Coating liquid, coating liquid for manufacturing electrode plate, undercoating agent, and use thereof

A coating liquid and electrode plate technology, which is applied in the direction of electrode manufacturing, electrode collector coating, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of insufficient adhesion and flexibility of collectors, active material layer Eliminate problems such as peeling and high contact resistance, achieve excellent adhesion and electrolyte resistance, and improve contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] A specific method for preparing the electrode plate coating liquid of the present invention will be described. First, a powdery active material appropriately selected from the materials listed above and a powdery conductive additive used if necessary are added to a coating solution containing a hydroxyl group-containing resin and an organic acid and / or its derivatives in the above ratio. , using conventionally known dispersers such as homogenizers, ball mills, sand mills, and roll mills, or planetary mixers (planetary mixers) for mixing and dispersing, thereby preparing the electrode plate of the present invention. liquid.

[0066] The method for producing an electrode plate of the present invention is characterized by using the above-mentioned coating liquid for an electrode plate of the present invention. As the current collector used to manufacture the electrode plate, for example, as the positive electrode current collector, aluminum, tantalum, niobium, titanium, h...

Embodiment

[0097] Next, an Example and a comparative example are given, and this invention is demonstrated more concretely. In addition, this invention is not limited to these Examples. "Part" or "%" in the text is a mass basis unless otherwise specified.

[0098] [Example (I) using polyvinyl acetal resin]

[0099]

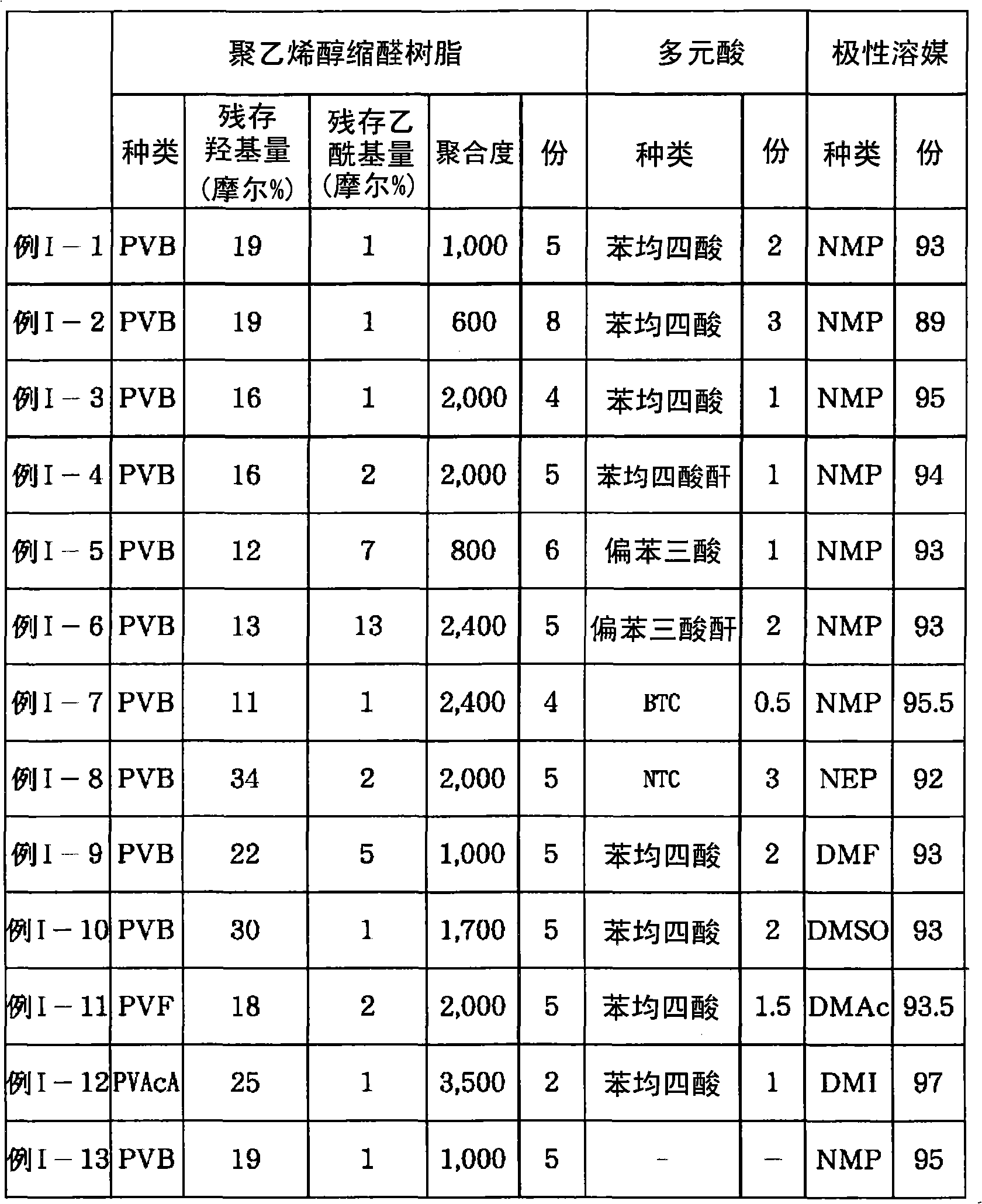

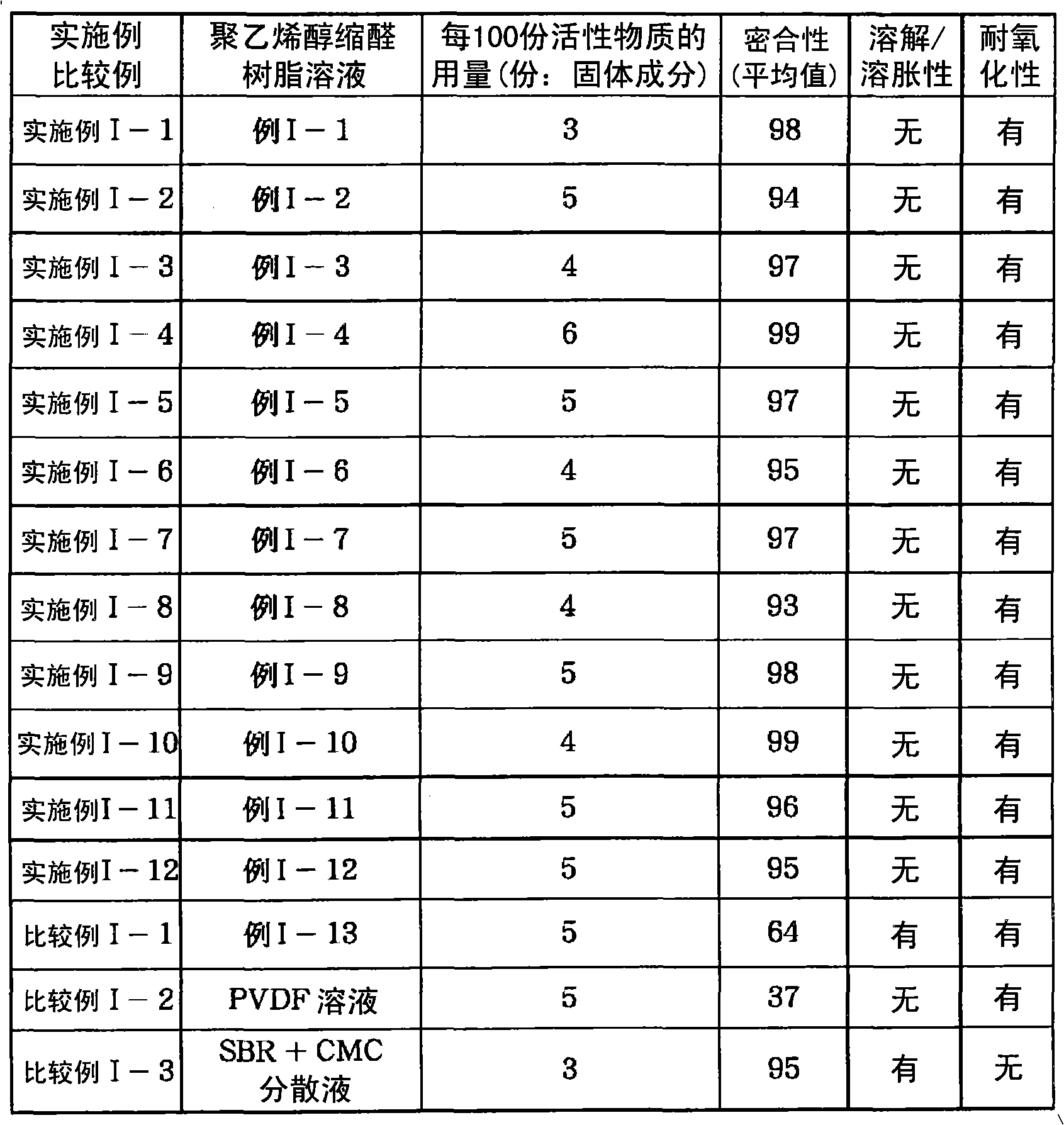

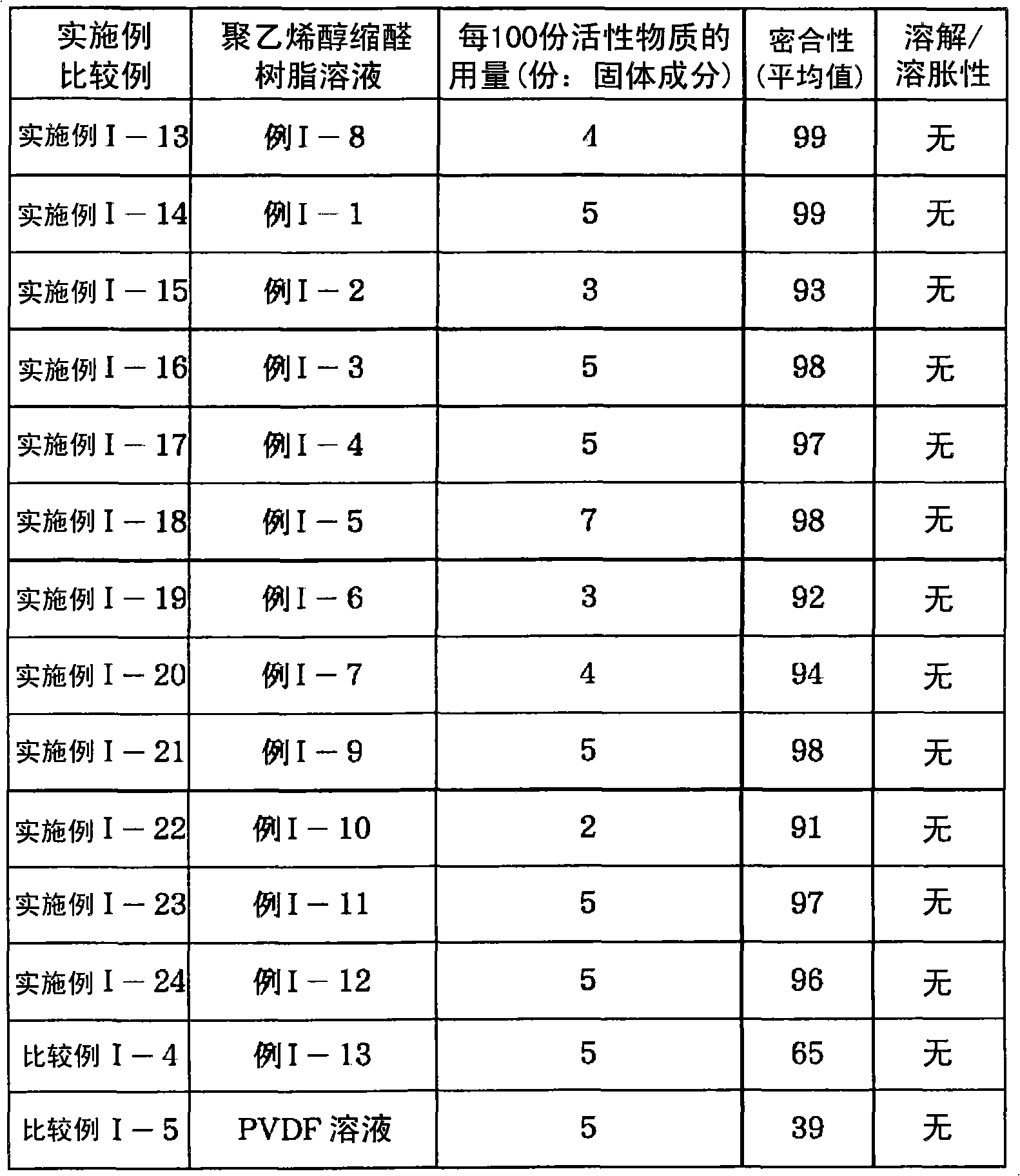

[0100] The composition of each polyvinyl acetal resin solution used in the Example and the comparative example is shown in Table I-1. In addition, regarding the polar solvent used in each polyvinyl acetal resin solution, N-methyl-2-pyrrolidone is abbreviated as NMP, N-ethyl-2-pyrrolidone is abbreviated as NEP, N,N-dimethylformaldehyde Amide is abbreviated as DMF, dimethylsulfoxide is abbreviated as DMSO, N,N-dimethylacetamide is abbreviated as DMAc, and 1,3-dimethyl-2-imidazolinone is abbreviated as DMI.

[0101]

[0102] Disperse polyvinyl butyral resin in 93 parts of NMP [manufactured by Denki Kagaku Kogyo Co., Ltd., DENKA BUTYRAL #4000-2 (the amount of residual hydro...

Embodiment I-1

[0113] Embodiment I-1 (coating solution, electrode plate)

[0114] The positive electrode coating liquid containing the positive electrode active material used in this example was produced by the following method. As the material of the positive electrode coating liquid, 90 parts of LiCoO having a particle size of 1 to 100 μm 2 Powder, 5 parts of acetylene black as a conductive auxiliary agent, 60 parts of the solution of the example I-1 of the above-mentioned Table I-1 as a binder, are stirred and mixed for 120 minutes by a planetary mixer at a speed of 60 rpm, Thus, a slurry-like positive electrode coating liquid containing a positive electrode active material was obtained.

[0115] Using the positive electrode coating solution obtained above, the current collector made of aluminum foil with a thickness of 20 μm is used as a substrate, and after the positive electrode coating solution is applied on one side of the substrate by a comma roll coater, the Dry in an oven at 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com