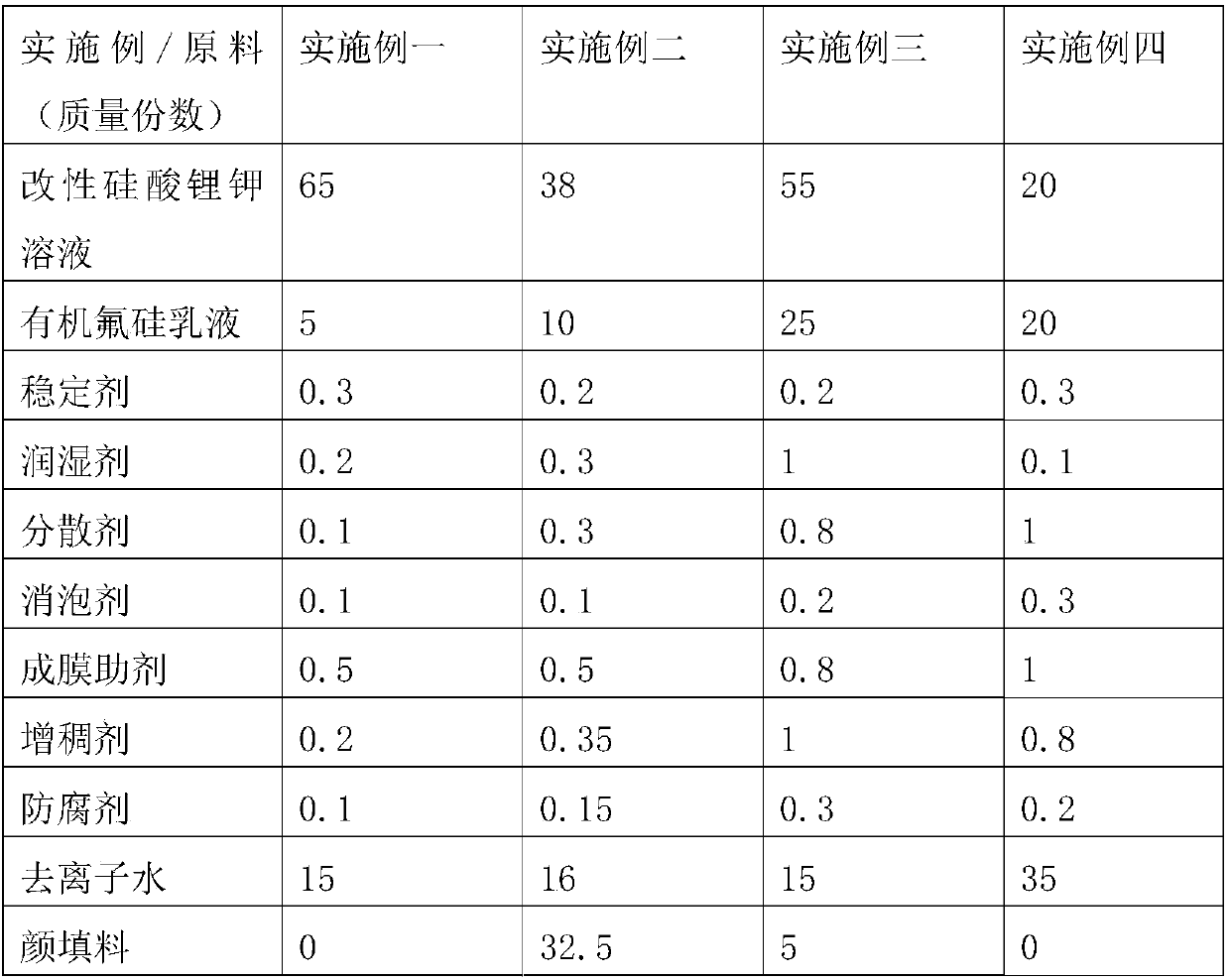

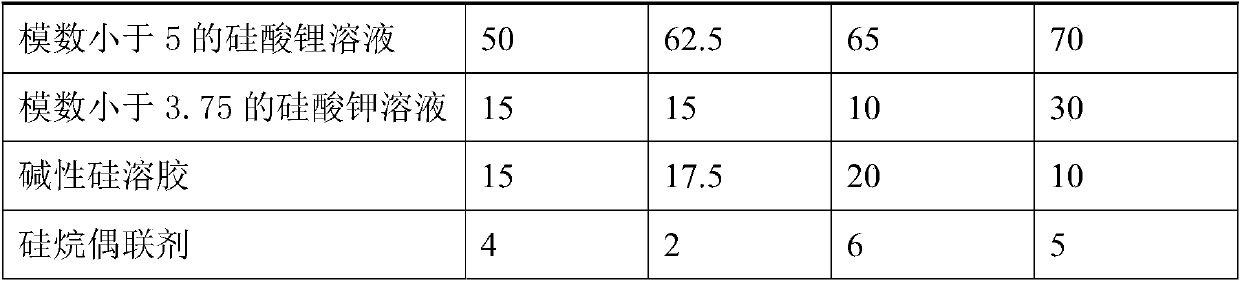

Inorganic potassium lithium silicate solution composite organic fluorosilicone coating and preparation method thereof

ActiveCN107779090AImprove permeabilityExcellent weather resistance and stain resistanceAntifouling/underwater paintsPaints with biocidesSilicic acidPotassium silicate

The invention discloses an inorganic potassium lithium silicate solution composite organic fluorosilicone coating which is prepared from, by weight, 20-65 parts of modified potassium lithium silicatesolution, 5-25 parts of organic fluorosilicone emulsion, 0.2-0.3 part of stabilizing agents, 0.1-1 part of wetting agents, 0.1-1 part of dispersing agents, 0.1-0.3 part of defoaming agents, 0.5-1 partof coalescing agents, 0.2-1 part of thickening agents, 0.1-0.3 part of preservative and 15-35 parts of deionized water. The invention further discloses a preparation method of the coating. Low-modulus lithium silicate and potassium silicate mixed solution and basic silica sol serve as main raw materials, organic silane coupling agents serve as modifying agents, so that stable potassium lithium silicate mixed solution is prepared, the stable potassium lithium silicate mixed solution and the organic fluorosilicone emulsion are coldly spliced and combined to serve as film-forming materials of the coating, pigments, fillers and various additives are added, and a multifunctional inorganic and organic fluorosilicone composite system coating is prepared. The coating is wide in application, and acoating film is excellent in physical and chemical performance.

Owner:固克节能科技股份有限公司

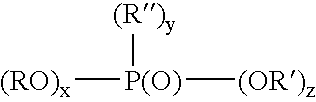

Coating composition for plastic substrates

InactiveUS20050271882A1Lessens need to flexibilizeSynthetic resin layered productsPretreated surfacesPolyolefinAlcohol

A coating composition for coating plastic substrates is disclosed which comprises at least one hydroxyl-functional film forming polymer, at least one polyisocyanate compound; and a novel adhesion promoter additive. The adhesion promoter additive comprises (A) at least one modified polyolefin; and (B) at least one component selected from the group consisting of monohydric alcohols, epoxy functional silanes, and mixtures thereof. The invention also relates to coated plastic substrates and method of coating such substrates.

Owner:AKZO NOBEL COATINGS INT BV

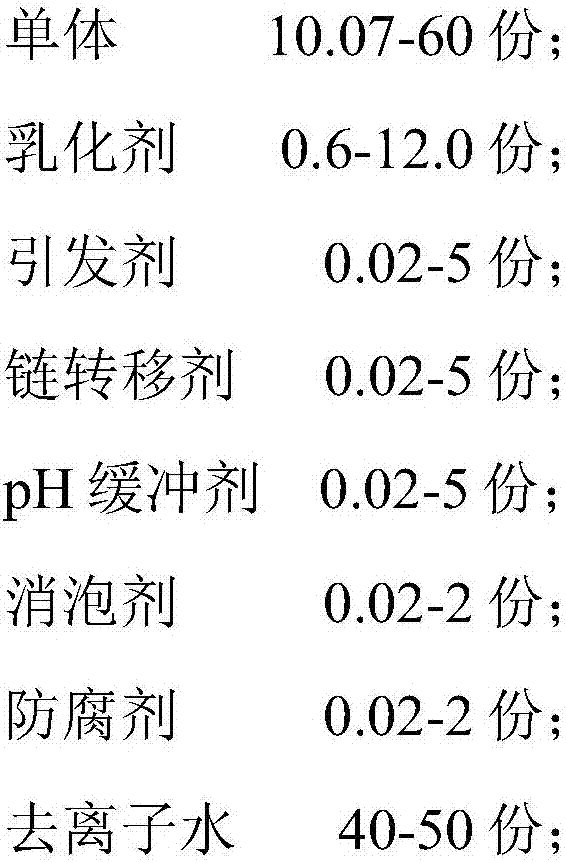

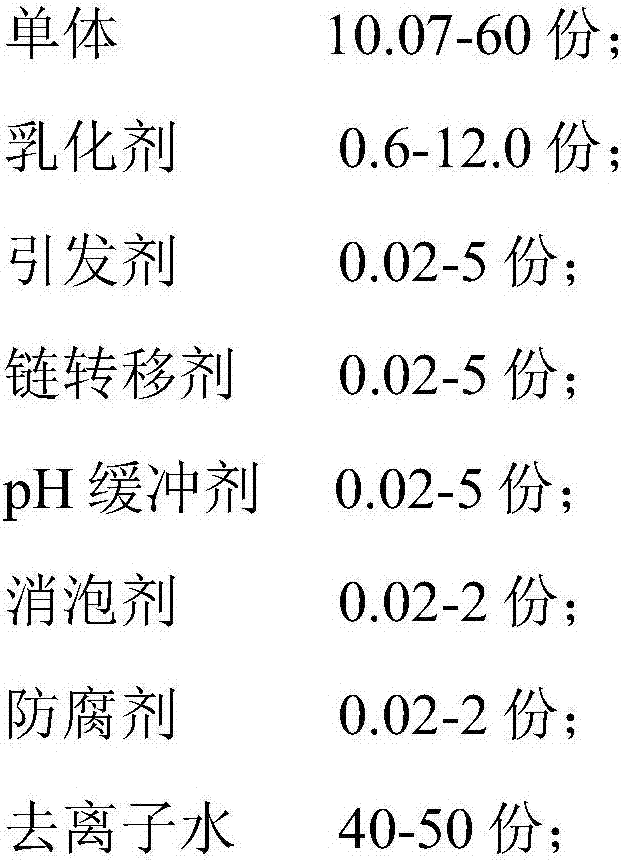

Primer emulsion and preparation method and application thereof

The invention relates to the technical field of building coatings, and particularly discloses a primer emulsion and a preparation method and application thereof. The primer emulsion is prepared from the following raw material components in parts by mass: 10.07 to 60 parts of monomers, 0.6 to 12.0 parts of emulsifier, 0.02 to 5 parts of initiator, 0.02 to 5 parts of chain transfer agent, 0.02 to 5 parts of pH (potential of hydrogen) buffer agent, 0.02 to 2 parts of defoaming agent, 0.02 to 2 parts of preservative, and 40 to 50 parts of deionized water, wherein the monomers comprise main monomer, polarity monomer, and self-crosslinking monomer. The primer emulsion is applied to the field of bottom-sealing coatings. The bottom-sealing coating prepared by the primer emulsion has the advantages that the particle size distribution is narrow, the particle size is more uniform, and the hardness, adhesion force, water permeating property and the like of the paint film are excellent.

Owner:HENGSHUI XINGUANG CHEM

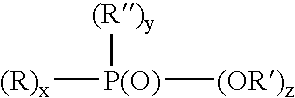

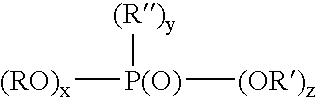

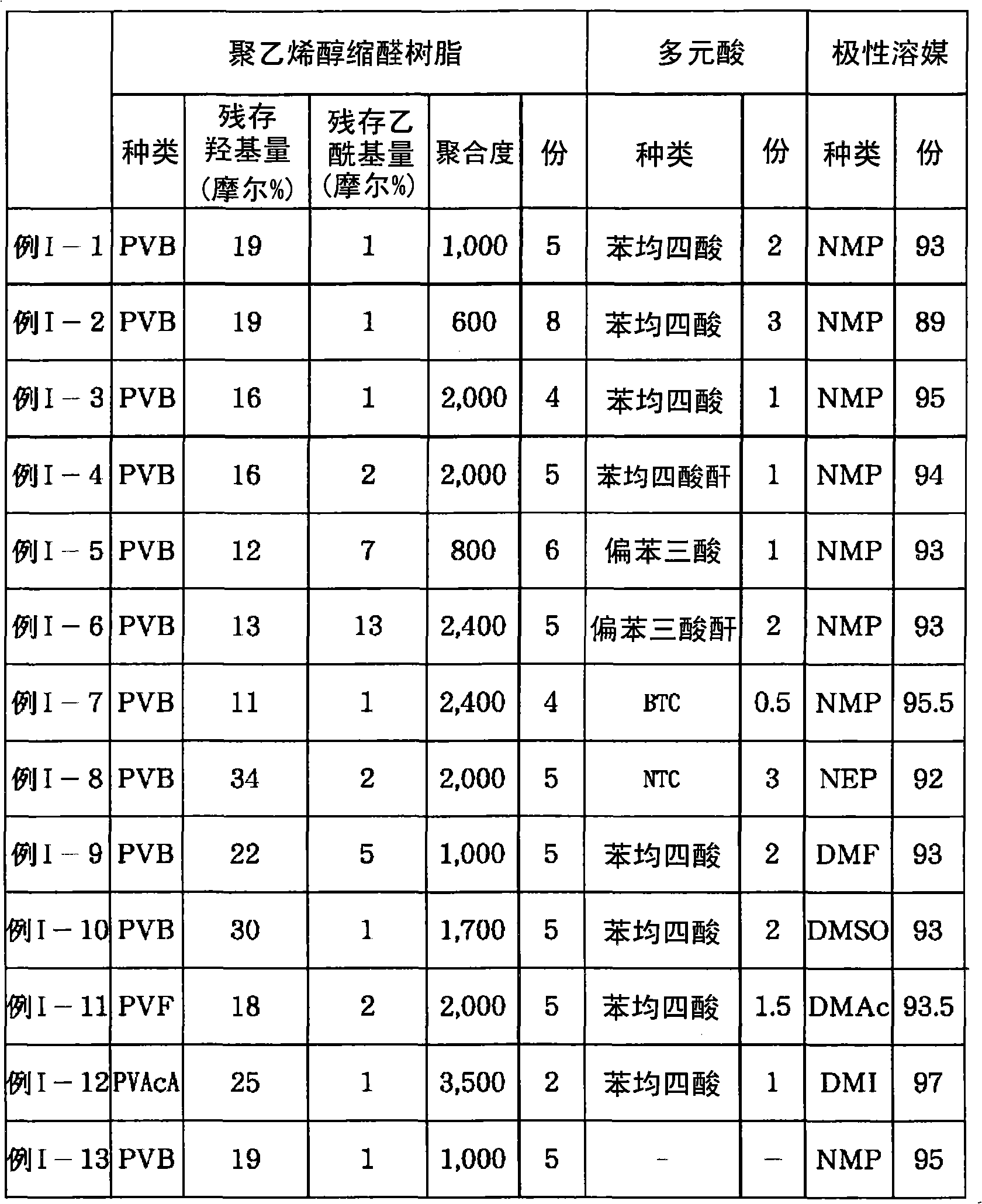

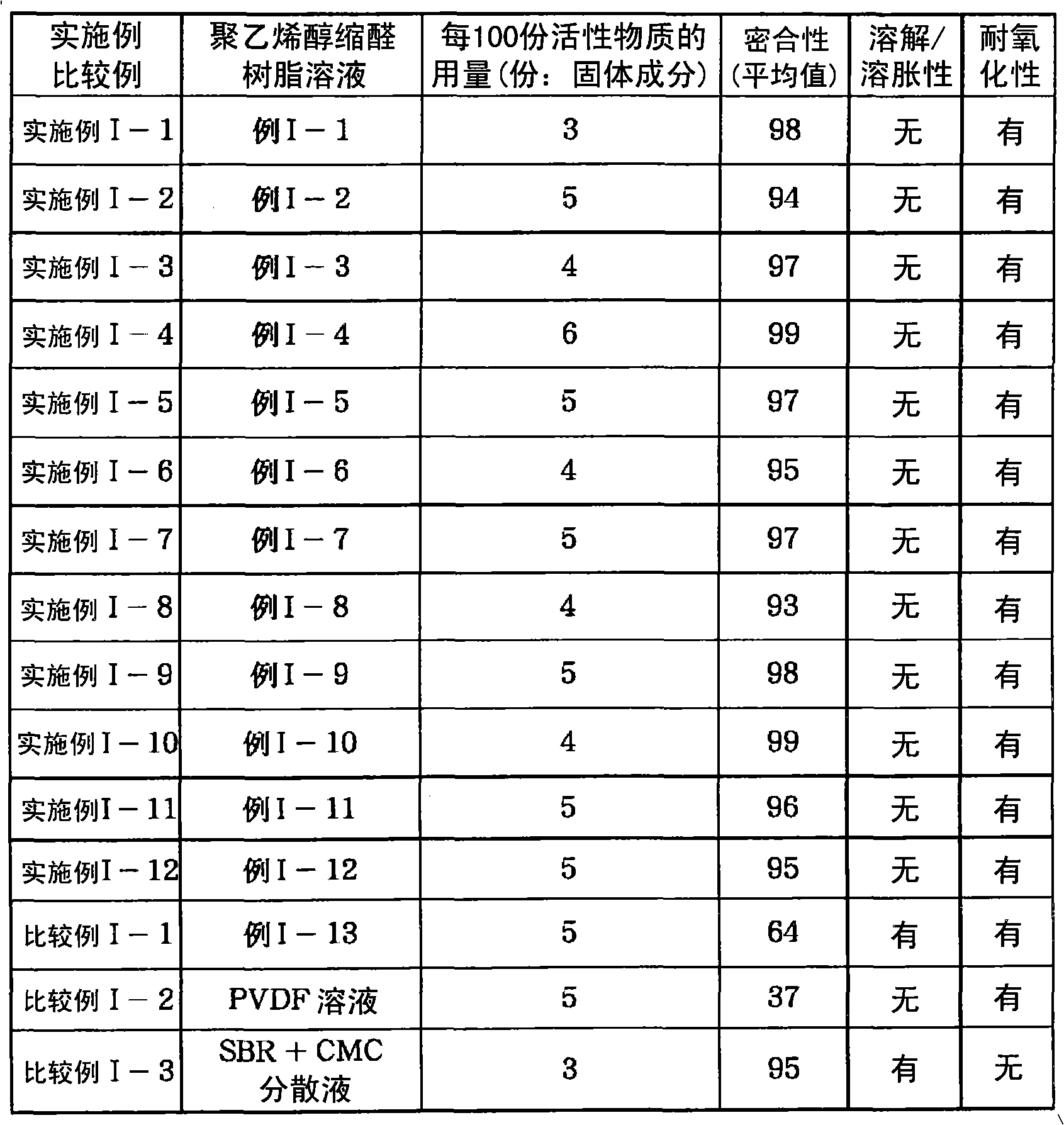

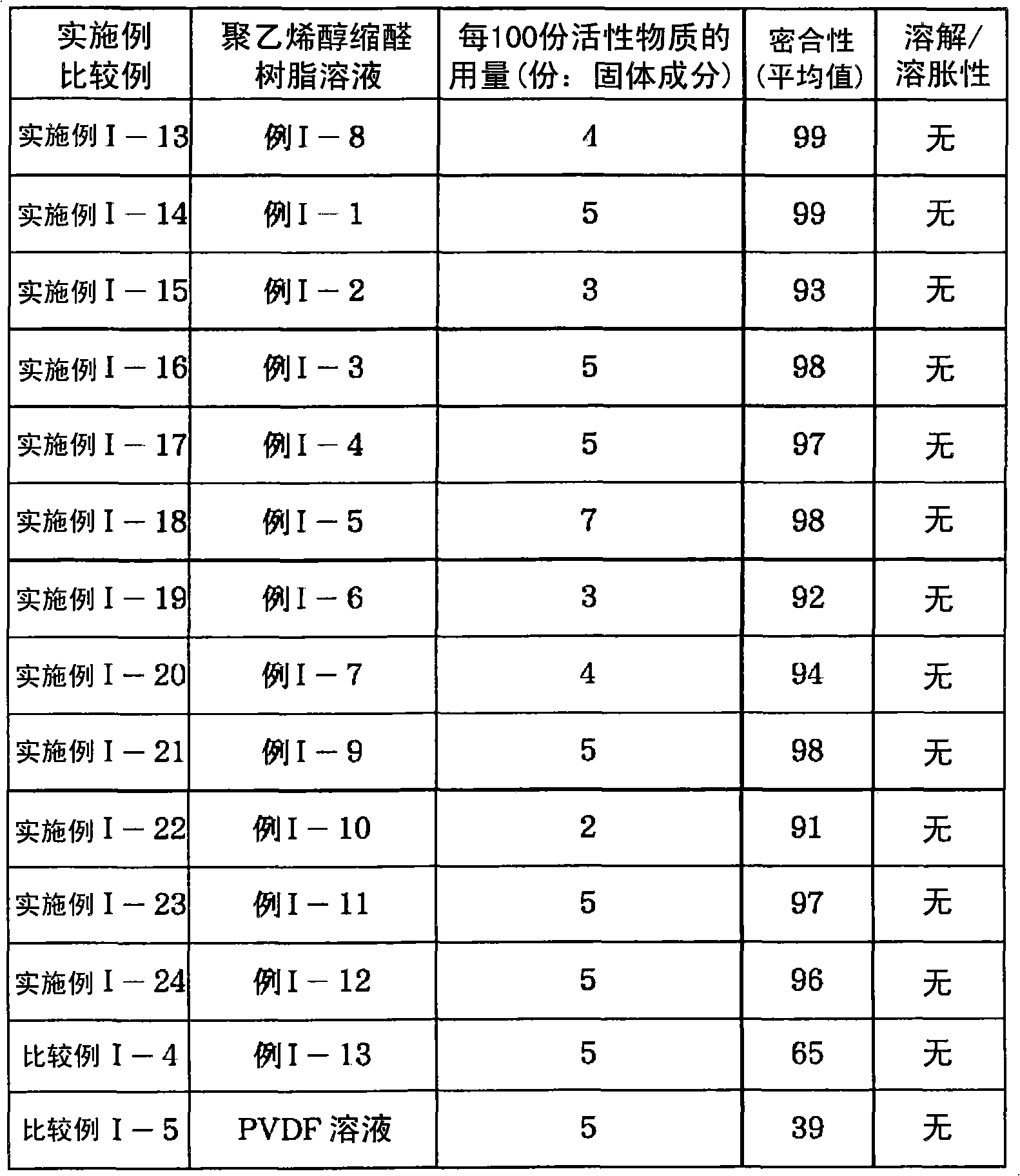

Coating liquid, coating liquid for manufacturing electrode plate, undercoating agent, and use thereof

InactiveCN102046742AExcellent adhesionGood solvent resistanceElectrode thermal treatmentHybrid capacitor electrodesMetallic materialsCopper foil

Disclosed is a coating liquid characterized by comprising a hydroxyl group-containing resin, an organic acid and / or a derivative thereof contained in a polar solvent, the hydroxyl group-containing resin being at least one resin selected from (1) polyvinyl acetal resins, (2) ethylene-vinyl alcohol copolymers, (3) unmodified and / or modified polyvinyl alcohols, and (4) cyanoethyl group-containing polymers. Also disclosed are a coating liquid for manufacturing an electrode plate, an undercoating agent, and use thereof. The coating liquid capable of forming a film, which has excellent adhesion and solvent resistance, on the surface of a metal material such as an aluminum material can be provided. Furthermore, a coating liquid for manufacturing an electrode plate for a battery or a polarizing electrode plate for a capacitor comprising an active material layer having excellent adhesion and electrolyte resistance to a current collector formed of, for example, an aluminum foil or a copper foil and having an improved contact resistance to the current collector, an undercoating agent, an electrode plate; a method for manufacturing the electrode plate, a battery, and a capacitor can be provided.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

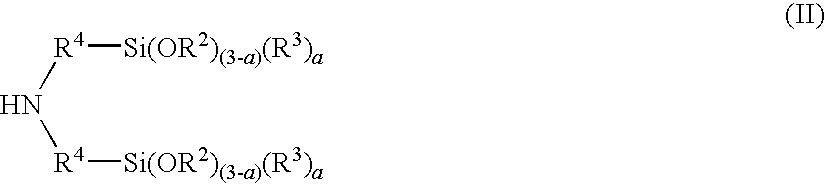

Low-temperature adhesive undercoat composition

InactiveUS20100043945A1Good adhesion promotionAdhesive processes with surface pretreatmentLaminationAdhesiveAdduct

A method for producing an adhesive undercoat on a substrate S1 with a substrate temperature of lower than 5° C. The adhesive undercoat composition comprises at least one mercaptosilane MS or an adduct of mercaptosilane and either at least one polysilane PSA, comprising at least one secondary or tertiary amino group, or at least one polysilane PS and at least one aminosilane AS, comprising at least one secondary or tertiary amino group. This method is particularly suited for the gluing of glass, particularly of glass ceramics, preferably for repairing windows of motor vehicles in cold temperatures.

Owner:SIKA TECH AG

Composition of a thermaly insulating coating system

InactiveUS8287998B2High infrared reflectivityReduce absorptionPigmenting treatmentCeramic layered productsParticulatesCoating system

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Water-based primer composition

Provided is a water-based primer composition, which is characterized in that it comprises: (A) an aqueous dispersion of a chlorine-free modified polyolefin, the dispersion being obtained by dispersing in an aqueous medium a polyolefin (a) modified with an unsaturated carboxylic acid or an acid anhydride, the modified polyolefin (a) having a melting point of 120 DEG C or lower and a weight-average molecular weight of 50,000 to 150,000; (B) a water-soluble or water-dispersible polyol resin; and (C) a pigment, and that the ingredient (A) / ingredient (B) weight ratio is from 20 / 80 to 85 / 15 on a solid basis and the ingredient (C) is contained in an amount of 0.5-200 parts by weight per 100 parts by weight of all solid resins in the composition. Also provided is a method of coating a plastic molding with the water-based primer composition.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com