Primer emulsion and preparation method and application thereof

A technology of emulsion and primer, applied in the direction of primer, coating, etc., can solve the problems of poor film compactness, poor sealability, poor water permeability, etc., and achieve high viscosity, narrow particle size distribution, excellent paint film compactness and surface The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In one embodiment, the preparation method at least includes the following steps:

[0048] Step 1, taking each component according to the above-mentioned raw material ratio;

[0049] Step 2, divide the long-chain reactive emulsifier into a first reactive emulsifier and a second reactive emulsifier, divide the deionized water into the first deionized water, the second deionized water, and the third deionized water and the fourth deionization;

[0050] Step 3, dissolving the emulsifier: dissolving the first reactive emulsifier and the short-chain reflective emulsifier with the first deionized water to obtain an emulsifier solution;

[0051] Step 4, dissolving of initiator: the initiator is divided into the first initiator and the second initiator, then the first initiator is dissolved in the second deionized water to form the first initiator solution, and the second initiator is dissolved in In the third deionized water, a second initiator solution is formed;

[0052] Ste...

Embodiment 1

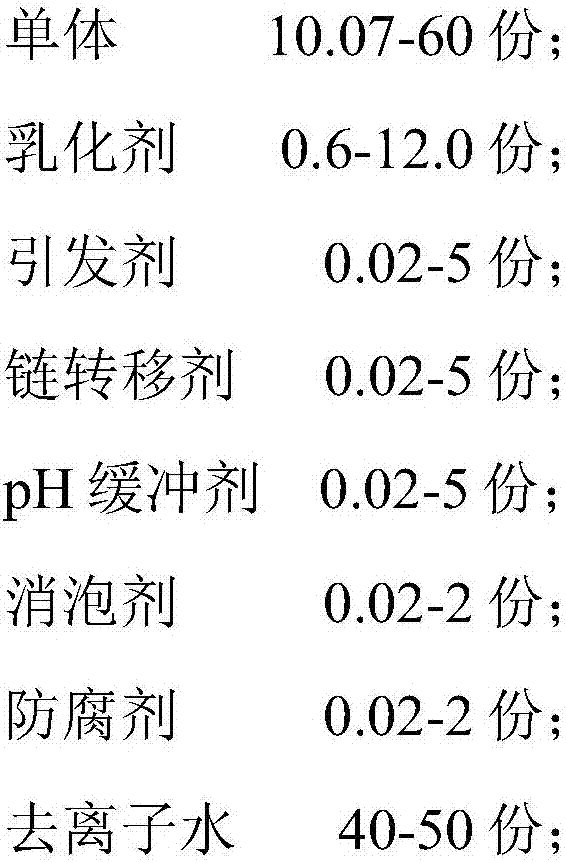

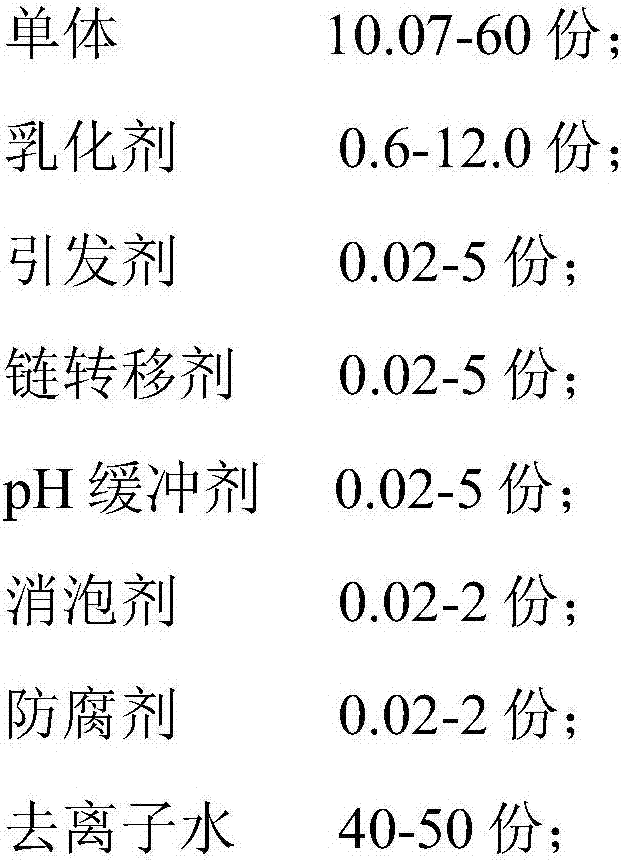

[0064] The invention provides a primer emulsion, comprising the following raw material components in parts by mass: deionized water: 53.18 parts, sodium bicarbonate: 0.07 parts, isomerized tridecanol polyoxyethylene ether TO-8: 0.1 parts, not Saturated allyl alkyl ammonium sulfate SR-10: 0.9 parts, potassium persulfate: 0.2 parts, vinyltriethoxysilane: 0.2 parts, SIPOMER PAM100: 0.4 parts, butyl acrylate: 37 parts, styrene: 13.5 parts, sodium allyloxy hydroxysulfonate: 0.3 parts, hydroxyethyl acrylate: 2.4 parts, butyl methacrylate: 1 part, dodecyl mercaptan: 0.1 parts, defoamer: 0.1 parts, anti-corrosion Agent: 0.1 part, liquid caustic soda: 0.45 part.

Embodiment 2

[0066] The invention provides a primer emulsion, which includes the following raw material components in parts by mass: deionized water: 53.18 parts, sodium bicarbonate: 0.07 parts, nonylphenol ethoxylate NE-10: 0.1 parts, unsaturated allyl Alkyl ammonium sulfate SR-10: 0.9 parts, potassium persulfate: 0.2 parts, vinyltriethoxysilane: 0.2 parts, SIPOMER PAM100: 0.4 parts, butyl acrylate: 37 parts, styrene: 13.5 parts, Sodium Allyloxy Hydroxysulfonate: 0.3 parts, Hydroxyethyl Methacrylate: 2.4 parts, Butyl Methacrylate: 1 part, Dodecyl Mercaptan: 0.1 parts, Antifoaming Agent: 0.1 parts, Preservative : 0.1 part, liquid caustic soda: 0.45 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com