Super-wear-resisting super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and super-wear-resistant technology, used in coatings, polyurea/polyurethane coatings, primers, etc., can solve problems such as difficulty in use and need to improve wear resistance, saving costs and enhancing decorative effects , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method comprises the following steps:

[0045] (1) Primer preparation: Mix polyether polyol resin and micropowder particles mechanically for 30-60 minutes until uniform, let stand for degassing for 60-120 minutes, then add isocyanate and fumed silica, and stir rapidly for 2-10 minutes until uniform Finally, it is coated on the surface of the substrate by brushing or spraying, and the thickness of the film is set to 0.5 μm to 10 mm through the number of coating passes and the amount of coating, and cured at room temperature for 1 to 2 hours; the cured resin is sandblasted, Grinding with coarse sandpaper or grinding wheel to remove the smooth crust surface to obtain a rough surface, the wear thickness is 0.5-5μm, the high-pressure sandblasting refers to the compressed air pressure of 0.5-1Mpa, the sandblasting is silica sand or corundum, and the particle size is 40-60 mesh ;

[0046] (2) Topcoat preparation: Add hydrophobic nanoparticles or hydrophobically ...

Embodiment 1

[0048] In 100g of solvent-free aliphatic polyether polyol resin, add 50g of sludge powder ( figure 1 a) Stir mechanically for 30 minutes until uniform, let it stand for degassing for 60 minutes, then add 50g of di-tetramethylbenzene diisocyanate and 1g of fumed silica, stir rapidly for 2 minutes until uniform, then brush on the surface of the substrate, and obtain porous after curing at room temperature for 1 hour Rigid polyurethane resin primer ( figure 1 b); Disperse 40g of hydrophobic zinc oxide nanoparticles in 1L of acetone solution, obtain a uniformly dispersed superhydrophobic coating after ultrasonic dispersion and mechanical stirring for 30min, and spray it on the resin surface after high-pressure sandblasting rough treatment, at room temperature After drying, a super-abrasive and super-hydrophobic coating can be obtained, and its surface micromorphology is as follows: figure 1 As shown in c, its water contact angle is 167.3°, and its rolling angle is 2.8°.

Embodiment 2

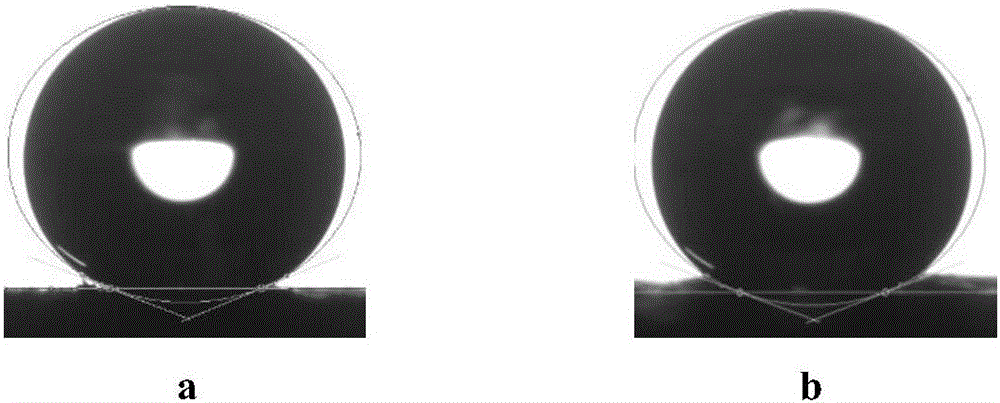

[0050] Add 400g of fly ash to 400g of solvent-free aliphatic polyether polyol resin, stir mechanically for 60min until uniform, let it stand for degassing for 120min, then add 400g of di-tetramethylbenzene diisocyanate and 5g of fumed silica, stir rapidly for 10min until uniform Afterwards, it is brushed on the surface of the substrate, cured at room temperature for 2 hours, and then polished with a grinding wheel to obtain a rough surface; disperse 20g of silicon dioxide hydrophobic nanoparticles with a particle size of 5-200nm in 1L of butyl acetate solution, ultrasonically disperse, and mechanically stir Obtain evenly dispersed superhydrophobic coating after 30min, after brushing it on the above-mentioned rough surface and drying at normal temperature, you can obtain super wear-resistant superhydrophobic coating ( figure 2 a), after the film was rubbed 2000 times by fingers ( figure 2 The water contact angle of b) is 154.3° ( figure 2 c), the rolling angle is 7.6°, or t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com