Epoxy zinc-rich paint

An epoxy zinc-rich coating and coating technology, applied in the field of coatings, can solve the problems of corrosion resistance, chemical resistance and solvent resistance, the impact resistance of coatings, general adhesion and other problems, to achieve excellent adhesion, The effect of excellent anti-rust performance and good film corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the present embodiment, prepare described epoxy zinc-rich paint, by weight, component A contains:

[0033] 75% E-20 Epoxy 5

[0034] Zinc powder 80

[0035] Methyl isobutyl ketone 23,

[0036] Part B contains:

[0037] NX-2018 curing agent 5

[0038] Xylene 60,

[0039] The mass ratio of component A to component B is 2:1.

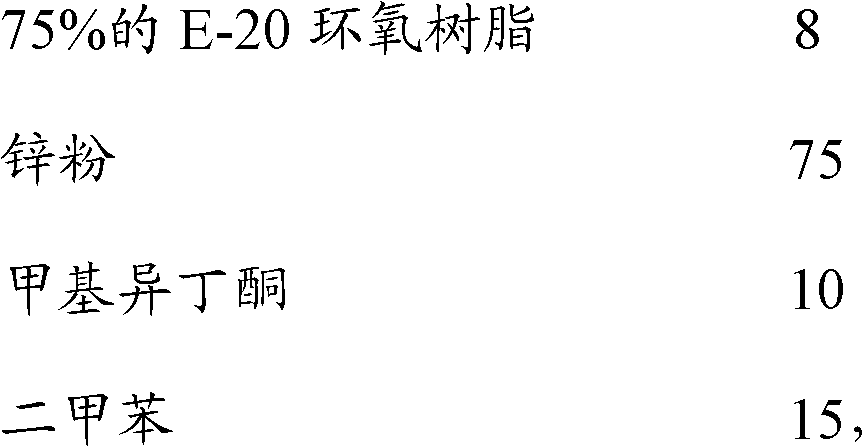

Embodiment 2

[0041] In the present embodiment, to prepare the described epoxy zinc-rich paint, by weight, component A contains:

[0042] 75% E-20 epoxy resin 10

[0043] Zinc powder 60

[0044] Xylene 40,

[0045] Part B contains:

[0046] NX-2018 curing agent 22

[0047] n-Butanol 74,

[0048] The mass ratio of component A to component B is 5:1.

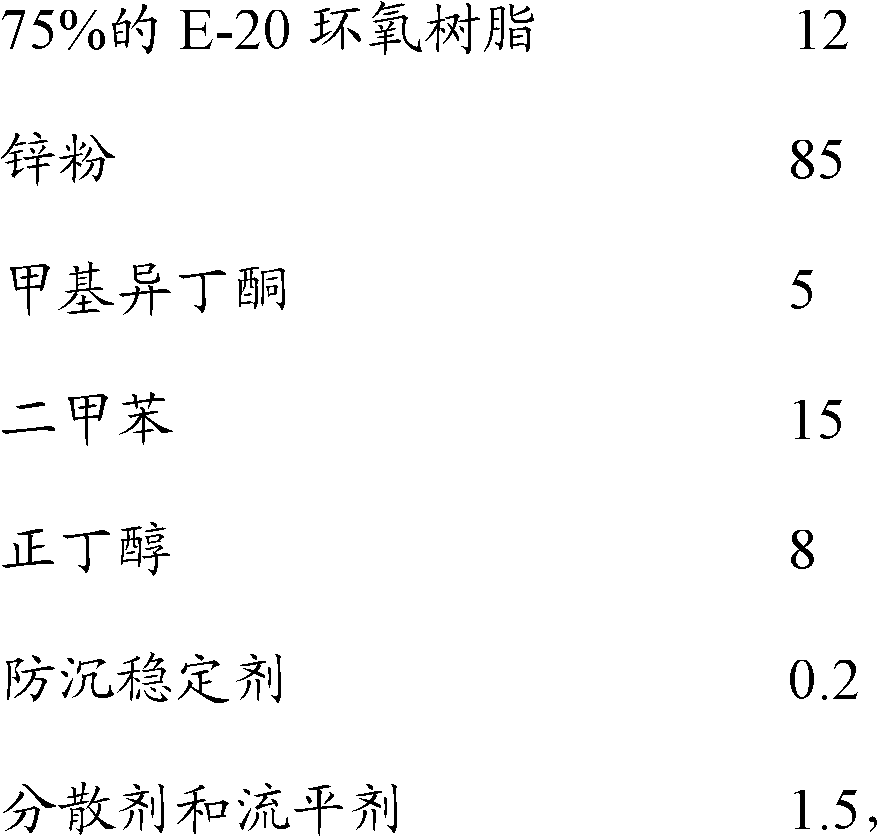

Embodiment 3

[0050] In the present embodiment, to prepare the described epoxy zinc-rich paint, by weight, component A contains:

[0051] 75% E-20 epoxy resin 20

[0052] Zinc powder 90

[0053] n-Butanol 15,

[0054] Part B contains:

[0055] NX-2018 curing agent 15

[0056] Xylene 90,

[0057] The mass ratio of component A to component B is 8:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com